Electrolytic process apparatus

a technology of electrolysis process and electrolysis chamber, which is applied in the direction of electrolysis apparatus, electrical-based machining apparatus, machining electric circuits, etc., can solve the problems of increasing the cost associated with plating the cathode, the inability to obtain a uniform thickness of deposited material on the cathode, and the inability to justify the cost of producing a conforming anode. , to achieve the effect of improving the electrolytic process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The following description relates to plating applications (where the work is connected to the negative terminal of the power supply). However, it is to be understood that the apparatus can be used in a wide range of electrolytic processes such as Plating, Anodising, Etching, Electro cleaning, Electro polishing, Electrophoretic painting, Electro colour, etc . . .

[0034]“The Work” (the part to be treated) can be either negative (in the case of plating applications) or positive in the case of anodising or as required by the particular process. In the case of some applications, such as electro colour, a mixture of AC & DC can also be used.

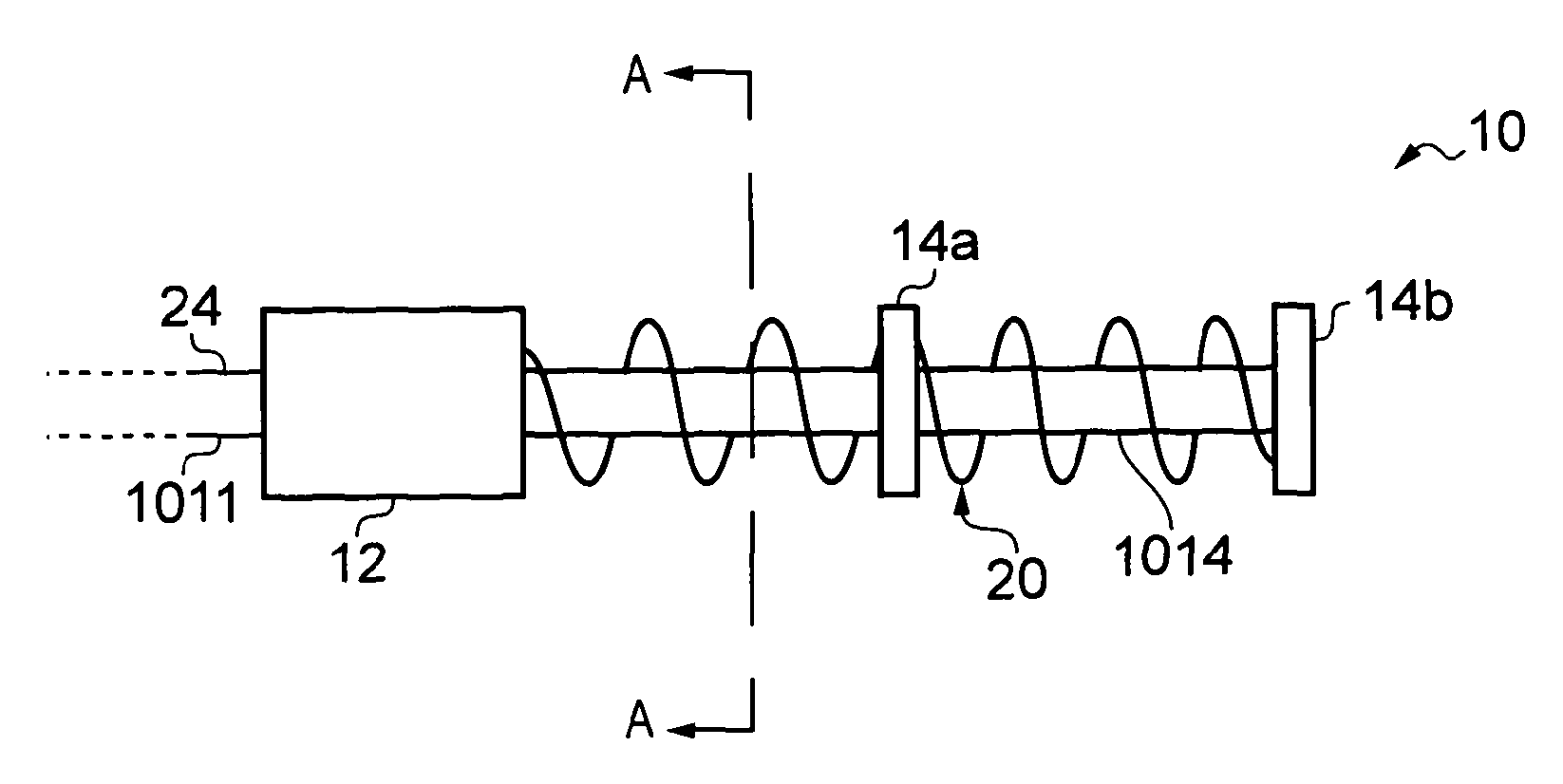

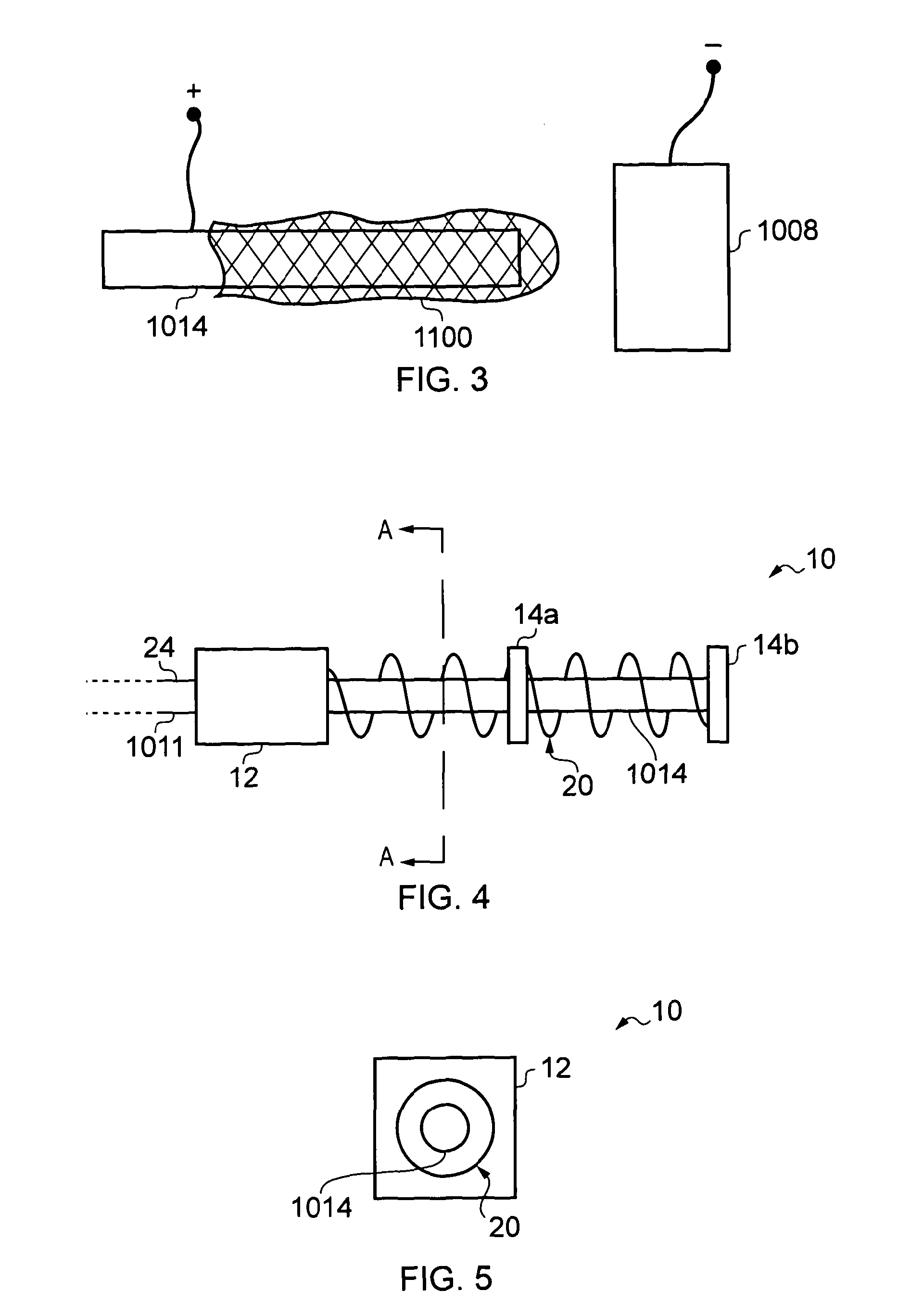

[0035]Referring to FIG. 4 a guarded auxiliary anode 10 is shown according to an embodiment of the invention. The guarded auxiliary anode 10 includes an anode 1014 arranged to be electrically coupled to the positive terminal 1010 of a direct current (DC) power supply, such as a rectifier, via an electrically insulated connecting wire 1011. Suitable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltages | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com