Immersed gas ceramic inner heater sleeve and preparation method thereof

An inner heater and immersion technology, which is applied in the field of immersion gas-fired ceramic inner heater sleeve and its preparation, can solve the problems of restricting the popularization and application of the inner heating technology and the high cost of equipment upgrading, and achieve good melt stability and high temperature. The effect of gas heat dissipation performance and high mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

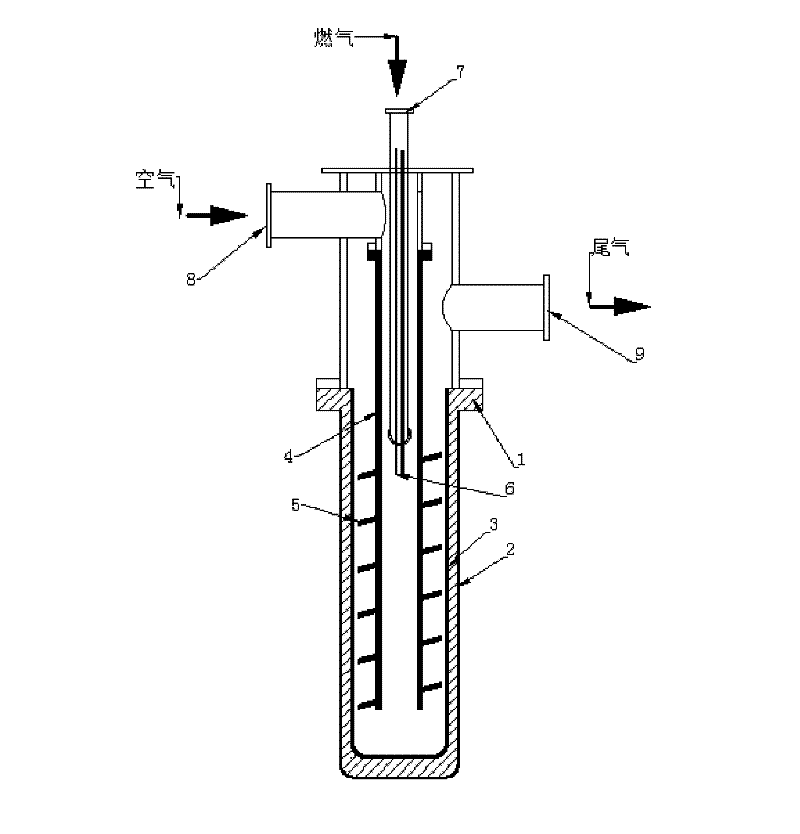

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0016] As shown in the accompanying drawings, the immersion-type gas ceramic internal heater of the present invention includes a SiC composite ceramic outer tube 1 with one end closed and immersed in molten metal, and the outer layer of the outer tube is coated with Si 3 N 4 / AlN anti-wetting layer 2, the inner layer is coated with dense SiO 2 An anti-oxidation layer 3, a SiC ceramic inner tube 4 with openings at both ends is built in the outer tube, the outer layer of the inner tube is provided with cooling fins 5, a gas pipeline 7 is inserted inside the ceramic inner tube, and the upper opening of the inner tube is connected with the compressed air pipeline 8 connect. The outer layer of the inner tube is equipped with SiC cooling fins, which have high thermal conductivity and can effectively conduct heat to the outer tube to heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com