Lubricant for metal cold working and preparation method thereof

A lubricant and cold processing technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of large amount of lubricant used, inability to form continuous, affect production progress, etc., to improve surface quality, inhibit oxidation failure, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

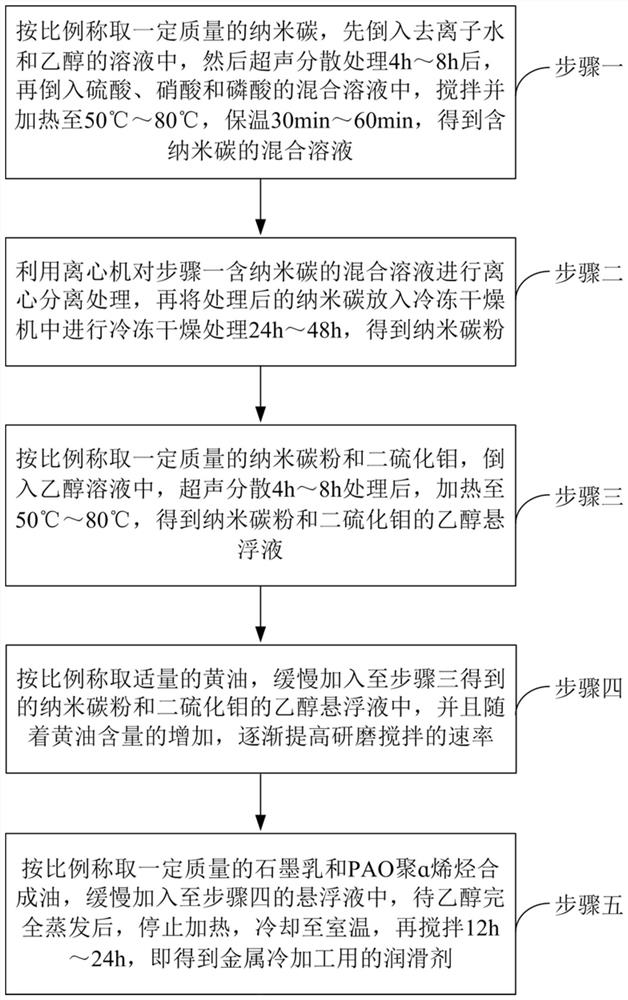

[0036] Such as figure 1 Here, the present invention also provides a method of preparing a metal cold working lubricant, comprising the following specific steps:

[0037]Step 1, in proportion to the nanocarbon of a certain mass, first pour the solution of deionized water and ethanol (analyze pure, concentration of 99.7%), and then ultrasonic dispersion treatment for 4 h h hours, then pour the sulfuric acid, nitric acid and phosphoric acid. In the mixed solution, stirred and heated to 50 ° C to 80 ° C, heat insulation for 30 min to 60 min to give a nanocarbon mixed solution;

[0038] Among them, the volume ratio of sulfuric acid (analyzed purity, concentration of 98.3%), nitric acid (purified, concentration of 65%) and phosphoric acid (analytical purity, concentration of 85%) is 1: 1: 3.

[0039] Step 2, by centrifugal mixing solution with a centrifuge, a mixed solution containing a nanophyletal mixture was centrifuged, and the rotational speed was set to 10,000 rpm to 15,000 rpm, a...

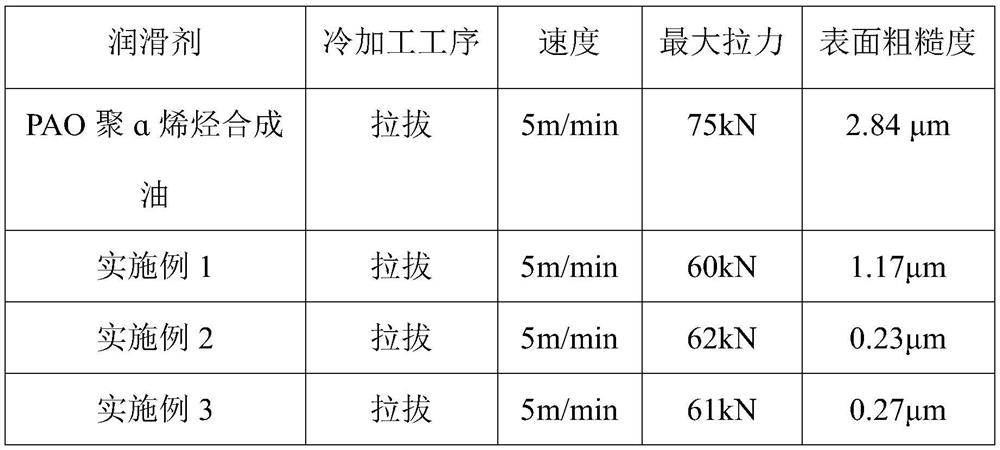

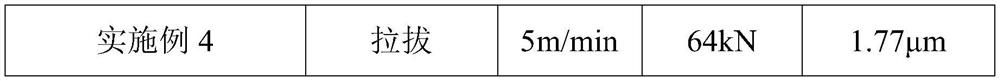

Embodiment 1

[0046] 1): 1 g of nanocarbon (graphene), poured into 500 ml of deionized water and 500 mL of ethanol, and after the ultrasonic dispersion of 4 h, 10 ml of sulfuric acid, 10 ml of nitric acid and 30 ml of phosphoric acid mixed solution, stirred and heated To 50 ° C, heat insulation for 30 min to obtain a mixed solution containing nanocarbon;

[0047] 2): The mixed solution obtained by nanocarbon (graphene) by centrifuge is obtained by centrifugation, and the rotational speed is set to 10000 rpm, and the treatment-processed nanocarbon (graphene) is placed in a freeze dryer. Dry treatment 24 h to give nanofin powder (graphene);

[0048] 3): 1. 1 g of nano toner (graphene) and 5 g of molybdenum sulfide (molybdenum sulfide is a purity, content of ≥98%), poured into 500 ml of ethanol solution, ultrasonic dispersion 4 h, heated to 50 ° C;

[0049] 4): Weigh 5g calcium-based grease butter, slowly add to nano toner (graphene) and molybdenum sulfide ethanol suspension, with the increase of ...

Embodiment 2

[0053] 1): Taking 50 g of nanocarbon, poured into 2000 ml of deionized water and 2000 ml of ethanol, ultrasonic dispersion 8 h, poured into 200 ml of sulfuric acid, 200 ml of nitric acid and 600 ml of phosphoric acid mixed solution, stirred and heated to 80 ° C, Holding 60 min to give a nanocarbon mixed solution;

[0054] 2): Use the centrifuge to obtain centrifugal separation treatment, the rotational speed is set to 15,000 rpm, and the treatment-processed nanocarbon is placed in a freeze dryer for freeze drying treatment for 48 h to obtain nanotonic powder. ;

[0055] 3): Weigh 50g nano toner and 100 g of molybdenum disulfide (molybdenum sulfide is a purified, ≥98%), poured into 500 ml of ethanol solution, ultrasonic dispersion 8 h, heated to 80 ° C;

[0056] 4): Weigh 200g calcium-based grease butter, slowly add to the ethanol suspension of nanotonic powder and molybdenum disulfide, and gradually increase the grinding stirring rate as the butter content increases.

[0057] 5): ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com