Hard alloy with iron-aluminum intermetallic compound as main binding phase and preparation method of hard alloy

A technology of cemented carbide and binder phase, which is applied in the field of cemented carbide materials and its preparation, can solve the problems of unsuitability for industrial production and complex operation, and achieve excellent high-temperature oxidation resistance and sulfur corrosion resistance. The preparation method Simple, evenly textured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

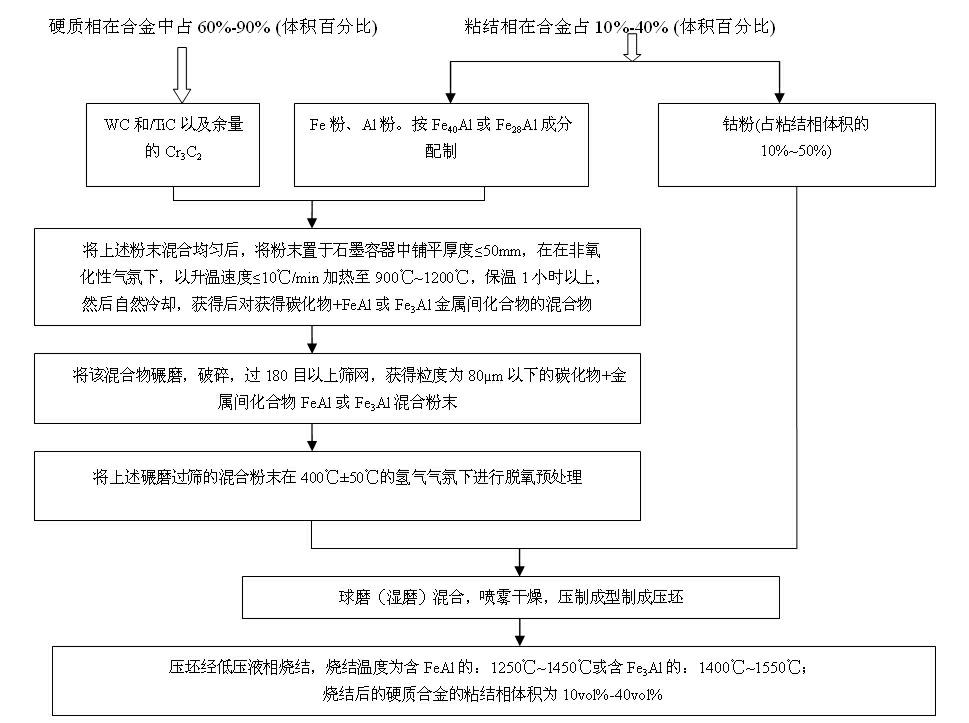

[0021] Embodiment 1: According to figure 1 Process shown, press Fe 40 For the composition ratio of Al, mix the iron powder and aluminum powder with a mass percentage of 1.94% and the balance of tungsten carbide powder evenly; place the above mixed powder in a graphite container and spread it to a thickness of 50 mm, and in a non-oxidizing atmosphere, at 10 ° C Heating to 900°C at a heating rate of / min, keeping it warm for 7 hours, and then cooling naturally to obtain a mixture of tungsten carbide and FeAl intermetallic compound; grind the mixture, crush it, and pass it through a 250-mesh sieve to obtain tungsten carbide with a particle size of 58 μm or less and the mixed powder of FeAl intermetallic compound; the mixed powder of the above-mentioned tungsten carbide and FeAl intermetallic compound is subjected to deoxygenation pretreatment under the hydrogen atmosphere of 400°C±50°C; then, the mass percentage is 3.00% cobalt powder and 0.23% Cr 3 C 2powder, and then wet-mil...

Embodiment 2

[0022] Embodiment 2: According to figure 1 Process shown, press Fe 28 For the composition ratio of Al, mix the iron powder and aluminum powder with a mass percentage of 2.34% and the rest of the tungsten carbide powder evenly; place the above mixed powder in a graphite container with a thickness of 50 mm, and in a non-oxidizing atmosphere, at 10 ° C / min heating rate to 900°C, heat preservation for 7 hours, and then natural cooling to obtain tungsten carbide and Fe 3 A mixture of Al intermetallic compounds; the mixture is ground, crushed, and passed through a 250-mesh sieve to obtain tungsten carbide and Fe with a particle size of 58 μm or less 3 Mixed powder of Al intermetallic compound; the above tungsten carbide and Fe 3 The mixed powder of Al intermetallic compound is subjected to deoxidation pretreatment in a hydrogen atmosphere at 400°C±50°C; then, the mass percentage is 3.00% of cobalt powder and 0.24% of Cr 3 C 2 powder, then with the balance of the above tungsten ...

Embodiment 3

[0023] Embodiment 3: According to figure 1 Process shown, press Fe 40 For the composition ratio of Al, mix the iron powder and aluminum powder with a mass percentage of 3.44% and the balance of tungsten carbide powder evenly; place the above mixed powder in a graphite container and spread it to a thickness of 50 mm, and in a non-oxidizing atmosphere, at 10 ° C Heating to 900°C at a heating rate of / min, keeping it warm for 7 hours, and then cooling naturally to obtain a mixture of tungsten carbide and FeAl intermetallic compound; grind the mixture, crush it, and pass it through a 250-mesh sieve to obtain tungsten carbide with a particle size of 58 μm or less and the mixed powder of FeAl intermetallic compound; the above mixed powder of tungsten carbide and FeAl intermetallic compound is subjected to deoxidation pretreatment under the hydrogen atmosphere of 400°C±50°C; then, the mass percentage is 0.61% of cobalt powder and 0.18% Cr 3 C 2 powder, and then wet-milled and mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com