Soft film-coated color plate and production process thereof

A production process and film coating technology, applied in the direction of layered products, metal layered products, synthetic resin layered products, etc., can solve the problems of affecting the health of environmental personnel, non-compliance with environmental protection trends, VOC emissions, etc., and achieve rich functionality , excellent durability, good high temperature oxidation resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] 1. Preparation example of hot melt adhesive film: Take 60kg linear low density polyethylene resin, 20kg ethylene-vinyl acetate copolymer, 10kg ethylene-octene copolymer, 3kg poly-α-methylstyrene resin, 5kg polyurethane Ester, 0.5kg8-hydroxyquinoline zinc, 1kg vinyltrimethoxysilane, 2kg gum arabic, 5kg talcum powder, 0.3kg antioxidant 1010 are placed in a high-speed mixer, and mix well to obtain a mixture; then the mixture Placed in a twin-screw extruder, the temperature of each section of the twin-screw extruder is 180°C in the first zone, 180°C in the second zone, 185°C in the third zone, 190°C in the fourth zone, 180°C in the fifth zone, and 180°C in the sixth zone. 1. After extrusion and granulation, hot-melt adhesive particles are obtained; then the hot-melt adhesive particles are placed in a casting machine at 120° C., and a hot-melt adhesive film is obtained through casting processing.

[0042] 2. Preparation example of fiber textile material: fiber textile materi...

Embodiment 1

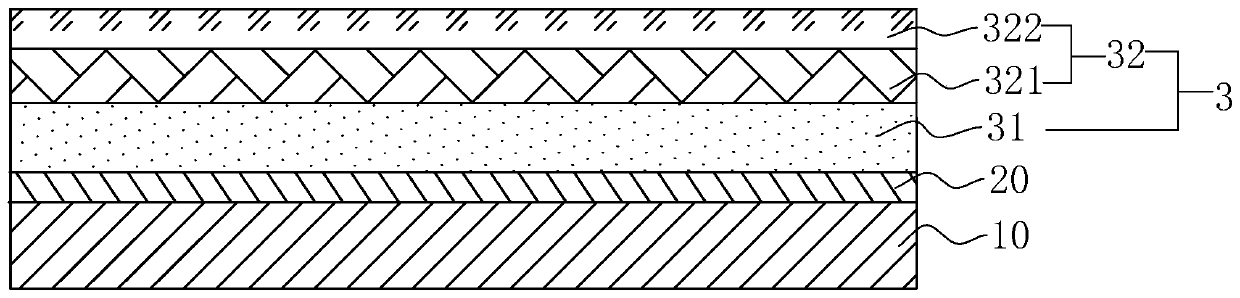

[0044] Embodiment 1: a kind of soft feeling coated color board, see figure 1 , its layer structure from bottom to top is: metal substrate 10, chemical treatment layer 20 formed on the surface of metal substrate 10, and hot-melt adhesive fiber textile material layer 30 on the chemical treatment layer 20, wherein the hot-melt adhesive fiber textile material The layer 30 includes a hot melt adhesive layer 31 and a fiber textile material layer 32, and the fiber textile material layer 32 is composed of a fiber fabric layer 321 and a PU film layer 322 bonded and compounded.

[0045] A soft-feeling coating material is produced by the following process:

[0046] S1: Prepare the fiber textile material and preheat it to 100°C for later use; then stick a hot melt adhesive film with a thickness of 40 μm on the heated fiber textile material so that the hot melt adhesive film is in contact with the underlying fiber fabric of the fiber textile material , apply pressure to the hot-melt adhes...

Embodiment 2

[0049] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the preheating temperature of the fiber textile material in S1 is 70°C, the thickness of the hot melt adhesive film is 4 μm, and the pressing pressure of the pressure roller is 4kgf; the metal substrate in S3 The heating temperature was 130° C., and the pressing pressure of the pressure roller was 4 kgf.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com