Temperature-sensitive material for heat-seeking type temperature-sensitive cables, and preparation method thereof

A heat-sensitive cable and heat-sensitive material technology, which is applied in the field of materials, can solve problems such as excessive resistance of heat-sensitive cables, increased resistance between electrodes, and unstable thermoelectric performance, so as to avoid oxidation and corrosion of hot electrodes, increase the length of finished products, Eliminate the effect of the interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

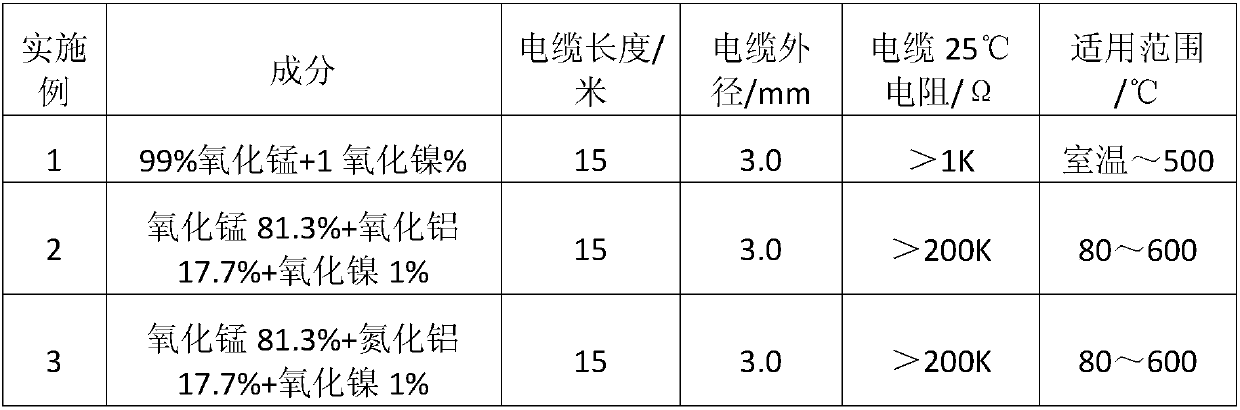

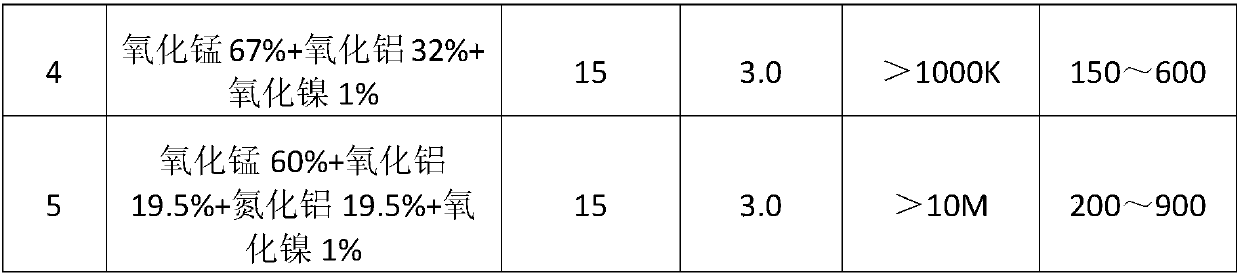

Embodiment 1

[0021] Weigh 495g of manganese oxide and 5g of nickel oxide, add 400ml of absolute ethanol, stir evenly at a high speed, dry, put in a muffle furnace for heat treatment at 1270°C for 2 hours, pass through a 200-mesh sieve after crushing, and add cellulose Put the adhesive and water into the extruder to make a double-hole porcelain column, dry it for five days, remove the adhesive, pass the K-type thermode through the ceramic column, and then put it into an inconel 600φ16×1.5 alloy tube. Reduce the diameter to φ3, and process it so that it is densely packed between the electrode and the outer protection tube.

Embodiment 2

[0023] Weigh 406.5g of manganese oxide, 88.5g of aluminum oxide, and 5g of nickel oxide, add 400ml of absolute ethanol, stir evenly at a high speed, then dry them, put them in a muffle furnace for heat treatment at 1270°C for 2 hours, and pass through 200 mesh points after crushing. Sample sieve, add cellulose adhesive and water, put it into an extruder to make a double-hole porcelain column, dry it for five days, remove the adhesive, pass the K-type thermode through the ceramic column, and then put it into an inconel 600φ16 In the ×1.5 alloy tube, the diameter is reduced to φ3, so that it is densely packed between the electrode and the outer protection tube.

Embodiment 3

[0025] Weigh 406.5g of manganese oxide, 88.5g of aluminum nitride, and 5g of nickel oxide, add 400ml of absolute ethanol, stir evenly at a high speed, dry, heat treat, put in a muffle furnace for heat treatment at 1270°C for 2 hours, and pass through the 200-mesh sampling sieve, add cellulose adhesive and water, put it into an extruder to make a double-hole porcelain column, dry it for five days, remove the adhesive, pass the K-type thermode through the ceramic column, and then install Put it into an inconel 600φ16×1.5 alloy tube, reduce the diameter to φ3, and process it so that it is densely packed between the electrode and the outer protection tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com