Lubricant and preparation method thereof

A lubricant and tackifier technology, applied in the field of lubricants and their preparation, can solve the problems of easy coking of lubricants, enlarged wheel belt mesh cracks, peeling, and lubricant throwing out, etc., so as to avoid close contact with high temperature equipment, excellent high temperature oxidation resistance, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

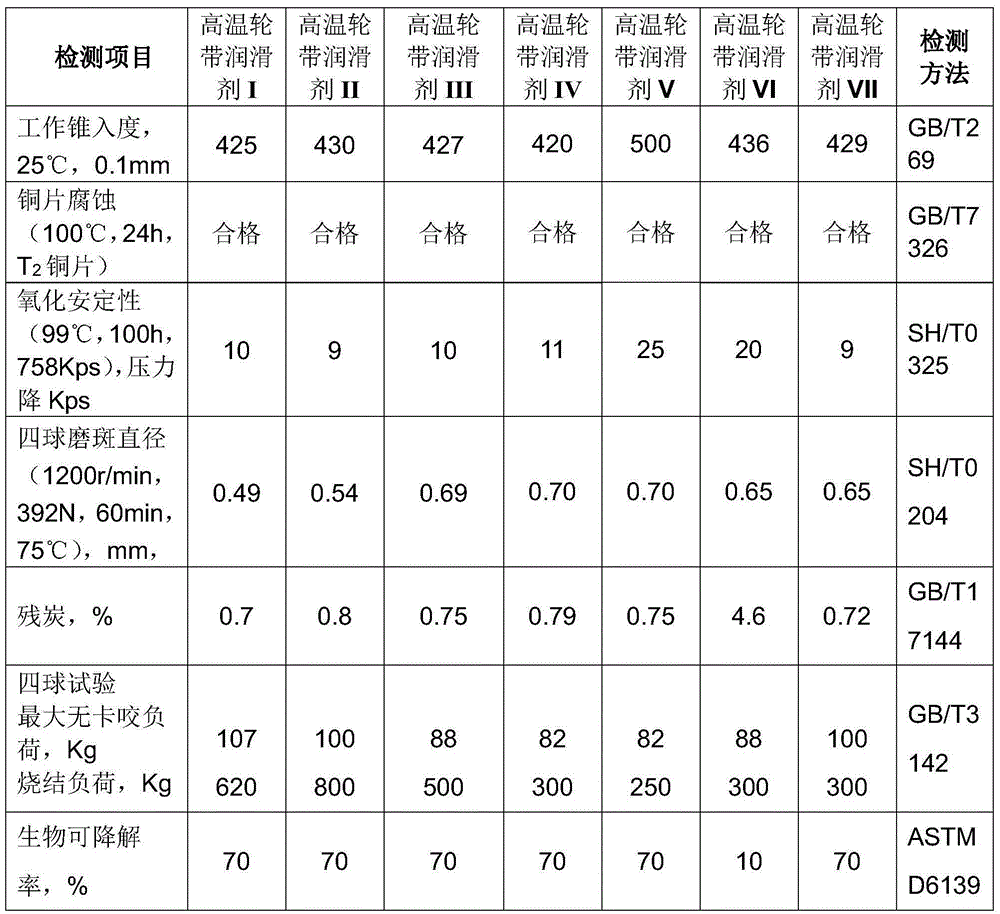

Examples

preparation example Construction

[0042] The present invention also provides a preparation method of the lubricant according to the present invention, comprising the following steps: uniformly mixing the components, and grinding the obtained materials to obtain the lubricant.

[0043] More preferably, include the following steps:

[0044] (1) Pour the base oil into a clean stainless steel blending kettle for heating, heat to 80-100°C, add antioxidant, and stir at a constant temperature of 80-100°C; (2) Cool down, add tackifier, extreme pressure and anti-wear agent, solid additive and dispersant, stir evenly;

[0045] (3) The material in the blending kettle is beaten out, and the lubricant is obtained after being ground by a three-roll mill.

[0046] The heating temperature is preferably 90°C, and the constant temperature stirring temperature is preferably 90°C.

Embodiment 1

[0050] Pour 30 parts of base oil dipentaerythritol ester (American HATCOL Company, brand HATCOL3165, the same below) and 26 parts of pentaerythritol ester (American HATCOL Company, brand HATCOL2999, the same below) into a clean stainless steel mixing kettle, heat to 90 ° C, add anti Oxygen agent p, p-octyl diphenylamine (Corning Chemical (China) Co., Ltd., brand L01, the same below) 2 parts, uniformly stirred at 90°C for 30min; Company, trademark Priolube3986, the same below) 15 parts, uniformly stirred at 55°C for 30min; Solid additive light calcium carbonate (Shanghai Huayi Group Huayuan Chemical Co., Ltd., brand light calcium carbonate, the same below) 10 parts, colloidal graphite (Shanghai Qiju Chemical Co., Ltd., brand colloidal graphite-00#, the same below) 13 1 part, stirred evenly at 55°C for 1 hour; cooled to 40°C, added 1 part of dispersant alkyl succinimide (Beijing Huatong Ruichi Technology Industry and Trade Co., Ltd., brand SRF-111, the same below), and stirred e...

Embodiment 2

[0052] Pour 30 parts of base oil dipentaerythritol ester and 28 parts of pentaerythritol ester into a clean stainless steel blending kettle, heat to 90°C, add 2 parts of antioxidant p-octyldiphenylamine, and stir evenly at 90°C for 30 minutes; cool down to 60°C ℃, add 15 parts of tackifier complex ester, and stir evenly for 30 minutes at 55 ℃; add 1 part of extreme pressure antiwear agent antimony dialkyldithiocarbamate, 10 parts of solid additive light calcium carbonate, 13 parts of colloidal graphite, Stir evenly at 55°C for 1 hour; cool down to 40°C, add 1 part of dispersant alkyl succinimide, and stir evenly for 30 minutes; use a three-roll mill to grind the material once out of the kettle to obtain the finished high-temperature tire lubricant II.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com