A protection method for electrification inside a spacecraft circuit board

A technology for circuit boards and internal electrification, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of increased shielding layer thickness, high radiation-induced resistivity, and limited protective effect of internal electrification effects, and achieve lower resistivity, Strong adaptability, the effect of reducing the risk of discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0031] 1. Preparation of polyaniline nanoparticles:

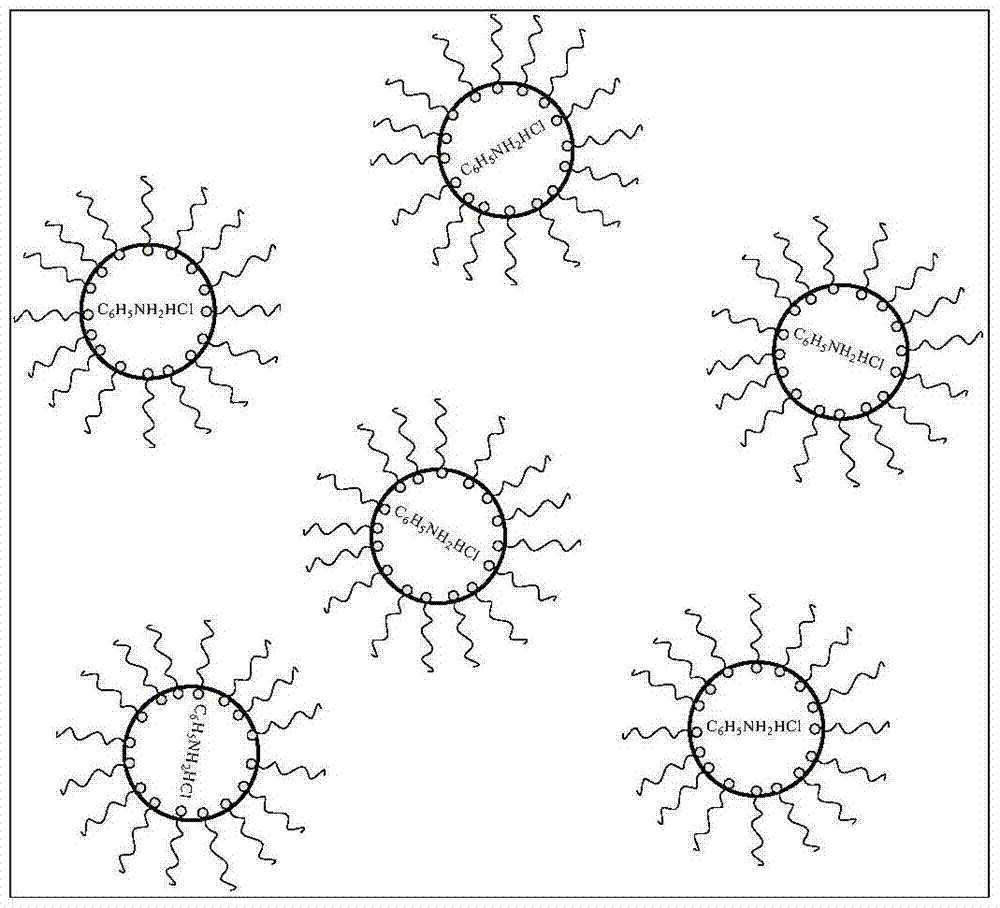

[0032] (1) get xylene 80ml in the beaker of 250ml, add 1g sodium dodecylbenzenesulfonate (SDBS) therein, seal and stir 1h, wherein xylene is an organic phase solvent, and sodium dodecylbenzenesulfonate is Surfactant.

[0033] (2) get 40ml of hydrochloric acid whose volume percentage concentration is 25%, add 3.3ml of aniline to it, seal and stir for 1h;

[0034] (3) adding the aniline hydrochloric acid solution into the separating funnel, adding it dropwise to the organic phase, sealing and stirring for 1 h to obtain emulsion system 1; wherein aniline is the raw material for preparing polyaniline by reaction, and hydrochloric acid plays a role of doping, In order to improve the conductivity of polyaniline, the water in the aniline hydrochloric acid solution is combined with the hydrophilic group of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com