Preparation method of yellow conductive zirconia ceramic

A technology of zirconia ceramics and zirconia powder, which is applied in the field of preparation of yellow conductive zirconia ceramics, can solve problems such as incompatibility of structure and function, poor adjustability of resistivity, unsatisfactory mechanical properties, etc., and achieve huge market practical value , adjustable resistivity, and facilitate large-scale automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

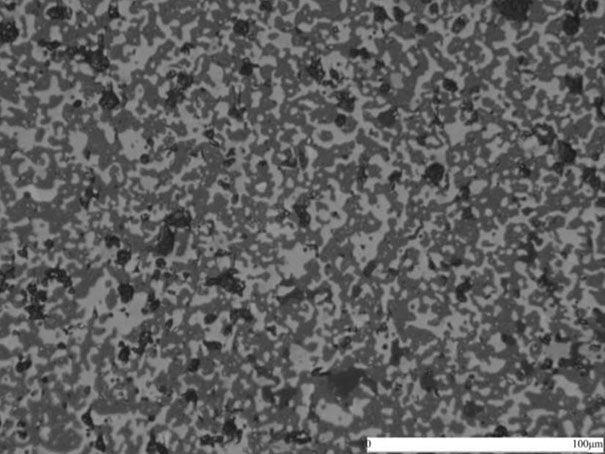

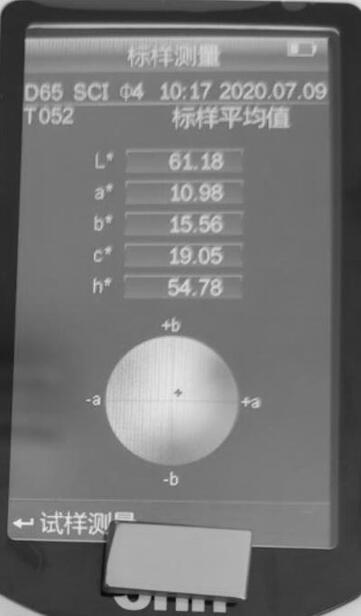

Embodiment 1

[0039] A preparation method of yellow conductive zirconia ceramics, the steps are as follows:

[0040] (1) Mix zirconia powder, titanium carbide powder, Ti powder, graphene, and hafnium oxide in a mass ratio of 60:32:15:5:3 to obtain a mixture;

[0041] The zirconia powder: the zirconia content is 95%, the average particle size is 0.5nm, and contains stabilizer Y 2 o 3 , the content is 5%;

[0042] The mixture is mixed with binder and deionized water to form a slurry, and ball milled in a ball mill tank for 12 hours.

[0043] Described binding agent: be PVA, mass percentage concentration is 5.0%, and binding agent consumption is 6% of mixture quality;

[0044] The consumption of described water is 120% of mixture quality.

[0045] (2) Dry the ball-milled slurry at 80° C., sieve and granulate through a swing granulator; obtain granulated powder; and sieve: the sieve mesh is 80 mesh.

[0046](3) Put the granulated powder into the mold, and mold it with a press at a pressure...

Embodiment 2

[0051] A preparation method of yellow conductive zirconia ceramics, the steps are as follows:

[0052] (1) Mix zirconia powder, titanium nitride powder, titanium oxide powder, phenolic resin, and alumina in a mass ratio of 35:55:25:15:5 to obtain a mixture;

[0053] The zirconia powder: the zirconia content is 90%, the average particle size is 1 μm, and the stabilizer CeO is contained 2 , the content is 10%;

[0054] The mixture is mixed with binder and water to form a slurry, and ground for 3 hours in a sand mill.

[0055] Described binding agent: be PVB, mass percent concentration is 5.0%, binding agent consumption is 10% of mixture quality;

[0056] The consumption of described water is 150% of mixture quality.

[0057] (2) Spray granulate the ball-milled slurry, and sieve to obtain granulated powder with a particle size of 60-100 mesh.

[0058] (3) Put the granulated powder into a mold, and mold it with a press at a pressure of 250 MPa to obtain a green body.

[0059]...

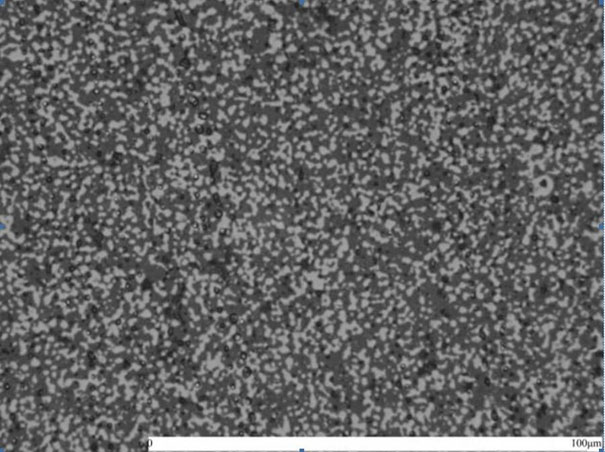

Embodiment 3

[0063] A preparation method of yellow conductive zirconia ceramics, the steps are as follows:

[0064] (1) Mix zirconia powder, titanium carbonitride powder, butyl titanate, carbon black, and lanthanum oxide in a mass ratio of 70:25:30:10:2 to obtain a mixture;

[0065] The zirconia powder: the zirconia content is 98%, the average particle size is 5 μm, and the stabilizer MgO is contained, and the content is 2%;

[0066] The mixture is mixed with binder and absolute ethanol to form a slurry, and ball milled in a ball mill tank for 3 hours.

[0067] Described binding agent: be phenolic resin, mass percent concentration is 10.0%; The amount of binding agent is 15% of mixture quality;

[0068] Described dehydrated alcohol consumption is 200% of compound quality.

[0069] (2) Spray granulation of the ball-milled slurry;

[0070] (3) Put the granulated powder into the mold, and mold it with a press at a pressure of 200MPa to obtain a green body;

[0071] (4) Put the pressed cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com