A kind of method that molten salt electric deoxidation method prepares v-4cr-4ti alloy

A v-4cr-4ti, molten salt electro-deoxidation technology, applied in the field of non-ferrous metallurgy and electrochemistry, can solve the problems of low cathode conductivity, metal volatilization loss, low current efficiency, etc., achieve high melting point, low production cost, The effect of high current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

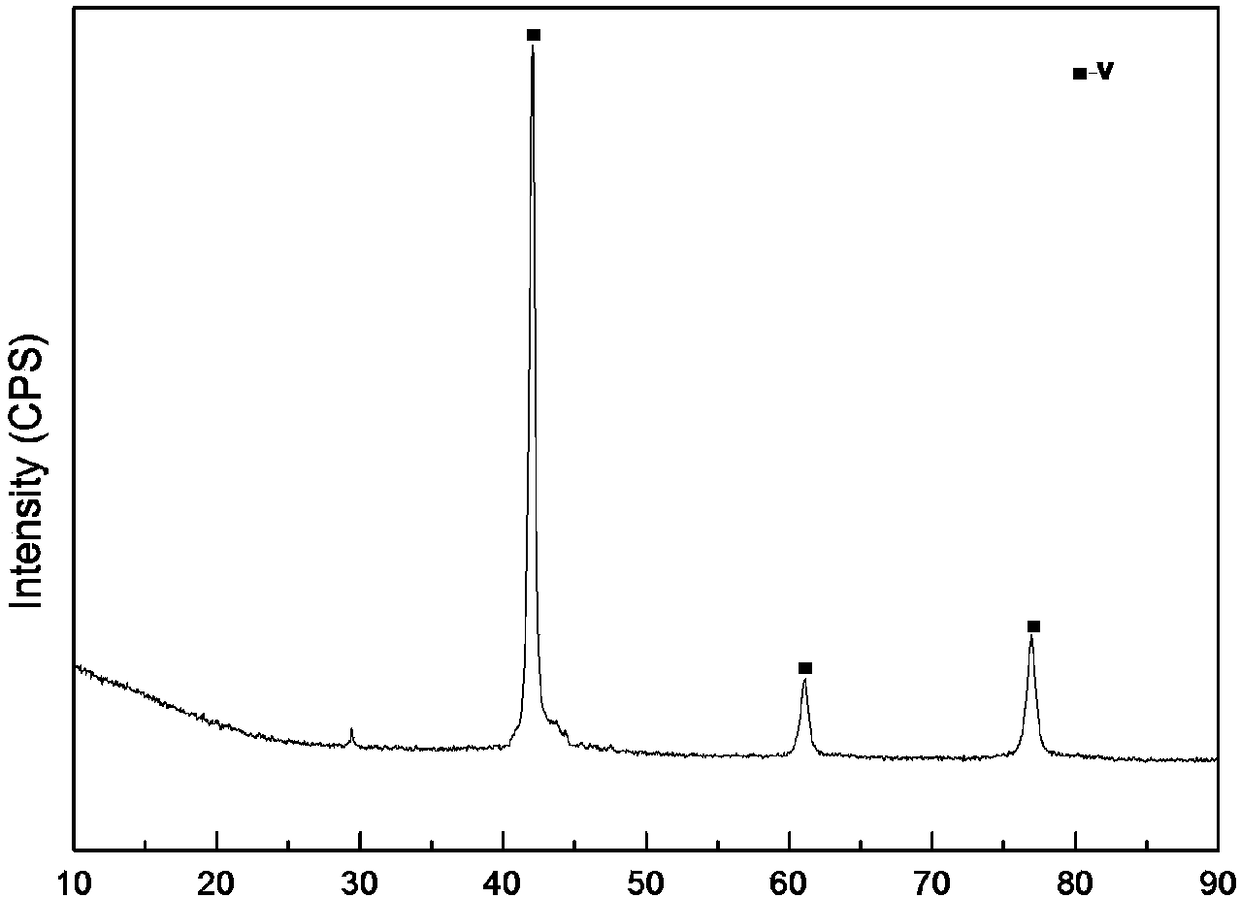

[0028] The method for preparing V-4Cr-4Ti alloy by molten salt electro-deoxidation method comprises the following steps:

[0029] Step 1, mixing and pressing:

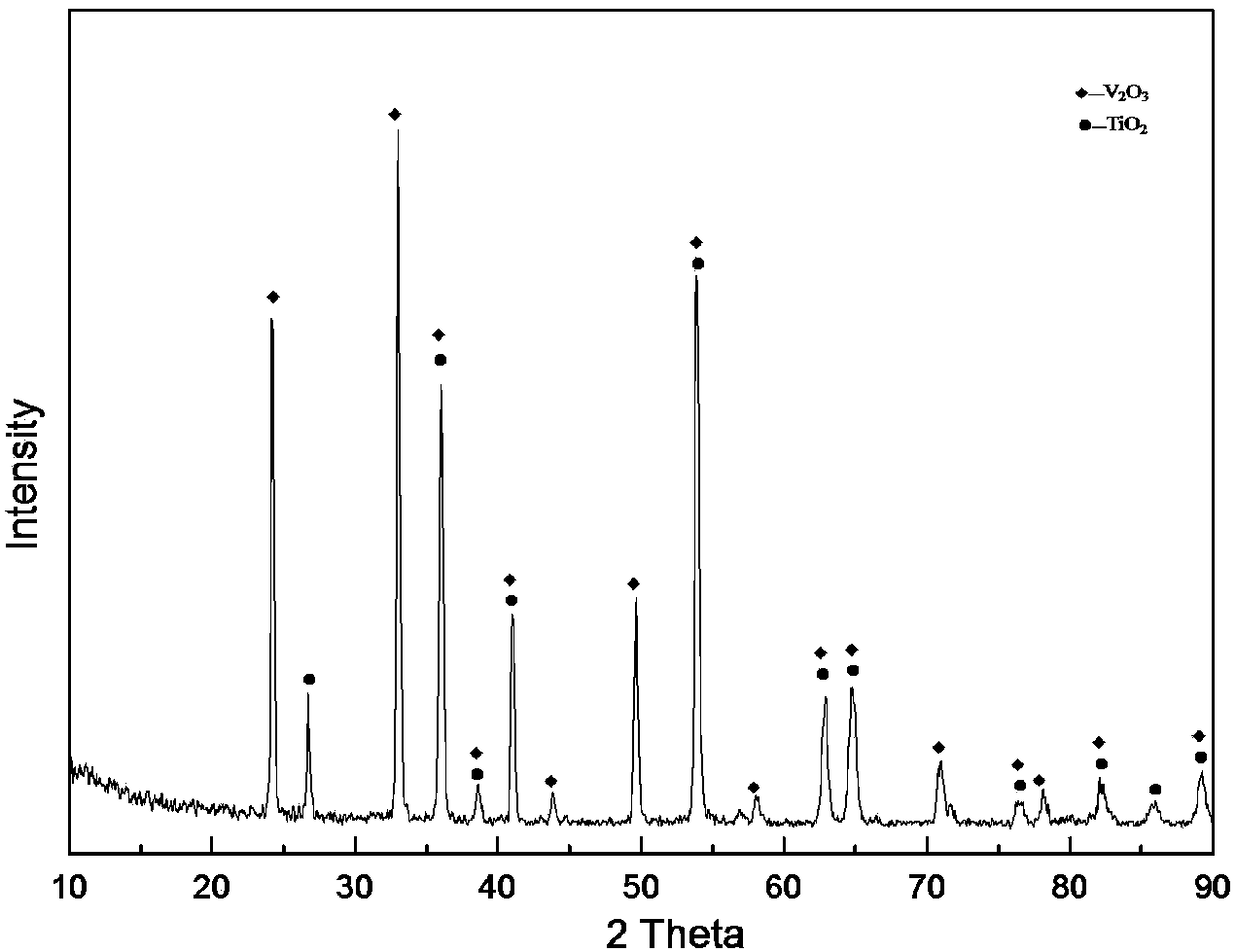

[0030] (1) By mass percentage, V 2 o 3 Powder: 91.53%, Cr 2 o 3 Powder: 3.96%, TiO 2 Powder: 4.51%, mixed in a ball mill tank for 5 hours;

[0031] (2) Put the mixed material in a steel mold and press it into a mixed oxide tablet; wherein, the molding pressure is 100 MPa, and the pressure is kept for 8 minutes; a tablet with a diameter of 10 mm and a height of 3 mm is obtained;

[0032] Step 2, tablet sintering:

[0033] Sintering the pressed tablet under vacuum conditions, the sintering temperature is 1000°C, and the sintering time is 1h, to obtain a mixed oxide sintered body;

[0034] Step 3, molten salt electrolysis:

[0035] (1) Wrap the mixed oxide sintered body with a molybdenum mesh and connect it with a molybdenum rod to form a cathode. A high-purity graphite rod is used as an anode, and is inserted in ...

Embodiment 2

[0040] The method for preparing V-4Cr-4Ti alloy by molten salt electro-deoxidation method comprises the following steps:

[0041] Step 1, mixing and pressing:

[0042] (1) By mass percentage, V 2 o 3 Powder: 92.4%, Cr 2 o 3 Powder: 3.75%, TiO 2Ti powder: 3.2%, Ti powder: 0.65%, mixed in a ball mill tank for 8 hours;

[0043] (2) The mixed material is placed in a steel mold and compressed into a mixed oxide tablet; wherein, the molding pressure is 60MPa, and the pressure is maintained for 10min; the obtained diameter is 10mm, and the height is a tablet of 3mm;

[0044] Step 2, tablet sintering:

[0045] Sinter the pressed tablet under an argon atmosphere, the sintering temperature is 1000°C, and the sintering time is 3h, to obtain a mixed oxide sintered body;

[0046] Step 3, molten salt electrolysis:

[0047] (1) Wrap the mixed oxide sintered body with a molybdenum mesh and connect it with a molybdenum rod to form a cathode. A high-purity graphite rod is used as an ano...

Embodiment 3

[0051] The method for preparing V-4Cr-4Ti alloy by molten salt electro-deoxidation method comprises the following steps:

[0052] Step 1, mixing and pressing:

[0053] (1) By mass percentage, V 2 o 3 Powder: 93.2%, Cr 2 o 3 Ti powder: 4%, Ti powder: 2.8%, mixed in a ball mill tank for 8 hours;

[0054] (2) Put the mixed material in a steel mold and press it into a mixed oxide tablet; wherein, the molding pressure is 100 MPa, and the pressure is kept for 5 minutes; a tablet with a diameter of 10 mm and a height of 4 mm is obtained;

[0055] Step 2, tablet sintering:

[0056] Sinter the pressed tablet under the protection of argon, the sintering temperature is 1200°C, and the sintering time is 1h to obtain a mixed oxide sintered body;

[0057] Step 3, molten salt electrolysis:

[0058] (1) Wrap the mixed oxide sintered body with a molybdenum mesh and connect it with a molybdenum rod to form a cathode. A high-purity graphite rod is used as an anode, and is inserted in para...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com