Manufacturing method of wear-resisting lining plate for rolling mill inlet guide

A wear-resistant lining, rolling mill technology, applied in metal material coating process, melt spraying, coating and other directions, can solve the problems of poor impact resistance, poor corrosion resistance, frequent replacement, etc., to improve strength and toughness, Good impact resistance and the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Taking the preparation of a wear-resistant liner for a rolling mill entrance guide with a specification of 210×140×28 (unit: mm) as an example, this embodiment provides a method for preparing a wear-resistant liner for a rolling mill entrance guide. The method includes the following steps:

[0037] 1. Matrix preparation

[0038] Select a forged 40Cr steel plate with a production specification of 210×140×30 (unit: mm) (with a 2mm machining allowance on the bottom surface), and after quenching and tempering at high temperature, rough machine the surface of the steel plate to a roughness of Ra =12.5~6.3μm.

[0039] The quenching temperature range is 850°C±10°C, and the cooling method is oil cooling; the tempering temperature is 520°C±10°C, and the cooling method can be water cooling, oil cooling or air cooling.

[0040] Among them, the rough machining method is mechanical cutting, including rough turning, planing and milling.

[0041] 2. Degreasing and activation of the...

Embodiment 2

[0054] This embodiment provides a wear-resistant liner, comprising a base of forged 40Cr quenched and tempered steel and a wear-resistant layer welded on the base by flame spray welding, wherein the composition of the wear-resistant layer is as follows in terms of mass percentage: C~0.6%, Cr ~15%, Si~3%, W~5.5%, Nb~1.5%, Fe~4%, Mn~0.1%, Mo~0.1%, B1.5%, the balance is Ni.

Embodiment 3

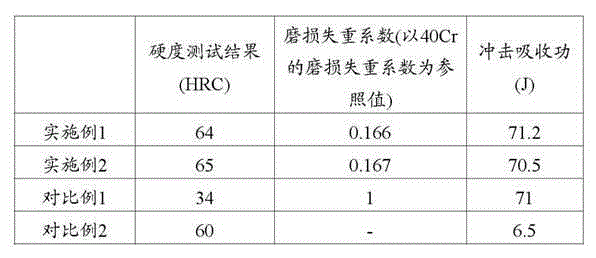

[0056] For the wear-resistant liner in Examples 1 and 2, the forged 40Cr quenched and tempered steel (860°C quenching oil cooling + 520°C tempering oil cooling) wear-resistant liner of the same specification, the Cr12MoV steel (quenching + low temperature tempering) of the same specification Fire heat treatment) wear-resistant liner for mechanical performance test - including surface hardness test, wear test and impact toughness test (standard U-shaped sample, measured at 20 ℃). The experimental results are shown in Table 1 below:

[0057] The mechanical property test result of table 1 embodiment and comparative example

[0058]

[0059] It can be seen from the test results of mechanical properties that the comprehensive mechanical properties of the wear-resistant liner of the present invention are greatly improved compared with the traditional wear-resistant liner, not only has good toughness, but also has high surface hardness and excellent wear resistance.

[0060] It c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com