Boron cast iron air cylinder sleeve carbon scraping ring coating and preparation and spraying method thereof

A cylinder liner and cast iron technology, applied in chemical instruments and methods, coatings, metal material coating processes, etc., can solve the problems of low structural hardness and easy damage of carbon scraping ring accessories, and achieve excellent heat resistance and high temperature hardness. and high temperature oxidation resistance, the effect of solving the problem of easy wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

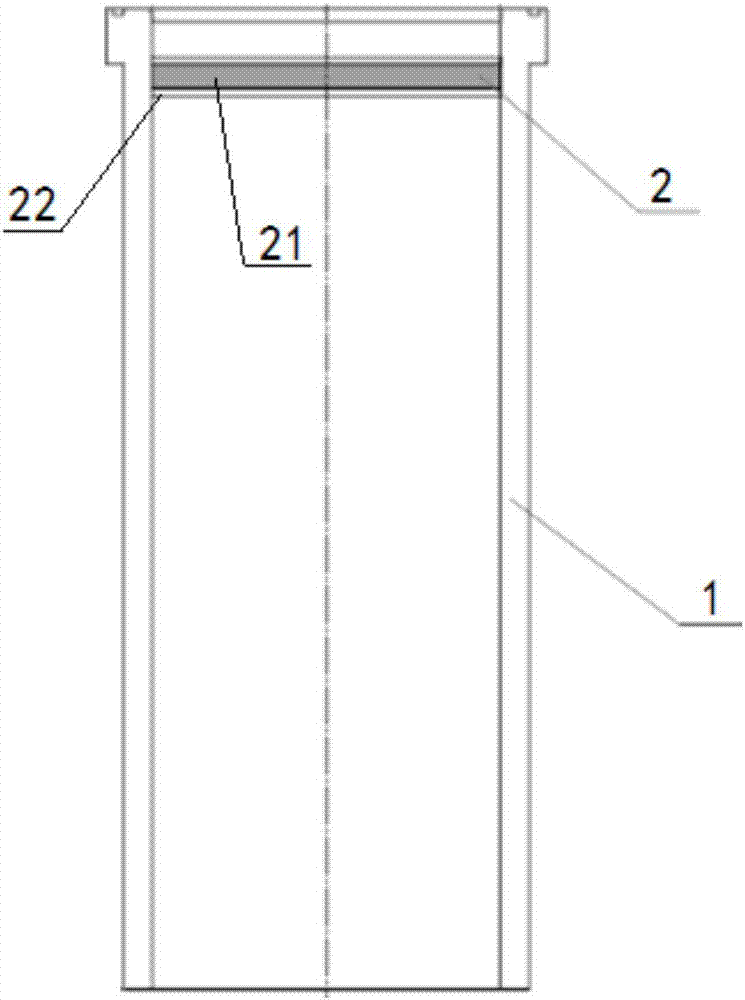

[0053] The boron cast iron cylinder liner scraping carbon ring coating 2 of the present embodiment, as figure 1 As shown, it is set on the neck of the cylinder liner 1, and the composition of the carbon scraping ring coating 2 is NiCr-Cr 3 C 2 Composite coating, NiCr alloy has excellent heat resistance, corrosion resistance, high temperature oxidation resistance and other properties, and also plays the role of binder phase, Cr 3 C 2 It has good high-temperature hardness and high-temperature oxidation resistance, acts as a hard phase, and mainly plays the role of second-phase particle dispersion strengthening in the coating, which can solve the problem that cylinder liner 1 is easily worn out under high-temperature and complex working conditions , The problem of low service life. Moreover, NiCr-Cr 3 C 2 It has a linear expansion coefficient close to that of the cylinder liner 1, thereby greatly reducing the spalling or even failure of the coating caused by thermal shock, t...

Embodiment 2

[0061] The carbon scraping ring coating of the boron cast iron cylinder liner of the present embodiment has the same basic structure as that of the embodiment 1, the difference and improvement are: NiCr-Cr 3 C 2 The thickness of the composite coating is 400 μm. After the cylinder liner 1 is sprayed with the carbon scraping ring coating 2, its inner diameter is usually 400 μm smaller than that of the cylinder liner. Therefore, a stepped shape is formed inside the cylinder liner; there are undercut grooves 22 on the top and bottom of the cylinder liner. The cutting edge 21 of the carbon scraping ring is formed in the middle, and the carbon deposit on the piston head is continuously scraped off by the knife edge during the reciprocating movement, so no thick carbon deposit can be formed, and the scraped carbon deposit is immediately blown away by the exhaust gas, and the oil film on the surface of the cylinder liner The cylinder liner and piston ring are not damaged, and the cyli...

Embodiment 3

[0063] The carbon scraping ring coating of the boron cast iron cylinder liner of the present embodiment, the basic structure is the same as embodiment 1, the difference and improvement are: the content of boron in the boron cast iron is 0.05%; NiCr-Cr 3 C 2 Composite coating thickness is 500μm, Cr 3 C 2 The content is 70%, NiCr is 30%.

[0064] Boron cast iron cylinder liner scraping carbon ring coating material preparation of the present embodiment: NiCr-Cr 3 C 2 Mixed nano powder, wherein, nano Cr 3 C 2 The preparation method of powder is:

[0065] Step 1: Mixing: put ammonium dichromate powder and nano-carbon black powder in distilled water with a weight ratio of 1:0.17, mix and stir evenly to form a fluid state, and add it to a square mold Compression molding is a precursor; after compression, it is a block to facilitate quick freezing;

[0066] Step 2: Quick freezing: Quickly transfer the precursor into a -100°C quick freezing space for quick freezing for 150 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com