Patents

Literature

63results about How to "Facilitate electrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method For Making A Fuel Cell

ActiveUS20110045386A1Facilitate electrolysisCell electrodesFinal product manufactureCell layerMetallurgy

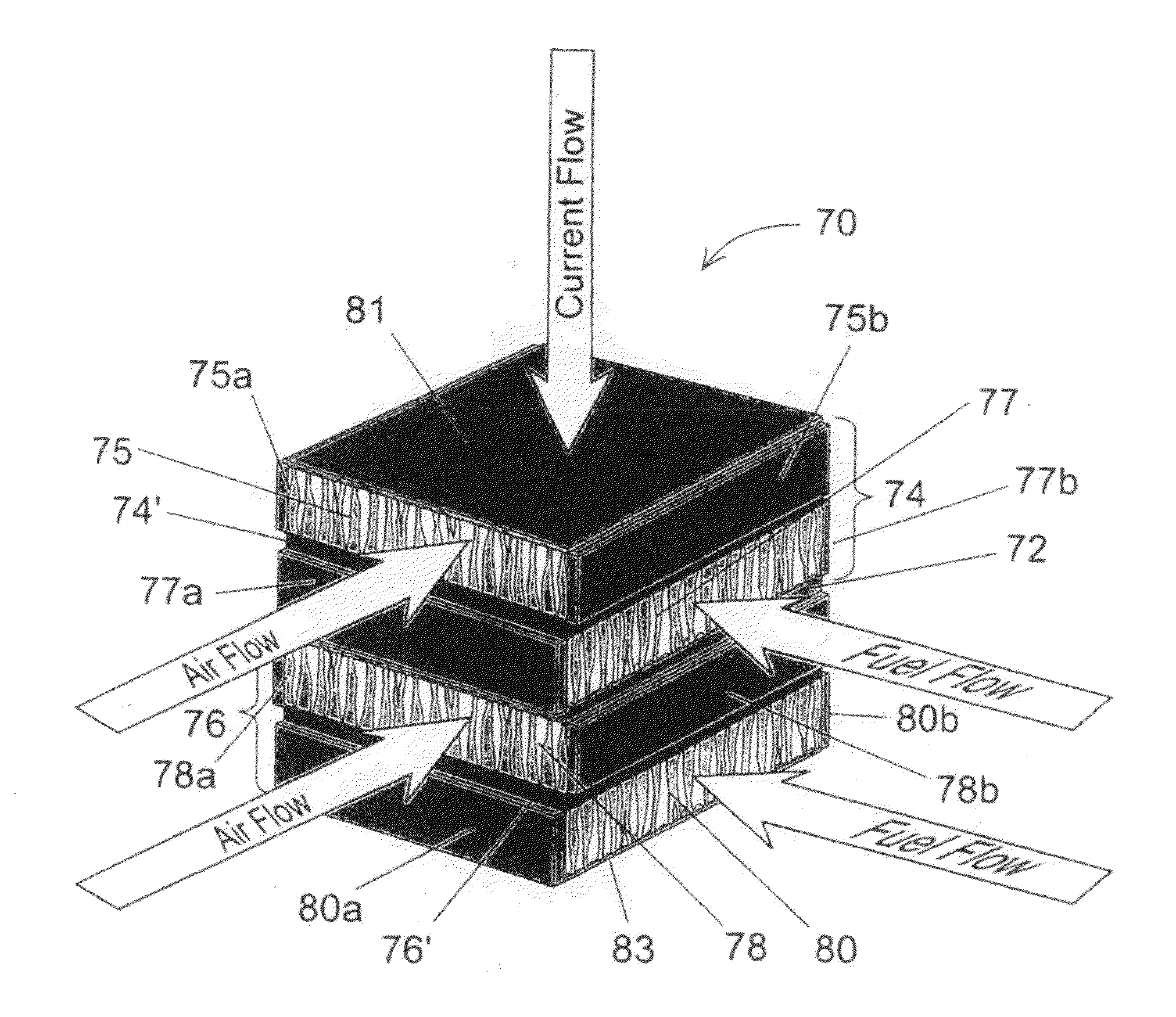

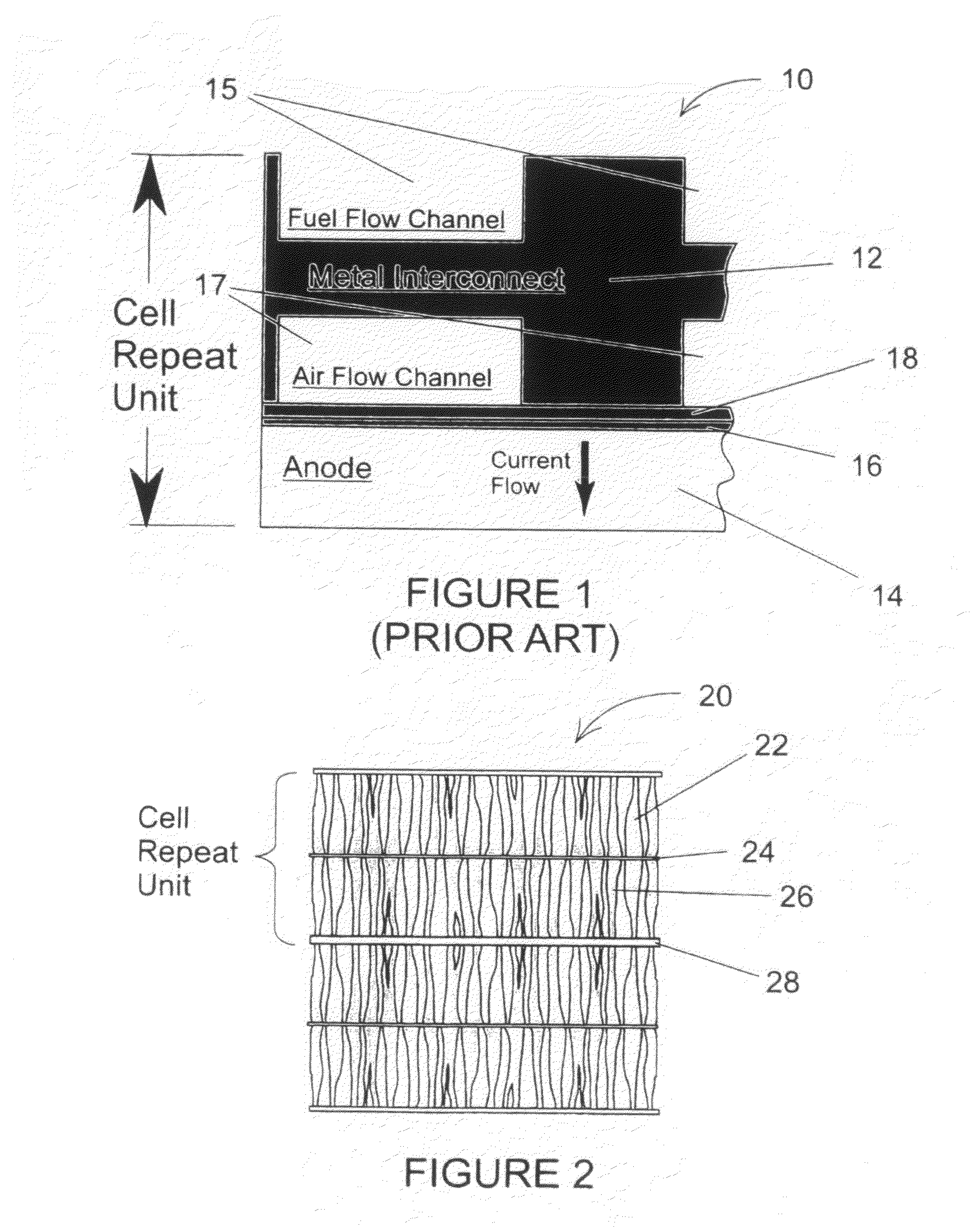

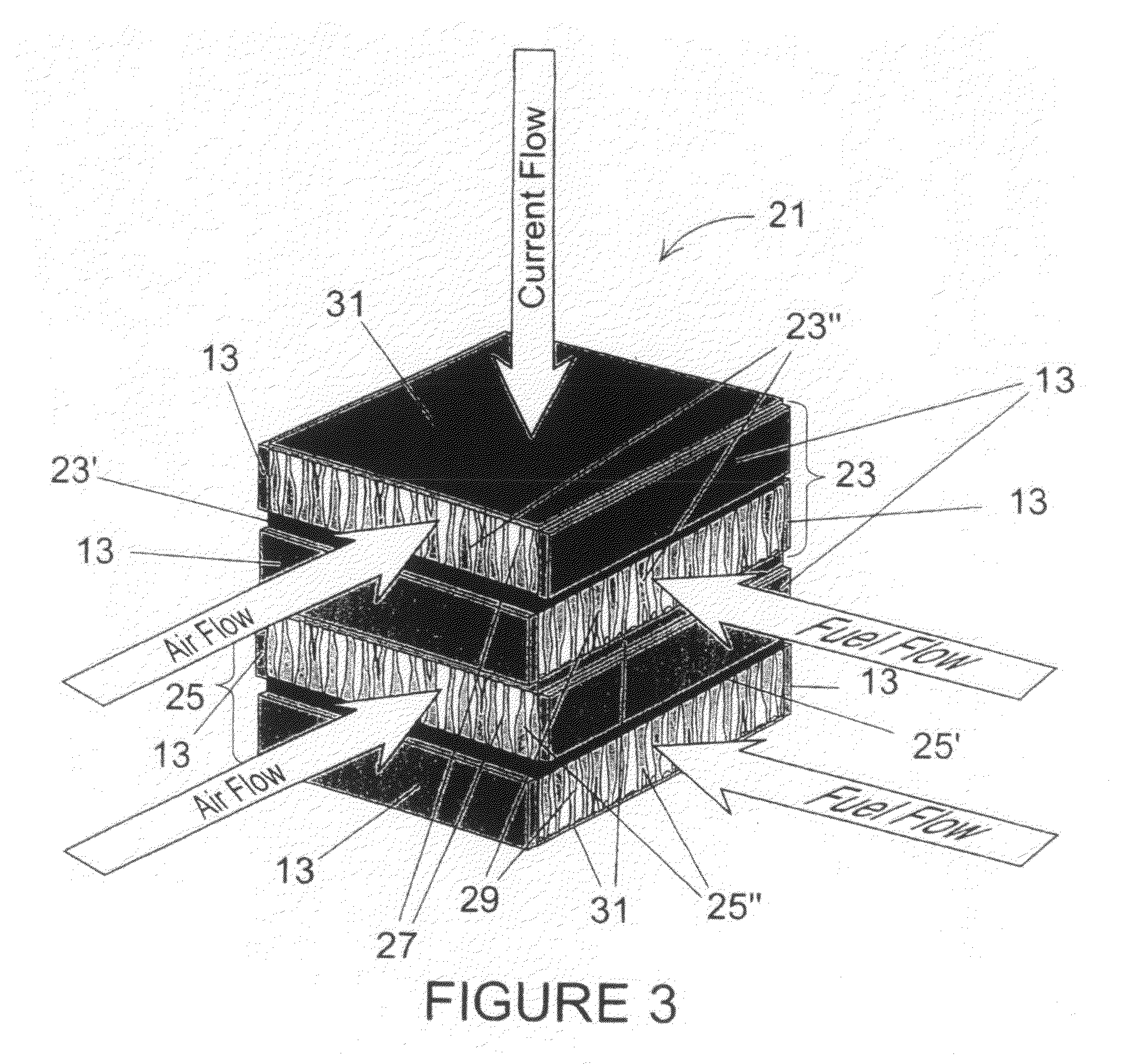

The invention is a novel solid oxide fuel cell (SOFC) stack comprising individual bi-electrode supported fuel cells in which a thin electrolyte is supported between electrodes of essentially equal thickness. Individual cell units are made from graded pore ceramic tape that has been created by the freeze cast method followed by freeze drying. Each piece of graded pore tape later becomes a graded pore electrode scaffold that subsequent to sintering, is made into either an anode or a cathode by means of appropriate solution and thermal treatment means. Each cell unit is assembled by depositing of a thin coating of ion conducting ceramic material upon the side of each of two pieces of tape surface having the smallest pore openings, and then mating the coated surfaces to create an unsintered electrode scaffold pair sandwiching an electrolyte layer. The opposing major outer exposed surfaces of each cell unit is given a thin coating of electrically conductive ceramic, and multiple cell units are stacked, or built up by stacking of individual cell layers, to create an unsintered fuel cell stack. Ceramic or glass edge seals are installed to create flow channels for fuel and air. The cell stack with edge sealants is then sintered into a ceramic monolithic framework. Said solution and thermal treatments means convert the electrode scaffolds into anodes and cathodes. The thin layers of electrically conductive ceramic become the interconnects in the assembled stack.

Owner:NASA

Method and device for controlling discharging power supply

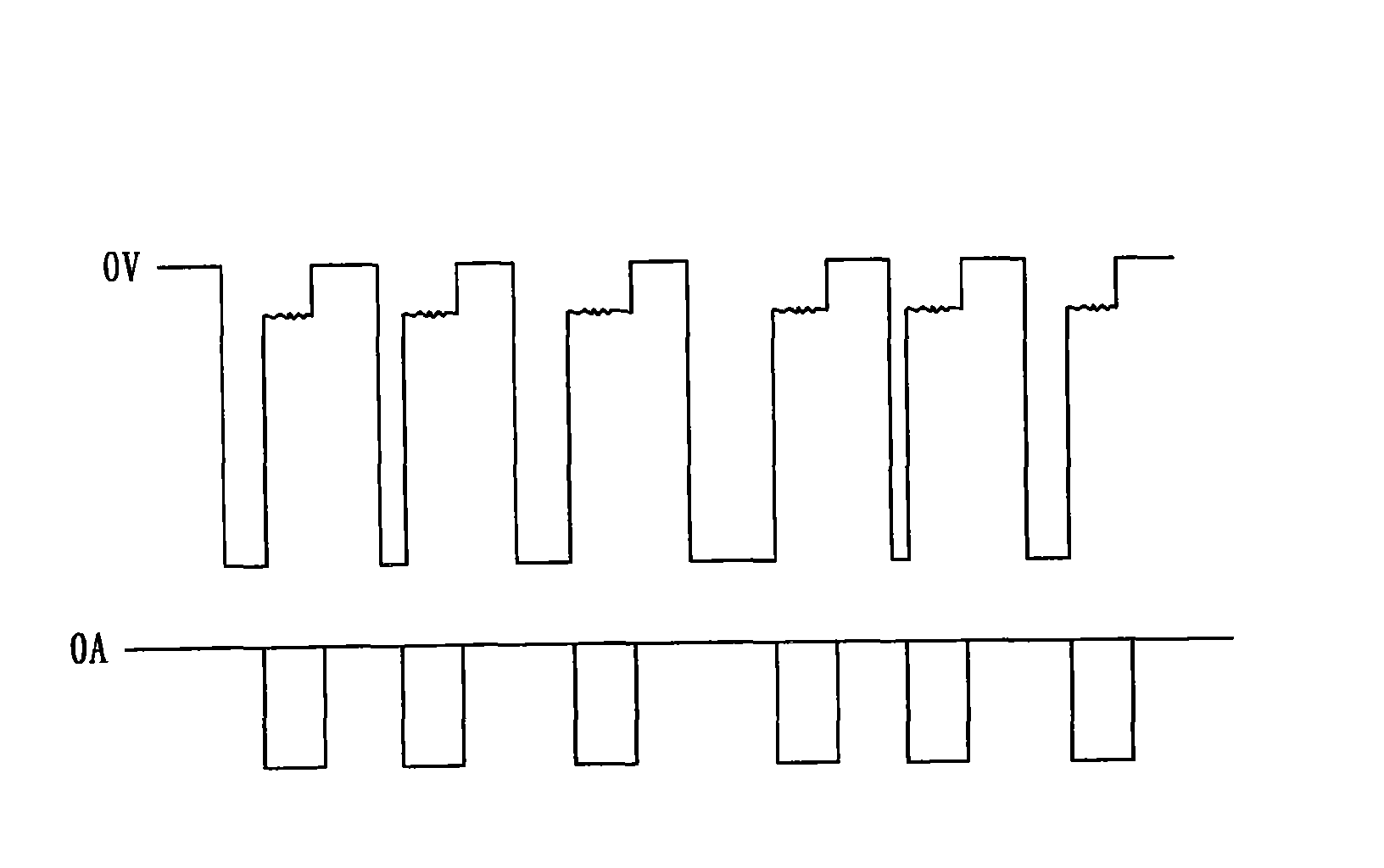

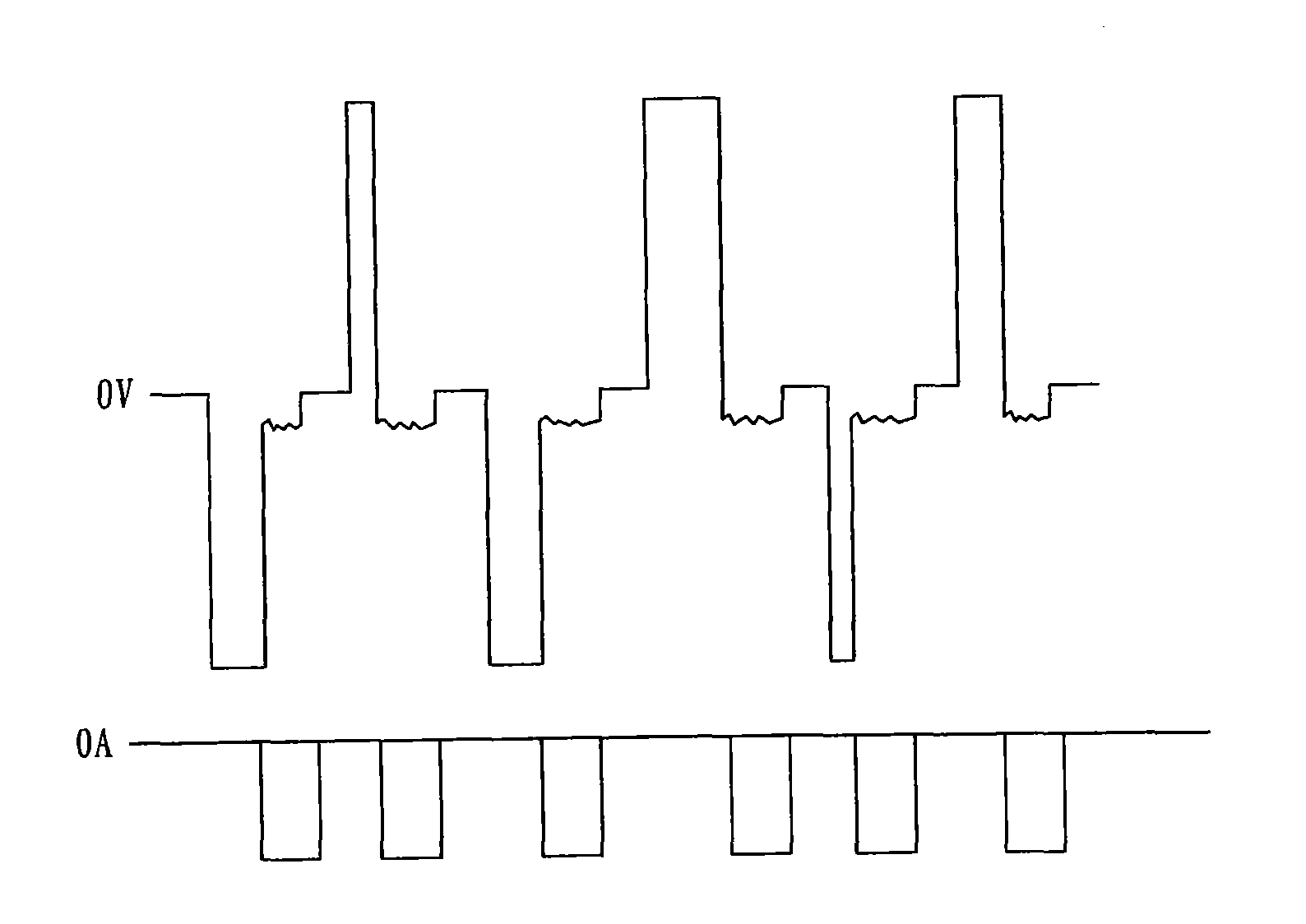

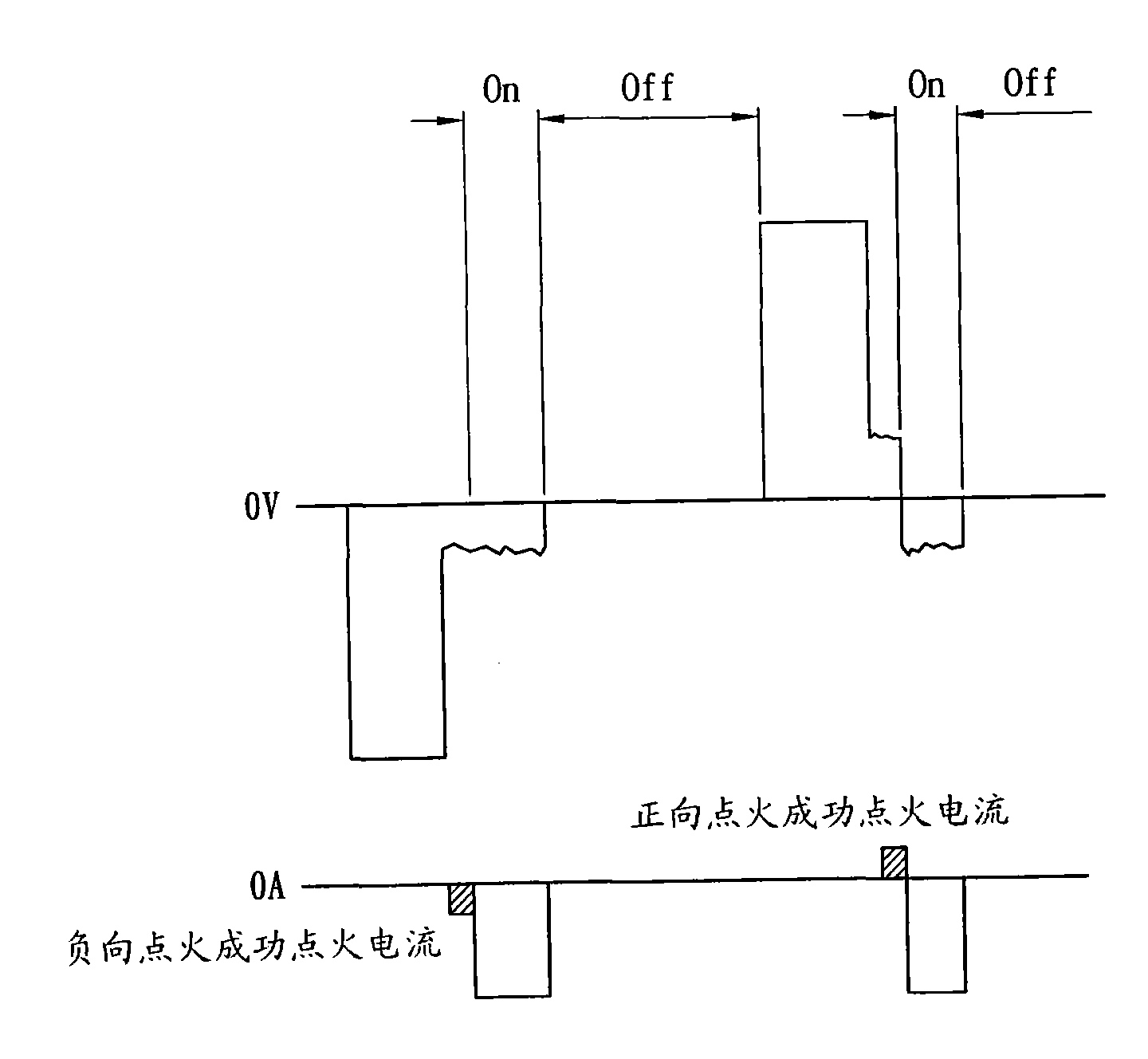

The invention discloses a method and a device for controlling a discharging power supply, and provides a novel method and a novel device for controlling the discharging power supply. The device consists of a bipolar ignition detection module, a discharging module and a micro control unit; the micro control unit is used for controlling an ignition direction and determining a gap state; the presentinterpolar state is detected and an electrolytic phenomenon is eliminated by a bipolar ignition detection discharging method; and in a state suitable for discharging, a discharging and cutting process is performed so as to realize homenergic discharging machining control. In the control method provided by the invention, an ignition detection program is controlled that positive operation can be reused after one or a plurality of negative ignition discharging periods if one positive ignition discharging period is finished; and an average voltage tends to zero. By the invention, the microwire machining efficiency is improved, and electrode loss is reduced; benefits of increasing the machining speed and reducing the used consumable can be achieved; and the linear cutting and discharging machining equipment manufacturing industry in China steps into the fine machining field.

Owner:IND TECH RES INST

Mixed collecting and crushing device and sewage comprehensive treatment system

ActiveCN106892517AImprove work efficiency and decontamination abilityEasy to handlePlastic recyclingMultistage water/sewage treatmentEngineeringSewage

Owner:GUANGZHOU WEI YE MARINE EQUIP CO LTD

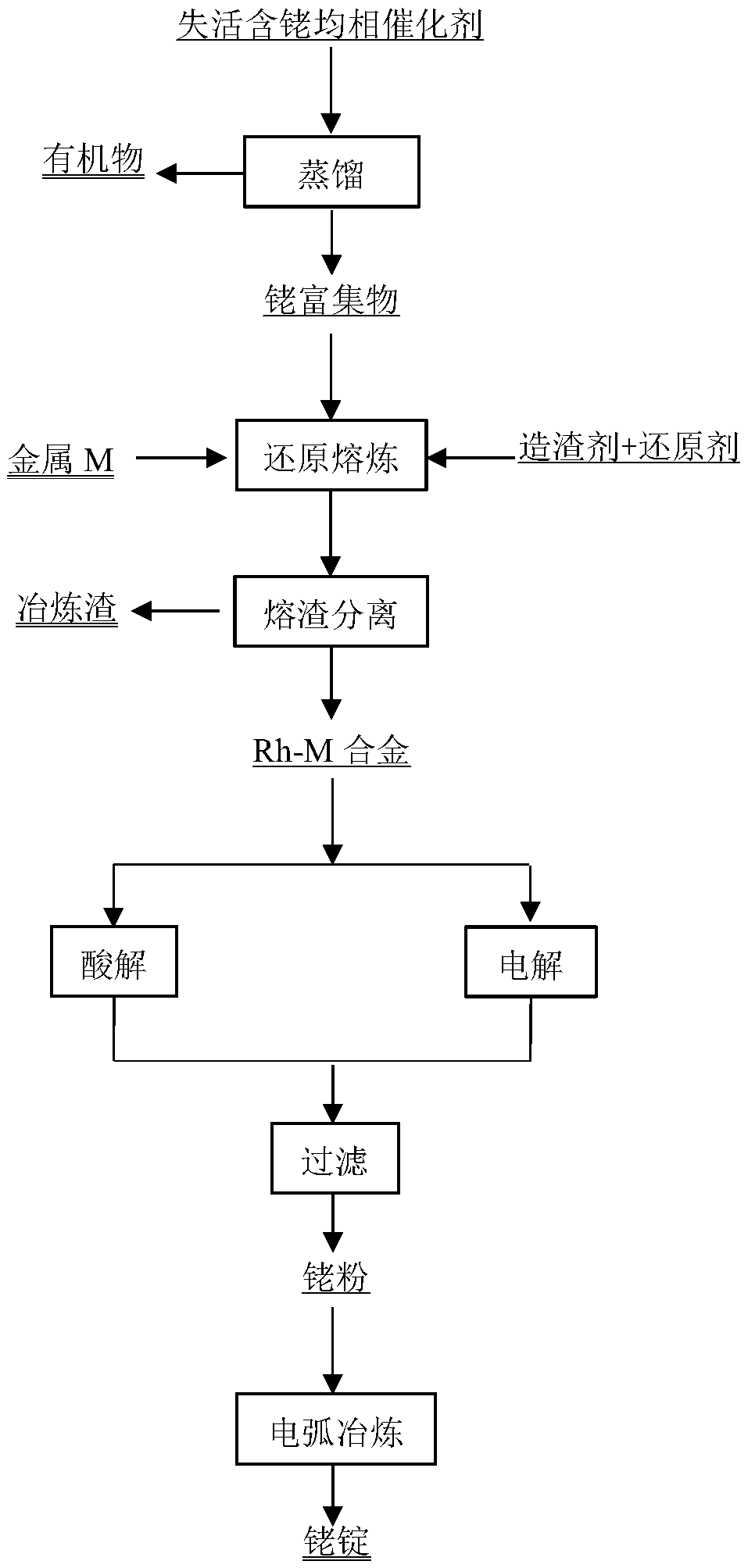

Method for recovering rhodium from inactive rhodium-containing homogeneous catalyst

ActiveCN108950233AAvoid pollutionHigh reactivityPhotography auxillary processesProcess efficiency improvementElectrolysisElectric arc furnace

The invention mainly belongs to the technical field of rhodium recovery and particularly relates to a method for recovering rhodium from an inactive rhodium-containing homogeneous catalyst. The methodcomprises the following steps that organic matter in the rhodium-containing homogeneous catalyst is recovered in a distillation mode at first, and rhodium concentrate is obtained; then the rhodium concentrate is mixed with transitional metal M, a reduction agent and a slag former, rhodium is recovered in a smelting manner and forms a low-melting-point Rh-M alloy together with the transitional metal M, then the Rh-M alloy is subjected to electrolysis or acidolysis to obtain rhodium powder, finally the rhodium powder is smelted through an electric-arc furnace, and accordingly a rhodium ingot isobtained. The method is suitable for various inactive rhodium-containing homogeneous catalysts, the situation that the organic matter is directly incinerated to cause air pollution is avoided, meanwhile, the high-melting-point rhodium can be converted into the low-melting-point high-reactivity Rh-M alloy, and subsequent rhodium smelting and purification are facilitated. The method has the advantages of being high in rhodium recovery rate and production efficiency, free of pollution and suitable for industrial application.

Owner:UNIV OF SCI & TECH BEIJING

Preparation process for producing epoxypropane by two-step extraction

ActiveCN103044359AReduce consumptionLow costCalcium/strontium/barium chloridesOrganic compound preparationTowerAqueous solution

The invention discloses a preparation process for producing epoxypropane by two-step extraction, belonging to the technical field of the production of fine chemical intermediates. The preparation process is characterized by comprising the following steps of: adding an extraction agent into aqueous mono-chloropropanol solution, and then extracting out mono-chloropropanol and discharging a water phase from the bottom of a first-stage extraction tower; adding the water phase from which the mono-chloropropanol is extracted into a complexing extraction agent to discharge hydrochloric acid, and discharging the water phase from the bottom of a second-stage extraction tower; pumping the extraction agent of the extracted mono-chloropropanol into a rectification tower, and separating out the mono-chloropropanol and the extraction agent; and pumping the separated mono-chloropropanol into a saponification reactor to perform saponification reaction with sodium hydroxide solution to generate crude epoxypropane, and rectifying the crude epoxypropane to obtain the epoxypropane product. According to the preparation process disclosed by the invention, the aqueous mono-chloropropanol solution is extracted to separate the hydrochloric acid from the aqueous mono-chloropropanol solution after the aqueous mono-chloropropanol solution is prepared by a traditional method, so that the consumption of the sodium hydroxide solution in the saponification process can be reduced, and the cost is saved.

Owner:山东昌邑海能化学有限责任公司

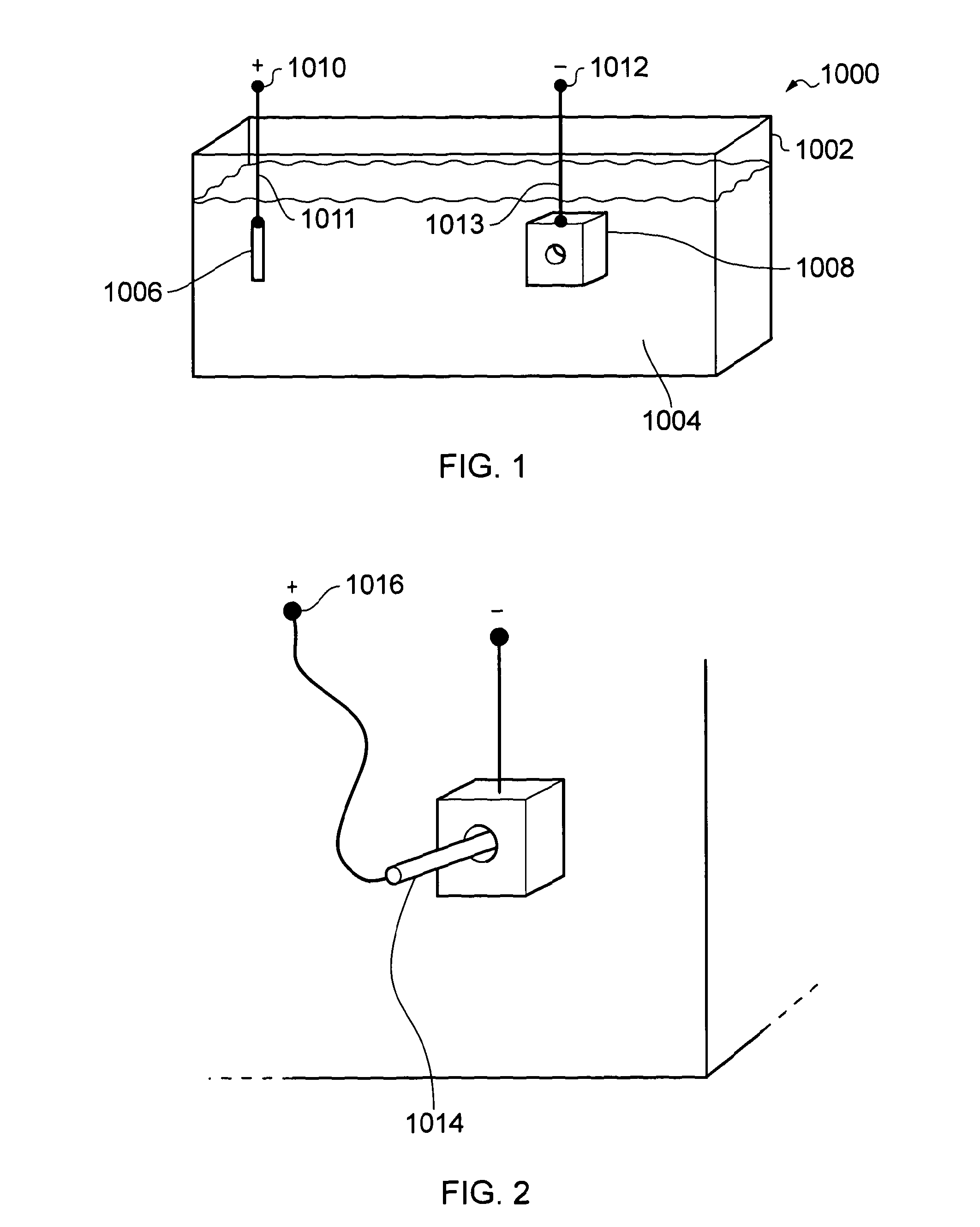

Method for disposing PCB through electrolysis

InactiveUS20070056857A1Improve conductivityFacilitate electrolysisSludge treatmentElectrolysis componentsElectrolysisWater cluster

A method for disposing of PCB including the steps of: putting a PCB containing liquid in an electrolysis tank; inserting an anode electric rod and a cathode electrode rod into the PCB containing liquid in the electrolysis tank; applying a high voltage current to the anode and cathode electrode rods; inserting an electric wave rod into the electrolysis tank; applying a supersonic wave to the electric wave rod, causing the PCB containing liquid to become an emulsion to increase the electroconductivity of the PCB containing liquid and to promote hydrolysis of the PCB containing liquid; and agitating the emulsion; wherein water clusters are decoupled in the emulsion of the PCB containing liquid and both the PCB and the liquid are electrolyzed while agitating the PCB containing liquid whereby chlorine separated from the PCB, hydrogen is generated from the liquid and hydrogen replaces chlorine in the PCB to form biphenyl.

Owner:KENJI SUZUKI & AIT

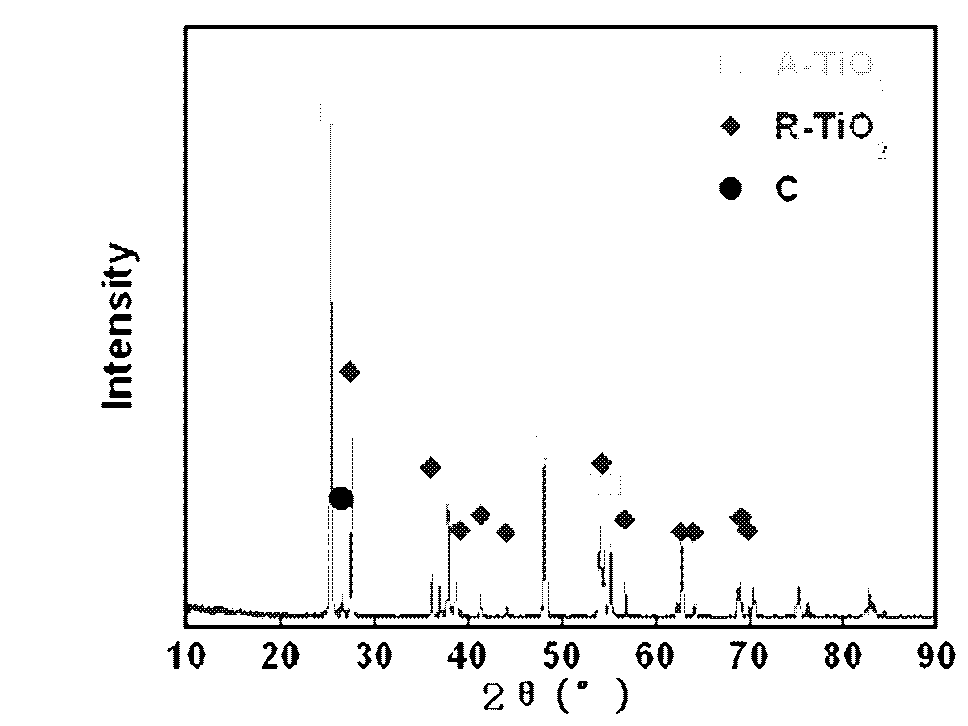

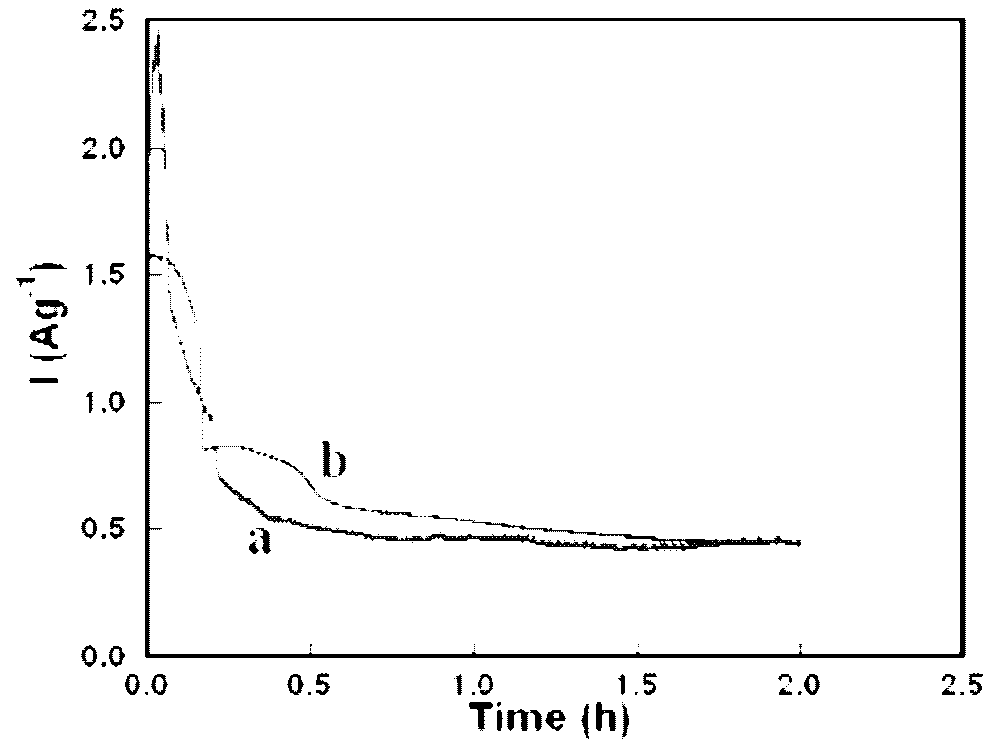

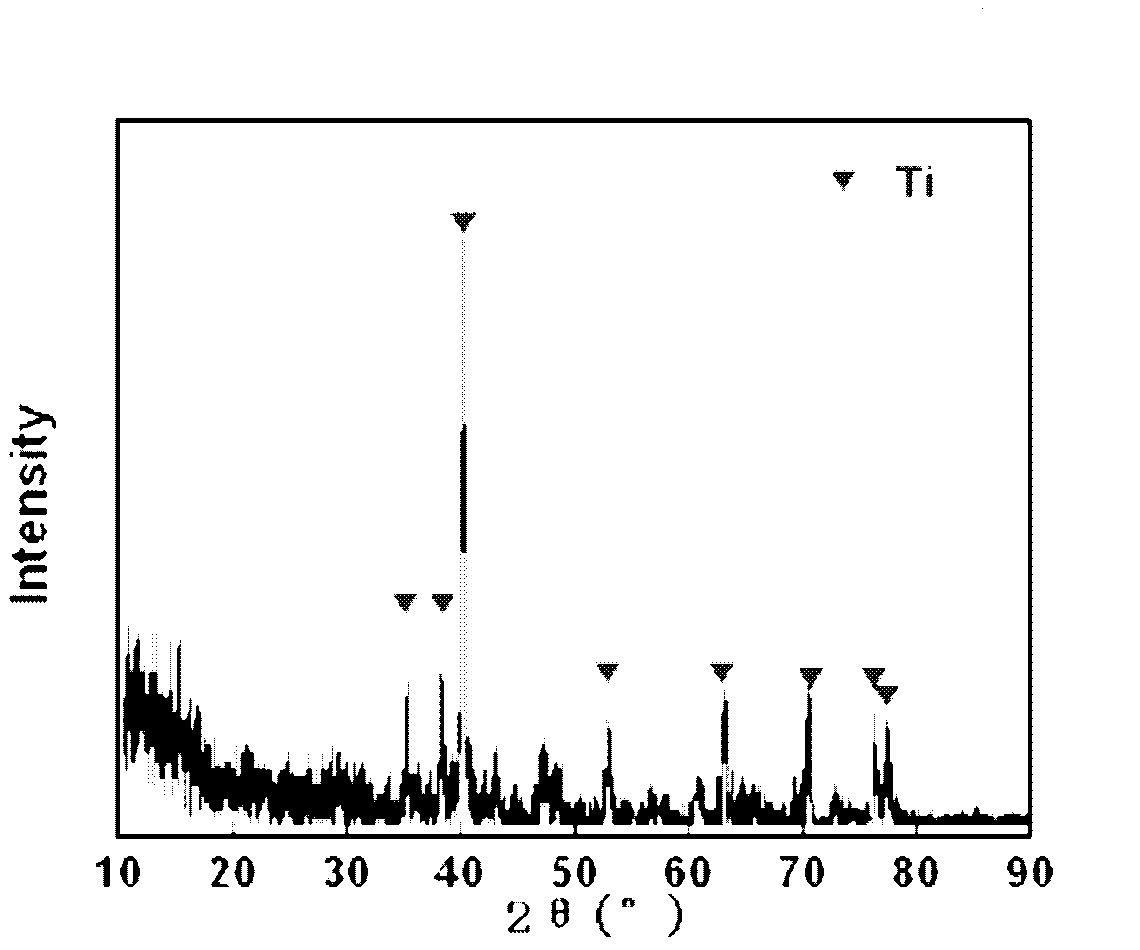

Method for improving TiO2 cathode deoxidizing process by utilizing carbonaceous additive

A method for improving TiO2 cathode deoxidizing process by utilizing a carbonaceous additive specifically comprises the following steps: mixing TiO2 and the carbonaceous additive according to the molar ratio of 2:1-19:1, and pressing a mixture into a block body with diameter of 10mm at the pressure of 1-5 t; performing heat treatment in the Ar protective atmosphere at the temperature of 800-1000 DEG C for 2-8 h to prepare a TiO2 / C composite cathode; using the TiO2 / C composite cathode prepared in the step 1 as a cathode, using a graphite rod as an anode, selecting CaC12 fused salt as an electrolyte system, exerting 2-3 V of bath voltage to perform electrolysis under the temperature condition of 800-950 DEG C for 5-20 h, removing an electrolysis product at the cathode, such asTi and TiCxOy compound at the normal temperature after finishing the electrolysis, and using deionized water and dilute acid to wash and remove chloride from electrolyte for many times. The method for improving the TiO2 cathode deoxidizing process by utilizing the carbonaceous additive has the advantages that the electrolysis time is shortened remarkably, the electrochemical reduction speed of the TiO2 cathode is accelerated accordingly, and a small quantity of added carbon powder enable the electrolysis products to become the compound of metal Ti and metal TiCxOy to be Ti and TiCxOy compound. By means of the method, the electrolytic process can be improved remarkably, remarkable reduction of energy loss is facilitated, and accordingly the production cost of the metal Ti is reduced.

Owner:UNIV OF SCI & TECH BEIJING

Manufacturing method of aluminium alloy strip used for printing CTP (computer-to-print) substrate

InactiveCN102248371AImprove crushing effectFacilitate electrolysisRoll mill control devicesMetal rolling arrangementsElectrolysisDislocation

The invention discloses a manufacturing method of an aluminium alloy strip used for printing a CTP (computer-to-point) substrate. By reasonably distributing hot rolling and cold rolling deformation, a better compound crushing effect and a dislocation distribution effect can be obtained, the grains are small, and the grain boundary quantity is increased, thus a tissue which is beneficial to electrolysis and can balance factors influencing the electrolysis can be obtained, and the mechanical properties are excellent.

Owner:JIANGSU ALCHA ALUMINUM CO LTD

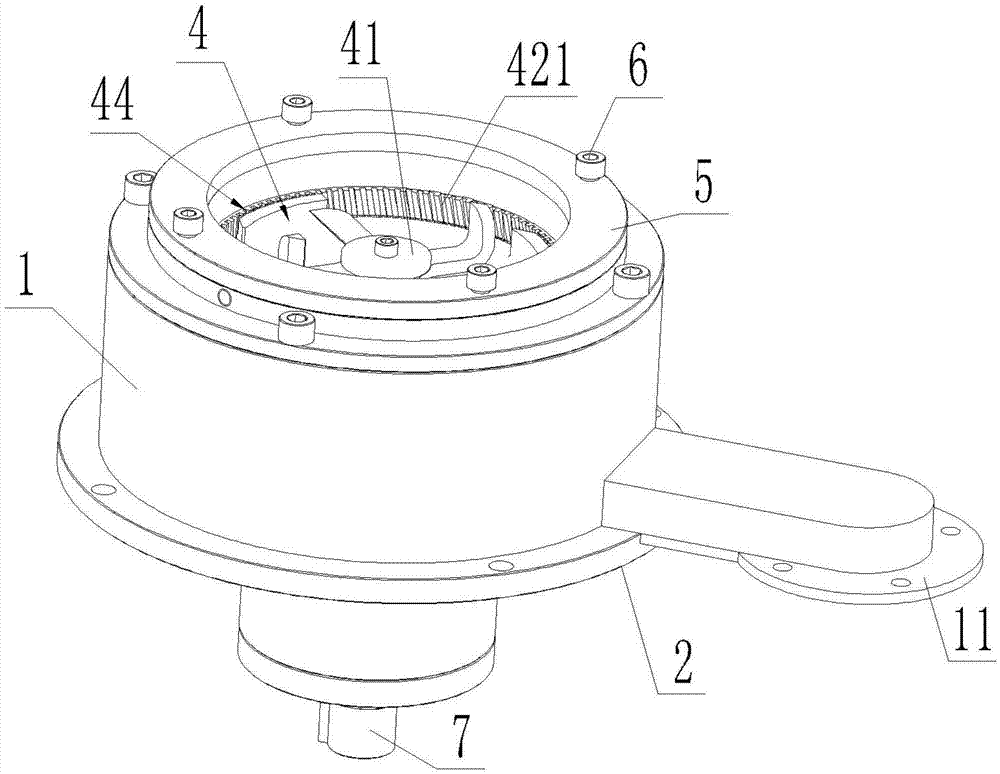

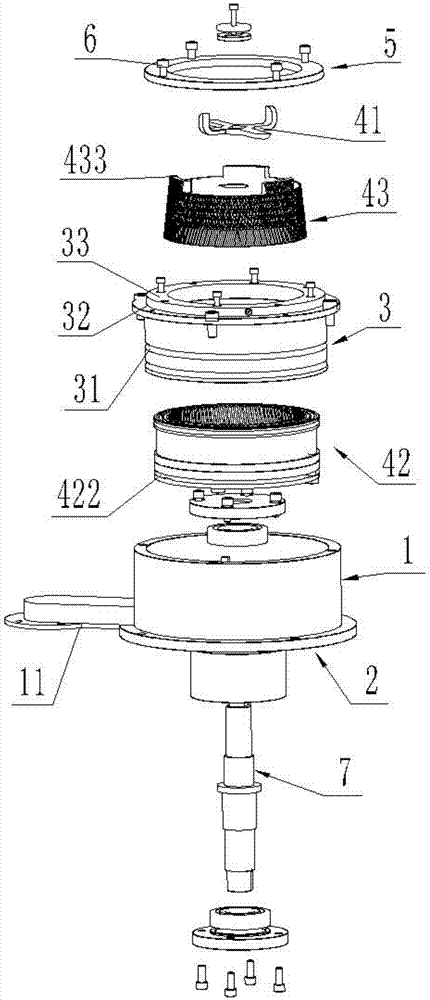

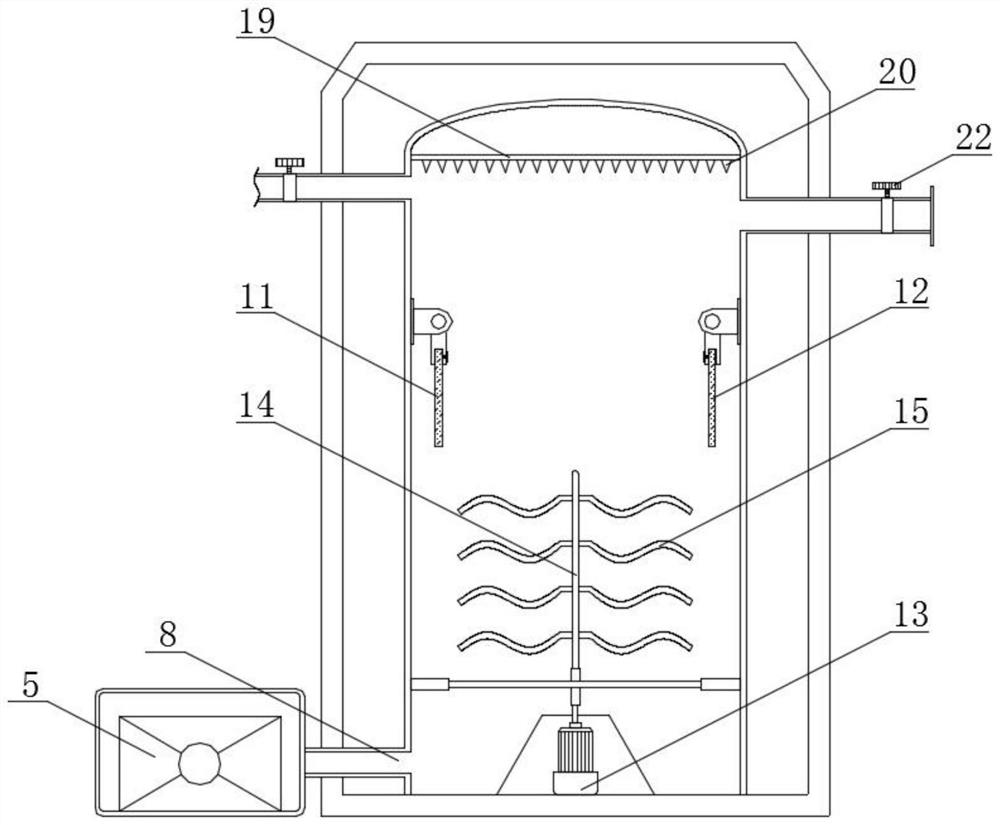

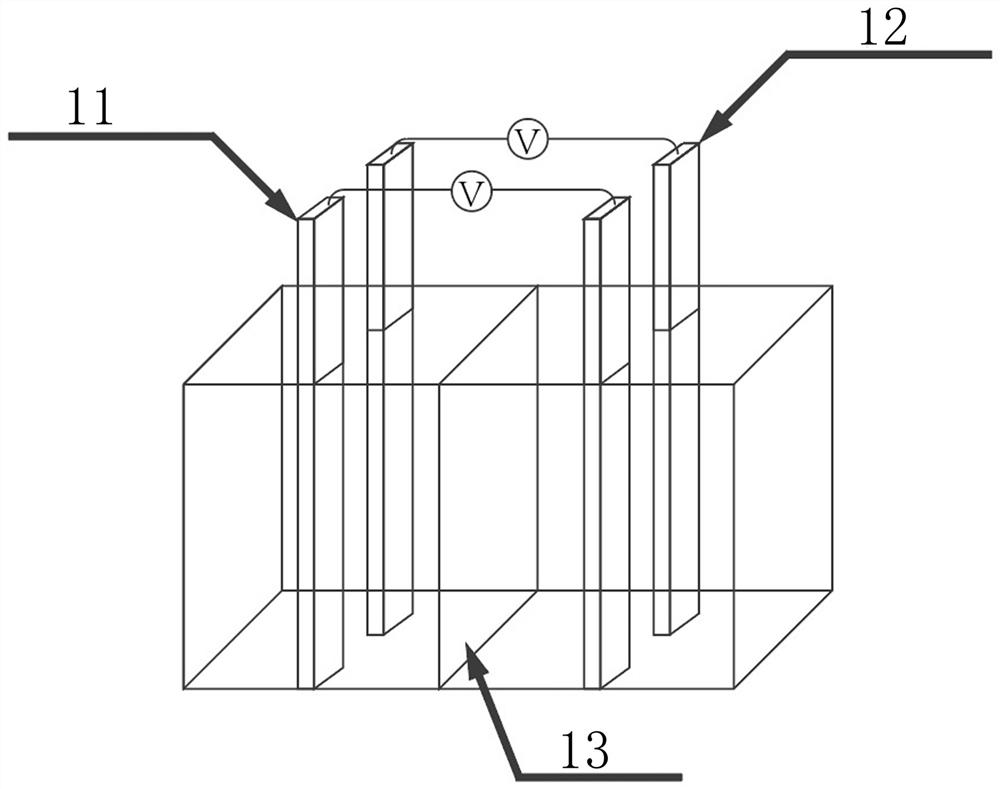

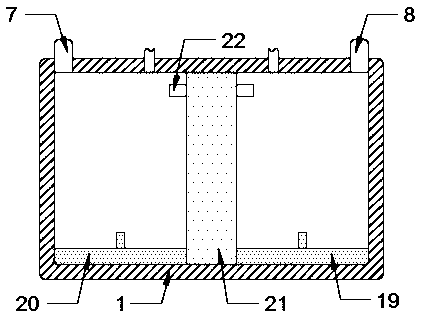

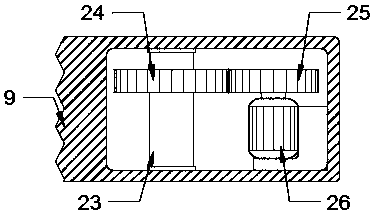

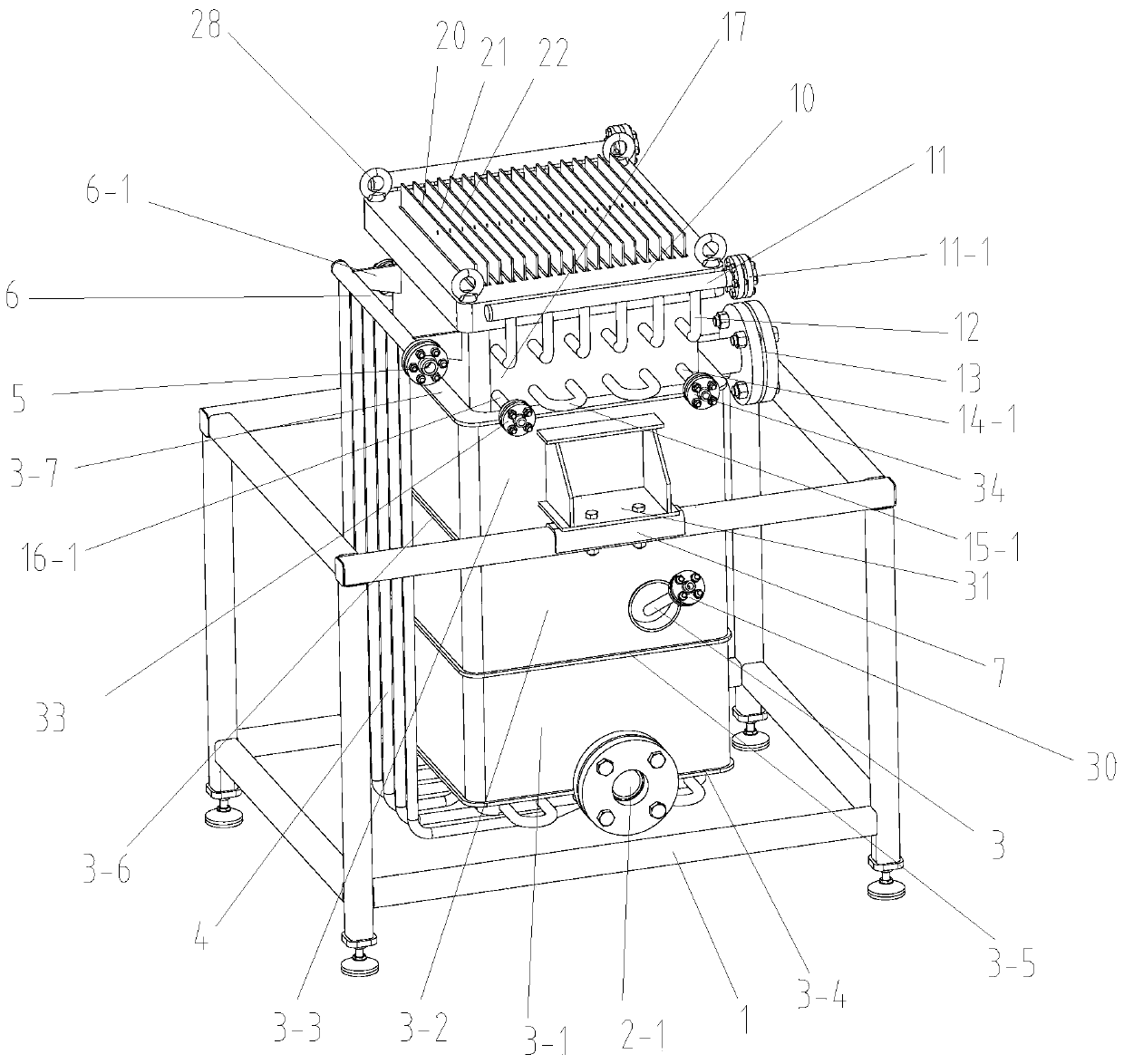

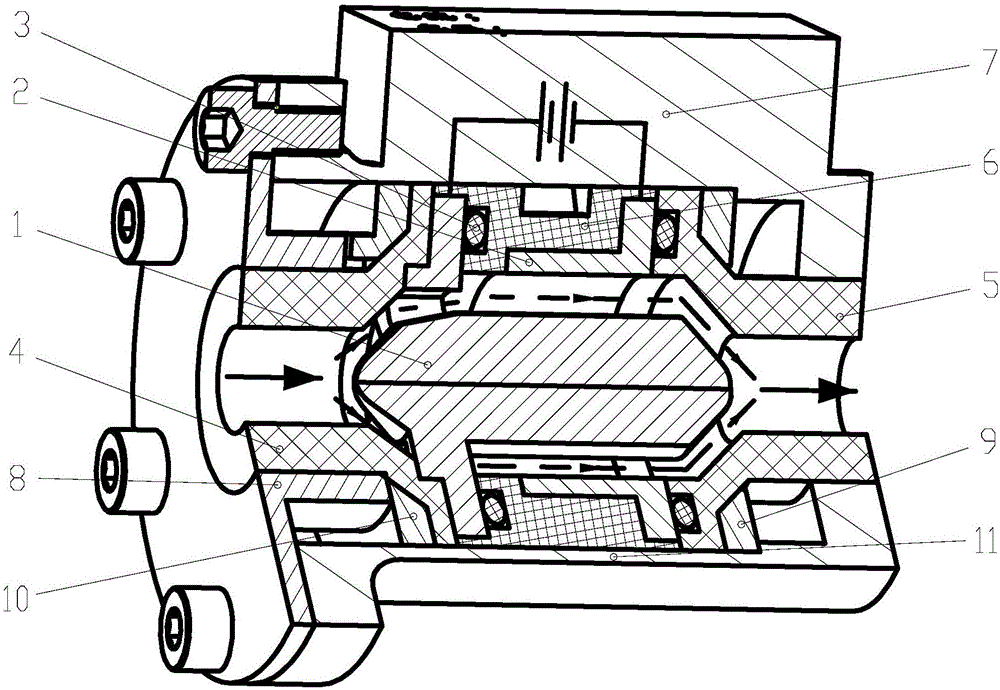

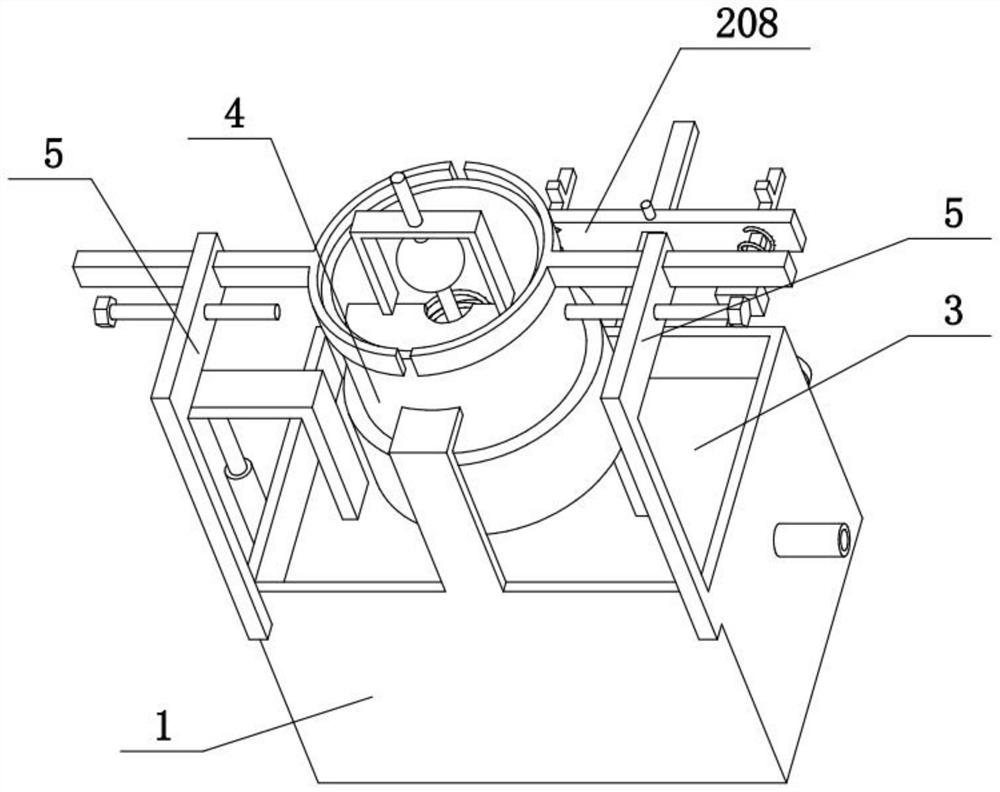

Novel electrolysis structure device for wastewater treatment

InactiveCN113526624AImprove electrolysis efficiencyIncrease mobilityRotary stirring mixersWater contaminantsElectrolysisElectric machinery

The invention discloses a novel electrolysis structure device for wastewater treatment. The device comprises a work box, a treatment tank and a purification tank, the treatment tank is arranged in the work box, and the purification tank is arranged on one side of the work box; a placement box is arranged at the bottom of one side of the working box, and a water pump is arranged in the placement box; and a fixing block is mounted in the middle of one side of the work box. Through the arrangement of the treatment tank and the matched work of the water inlet pipe, the water pump and the treatment tank, wastewater can enter from the lower part and exit from the upper part and can be forced to flow, so that the situation that the wastewater is difficult to completely pass through a magnetic field is avoided. A fixed rod and fixed teeth work together to support a positive electrode plate and an auxiliary electrode plate. After the device is connected to a power supply, the positive electrode plate and the auxiliary electrode plate are matched to work to electrolyze the wastewater, and a driving motor, a movable rod and stirring blades work together to improve the activity of the wastewater in the treatment tank, so that the structure can better electrolyze the wastewater.

Owner:南通市金宏电化设备有限公司

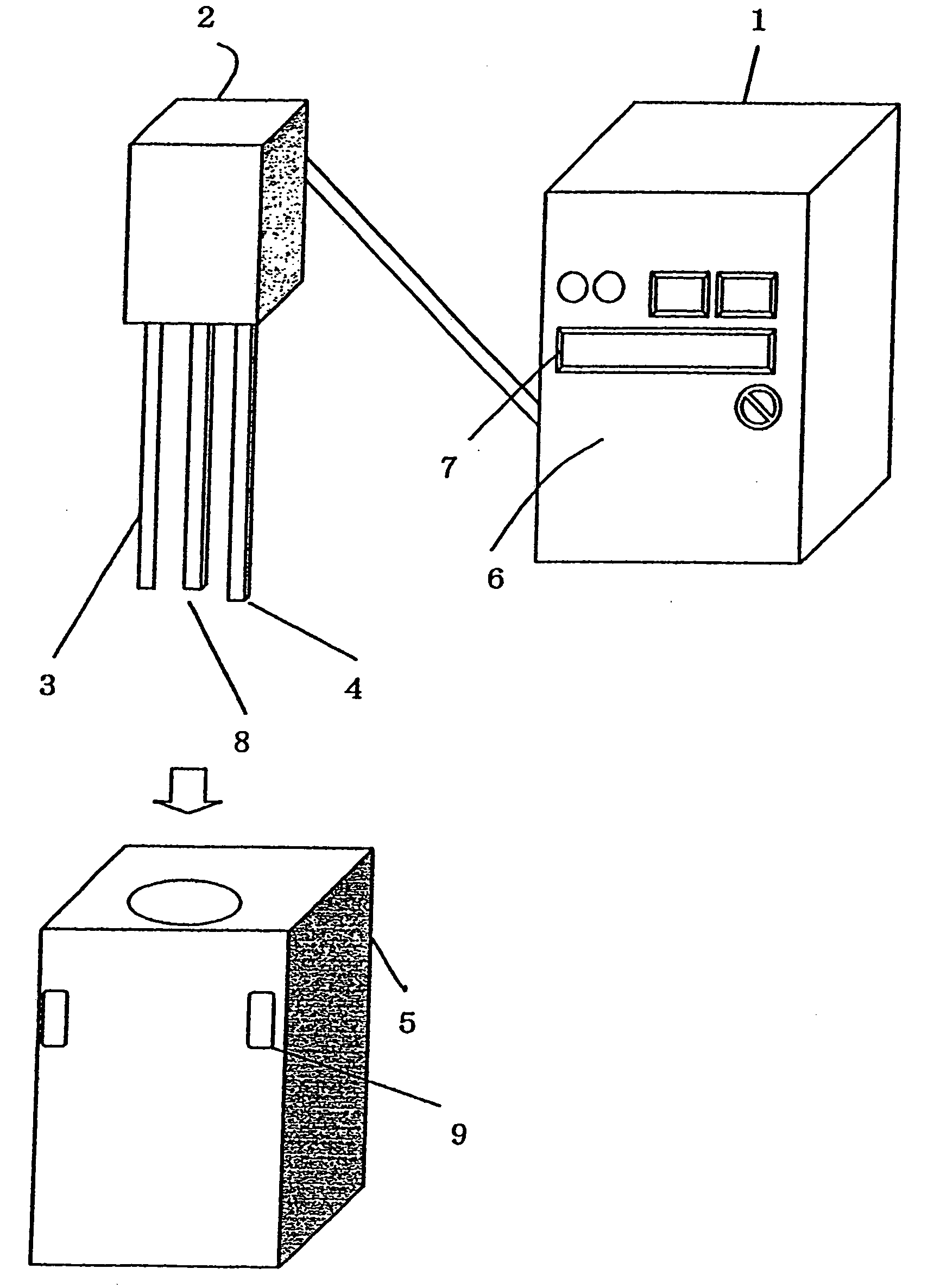

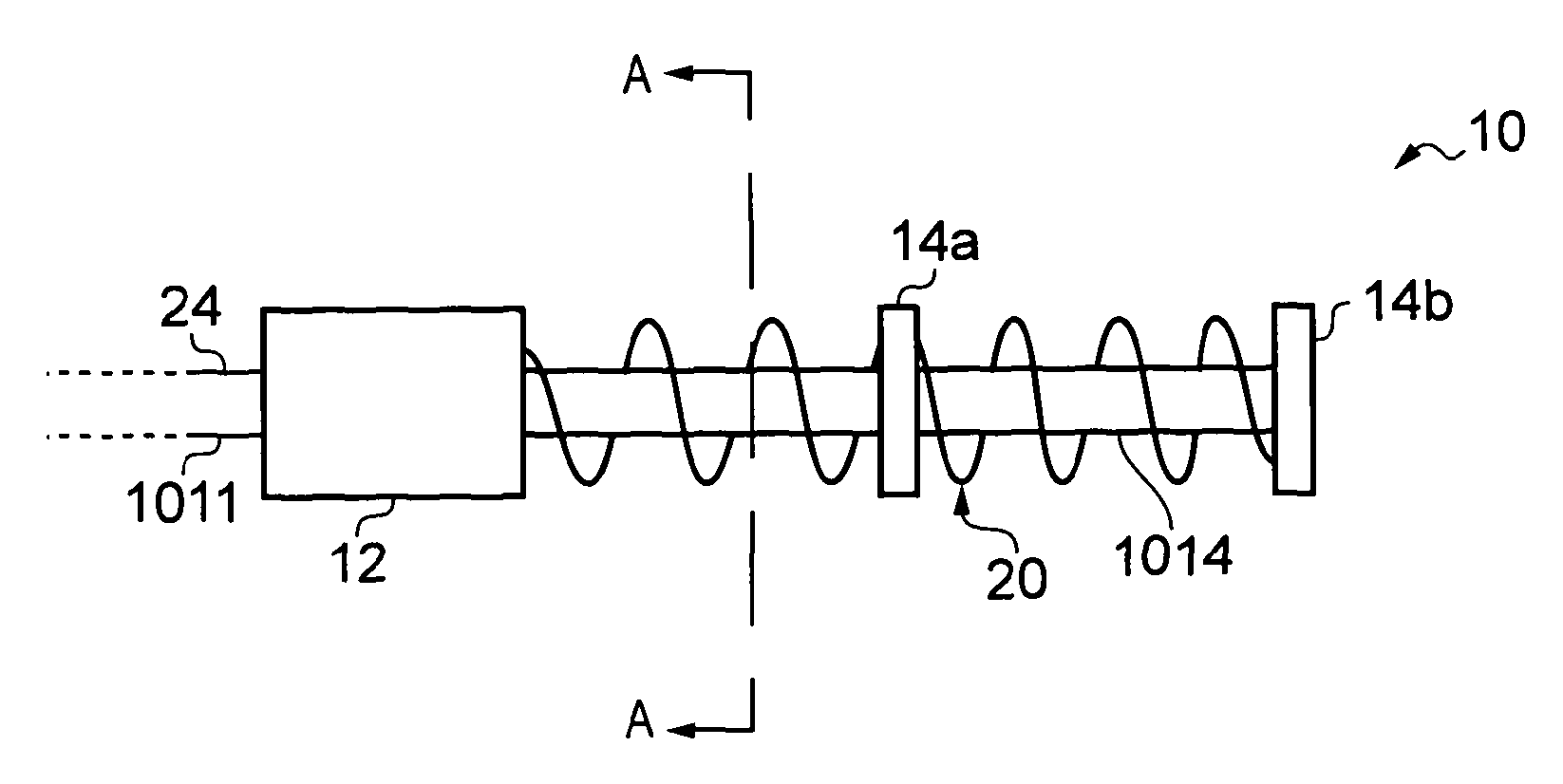

Electrolytic process apparatus

InactiveUS20120175246A1Facilitate electrolysisAvoid damageCellsMachining electric circuitsElectricityPower flow

Electrolytic process apparatus comprises a voltage source for electrically coupling to first and second electrodes, a detection circuit electrically coupled to the voltage source and a guard for providing a barrier between the first and second electrodes. The guard is arranged to permit current to travel within an electrolyte between the electrodes. The guard includes a guard conductor arranged to be electrically isolated from the electrodes. The guard conductor is arranged to be electrically coupled to the detection circuit such that the detection circuit can detect the presence of a current path between the guard conductor on the one hand and either electrode on the other hand.

Owner:AUTOMATION SOLUTIONS

Method for organic wastewater electro-fenton treatment adopting bentonite

ActiveCN102942241APromote decompositionSave electricityWater/sewage treatment by sorptionSodium BentoniteGraphite electrode

The invention provides a method for organic wastewater electro-fenton treatment adopting bentonite. The method comprises the following steps of 1, adding organic wastewater in an electrolytic cell, 2, adding dried bentonite into the electrolytic cell, 3, adding 0.1 to 0.2mL of a H2O2 solution into each liter of the organic wastewater, and 4, electrifying in the electrolytic cell at an electrolytic cell current of 5 to 40mA with continuous stirring for 3 to 6 hours so that organics in the organic wastewater are degraded by oxidation and is precipitated and separated, wherein an anode of the electrolytic cell is an iron sheet electrode; a cathode is a graphite electrode; after being carried out for 15 to 20min, an electrifying process is stopped for 30 to 40min and the electrifying cycle is repeated; and a stirring rate is in a range of 50 to 150r / min. Organic wastewater treated by the method satisfies discharge standards. Through cation exchange performances of bentonite, iron ions produced by electrolysis are transferred to bentonite layers so that the concentration of iron ions residual in wastewater is reduced and iron ion-modified bentonite having catalytic activity is obtained.

Owner:江阴智产汇知识产权运营有限公司

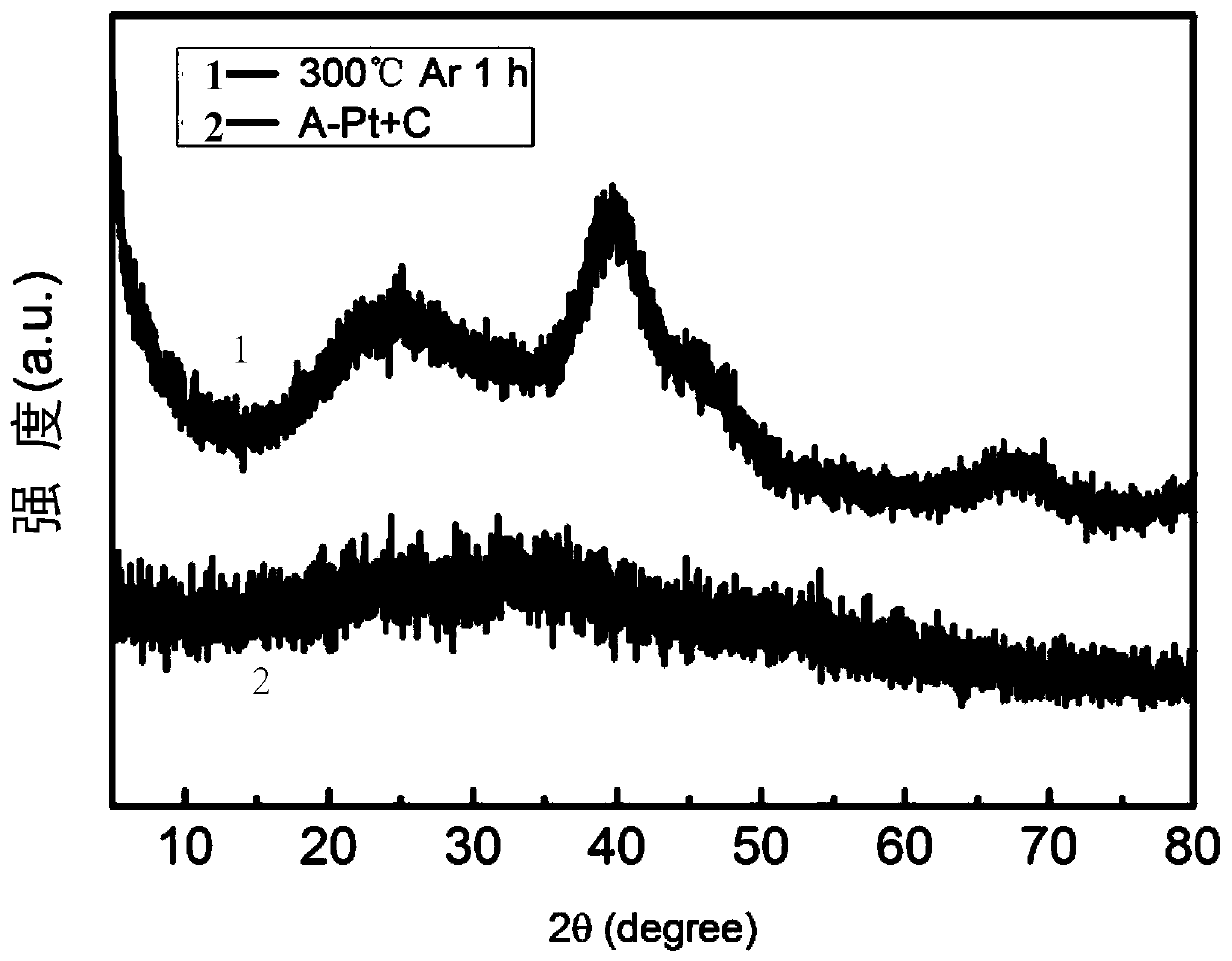

Amorphous Pt nano-catalyst as well as preparation method and application thereof

InactiveCN110918090ASimple methodMild preparation conditionsCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNano catalystPtru catalyst

The invention relates to an amorphous Pt nano-catalyst as well as a preparation method and application thereof. The preparation method of the amorphous Pt nano-catalyst comprises the following steps of adding a carbon-containing organic matter into a Pt ion precursor aqueous solution, and reacting at 25-40 DEG C for 10-16 hours to form an amorphous structure while Pt ions in a Pt ion precursor arereduced, therefore, obtaining the amorphous Pt nano-catalyst, wherein the carbon-containing organic matter is selected from at least one of pyrrole and polypyrrole.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

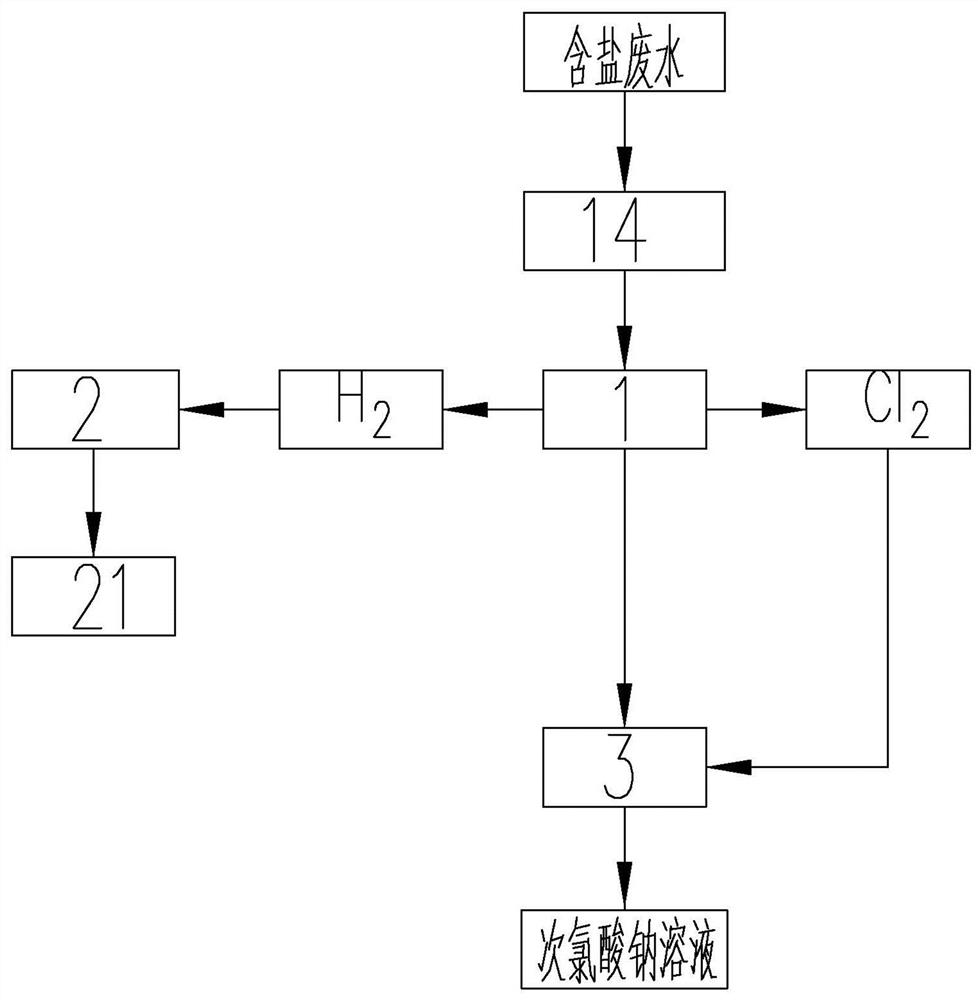

Salt-containing wastewater recycling device and process

The invention relates to a salt-containing wastewater recycling device and process. The device comprises an electrolytic cell, a hydrogen post-treatment device and an external COD detection device, wherein the electrolytic cell is provided with a COD removal electrode group, a hydrogen production electrode group and a diaphragm for isolating an anode chamber from a cathode chamber, the electrolytic cell is provided with a salt-containing wastewater inlet and an electrolytic solution outlet, and the hydrogen post-treatment device is connected to the cathode chamber of the electrolytic cell. According to the process, salt-containing wastewater is discharged into an electrolytic cell after COD detection, and when the COD of the salt-containing wastewater is larger than or equal to 10 mg / L, aCOD removal electrode group is started; when the COD of the salt-containing wastewater is lower than 10 mg / L, a hydrogen production electrode group is opened, and the COD removal electrode group is closed; and after electrolysis of the hydrogen production electrode group, chlorine is generated in an anode chamber, and hydrogen is generated in a cathode chamber. By adopting the method to recycle salt-containing wastewater, the damage of the salt-containing wastewater to the ecological environment can be reduced, and the available hydrogen and sodium hypochlorite solution can be obtained at thesame time.

Owner:NORTH CHINA POWER ENG

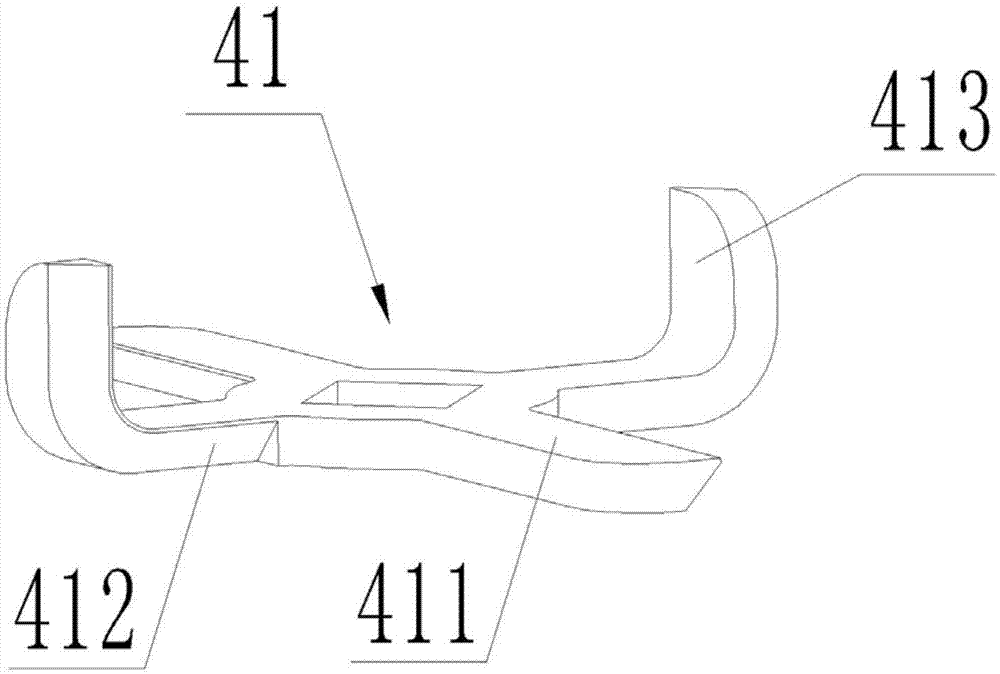

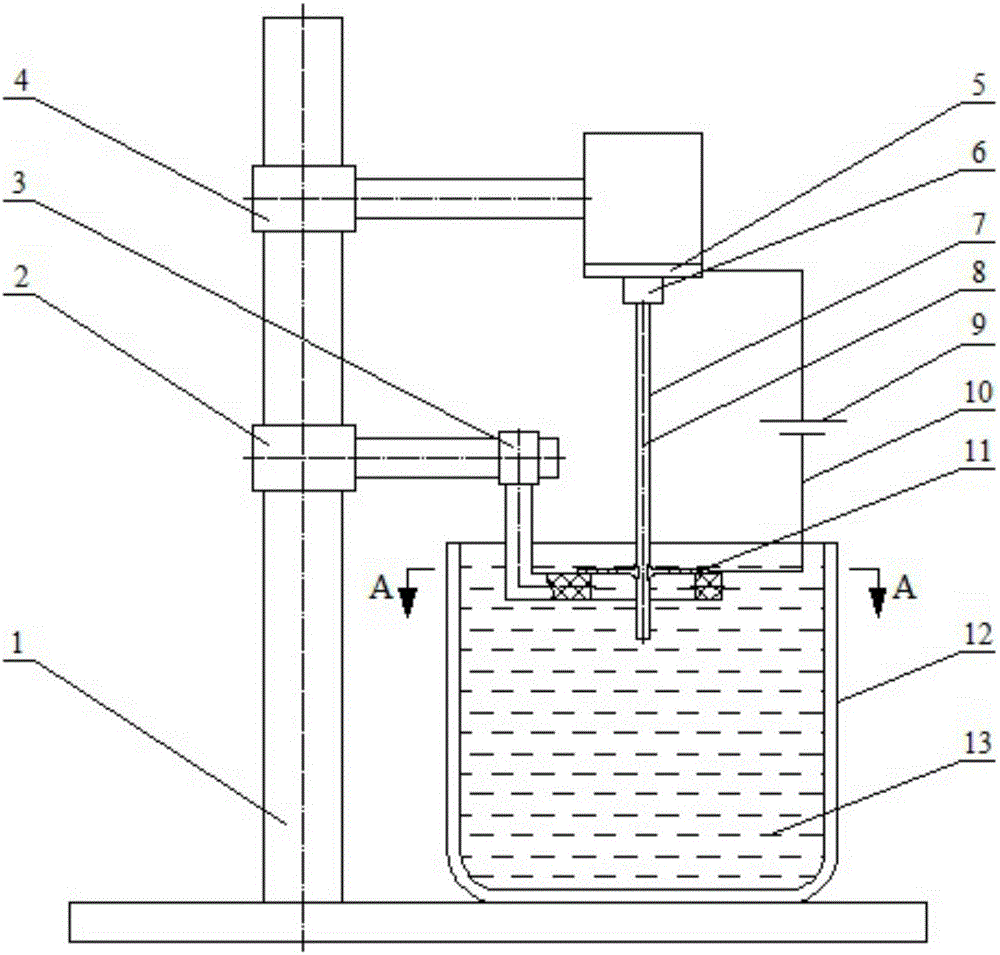

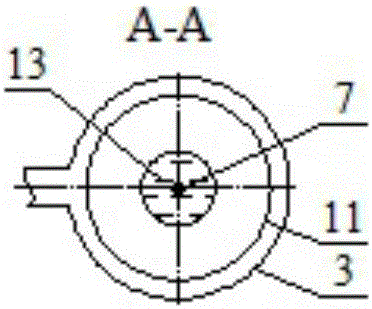

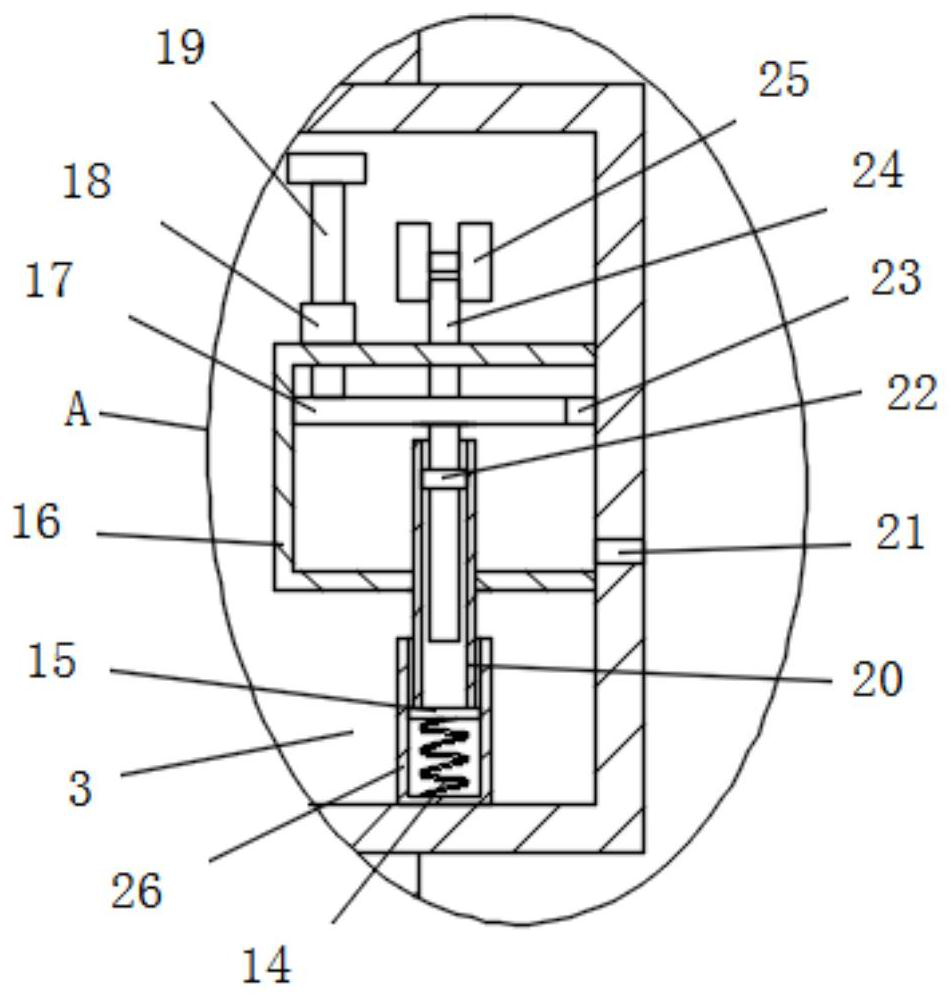

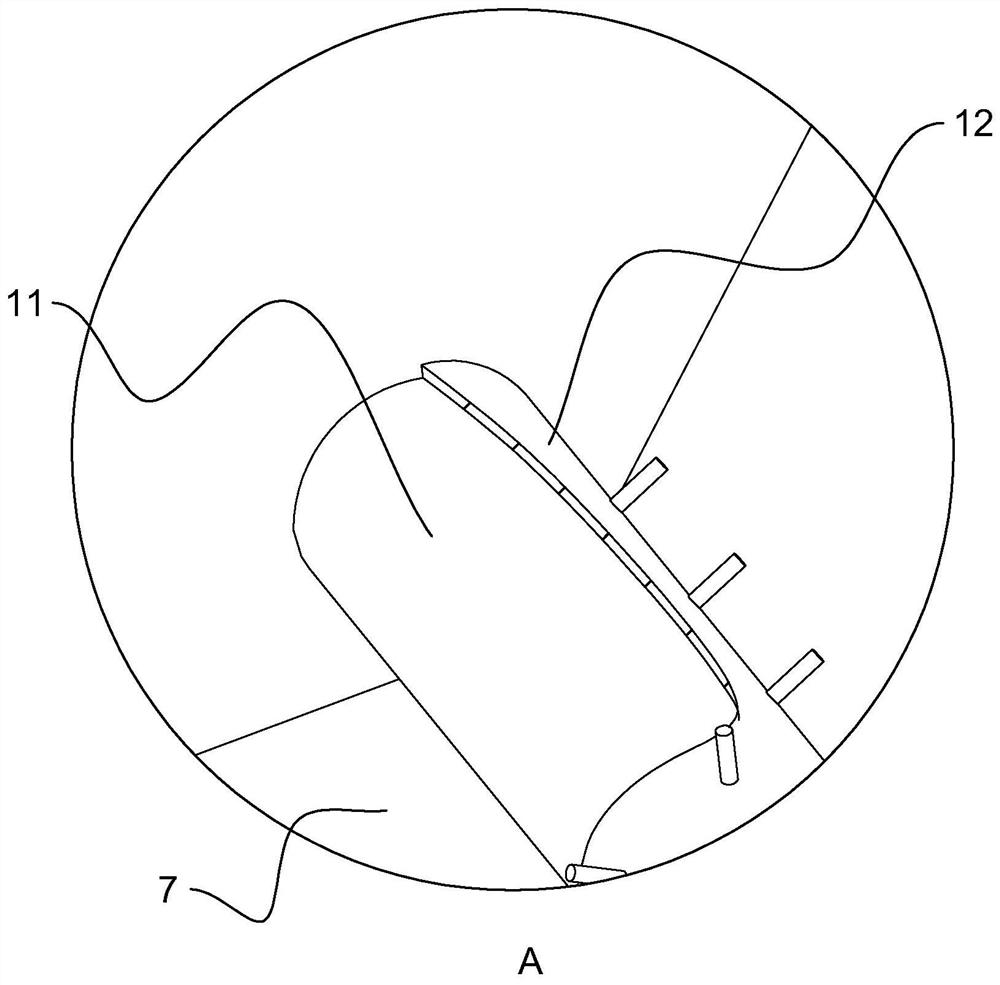

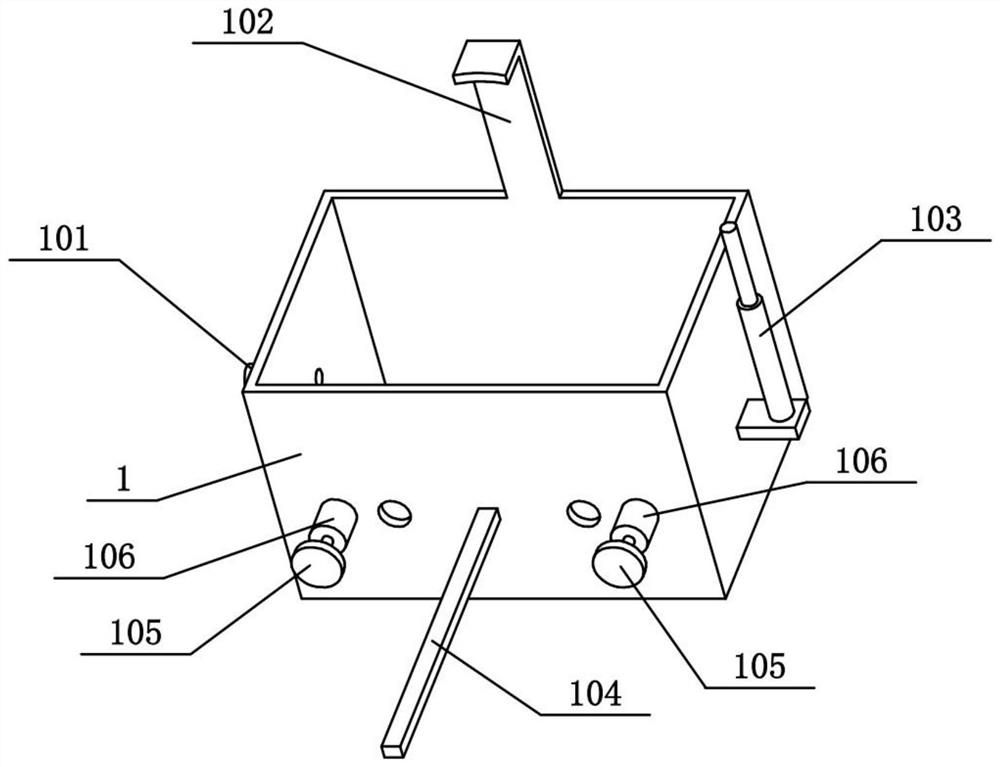

Connecting structure for vertically fixing probe rod and probe rod fixing method

ActiveCN106771377ASimple connection structureReduce drag torqueScanning probe microscopyBiomedical engineeringManufacturing quality

The invention discloses a connecting structure for vertically fixing a probe rod and a probe rod fixing method. The connecting structure comprises a conducting plate (5), wherein a magnet (18) is adsorbed at the upper side of the conducting plate (5); the conducting plate (5) is connected with an upper regulating frame (4); the lower surface of the conducting plate (5) is a plane; conducting glue (19) is coated on the lower surface of the conducting plate (5). The method comprises the following steps of 1, manufacturing the probe rod with one sharp and long end; 2, manufacturing a magnetic probe rod with one sharp and long end; 3, uniformly coating the conducting glue on the lower surface of the conducting plate; 4, vertically fixing the magnetic probe rod with one sharp and long end on the lower surface of the conducting plate. The connecting structure disclosed by the invention solves the problems that the connecting structure for fixing the probe rod in the prior art is difficult to realize the verticality of a short probe; an external instrument is needed; the axial line perpendicularity of the probe is regulated through the upper regulating frame or the connecting structure for fixing the probe rod; the regulation of the axial line perpendicularity of the probe is difficult; when the axial line of the probe is not perpendicular, the pinpoint of the probe on the axial line of the probe is influenced; the pinpoint manufacturing quality of the probe is influenced.

Owner:GUIZHOU UNIV

Aged refuse participating organic waste water electro-Fenton treatment method

ActiveCN102897921ASave electricityFavorable for electrolysis and microbial degradationBiological water/sewage treatmentDecompositionGraphite electrode

The present invention provides an aged refuse participating organic waste water electro-Fenton treatment method, which comprises the following steps that: organic waste water is added to an electrolyte tank, and aged refuse with a landfill age of 8-15 years is added, and per liter of the waste water is added with 0.1-0.2 mL of a H2O2 solution, wherein an anode electrode of the electrolyte tank is an iron sheet electrode, and a cathode electrode is a graphite electrode; a current of the electrolyte tank is switched on to 5-40 mA, wherein switching-off is performed for 30-40 min after every switching-on is performed for 15-20 min, cycle operation is performed, constant stirring is performed during the whole process, and a stirring rotation speed is 50-150 r / min; after the total time of 3-6 h, organics in the waste water are subjected to oxidation degradation, precipitate is separated, the discharged waste water meets the standard; and waste water is added again, is treated by using the same method, and can be continuously degraded, wherein the iron electrode is gradually oxidized and enters the solution during the electrolysis, and reacts with the added H2O2 to generate a strong oxidant .OH to promote pollutant decomposition.

Owner:苏州弘宇节能减排工程有限公司 +1

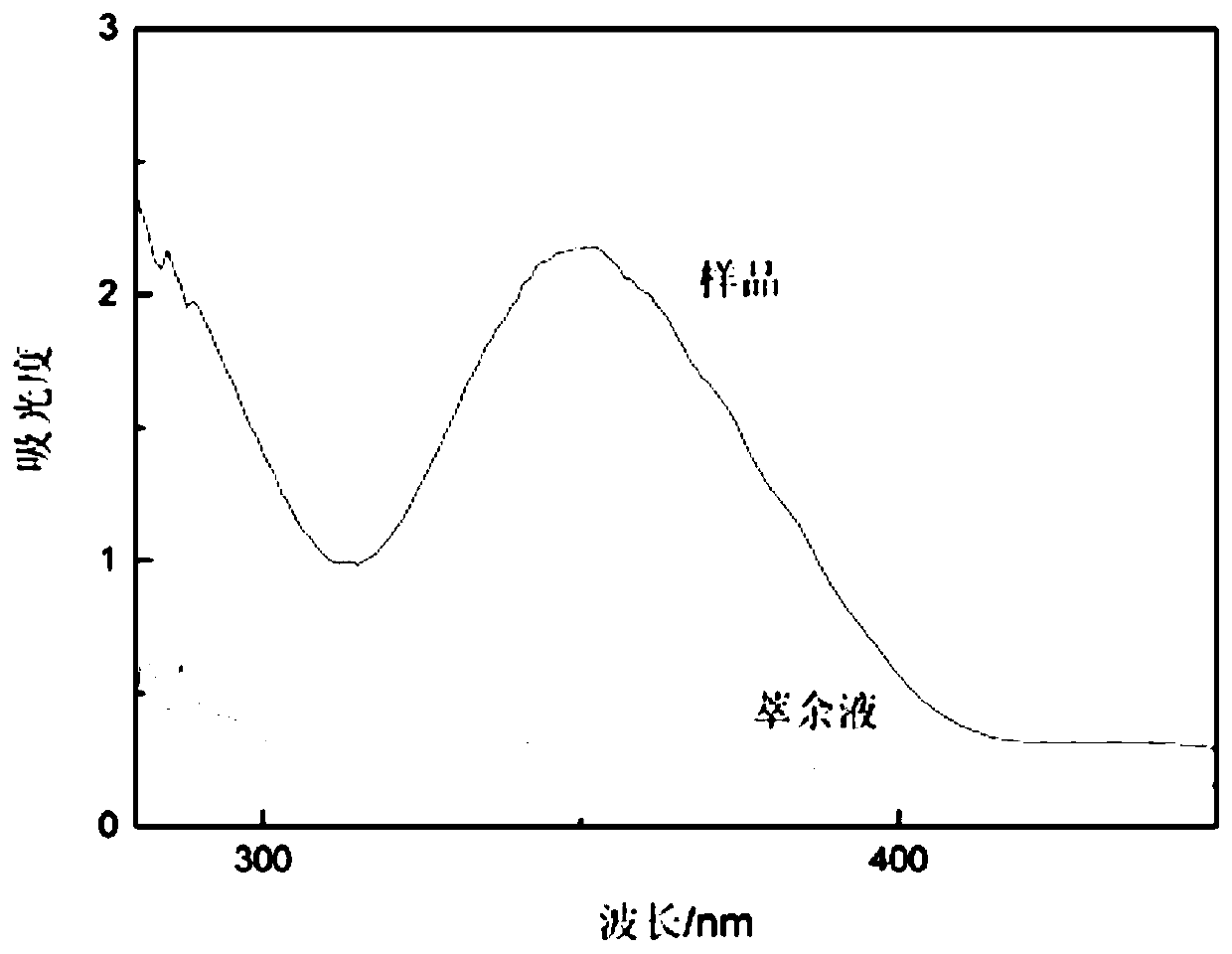

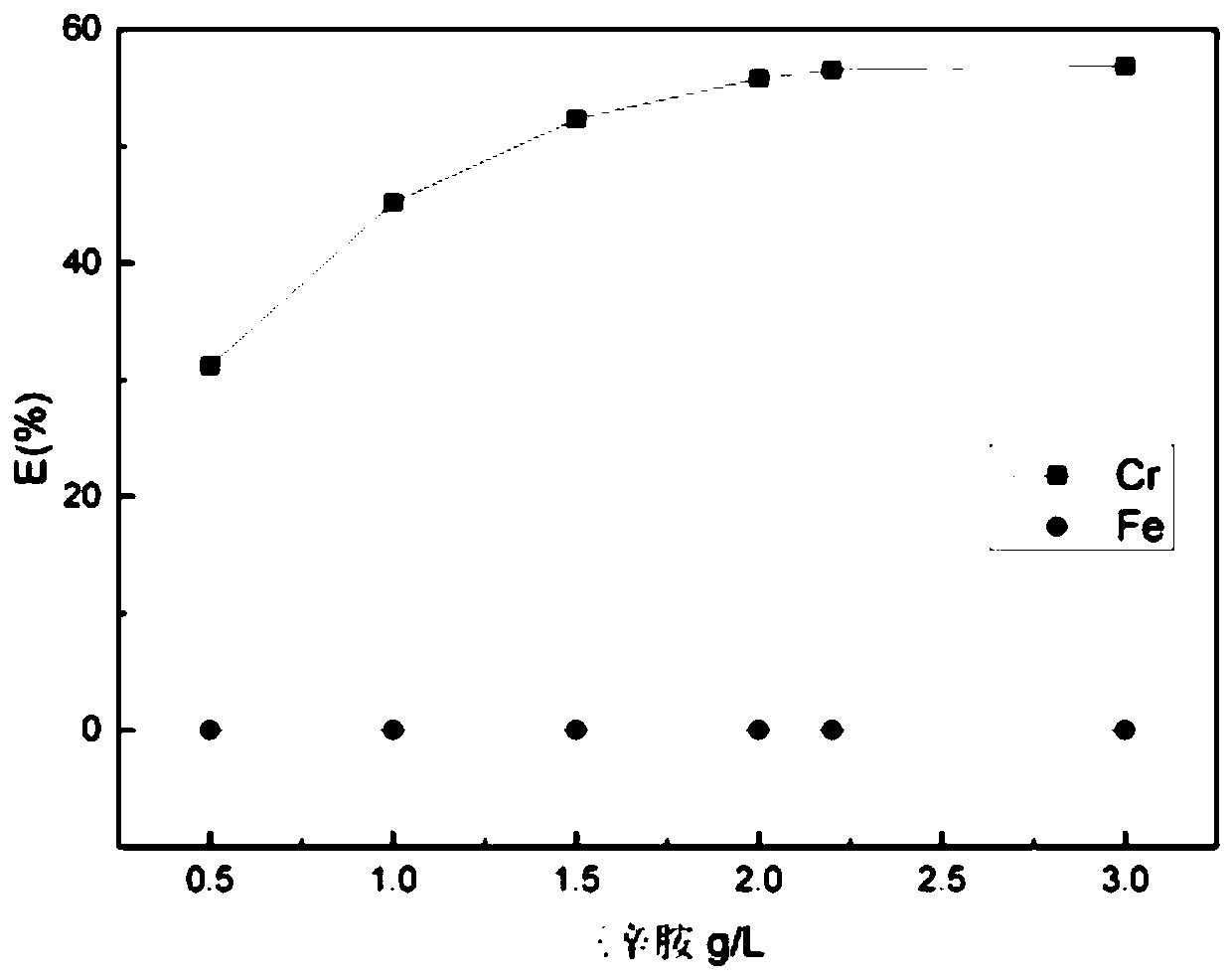

Method for extracting and recovering Cr(III) from high acid solution

InactiveCN109868368ANo secondary pollutionFast extractionElectrolysis componentsProcess efficiency improvementWater bathsLiquid waste

The invention belongs to the field of pickling waste liquor resourceful treatment and particularly relates to a method for extracting and recovering Cr(III) from a high acid solution and application.The method comprises the following steps that (1) a double-cell electrolytic tank is fixed through a flat clamp, an anionic membrane with the diameter being around 2.5 cm is arranged in the joint position of the electrolytic tank, high acid pickling waste liquor is poured into an anode electrolytic cell, and a diluted sulfuric acid solution is poured into a cathode electrolytic cell; (2) both an anode and a cathode are lead plate electrodes with the size being 7cm*2cm*0.2cm, a direct current power supply is adjusted after powering-on is performed, electrolyzing is performed under certain current and certain voltage, and the Cr(III) can be oxidized into Cr(VI) after electrolyzing is performed; and (3) a certain amount of a solution obtained after electrolyzing is weighed, an equal amount ofan extraction agent diluted by means of a diluter is added, stirring is performed for a certain period of time in a thermostat water bath, and separation recovering is performed after layering occurs. The method provided by the invention has the advantages that a stoste system is kept, no secondary pollution occurs, the extraction speed is high, the Cr(III) is subjected to extraction separation recovering under high acid severe conditions, equipment is simple, and a great amount of alkali and precipitation reagents do not need to be added.

Owner:NORTHEASTERN UNIV

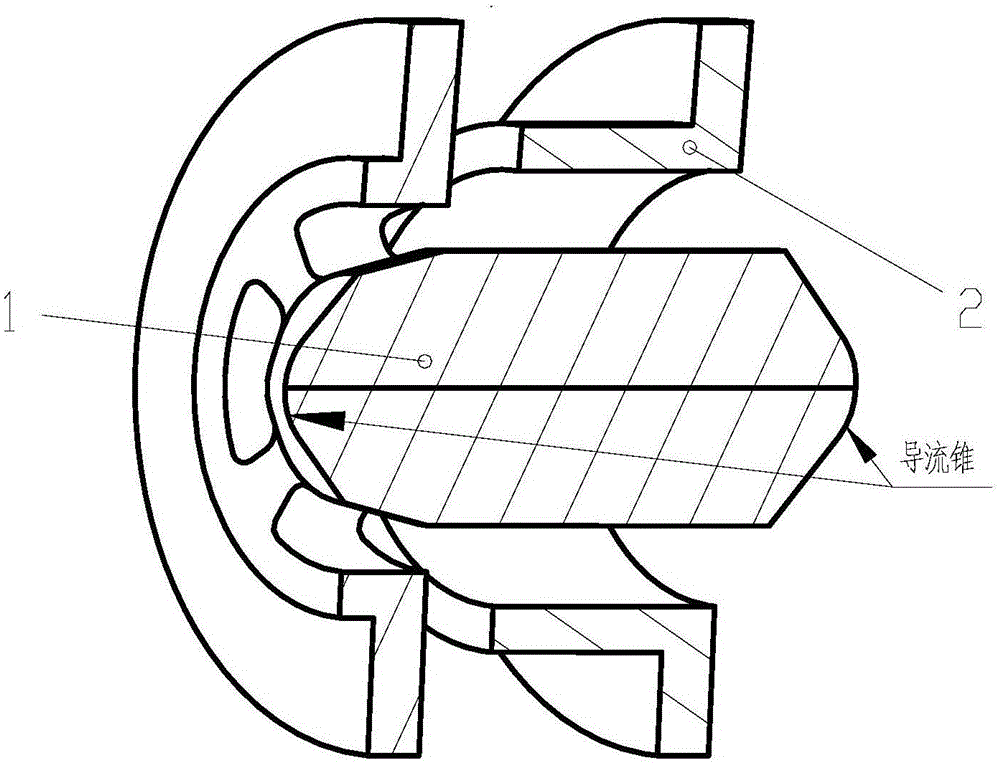

Device capable of stably outputting silver ions

ActiveCN104310537AFacilitate electrolysisAvoid turbulenceSpecific water treatment objectivesWater/sewage treatment using germicide/oligodynamic-processEngineeringMetal

The invention relates to a device capable of stably outputting silver ions, which comprises an anode, a cathode, O-shaped seal rings, a water inlet joint, a water outlet joint, an insulation seal cavity, a constant current power supply, a front end clamping cap, a water outlet metal lining, a water inlet metal lining and a housing, wherein the cathode is arranged on the right side in the insulation seal cavity inside the housing, contacts the end surface of the water outlet and is sealed by the O-shaped seal ring; the anode is arranged on the left side in the insulation seal cavity inside the housing and is sealed by the O-shaped seal ring; the water outlet metal lining is installed inside the housing; a water outlet is installed on the water outlet metal lining; a water inlet is installed on the right side of the anode; the water inlet metal lining is installed on the left side of the water outlet joint; the front end clamping cap is installed on the left end of the housing and contacts the water inlet metal lining; and installation force is transferred to the water inlet joint, anode, insulation seal cavity, cathode, water outlet joint and water outlet metal lining through the water inlet metal lining, so that the assembly is closely connected.

Owner:BEIJING SATELLITE MFG FACTORY

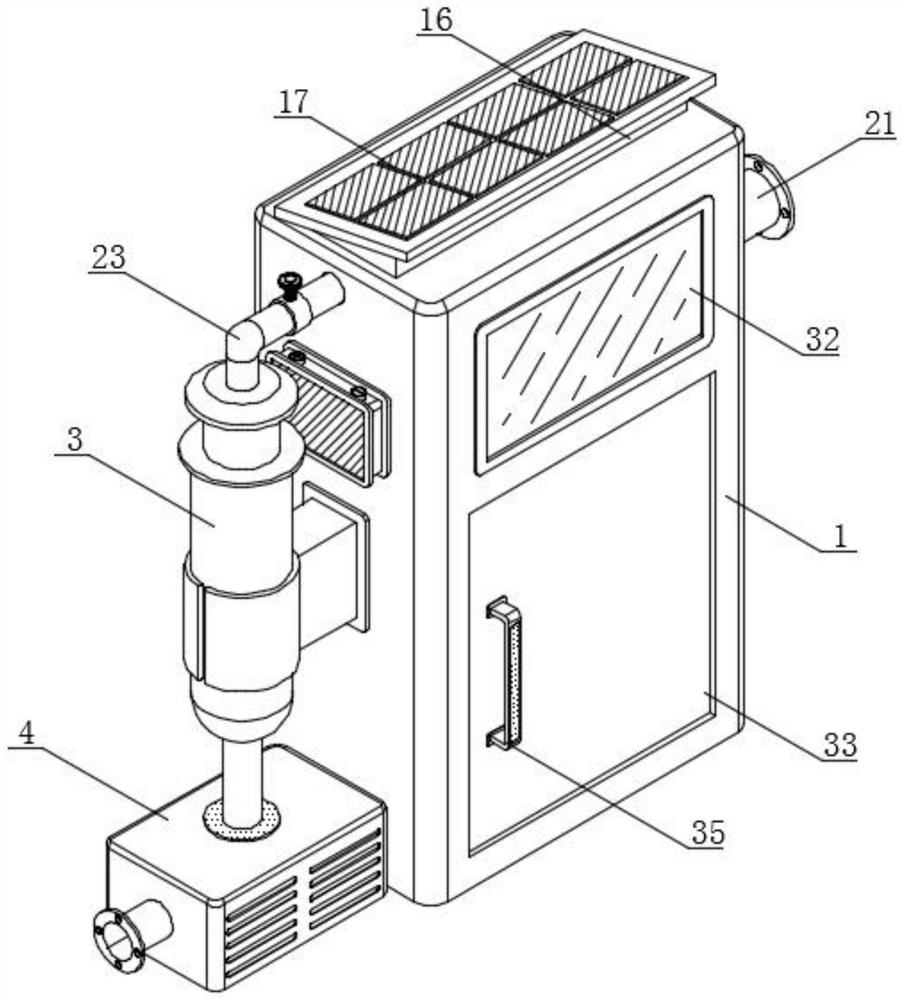

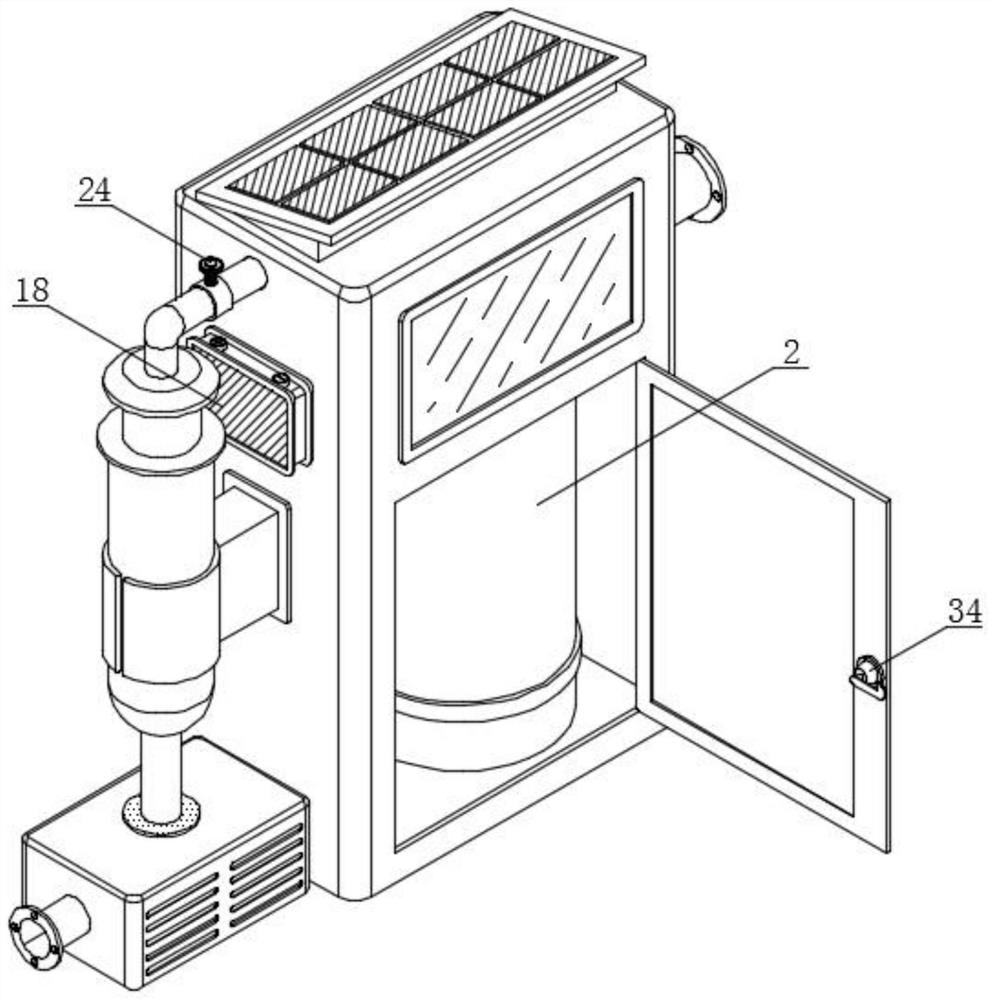

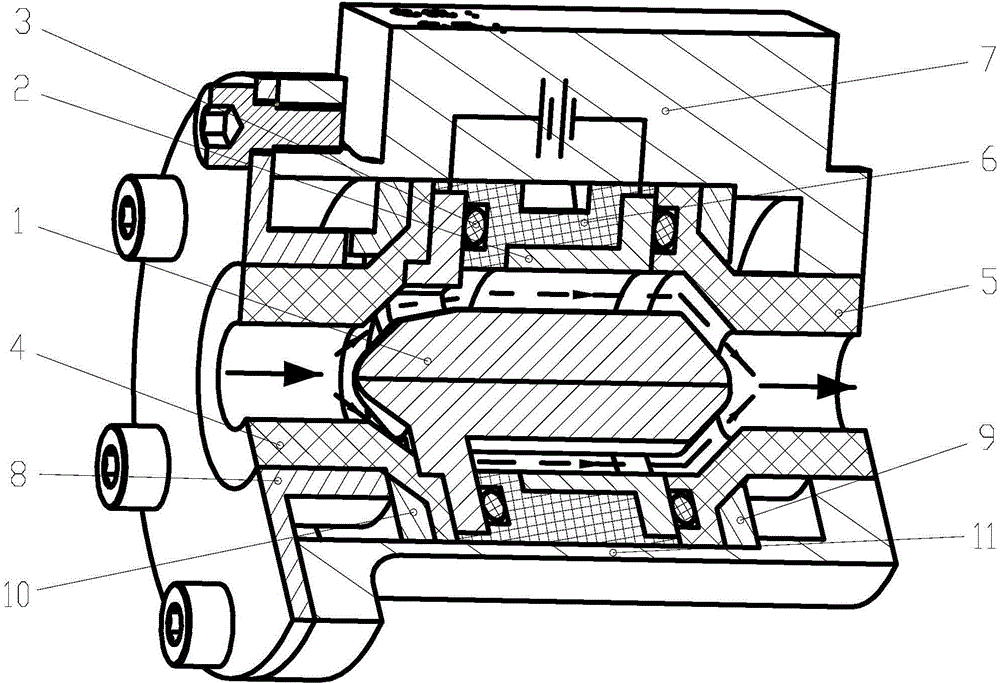

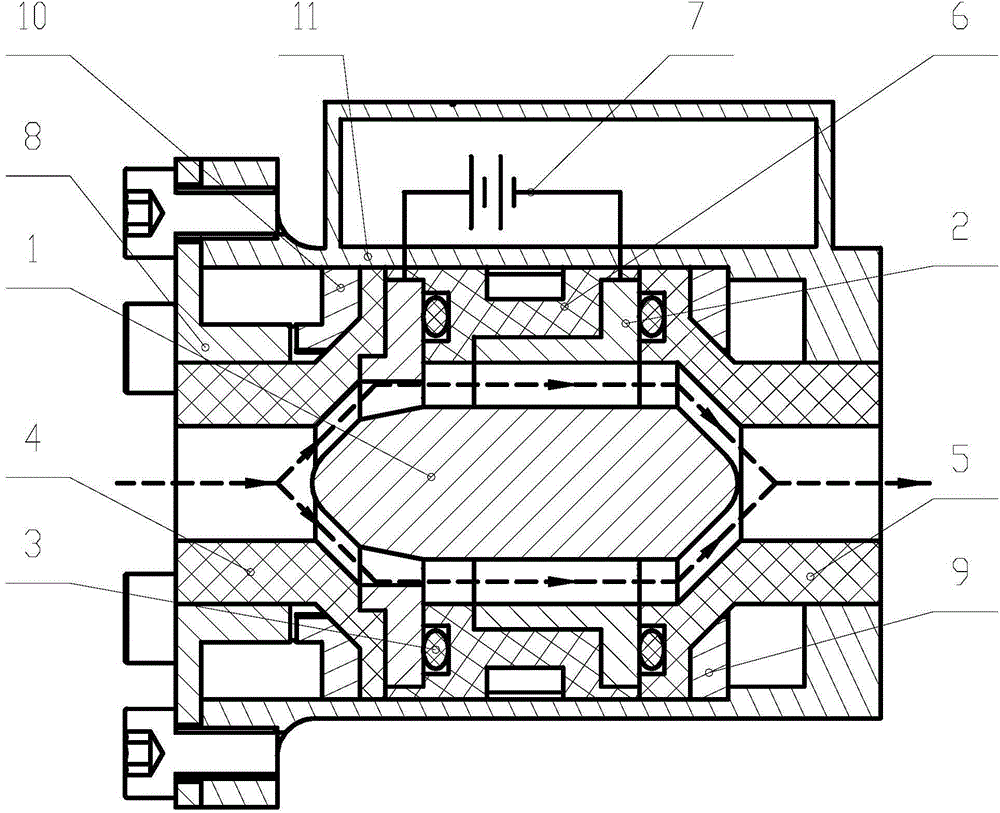

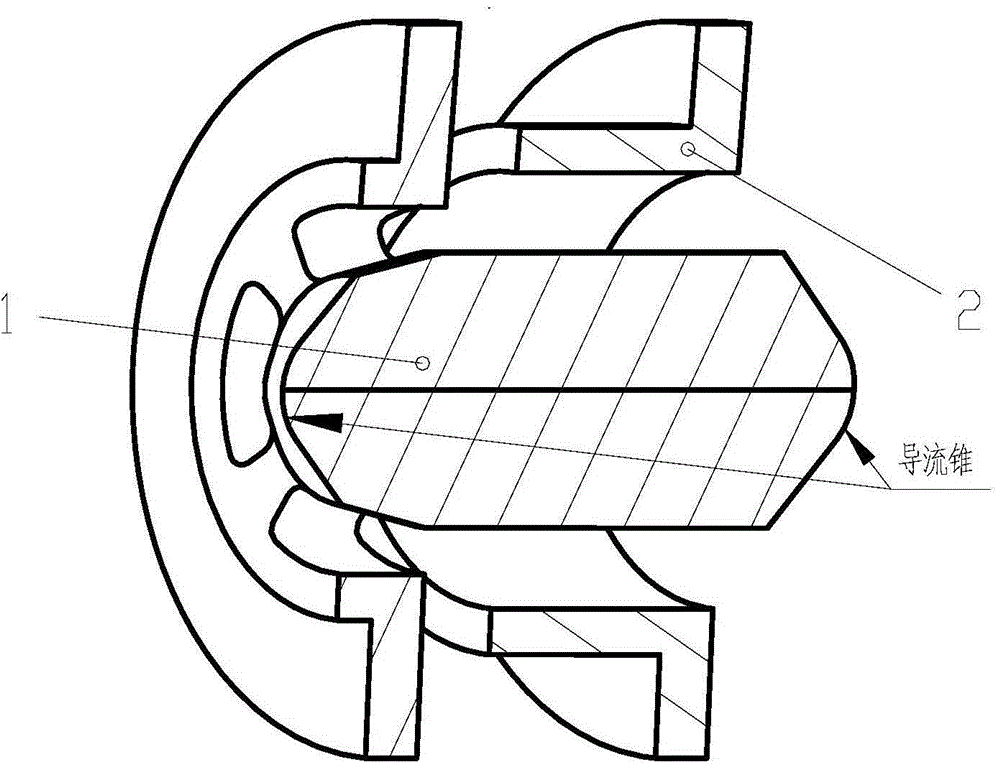

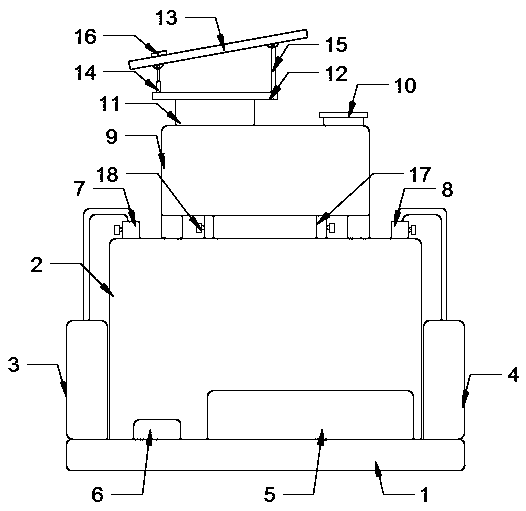

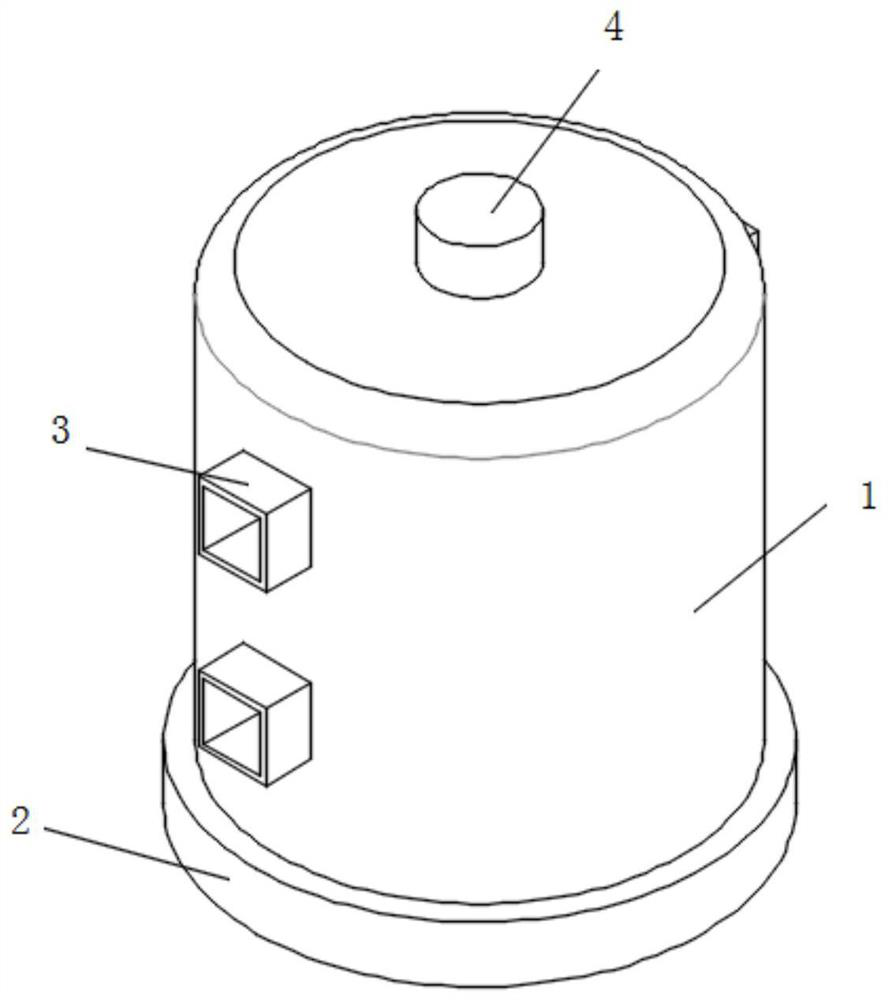

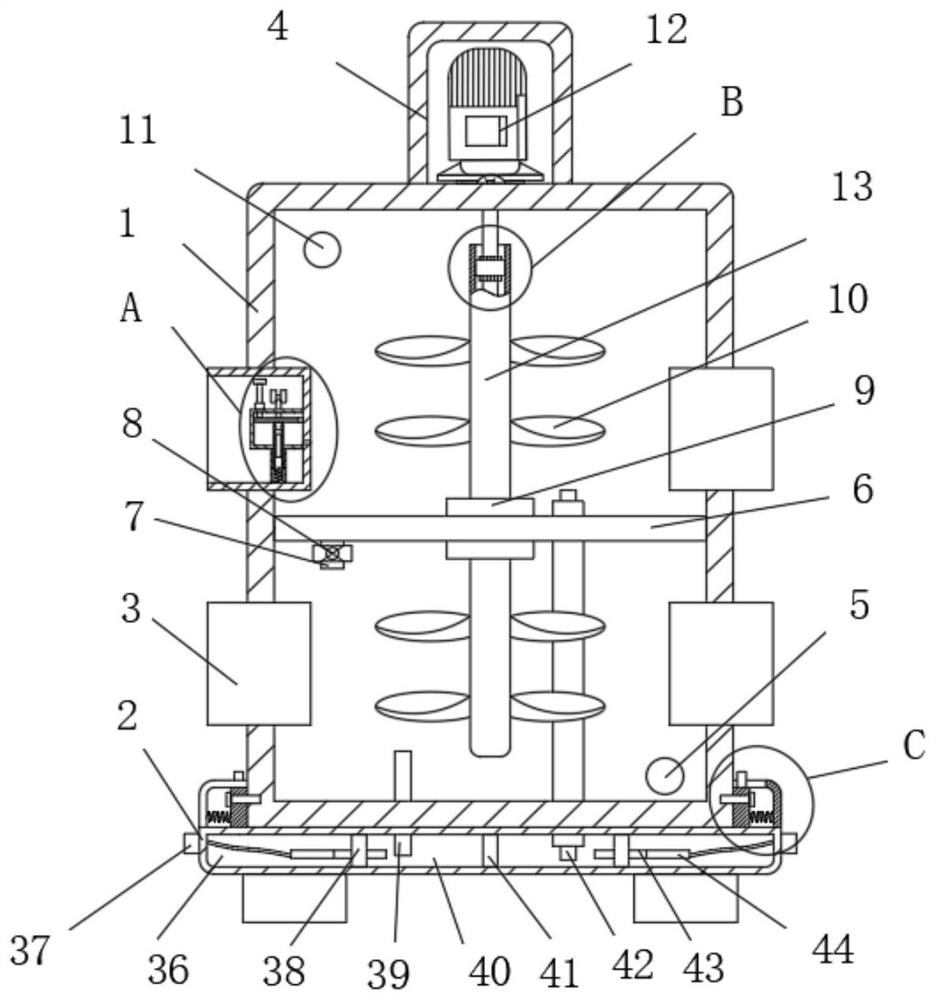

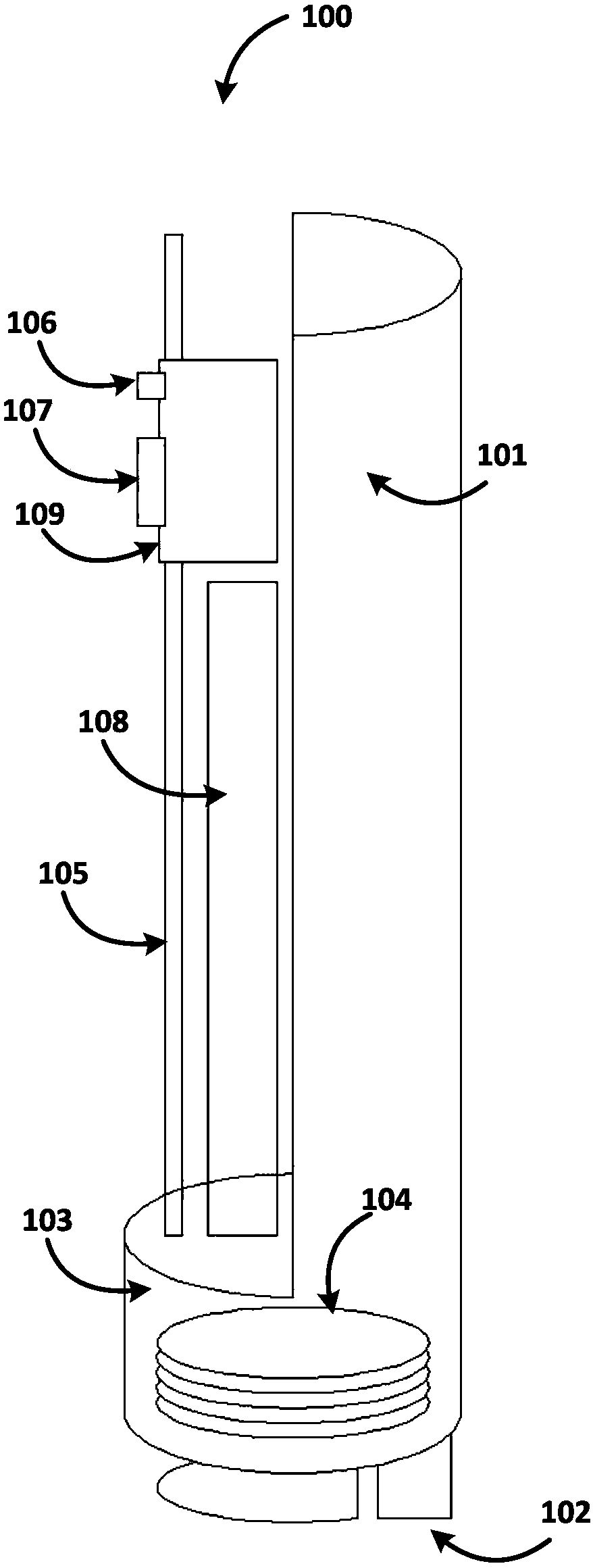

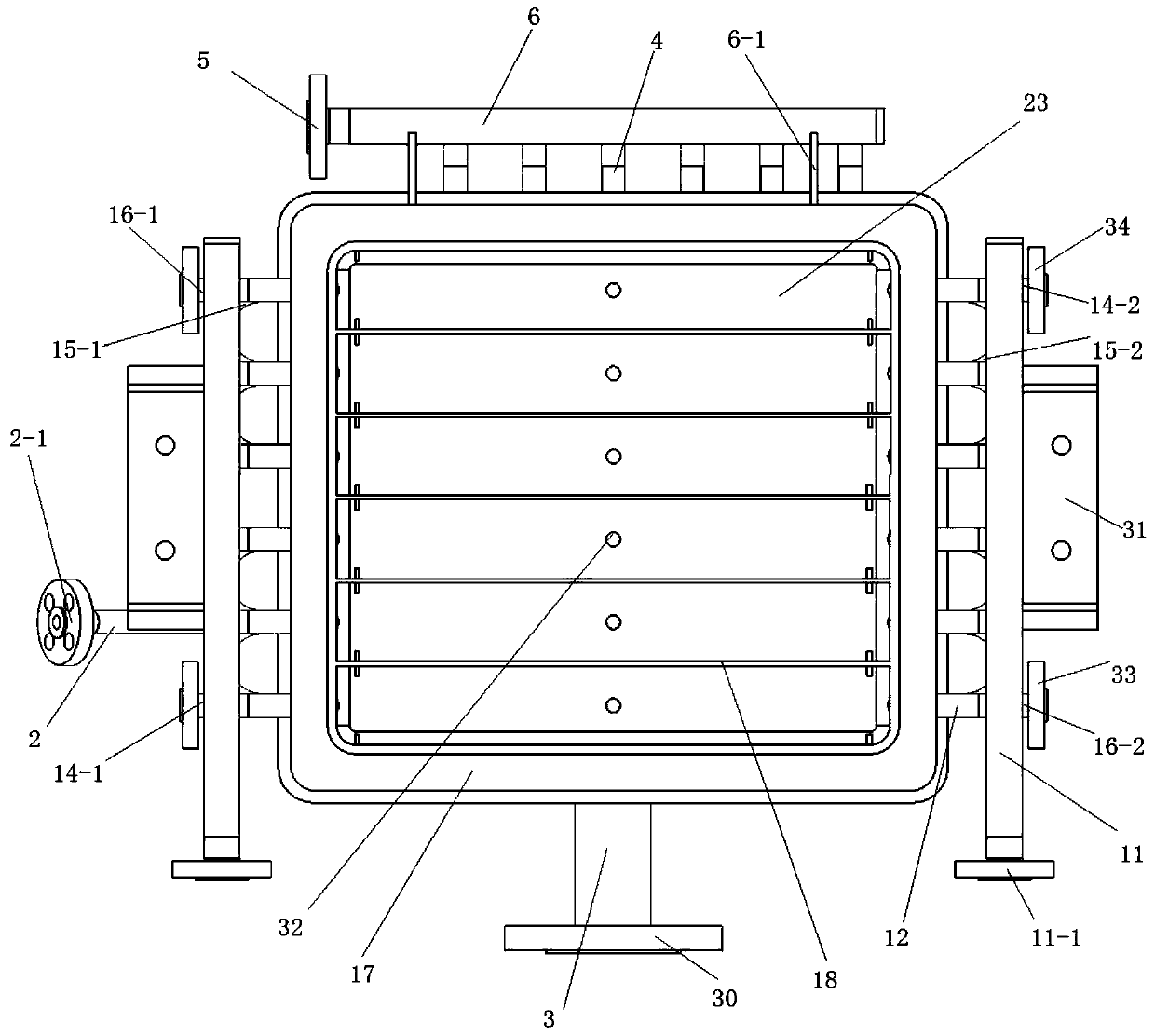

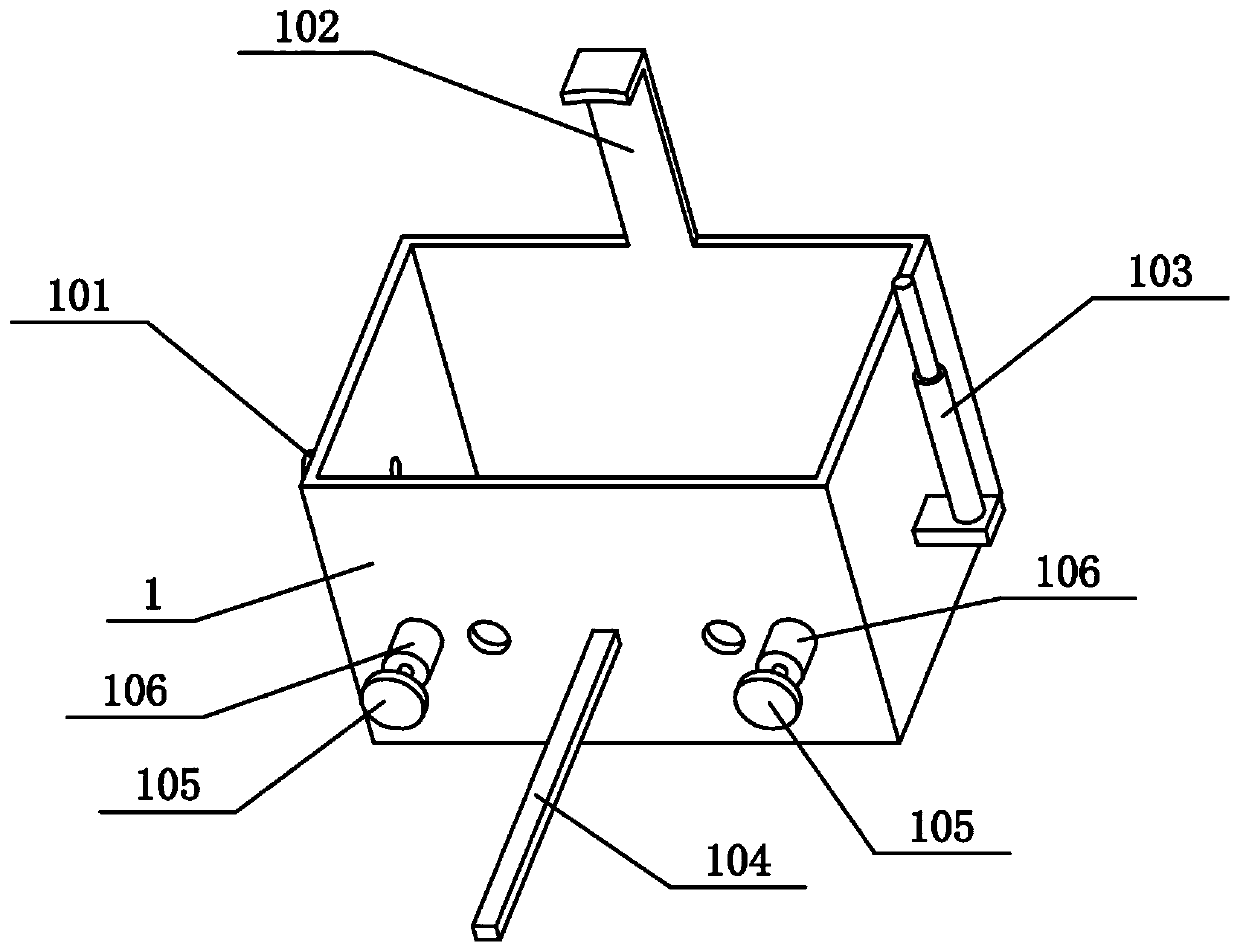

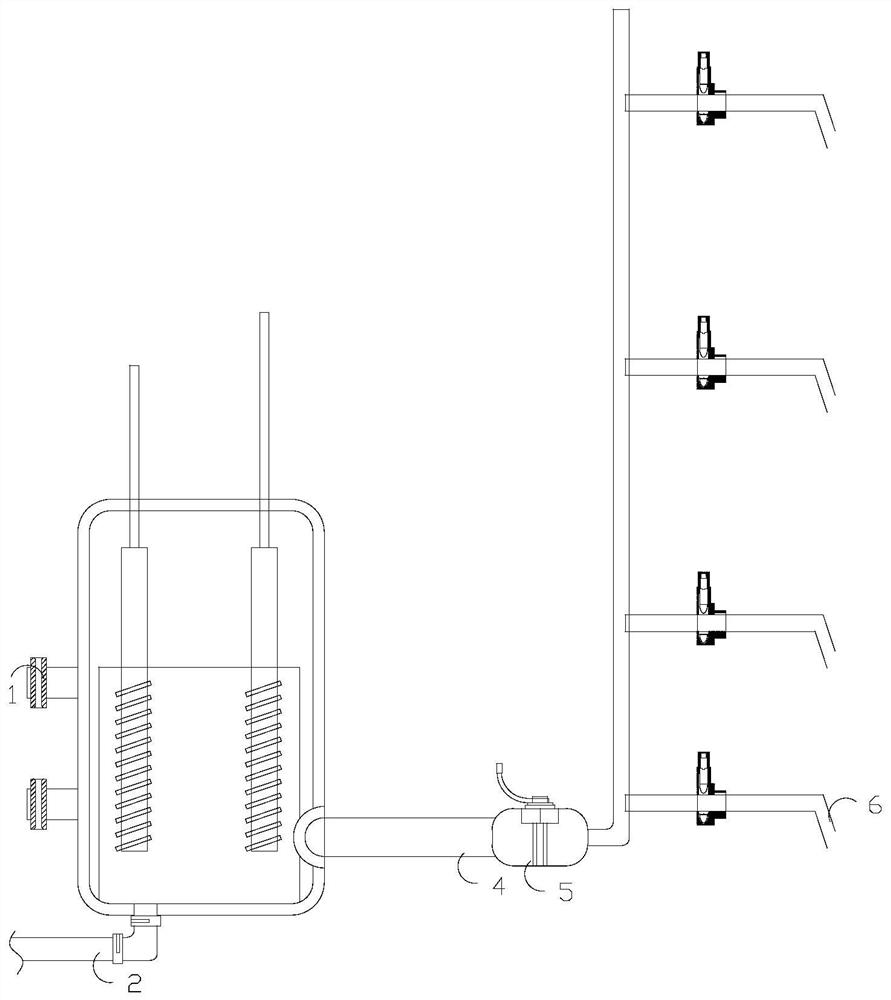

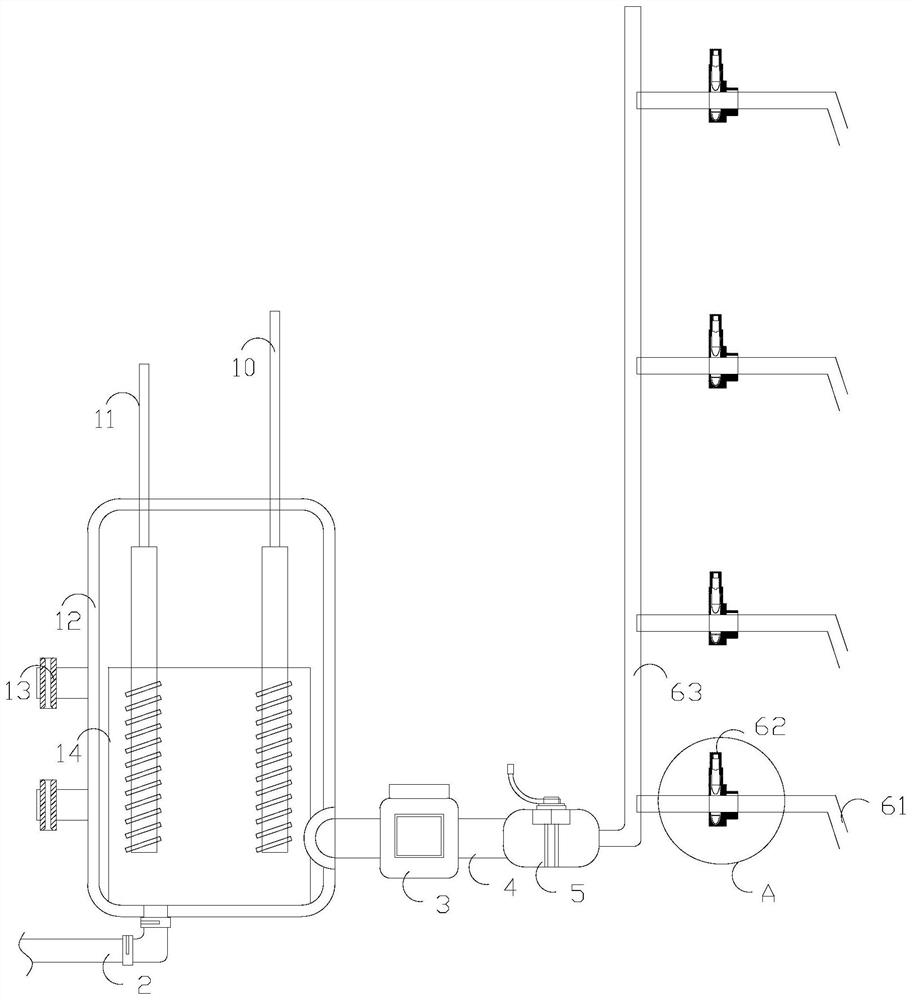

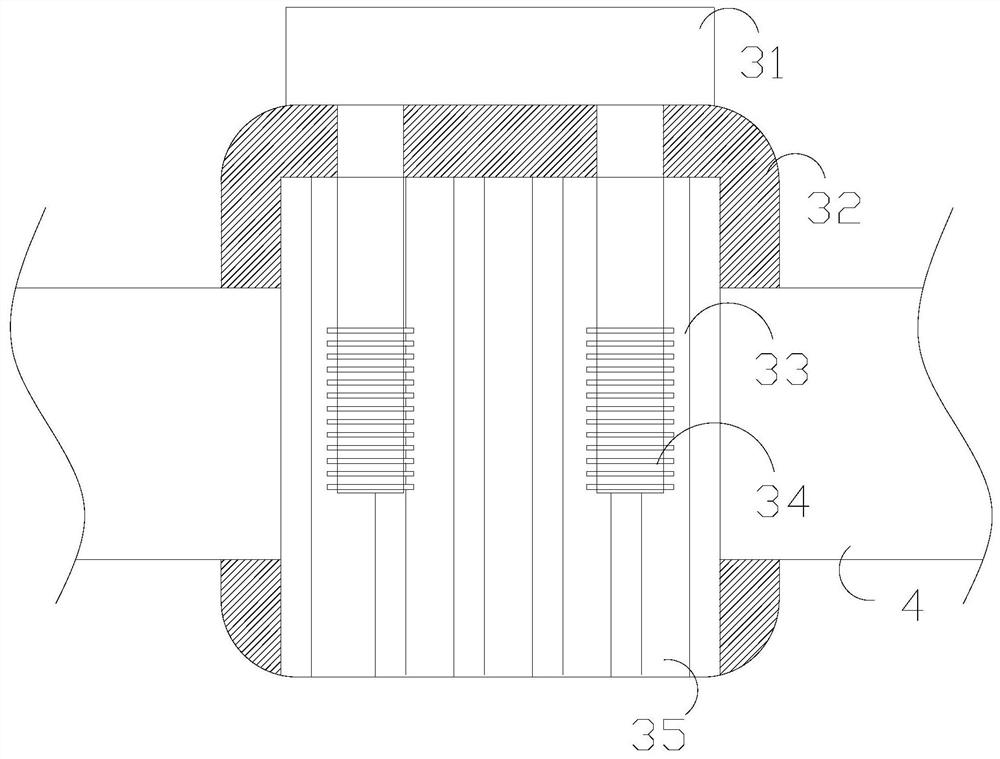

Electrolytic water hydrogen production electrolytic tank based on solar power generation

InactiveCN110552022AImprove electrolysis efficiencyFacilitate electrolysisCellsEnergy inputHydrogen productionEngineering

The invention discloses an electrolytic water hydrogen production electrolytic tank based on solar power generation. The electrolytic water hydrogen production electrolytic tank includes a base and atank body, the tank body is fixedly installed at the center of the top of the base, an oxygen storage tank and a hydrogen storage tank are installed on both sides of the tank body at the top of the base correspondingly, a diaphragm is fixedly installed in the tank body, a storage box is fixedly installed at the center of the top of the tank body, a liquid inlet port is formed in one end of the topof the storage box, a power box is fixedly installed at the other end of the top of the storage box, the top of the power box is rotatably connected with a supporting plate, an electric push rod anda vertical rod are fixedly installed at both ends of the top of the supporting plate correspondingly, and the tops of the electric push rod and the vertical rod are rotatably connected with solar panels. According to the electrolytic tank, in the process of automatically adding liquid to the tank body, the situation that the time and labor are wasted and the consumed cost is high in previous manual material loading is avoided, the electrolytic efficiency is improved, electric power can be stored to the great extent, long-time electrolysis is convenient, waste of electric power resources is greatly saved, and the hydrogen production cost is lowered.

Owner:北京八度阳光科技有限公司

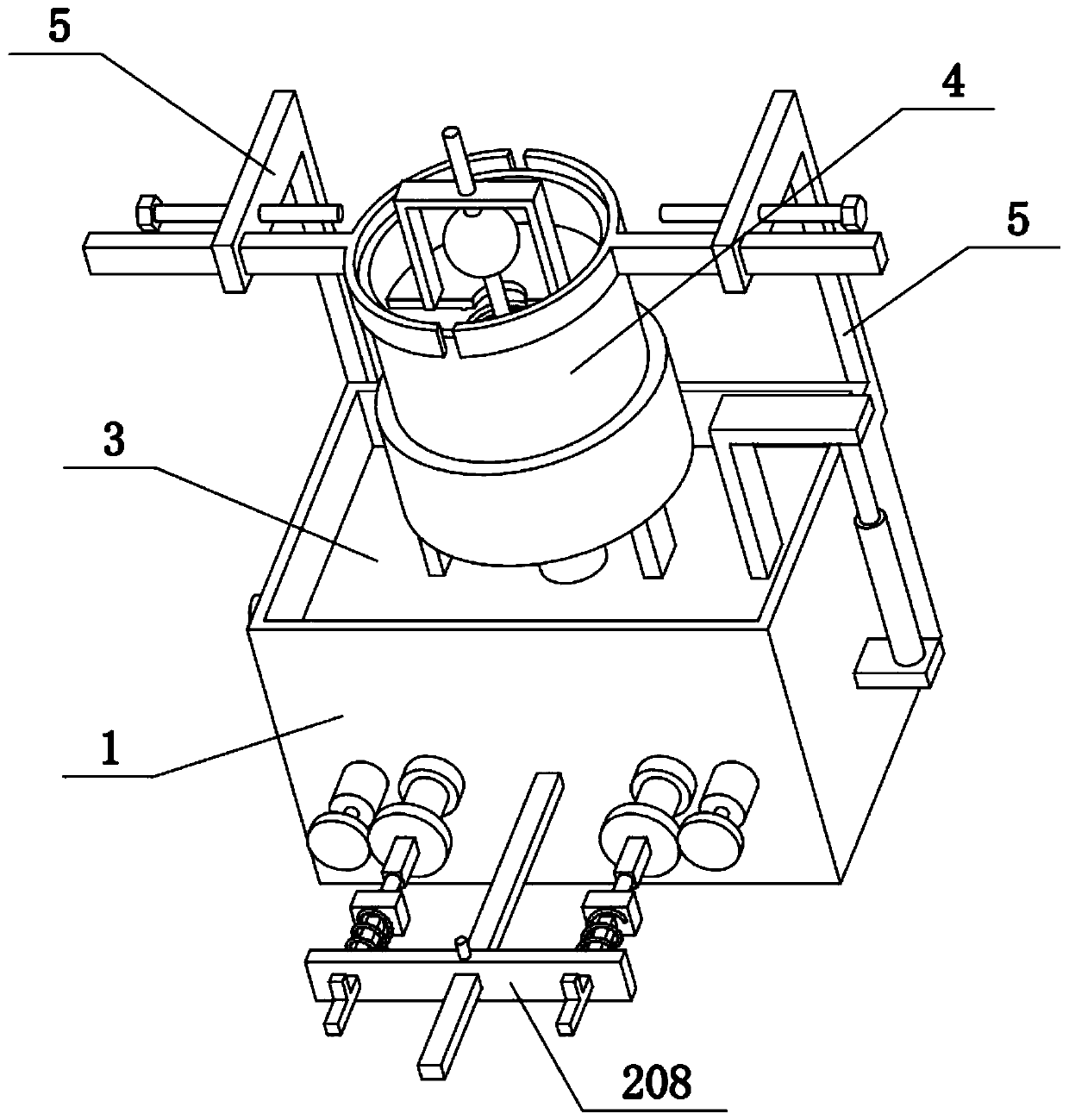

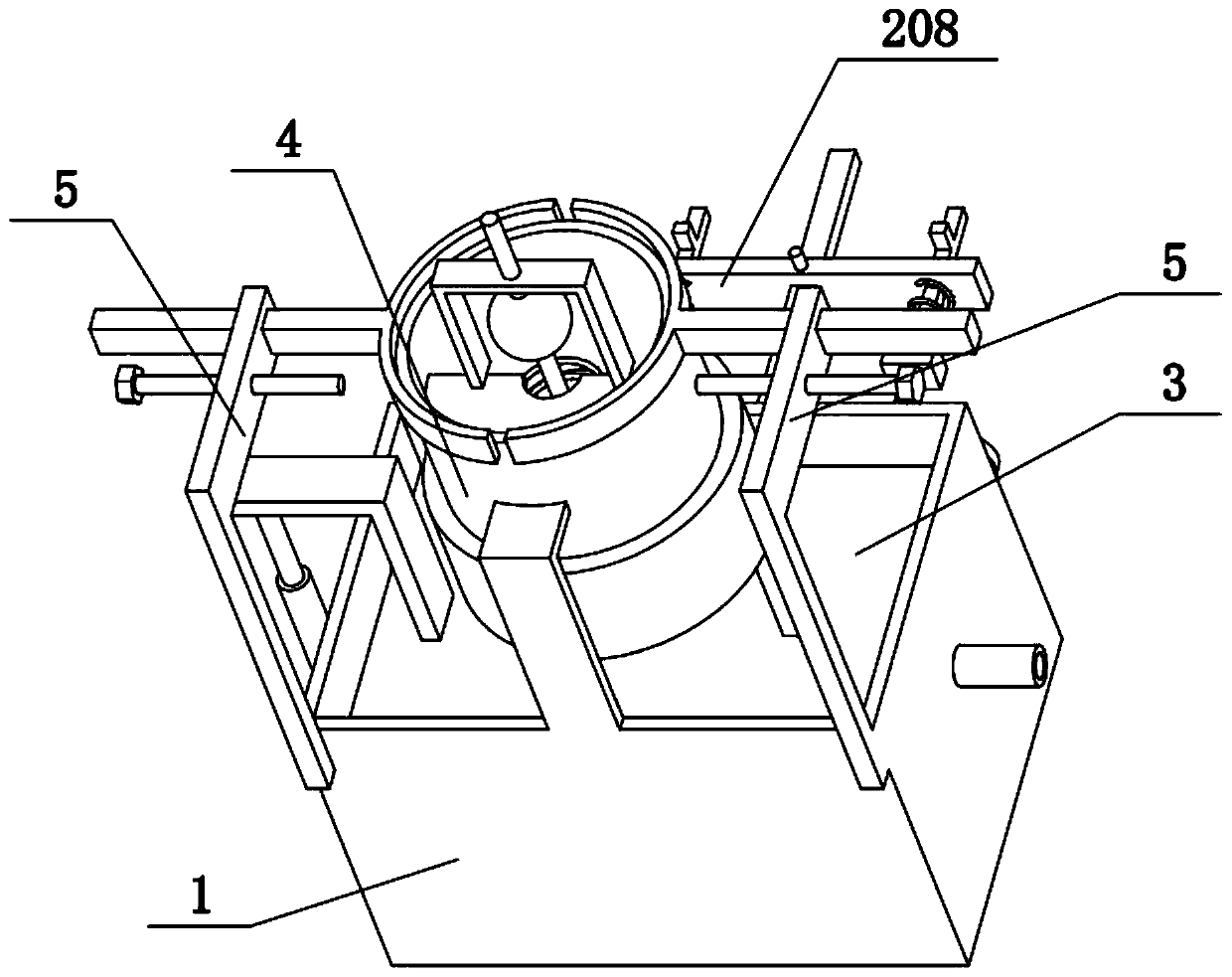

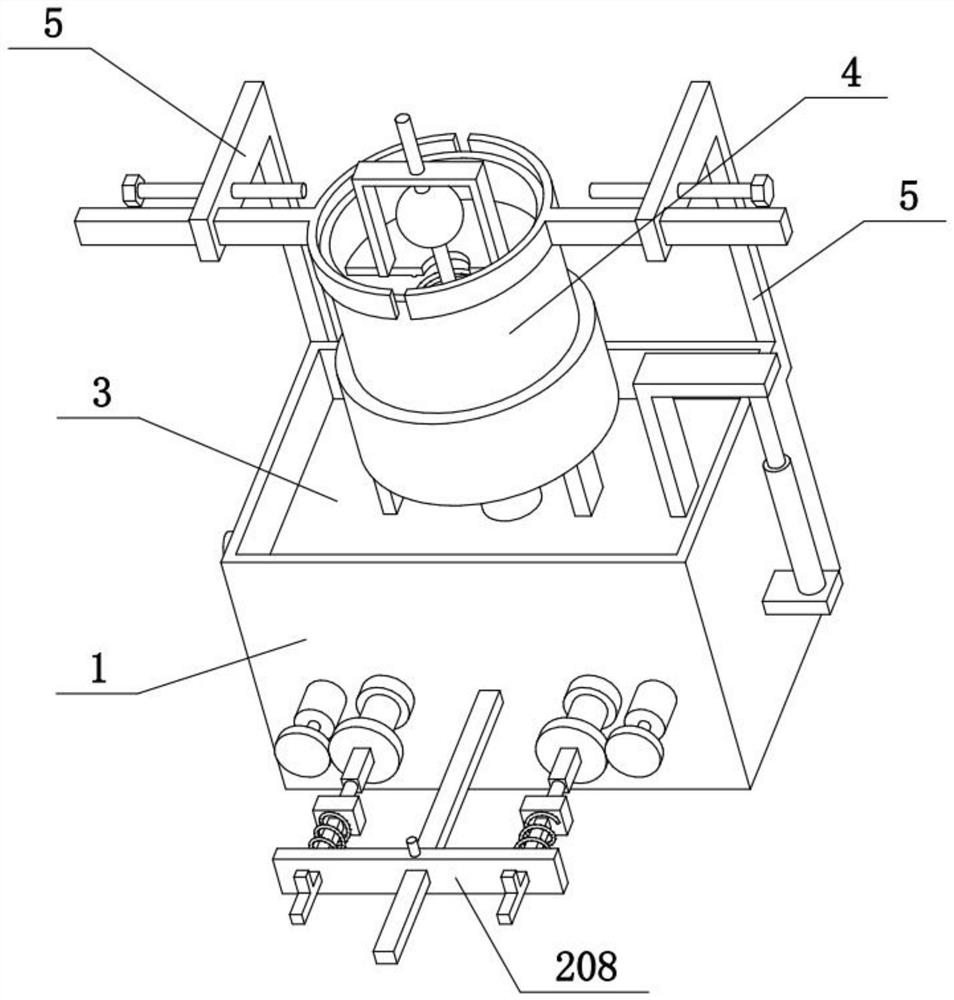

Electroplating wastewater treatment equipment capable of recovering rare metals and operation method of electroplating wastewater treatment equipment

ActiveCN113718299AHigh activityEvenly distributedElectrolysis componentsProcess efficiency improvementElectrolysisProcess engineering

The invention discloses electroplating wastewater treatment equipment capable of recovering rare metals. The equipment comprises a box body, a base is fixedly mounted on the lower side wall of the box body, a water inlet is formed in the side wall of the upper end of the box body, a water outlet is formed in the side wall of the lower end of the box body, partition plates are fixedly mounted on the inner side wall of the box body, a plurality of electrolysis boxes are mounted on the side wall of the box body, the multiple electrolysis boxes are symmetrically arranged, the partition plates are arranged among the multiple electrolysis boxes, water passing pipes are mounted on the side walls of the partition plates, electromagnetic valves are fixedly mounted on the water passing pipes, and recovering mechanisms used for recovering the rare metals are mounted in the multiple electrolysis boxes correspondingly. The invention further discloses an operation method of the electroplating wastewater treatment equipment capable of recovering the rare metals. The purpose of recovering the various rare metals can be achieved, multiple technological processes are not needed, and the working efficiency of electrolytic recovering is higher.

Owner:安徽省生态环境科学研究院

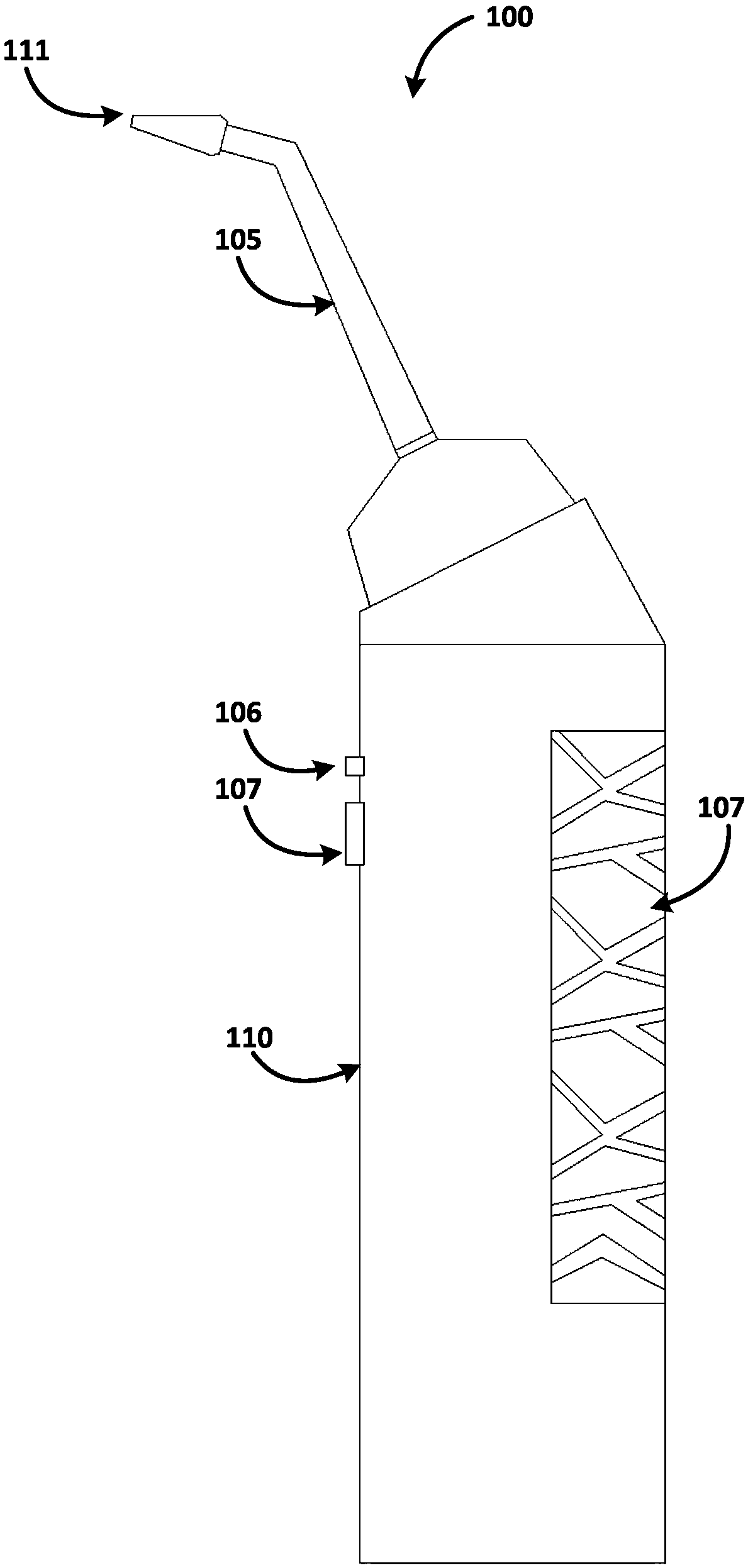

Electrolysis water toothpick

The invention relates to an electrolysis water toothpick. The electrolysis water toothpick comprises a water trough provided with a water inlet and a water outlet, a water electrolysis device and a water outlet pipe, wherein the bottom of the water outlet is close to the water trough, the water electrolysis device is arranged in the water trough to electrolyze water in the water trough into hydrogen and oxygen, and the water outlet pipe is connected with the water outlet. The invention also relates to a method for operating the electrolysis water toothpick. By adopting the electrolysis water toothpick or the method, water-draining mechanical parts such as motors can be omitted, and meanwhile a sterilization function is provided without additional sterilization preparations.

Owner:孙恒

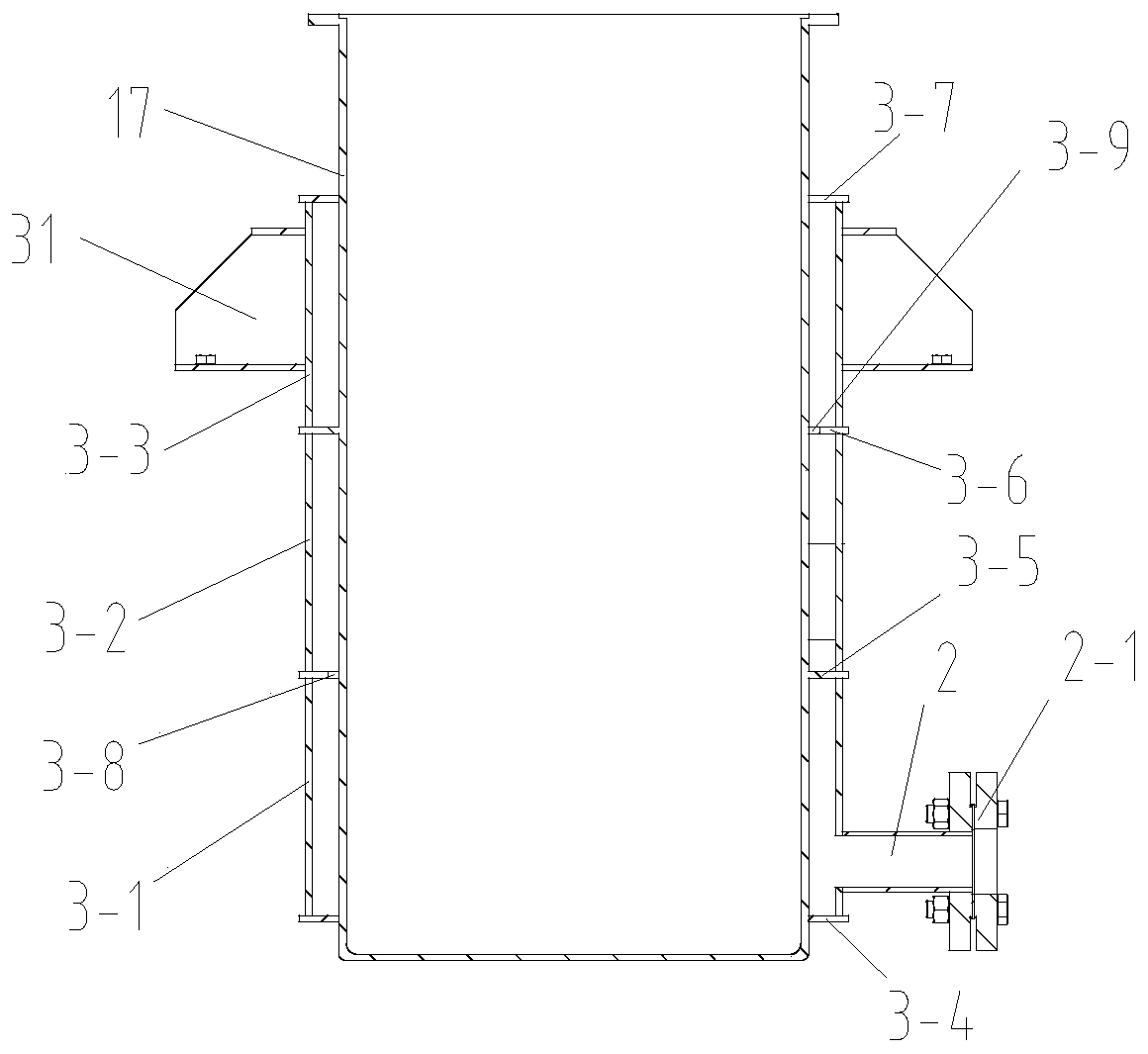

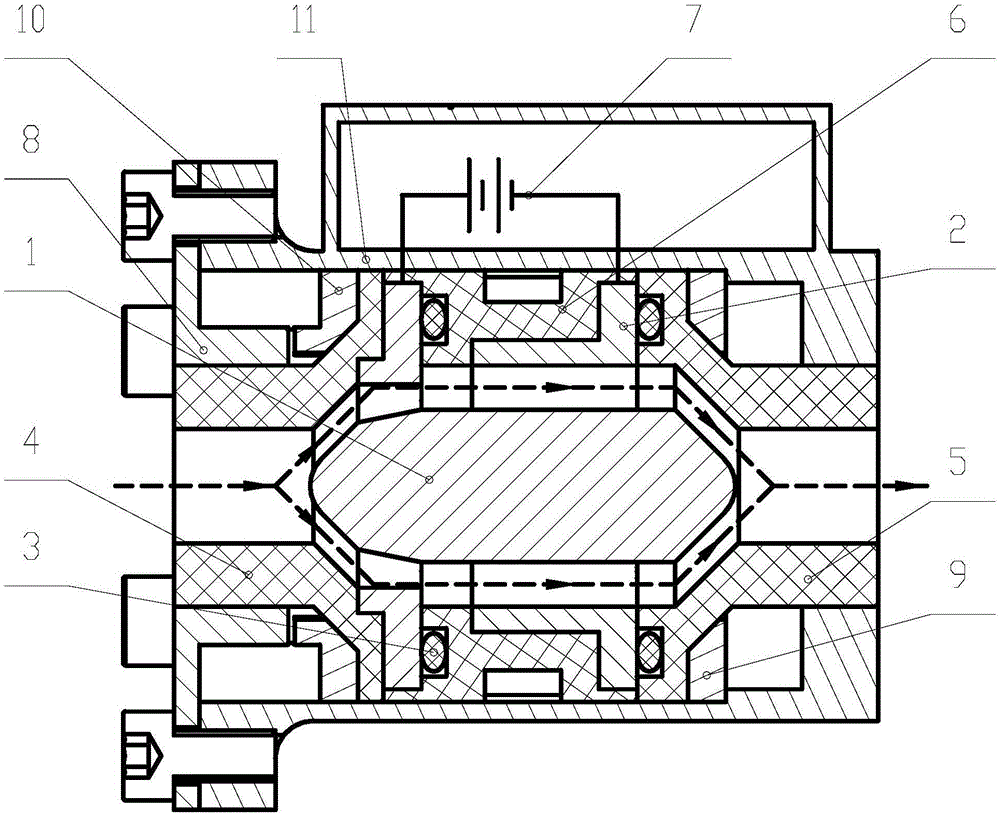

Multistage electrolysis method

ActiveCN111074287AThe method steps are simpleReasonable designCellsElectrode shape/formsElectrolytic agentPhysical chemistry

The invention discloses a multistage electrolysis method. The method comprises the following steps: 1, assembling an electrode plate mechanism; 2, installing a guide plate; 3, connecting the electrodeplate mechanism with a cell body; 4, injecting an electrolyte; and 5, electrolyzing the hexavalent uranium solution to form a tetravalent uranium solution. The method is simple in step, reasonable indesign and low in cost, the electrolysis process is convenient to operate, the hexavalent uranium solution forms the tetravalent uranium solution through multi-stage electrolysis, multiple electrodeplates are isolated and completely isolated from the wall plate of the electrolytic cell, short circuit of the electrode plates is avoided, and safety and reliability are high.

Owner:CHINA NUCLEAR POWER ENG CO LTD

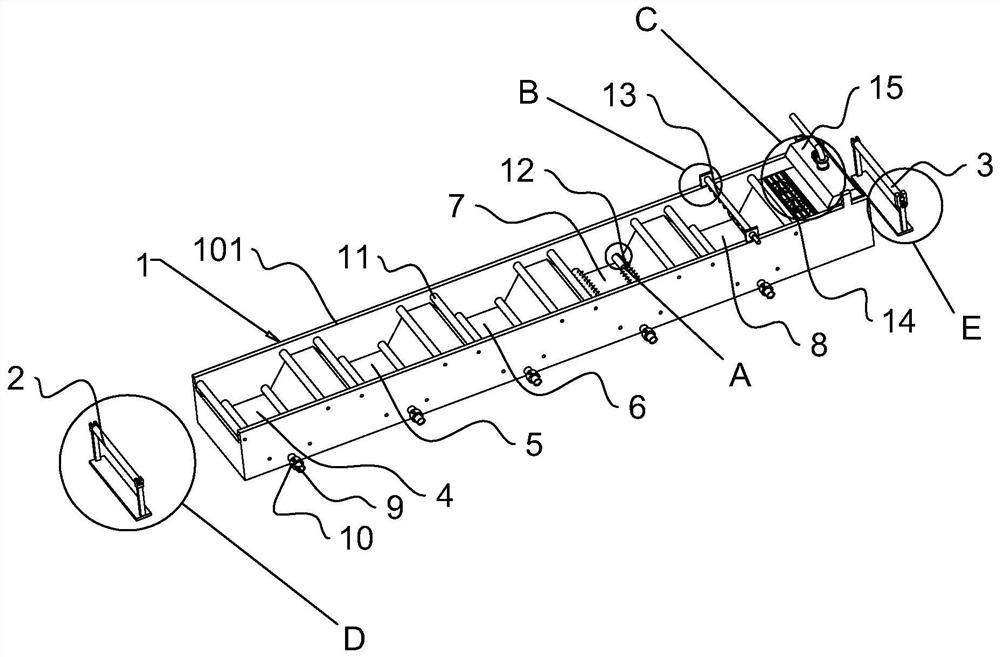

Heat engine fuel generating method and device

InactiveCN101289980AEvaporation-electrolysis facilitatesFacilitate electrolysisNon-fuel substance addition to fuelInternal combustion piston enginesElectrolysisEvaporation

The invention provides a method and a device for generating novel fuel used in a thermo motor. The device comprises a water circulation system consisting of a water tank, a water pump, a temperature control nozzle which are connected through conduits, and a thermo motor exhaust pipe evaporation-electrolysis device which comprises an indirectly-heated closed container arranged on the heated position of a tail gas exhaust pipe of the thermo motor and a direct current electric field which is arranged in the indirectly-heated closed container and is formed by a positive electrode and a negative electrode, wherein, a water jet of the temperature control nozzle is communicated into the indirectly-heated closed container of the thermo motor exhaust pipe evaporation-electrolysis device; a rotating shaft of the water pump is in transmission connection with a power output shaft of the thermo motor through a transmission mechanism; the temperature control nozzle has a temperature controller which controls the temperature control nozzle to spray water by the temperature of the indirectly-heated closed container; a temperature sensor of the temperature controller is arranged on the indirectly-heated closed container which has a combustible gas exhaust passage connected with an inlet pipe of the thermo motor; and the thermo motor exhaust pipe evaporation-electrolysis device is connected with the top part of the water tank through a gas-guide tube.

Owner:张普华

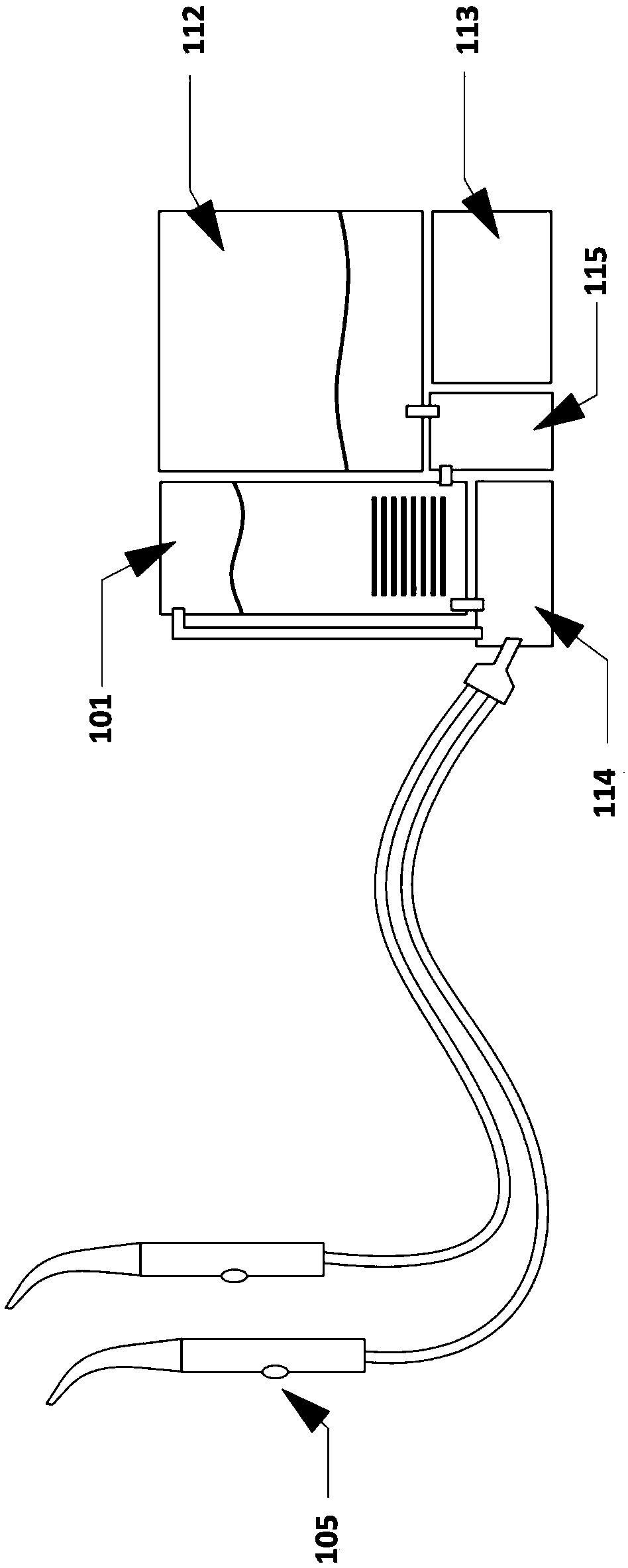

Electrolytic cleaning system and electrolytic cleaning method using electrolytic cleaning system

InactiveCN112024496AQuality improvementEasy to cleanCleaning using toolsCleaning using liquidsProcess engineeringEnvironmental engineering

The invention relates to an electrolytic cleaning system which comprises a cleaning device, an uncoiling device and a coiling device. The cleaning device is placed on the ground, the uncoiling deviceis placed on one side of the cleaning device in the length direction, and the coiling device is placed on the other side of the cleaning device in the length direction. The cleaning device comprises amachine body. An alkali washing pool, a cleaning pool, an electrolytic tank, a scrubbing pool and a flushing pool are sequentially arranged on the machine body in the length direction of the machinebody from the side where the uncoiling device is placed to the side where the coiling device is placed. The electrolytic cleaning system and the electrolytic cleaning method using electrolytic cleaning system have the effects that the cleaning effect of electrolytic cleaning can be improved through process electrolytic cleaning, and the probability that emulsified liquid adheres to the surface ofthe strip steel is reduced.

Owner:浙江协和陶瓷有限公司

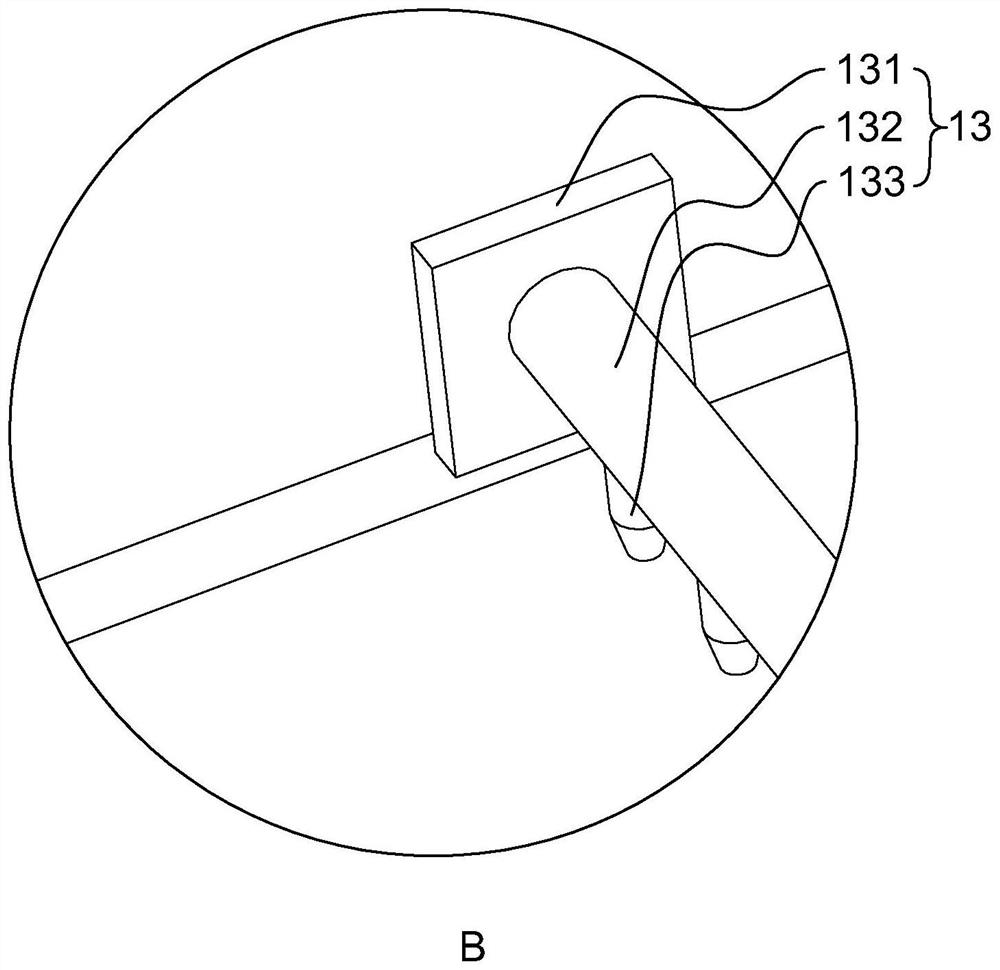

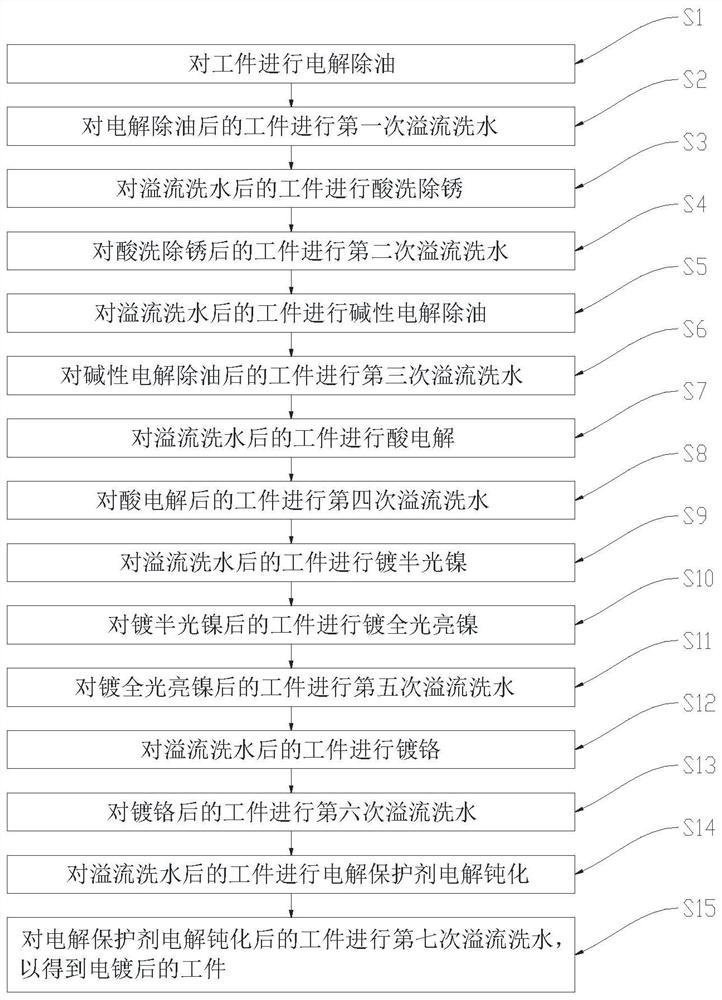

Process method for improving electroplating corrosion resistance

InactiveCN113151873AExtended service lifeFacilitate electrolysisSurface reaction electrolytic coatingElectrolysisWash water

The invention relates to the technical field of electroplating corrosion resistance, in particular to a process method for improving electroplating corrosion resistance. The method comprises the following steps of: performing electrolytic degreasing on a workpiece; performing acid pickling and rust removal on the workpiece after overflow water washing; performing alkaline electrolysis oil removal on the workpiece subjected to overflow water washing; performing acid electrolysis on the workpiece subjected to overflow water washing; performing semi-bright nickel plating on the workpiece subjected to overflow water washing; performing full-bright nickel plating on the workpiece plated with the semi-bright nickel; performing chromium plating on the workpiece subjected to overflow water washing; and performing electrolytic passivation on the workpiece subjected to overflow water washing through an electrolytic protective agent, so that the electroplated workpiece is obtained. After nickel and chromium are electroplated on the workpiece, the electrolytic protective agent is added for electrolysis and electrolytic passivation protection of a chromium plating layer, so that the corrosion resistance is improved, and the service life of the workpiece product is effectively prolonged.

Owner:深圳市通之泰科技有限公司

Method for degrading organic wastewater through electrolytic stimulation of mineralized refuse supported microorganisms

ActiveCN102863084AEasy to handlePromote degradationBiological water/sewage treatmentFloraTherapeutic effect

The invention provides a method for degrading organic wastewater through the electrolytic stimulation of mineralized refuse supported microorganisms. The method comprises the following steps: adding organic wastewater in an electrolytic cell and then adding the mineralized refuse, wherein the solid-to-liquid ratio of the mineralized refuse to the wastewater is 1:(500-1000) and the electrode materials of the two poles of the electrolytic cell are graphite; and connecting the current of the electrolytic cell, wherein the current between the two poles is 5-40mA; oxidizing and degrading the organic matter in the wastewater after 2-5 hours; and separating out precipitates so that the wastewater can reach the standard to be discharged. By utilizing the adaptability and strong treatment capability of the various floras carried by the mineralized refuse on organic polluted wastewater, the treatment effect can be enhanced; and as the microorganisms attach to the insides of the holes of the mineralized refuse and the impact on the active oxidation groups on electrode surfaces is low, the electrolytic current can be increased, the impact of the outside on the living environment in the holes is low, pollutants are adsorbed near the holes and the pollutants can be easily degraded.

Owner:江阴智产汇知识产权运营有限公司

Hydrogen chloride preparation process and system

ActiveCN111519203AFull electrolysisChange electrode positionCellsHydrogen chloride preparationElectrolysisHydrogen chloride

The invention relates to the field of hydrogen chloride preparation, in particular to a hydrogen chloride preparation process and a system. The method for preparing hydrogen chloride by the hydrogen chloride preparation system comprises the following steps: S1, adding sodium chloride and water into a reaction box, respectively electrifying two metal columns as a positive electrode and a negative electrode, and electrolyzing the sodium chloride and an aqueous solution to generate sodium hydroxide, hydrogen and chlorine; S2, rotating the two gear rings to correspondingly drive the two rotary drums and the two L-shaped plastic columns to rotate, and then changing the positions of the electrodes in the electrolysis process; S3, when the reaction box is filled with hydrogen and chlorine, extruding the hydrogen and the chlorine out of the gas outlet pipe, igniting the extruded hydrogen and chlorine by an igniter, and then generating hydrogen chloride gas; and S4, ejecting the blocking ball upwards by the hydrogen chloride gas in the sleeve , then opening the gas outlet hole, after the hydrogen chloride gas reaches the upper portion of the fixed cylinder, sleeving the upper end of the fixed cylinder with a collecting bag, and collecting the hydrogen chloride gas.

Owner:SHANDONG RIKE PLASTIC RUBBER TECH CO LTD

A device capable of stably outputting silver ions

ActiveCN104310537BFacilitate electrolysisAvoid turbulenceSpecific water treatment objectivesWater/sewage treatment using germicide/oligodynamic-processEngineeringSilver ion

Owner:BEIJING SATELLITE MFG FACTORY

Method for degrading organic wastewater through electrolytic stimulation of mineralized refuse supported microorganisms

ActiveCN102863084BEasy to handlePromote degradationBiological water/sewage treatmentMicroorganismLiquid ratio

The invention provides a method for degrading organic wastewater through the electrolytic stimulation of mineralized refuse supported microorganisms. The method comprises the following steps: adding organic wastewater in an electrolytic cell and then adding the mineralized refuse, wherein the solid-to-liquid ratio of the mineralized refuse to the wastewater is 1:(500-1000) and the electrode materials of the two poles of the electrolytic cell are graphite; and connecting the current of the electrolytic cell, wherein the current between the two poles is 5-40mA; oxidizing and degrading the organic matter in the wastewater after 2-5 hours; and separating out precipitates so that the wastewater can reach the standard to be discharged. By utilizing the adaptability and strong treatment capability of the various floras carried by the mineralized refuse on organic polluted wastewater, the treatment effect can be enhanced; and as the microorganisms attach to the insides of the holes of the mineralized refuse and the impact on the active oxidation groups on electrode surfaces is low, the electrolytic current can be increased, the impact of the outside on the living environment in the holes is low, pollutants are adsorbed near the holes and the pollutants can be easily degraded.

Owner:江阴智产汇知识产权运营有限公司

An aquarium water quality monitoring and detection system

ActiveCN112075383BEasy to adjustOpen and closeWithdrawing sample devicesWaste water treatment from animal husbandryWater qualitySump (aquarium)

The invention discloses an aquarium water quality monitoring and detection system, which comprises an electrolysis box, a water outlet pipe, a filter ring, a water inlet pipe, a valve, and a sample extraction system. A water inlet pipe is installed on one side of the bottom of the electrolysis box. Installed outside the aquarium, the aquaculture water that enters from the water inlet pipe enters the electrolytic cell, and after electrolysis of sodium ions, observe the attachments on the positive and negative poles to judge the sodium ion content of the aquaculture water at this level. The liquid is discharged from the outlet pipe, and then enters another level of water. It is tested again according to the above method, without sending it to the laboratory, and it is directly tested on the spot. The samples of aquaculture water are taken one by one, and the main pipe is used as the main delivery channel to deliver them to the location of the electrolytic box, so as to realize the extraction of different levels of water in the aquarium, and test while extracting, without loading and unloading in test tubes, which is more convenient for adjustment.

Owner:山东君合市政建设集团有限公司

A kind of hydrogen chloride preparation process and preparation system

ActiveCN111519203BFull electrolysisFacilitate electrolysisCellsHydrogen chloride preparationElectrolysisHydrogen chloride

The invention relates to the field of hydrogen chloride preparation, in particular to a hydrogen chloride preparation process and a preparation system. A method for preparing hydrogen chloride by a hydrogen chloride preparation system includes the following steps: S1, adding sodium chloride and water into a reaction box, electrifying two metal columns respectively as positive and negative electrodes, and electrolyzing sodium chloride and aqueous solution to generate hydrogen Sodium oxide, hydrogen and chlorine; S2, the rotation of two gear rings respectively drives the rotation of two drums and two L-shaped plastic columns, and then changes the electrode position during the electrolysis process; S3, when the reaction box is filled with hydrogen and chlorine Hydrogen and chlorine can be extruded from the outlet pipe, and the extruded hydrogen and chlorine are ignited by the igniter to generate hydrogen chloride gas; S4, the hydrogen chloride gas in the sleeve pushes the ball upwards, thereby opening the outlet hole, and then the hydrogen chloride gas is released. The gas reaches the upper part of the fixed cylinder, and the hydrogen chloride gas can be collected by putting a collection bag on the upper end of the fixed cylinder.

Owner:SHANDONG RIKE PLASTIC RUBBER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com