Electrolytic cleaning system and electrolytic cleaning method using electrolytic cleaning system

A technology of electrolytic cleaning and electrolytic cell, which is applied in the field of electrolytic cleaning and electrolytic cleaning system, which can solve the problems of poor cleaning effect and achieve the effect of improving quality and cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

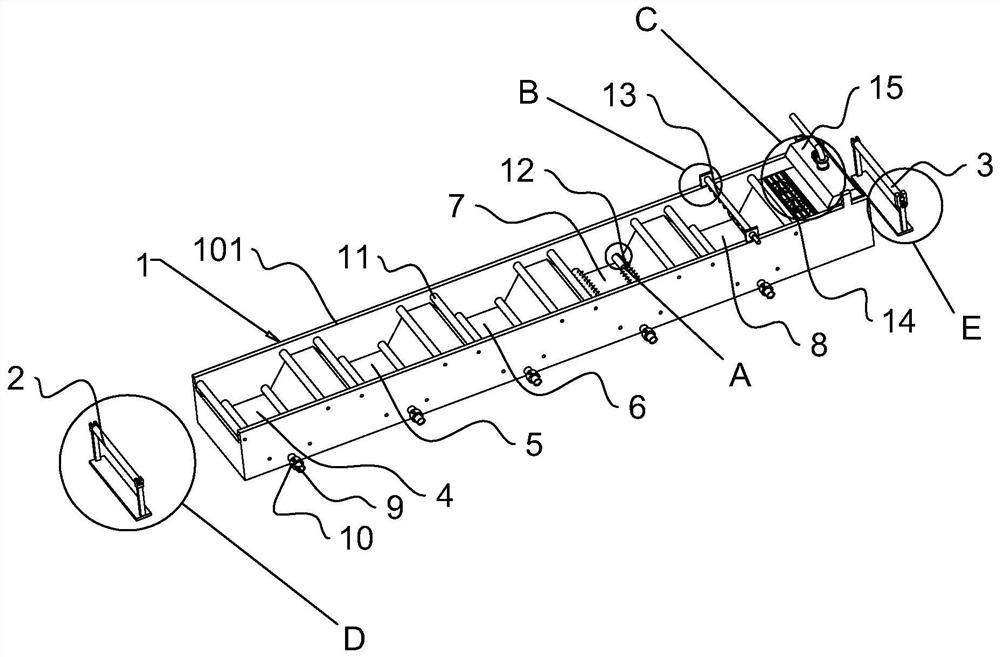

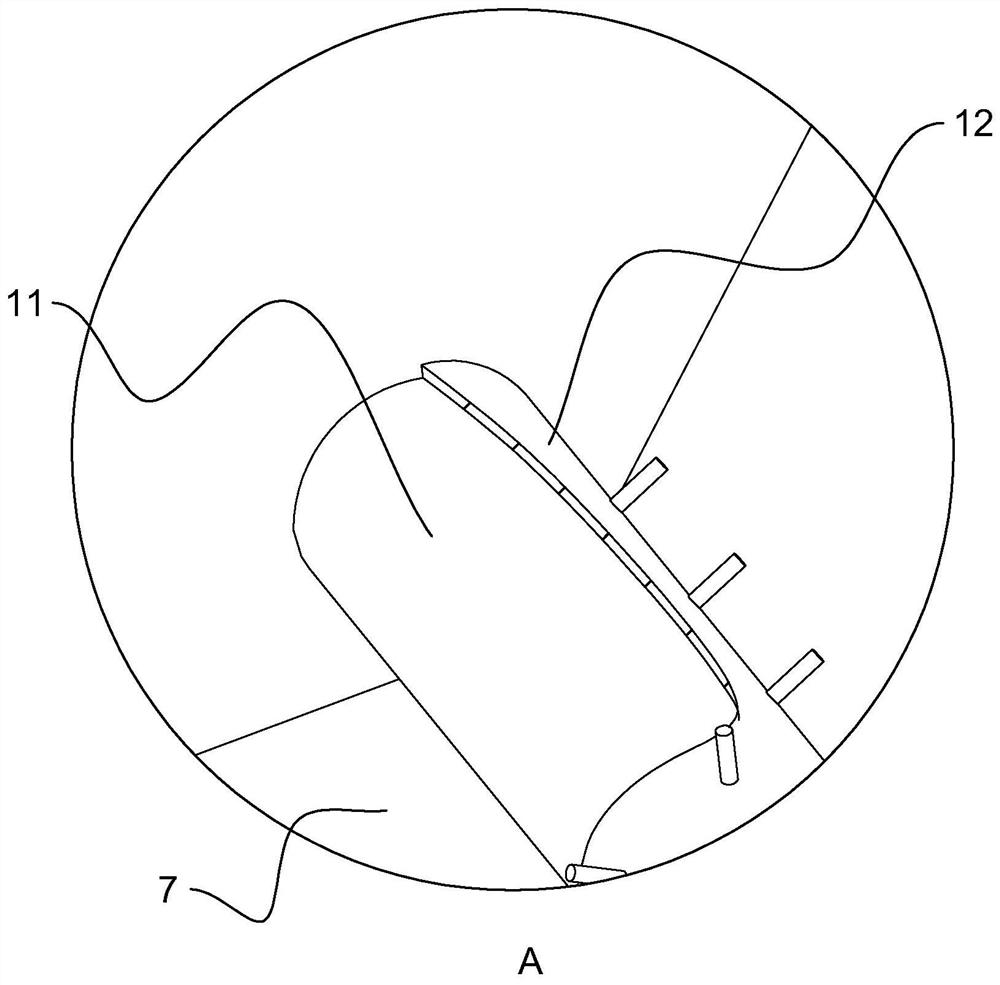

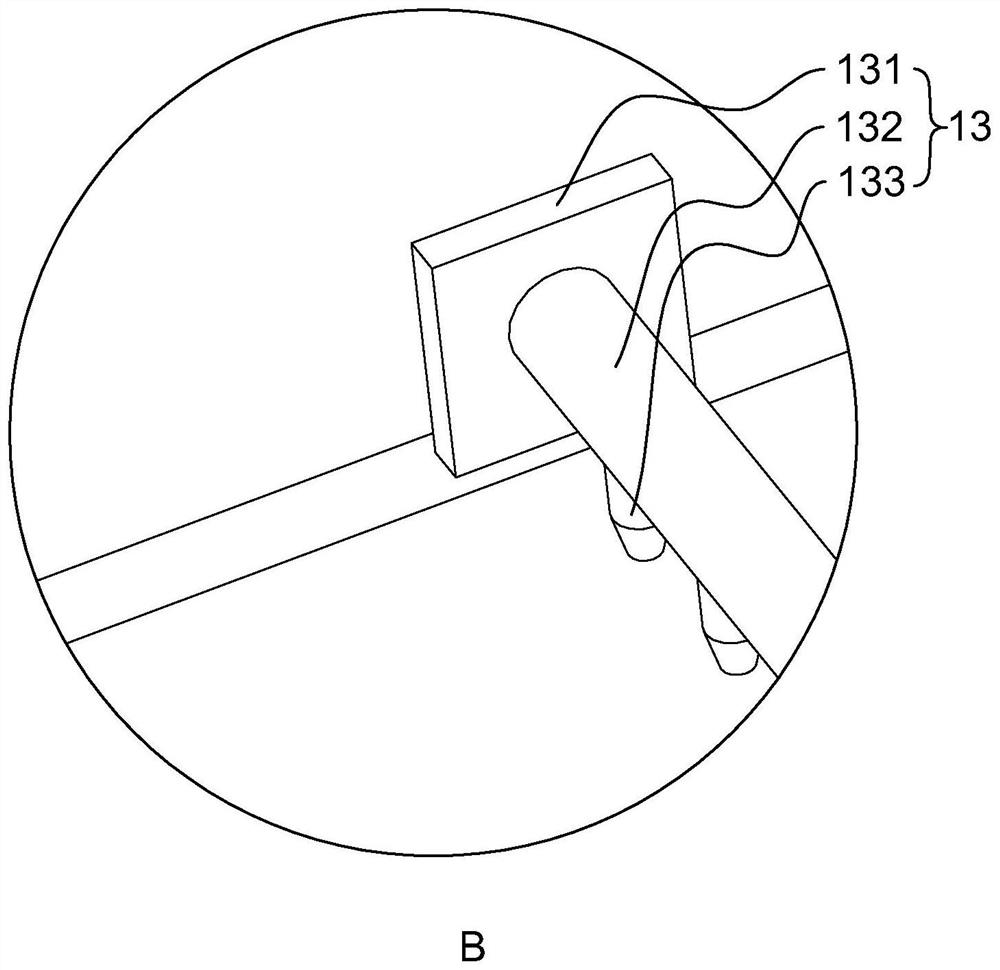

[0048] Contraction below Figure 1-6 Further detailed description of the present application.

[0049] 6 is provided within the electrolytic cell positive and negative electrodes, the power that the positive and negative electrodes of the pool water electrolysis, hydrogen and oxygen bubbles deposited by electrolysis of water, under the combined effect of the bubble and the mechanical motor polarization tearing, the strip steel surface residual film is removed, so as to achieve the purpose of cleaning.

[0050] The present application discloses an embodiment of the electrolytic cleaning system, with reference to figure 1 , Including placed on the floor cleaning apparatus 1, is placed on one side of the unwinding device and the winding device 2 is placed on the other side of a longitudinal direction of the cleaning apparatus cleaning a longitudinal direction of the device 3, a washing apparatus includes a body 101, the body 101 along the longitudinal direction of the body 101, from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com