PC conductive plastic and preparation method thereof

A conductive plastic and raw material technology, applied in the field of plastic modification, can solve problems such as static electricity, catastrophic accidents, performance degradation of photosensitive film, etc., and achieve the effects of long service life, fast delivery and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh the following materials:

[0034] PC material 7500g;

[0036] Carbon nanotube modified particles 800g;

[0037] Vinyl rubber 800g;

[0038] Preparation of PC conductive plastic:

[0039] a. Ventilate and dry PC material at 120°C-130°C for 2-3 hours to obtain dry PC material;

[0040] b. Weigh the dry PC material, zinc oxide, carbon nanotube modified particles and ethylene rubber according to the weight ratio, add them together into a high-speed mixer, and fully stir for 5 to 30 minutes to obtain a mixture;

[0041] c. Add the mixture obtained in step b into a screw extruder, melt, knead and extrude at 260° C. to 270° C., and cool and granulate to obtain the PC conductive plastic of Example 1.

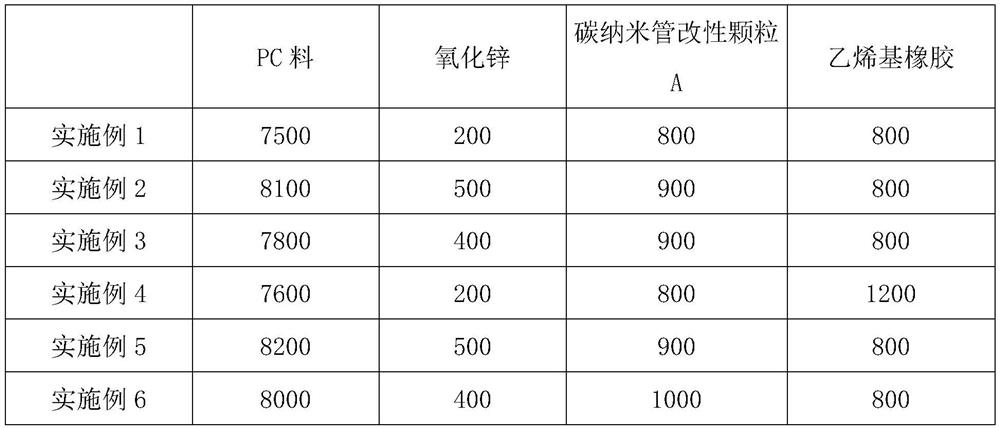

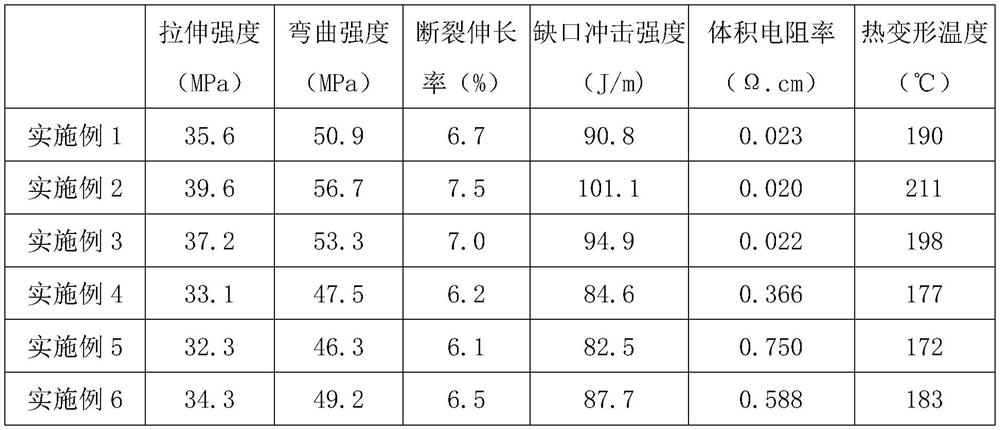

[0042] The component formula of embodiment 2-6 is as follows table, preparation method with reference to embodiment 1:

[0043]

[0044] The PC conductive plastic that embodiment 1-6 makes is processed into the shell of thickness 0.3mm, an...

Embodiment 7

[0050] Weigh the following materials:

[0051] PC material 7500g;

[0052] Zinc oxide 200g;

[0053] Primary polyvinylpyrrole-aminated carbon nanotubes 800g;

[0054] Vinyl rubber 800g;

[0055] Preparation of PC conductive plastic:

[0056] a. Ventilate and dry PC material at 120°C-130°C for 2-3 hours to obtain dry PC material;

[0057]b. Weigh the dry PC material, zinc oxide, primary polyvinylpyrrole-aminated carbon nanotubes and ethylene rubber according to the weight ratio, add them together into a high-speed mixer, and fully stir for 5 to 30 minutes to obtain a mixture;

[0058] c. Add the mixture obtained in step b into a screw extruder, melt, knead and extrude at 260° C. to 270° C., cool and granulate to obtain the PC conductive plastic of Example 7.

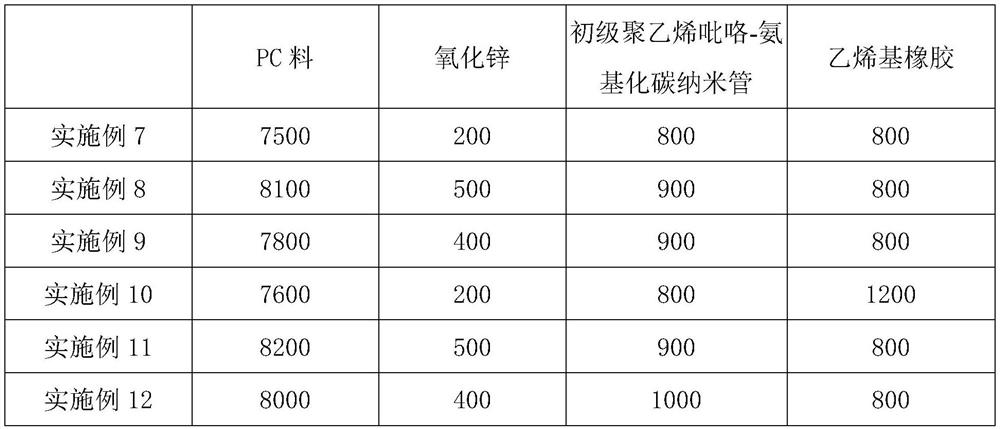

[0059] The component formula of embodiment 8-12 is as follows table, preparation method with reference to embodiment 7:

[0060]

[0061] The PC conductive plastic obtained in Examples 7-12 was processed into a s...

Embodiment 13

[0067] Weigh the following materials:

[0068] PC material 7500g;

[0069] Zinc oxide 200g;

[0070] 800g of intermediate end epoxy-based nitrile rubber modified carbon nanotubes;

[0071] Vinyl rubber 800g;

[0072] Preparation of PC conductive plastic:

[0073] a. Ventilate and dry PC material at 120°C-130°C for 2-3 hours to obtain dry PC material;

[0074] b. Weigh the dry PC material, zinc oxide, intermediate-end epoxy-based nitrile rubber modified carbon nanotubes and ethylene rubber according to the weight ratio, add them together to a high-speed mixer, and stir them thoroughly for 5 to 30 minutes to obtain a mixture;

[0075] c. Add the mixture obtained in step b into a screw extruder, melt, knead and extrude at 260°C-270°C, and cool and granulate to obtain the PC conductive plastic of Example 13.

[0076] The component formula of embodiment 14-18 is as follows, and the preparation method refers to embodiment 13:

[0077]

[0078] The PC conductive plastic obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com