A kind of multifunctional graphene electrothermal slurry and its multifunctional electrothermal film and its preparation method and application

A graphene and multi-functional technology, applied in the direction of electric heating devices, ohmic resistance heating, heating element materials, etc., can solve the problems of lengthening the process route of electric heating slurry and its film products, potential safety hazards, and lack of combination of chemical bond scales

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

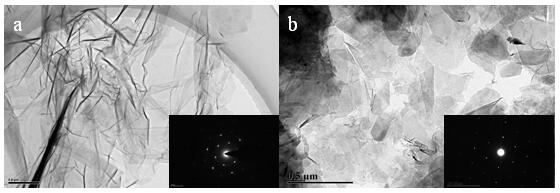

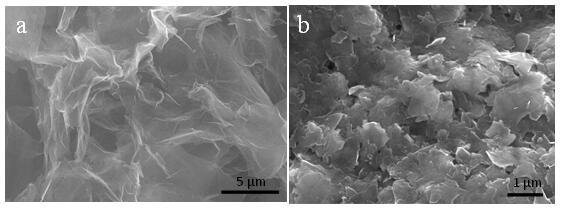

[0081] Graphene powder is prepared by electrochemical exfoliation method. The thickness of graphene is 0.5-3 nm, the lateral dimension is about 30-50 μm, and the crystal structure is complete. See the attached figure 1 (a), with figure 2 (a), the graphene microsheets are soft and transparent, and the crystal form is well maintained. Take 1 part by mass of graphene powder, disperse it in deionized water, the concentration of the dispersion is 0.5 mg / mL, add sodium lauryl sulfate as a hydrophilic agent (physical modifier), and disperse by ultrasonic vibration for 60 minutes.

[0082] Add 1 mass part of methylenebisacrylamide and 1 mass part of polyacrylic acid as a reaction emulsion to the dispersion, a total of 0.5 mass parts of additives, including 0.1 mass parts of polyoxyethylene ether methacrylate (dispersant), 0.1 Parts by mass of lauryl alcohol ester (film-forming aid), 0.05 parts by mass of potassium sorbate (preservative), 0.05 parts by mass of silicone oil (defoamer)...

Embodiment 2

[0086]Graphene powder is prepared by electrochemical exfoliation method. The thickness of graphene is 1-5 nm, the lateral size is about 2-10 μm, and the crystal structure is complete. Take 5 parts by mass of graphene powder and disperse it in the ethanol / water mixed solution. The concentration of the dispersion is 5 mg / mL. Add 3 parts by mass of potassium permanganate as an oxidant to introduce functional groups such as hydroxyl and carboxyl. After washing, hexamethylene diisocyanate is added to react with carboxyl or hydroxyl groups on the graphene microsheets to form amide bonds or carbamate bonds to activate graphene, and disperse by ultrasonic vibration.

[0087] Add 2 parts by mass of acrylic acid to the dispersion, 2 parts by mass of polyurethane as a reaction emulsion, a total of 2 parts by mass of additives, including 0.5 parts by mass of polyoxypropylene ether acrylate (dispersant), 0.5 parts by mass of propylene glycol methyl ether acetate ( film-forming aid), 0.5 pa...

Embodiment 3

[0091] The graphene powder was prepared by electrochemical exfoliation method, the thickness of graphene is 3-5 nm, and the lateral dimension is about 0.3-5 μm. figure 1 (b), with figure 2 (b), graphene microsheets have small lateral dimensions, complete crystal structure, and excellent conductivity. Take 10 parts by mass of graphene powder, add part of concentrated nitric acid for pre-oxidation, and introduce functional groups such as hydroxyl and carboxyl. After washing, γ-methacryloxypropyltrimethoxysilane was added to react with the hydroxyl groups on the graphene microchips, and then it was stably dispersed in the N,N-dimethylformamide / water mixture, and the concentration of the dispersion was 10 mg / mL.

[0092] Add 5 parts by mass of acrylic resin, 5 parts by mass of ammonia water as a reaction emulsion, a total of 5 parts by mass of additives, including 0.5 parts by mass of polyoxyethylene ether acrylate (dispersant), 0.5 parts by mass of propylene glycol butyl ether...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com