Patents

Literature

71results about How to "Full electrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature sintered hybrid conductive silver paste for chip package and preparation method thereof

ActiveCN107221373AFully dispersedAchieve low temperature sinteringNon-conductive material with dispersed conductive materialCable/conductor manufactureWater basedMicron scale

The invention discloses low-temperature sintered hybrid conductive silver paste for chip package and a preparation method thereof. The low-temperature sintered hybrid conductive silver paste comprises 50-95wt% of conductive silver powders and 5-50wt% of organic carrier. The conductive silver powders contain 20-60wt% of micrometer-scale flake silver powders, 5-40wt% of submicron-scale spherical silver powders and 20-60 wt% of nano-scale spherical silver powders. The organic carrier contains 3 to 30 wt% of binder, 40 to 97.9 wt% of solvent and 0.01 to 30 wt% of other additives. The surface modification of the micron-scale silver powders and the submicron-scale silver powders can adapt the decomposition temperature of a modified surface dispersant to that of a water-based ionic dispersant of such type, so as to realize the low-temperature sintering of hybrid silver paste.

Owner:SOUTH CHINA UNIV OF TECH

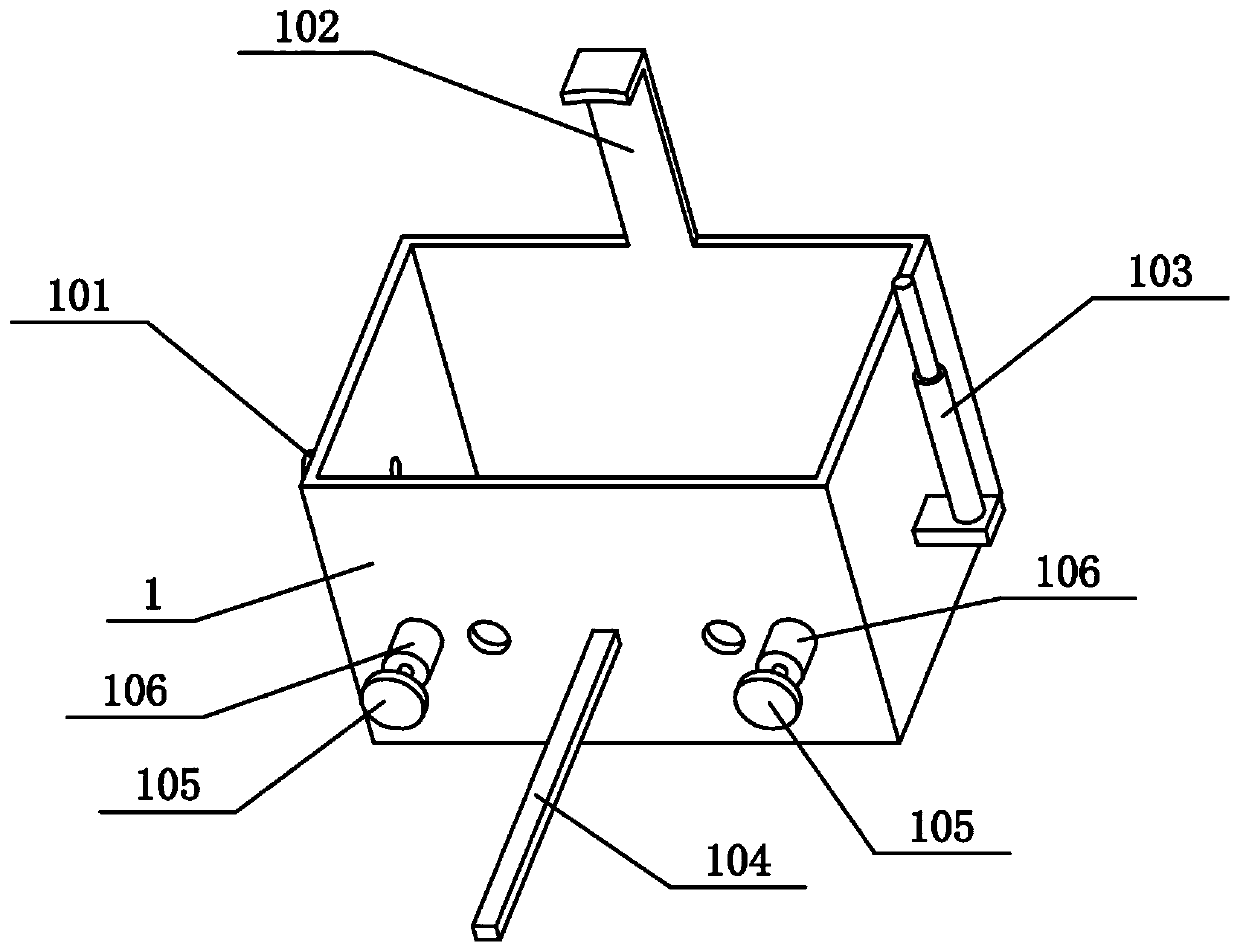

Electrolytic hydrogen fuel bi-motor and use method thereof

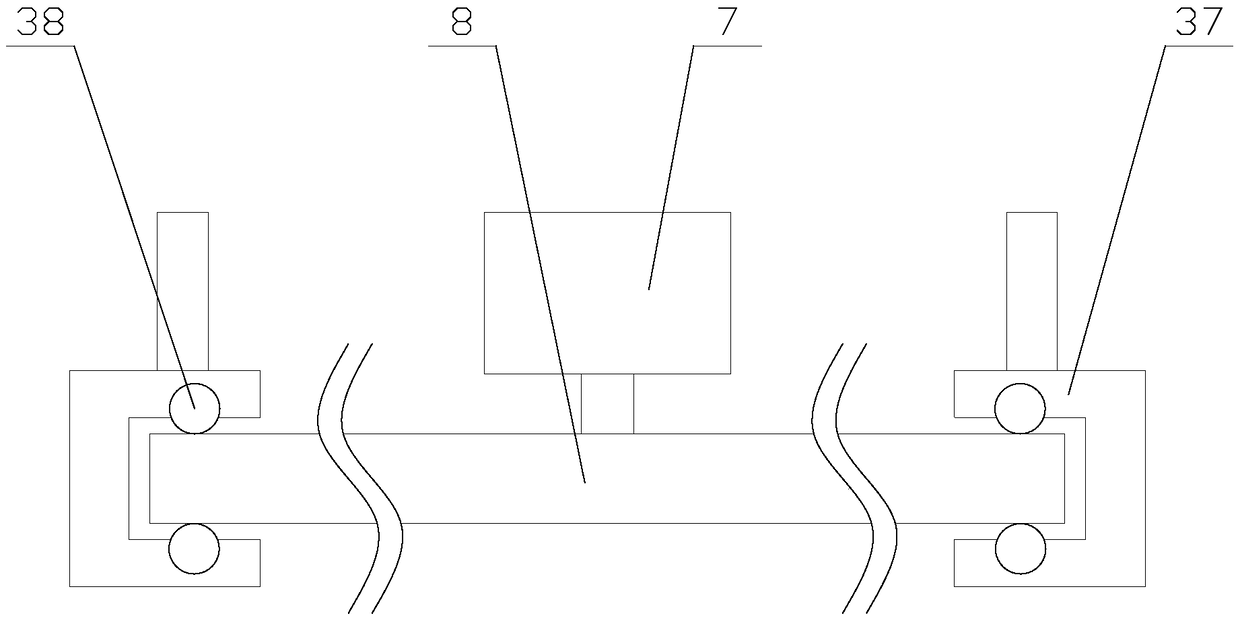

InactiveCN105065144AAvoid voltage changesAutomatic width adjustmentNon-fuel substance addition to fuelInternal combustion piston enginesElectrolysisGasoline

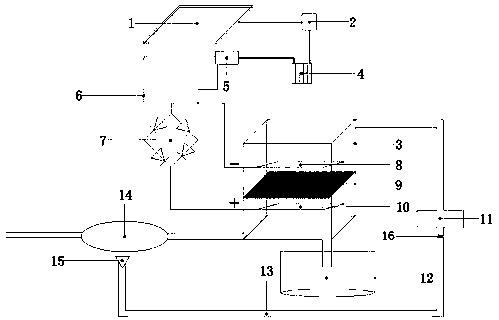

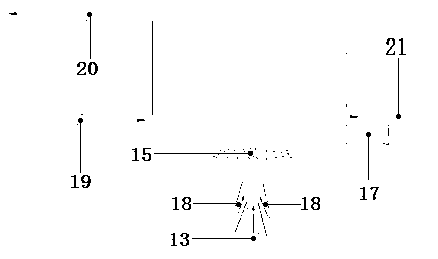

The invention discloses an electrolytic hydrogen fuel bi-motor. The electrolytic hydrogen fuel bi-motor comprises a water tank, an HHO generator, a motor and a constant-current pulse width regulator which is used for controlling current flowing into the HHO generator, wherein a liquid outlet I, a liquid inlet I and a gas vent are formed in the water tank; the HHO generator comprises multiple white steel sheets arranged in a sealed shell and an upper cover and a lower cover which press the multiple white steel sheets tightly; the multiple white steel sheets are arranged in a stacked manner; each white steel sheet is provided with a through hole I and a through hole II; a high temperature-resistant insulation pad is arranged between every two adjacent white steel sheets; and a cross-shaped through hole is formed in each high temperature-resistant insulation pad. The invention further discloses a use method of the electrolytic hydrogen fuel bi-motor. According to the electrolytic hydrogen fuel bi-motor, hydrogen generated through electrolysis of electrolyte is used as fuel of the motor in an electrolysis manner; the fuel saving rate can reach 20%-35%; the electrolytic hydrogen fuel bi-motor is applicable to various large, medium and small automobiles, steamships, small fishing vessels, fixed diesel engines, unmanned aerial vehicles and the like; and the electrolytic hydrogen fuel bi-motor is not limited by various automobiles or gasoline and diesel vehicles.

Owner:张建超

Sewage treatment device based on electrolytic flotation

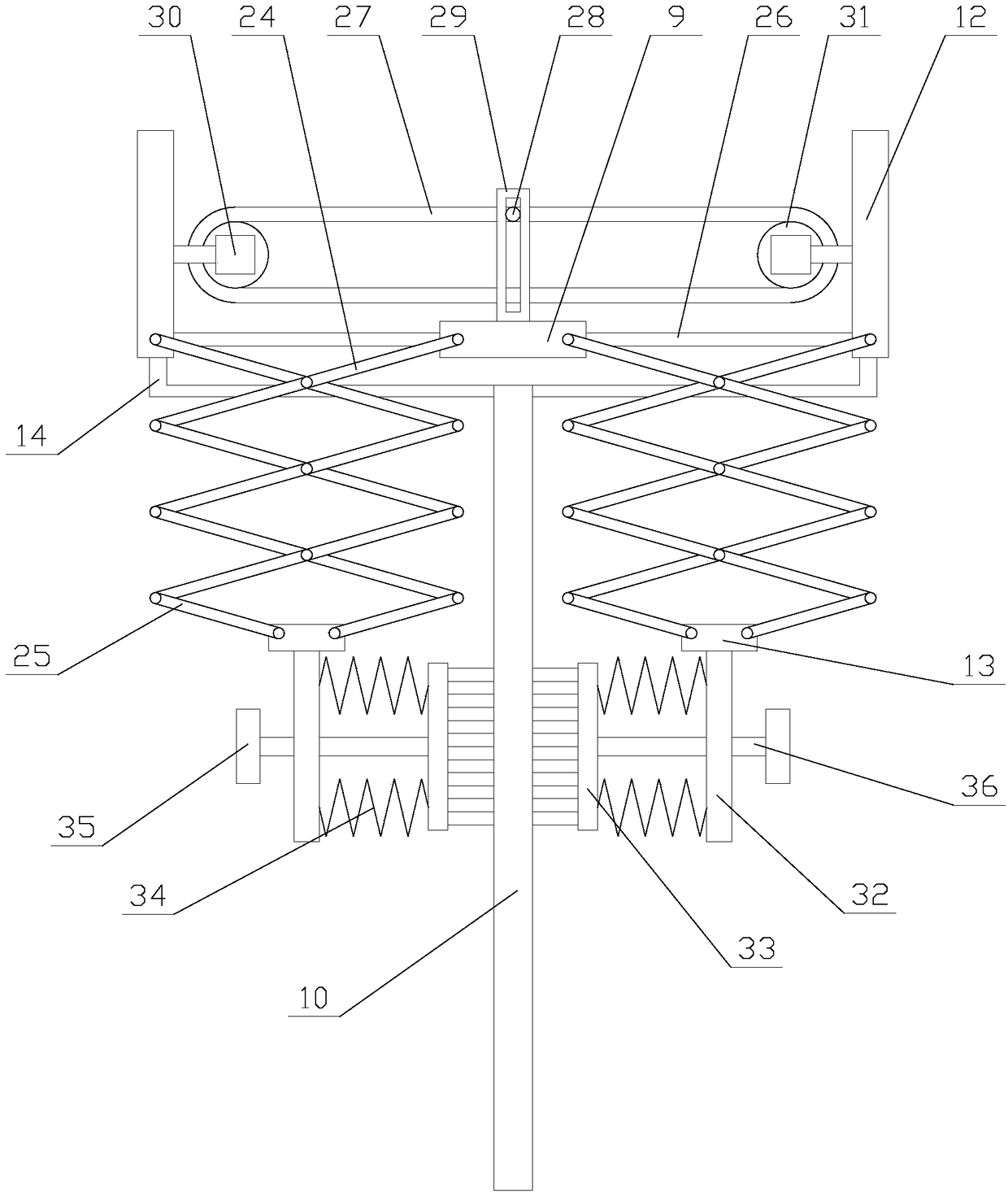

InactiveCN108821397AGuaranteed electrolysis efficiencyClean thoroughlyWater/sewage treatment by flotationPipingEngineering

The invention relates to a sewage treatment device based on electrolytic flotation. The sewage treatment device based on electrolytic flotation comprises an electrolysis tank, a water inlet pipe, a drainage pipe, a roof, a rotating mechanism, a stirring mechanism, an electrolysis mechanism and two supporting columns, wherein the electrolysis mechanism comprises a sliding plate, a driving assembly,a negative plate, two cleaning assemblies and two positive plates, the cleaning assemblies comprise lifting plates, telescopic units, lifting plates, connecting frames and cleaning units, and the stirring mechanism comprises a rotating shaft, slides, two sliding blocks, two bearings, two rotating units and two stirring units. According to the sewage treatment device based on electrolytic flotation, through the stirring mechanism, sewage flows on the bottom of the interior of the electrolysis tank are stirred, convenience is brought for suspended particles on the bottom to be in contact with hydrogen bubbles to make electrolysis more fuller, moreover, when the electrolysis mechanism generates the hydrogen bubbles, through the telescopic units, the driving assembly drives the lifting platesto move vertically to make the cleaning units clean the surface of the negative plate and to enable the negative plate to be in full contact with sewage, the electrolysis efficiency is ensured, and the practicability of equipment is improved.

Owner:SHENZHEN JIUPIN AIR PURIFICATION TECH CO LTD

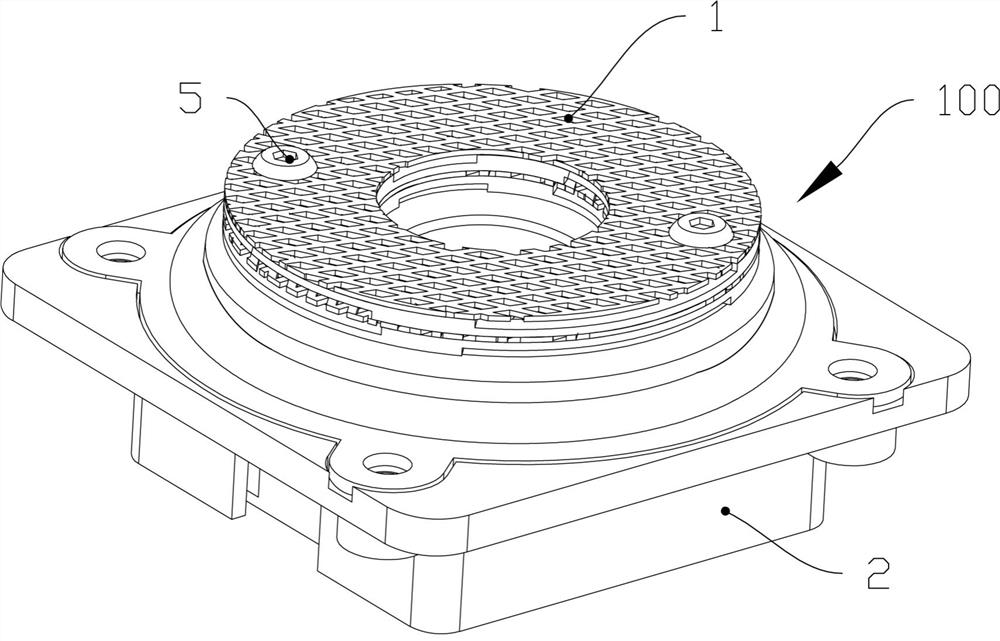

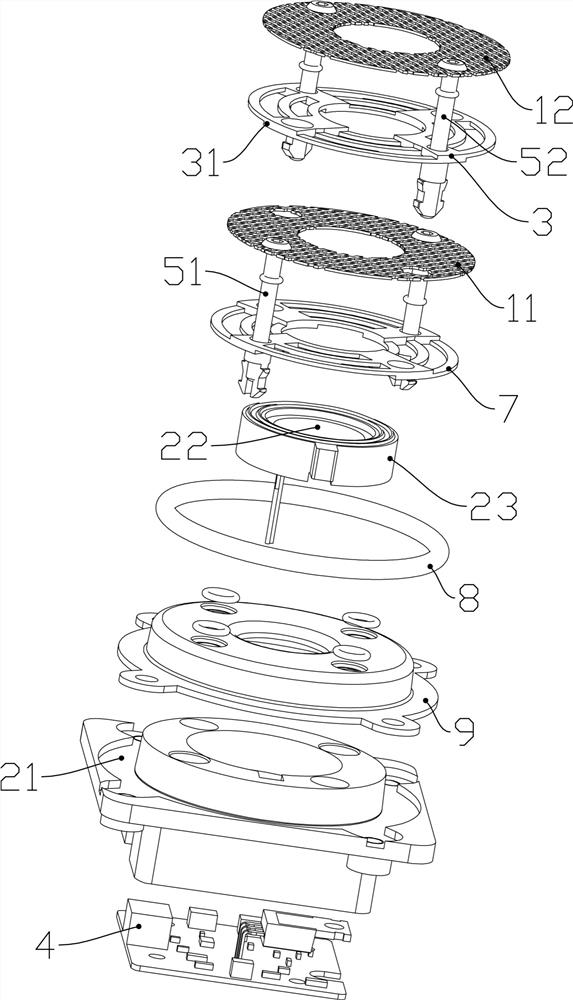

Integrated electrolysis atomization module and atomization device

PendingCN111825170ASmall footprintEasy maintenanceLavatory sanitoryLiquid spraying apparatusPhysicsElectrically conductive

The invention provides an integrated electrolysis atomization module and atomization device. The integrated electrolysis atomization module comprises an electrolysis assembly and an atomization assembly, the atomization assembly comprises an installation base and a flat plate atomization piece installed on the installation base, and the flat plate atomization piece is used for atomizing liquid above the flat plate atomization piece and spraying the atomized liquid upwards; the integrated electrolysis atomization module is characterized in that the electrolysis assembly comprises at least one electrolysis electrode pair, namely a first electrolysis electrode and a second electrolysis electrode, an electrical isolation distance is formed between the first electrolysis electrode and the second electrolysis electrode, the first electrolysis electrode and the second electrolysis electrode are connected to the installation base, and the projection of the electrolysis assembly avoids the flatplate atomization sheet when viewed from top to bottom; electric signal connection between the electrolysis electrode and the control circuit board is achieved through the conductive bolt (or in combination with the mounting base), mechanical connection of the electrolysis electrode can be achieved at the same time, the overall structure is simple, and a simple sealing structure can be adopted.

Owner:FOSHAN NANHAI KERI ELECTRONICS

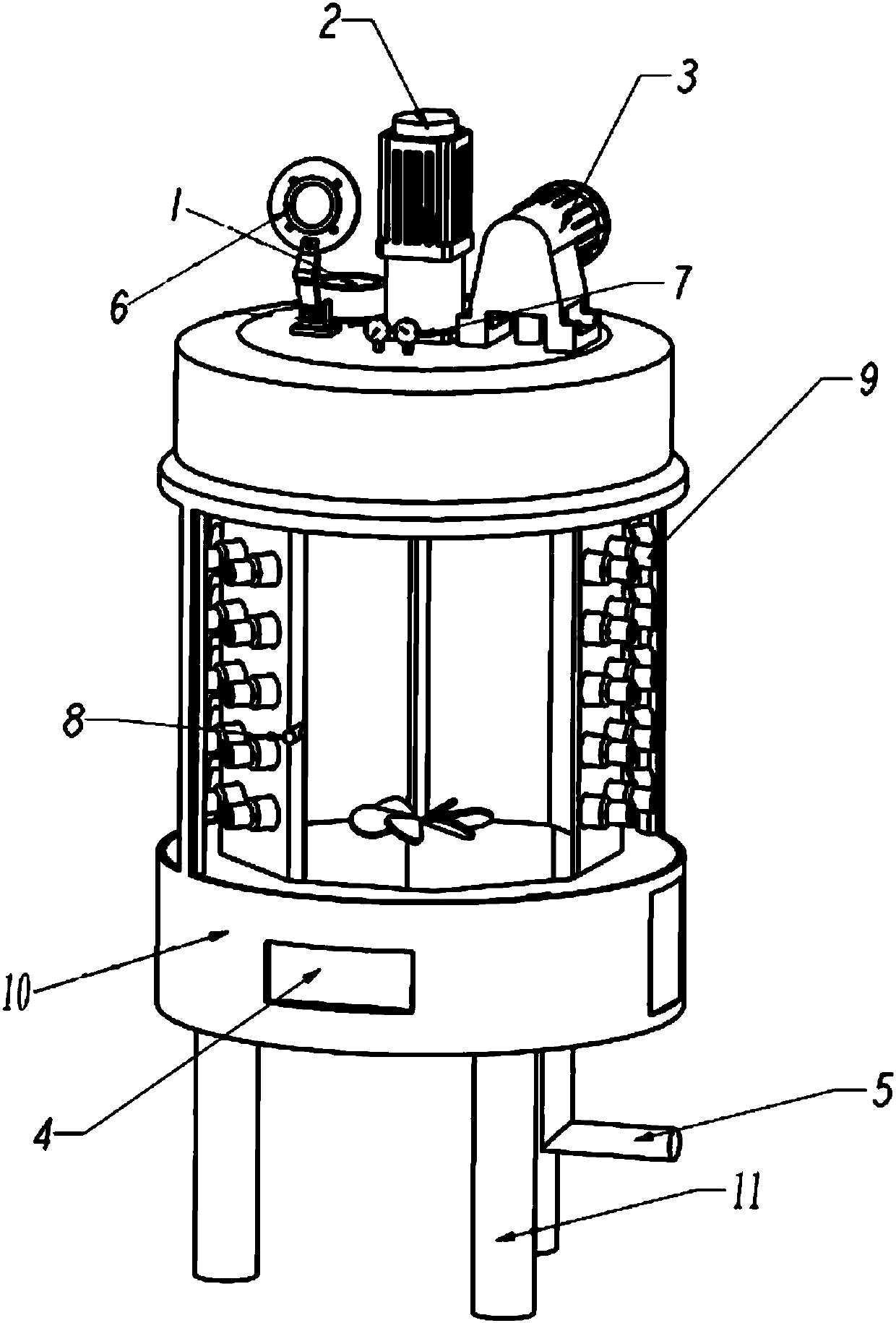

Vacuum stirring type ultrasonic wave dispersing breaking treatment tank

PendingCN107626244AImprove performanceFully dispersedShaking/oscillating/vibrating mixersGrain treatmentsBiochemical engineeringSlurry

The invention discloses a vacuum stirring type ultrasonic wave dispersing breaking treatment tank, which comprises a treatment tank body, wherein a stirring motor is arranged in the middle of the topend of the treatment tank body, both edges of the stirring motor are respectively provided with a material inlet and a vacuum pump, a sealing cover is movably arranged on the material inlet, the bottom portion of the treatment tank body is provided with a material outlet, and the treatment tank body is provided with a plurality of ultrasonic wave oscillators. According to the present invention, with the vacuum stirring type ultrasonic wave dispersing breaking treatment tank, the breaking and dispersing effect is good, the mixture of the carbon powder, the electric conduction agent and the binder can be completely electrolyzed, dispersed and broken in the vacuum stirring type ultrasonic wave dispersing breaking treatment tank, the electrode active particles and the electric conduction slurry can be mutually absorbed and dissolved, and the performance of the battery can be improved.

Owner:广州市声联超声波电子设备有限公司

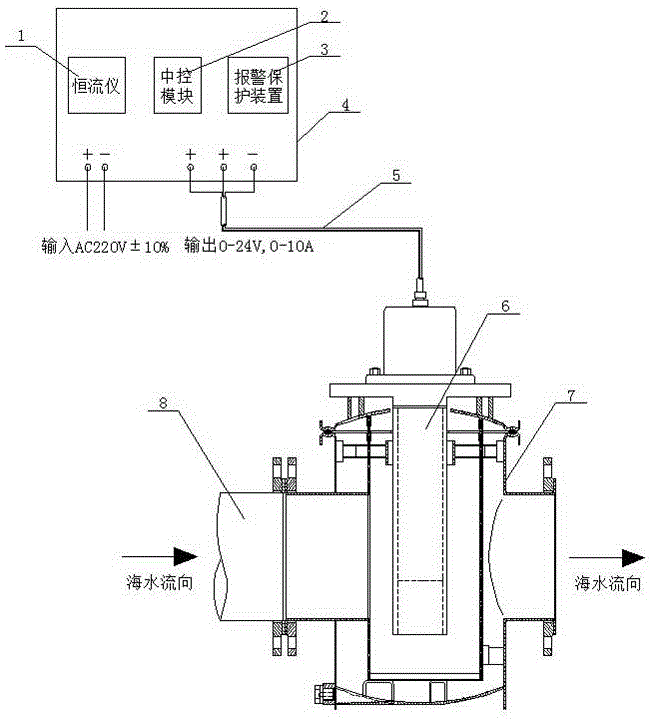

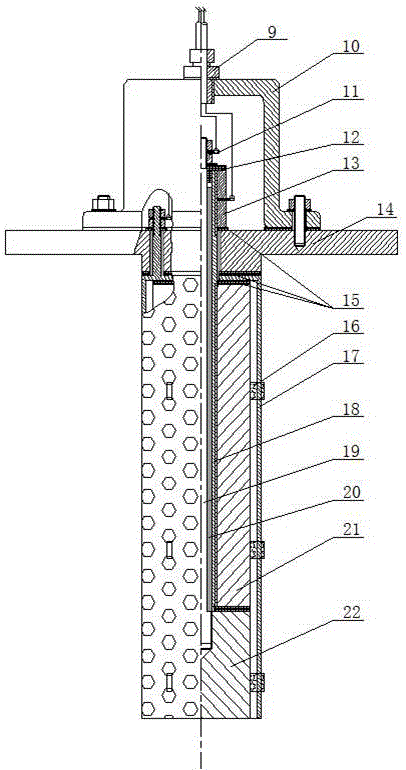

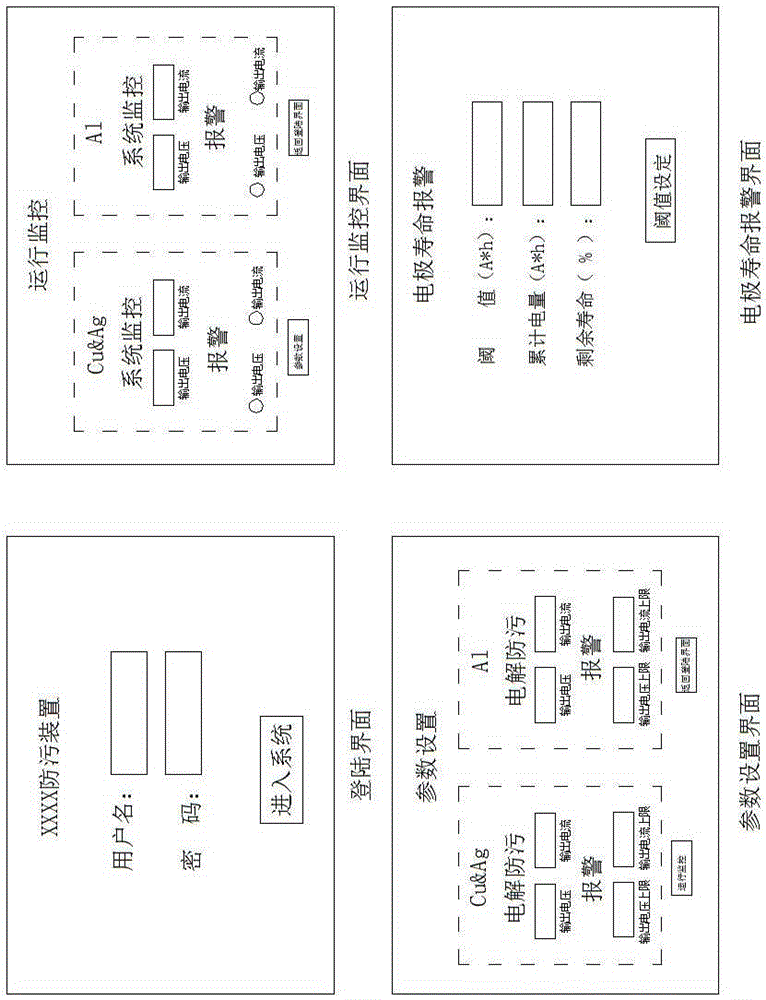

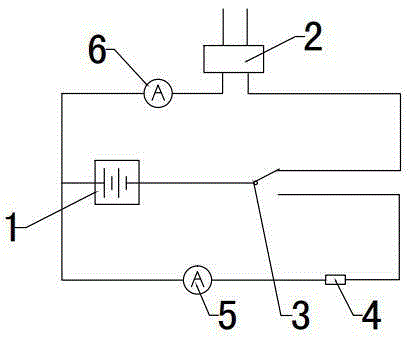

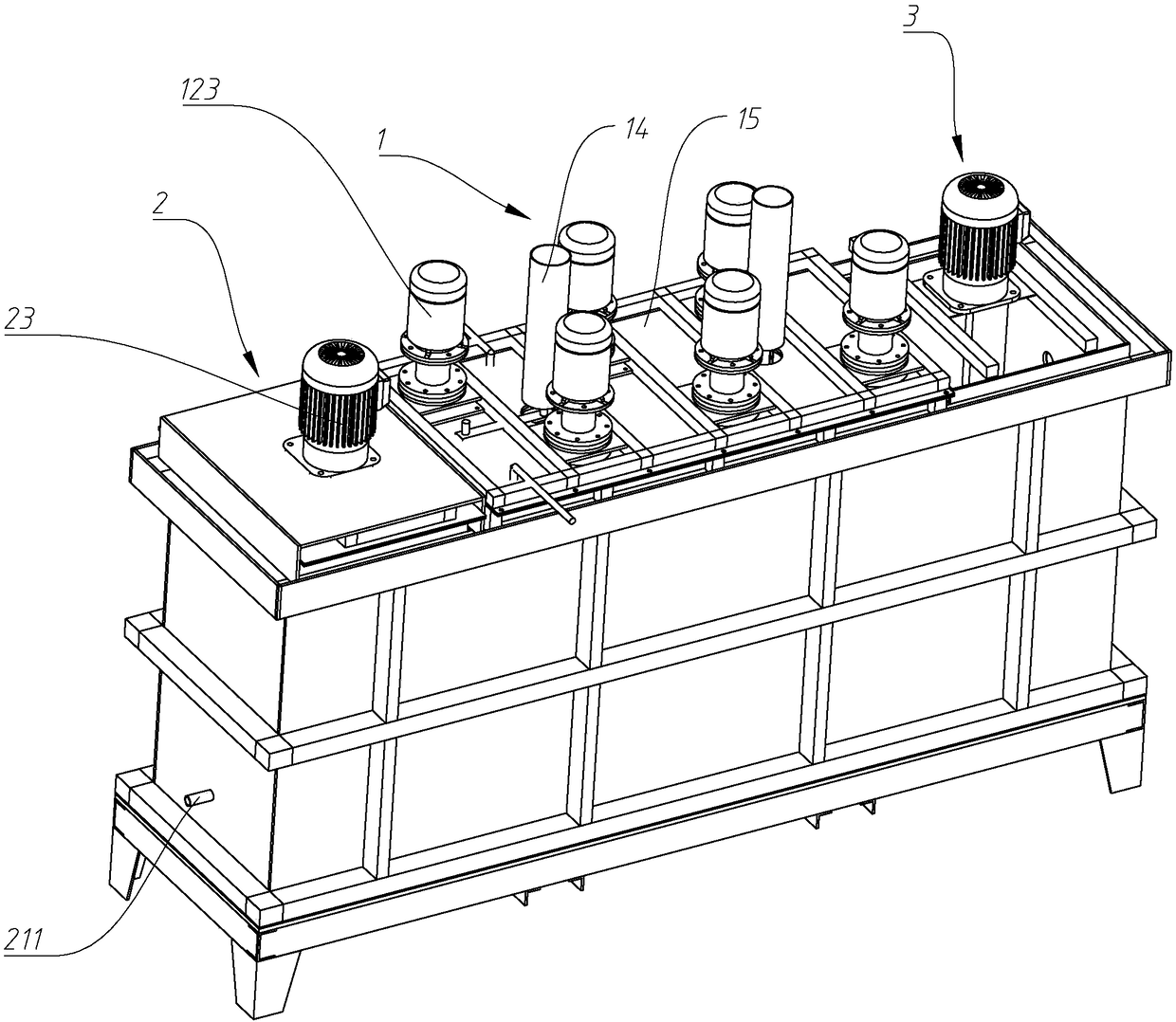

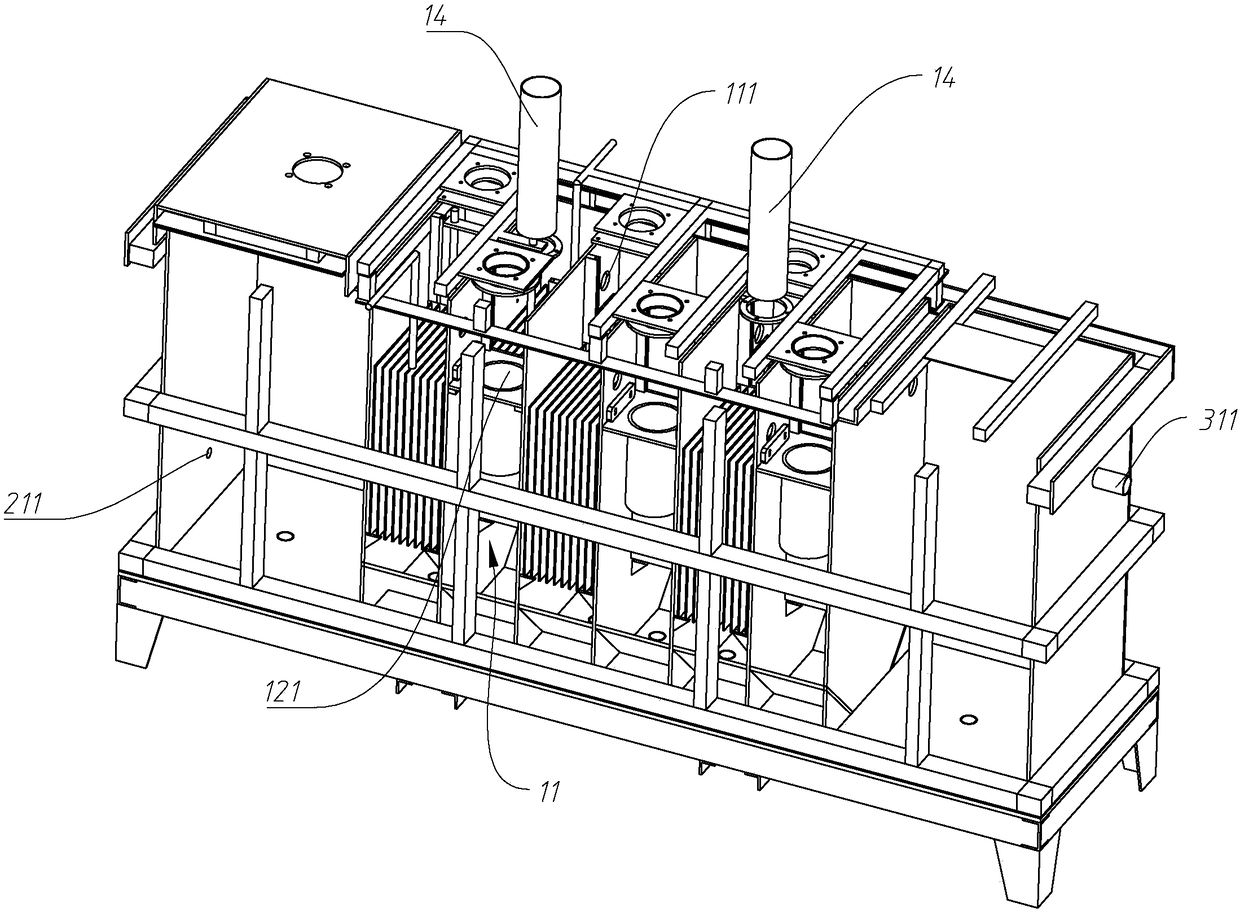

Integrated high-efficiency antifouling electrode and electrolysis antifouling device used for titanium alloy seawater pipeline

The invention provides an integrated high-efficiency antifouling electrode and an electrolysis antifouling device used for a titanium alloy seawater pipeline, and belongs to the field of halobios fouling control for seawater pipelines. The integrated high-efficiency antifouling electrode is designed with an independent cathode body, so that the key problem that hydrogen embrittlement can be easily generated on the titanium alloy seawater pipeline when the titanium alloy seawater pipeline is used as a cathode is solved; the cross section of the cathode body is a closed ring, and defines the outer side of an anode body, and thus, current produced by the anode body is enabled to be basically absorbed by the cathode body, and the problem that stray current corrosion is generated by electrolysis antifouling is avoided; the electrode is designed with an anode conductor, so that space required by installation of the electrode is obviously reduced, and meanwhile, two ways of anode electrolysis current can be controlled independently, and therefore, an antifouling compound is prepared with accurate concentration, and a good antifouling effect is ensured. The electrode is employed by the electrolysis antifouling device, and an alarm device for the service life of the electrode is designed, so that the safety problem possibly caused by anode overelectrolysis is solved, the titanium alloy seawater pipeline is enabled to gain a good halobios fouling control effect, and all related systems are enabled to be stable and safe in operation.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

High-strength permeable concrete additive and preparation method thereof

The invention provides a high-strength permeable concrete additive and a preparation method thereof, and relates to the technical field of concrete. The high-strength permeable concrete additive comprises 0.5-3 parts of micro-powder, 1-4 parts of ammonium sulfate, 1-4 parts of potassium sulfate, 1-4 parts of sodium sulfate, 1-4 parts of magnesium chloride, 6-12 parts of ferric sulfate, 1-4 parts of ferrous sulfate, 9-14 parts of calcium chloride, 0.05-0.3 part of sodium gluconate and 55-70 parts of water. Main components of the concrete additive are inorganic matters, less in toxicity and goodin aging resistance. The additive contains a large number of metal ions, the micro-powder is added, and the strength and the water permeability of permeable concrete can be effectively enhanced. Besides, the preparation method of the additive is simple in process, short in cycle, low in cost and applicable to industrial production.

Owner:XIAMEN UNIV OF TECH

Binder for pervious concrete and preparation method thereof

ActiveCN107129175AHigh strengthImprove water retention and permeabilityCeramicwareGluconic acidSodium sulfate

The invention provides a binder for pervious concrete and a preparation method thereof. The binder for pervious concrete comprises, by weight, 1 to 4% of ammonium sulfate, 1 to 4% of potassium sulfate, 1 to 4% of sodium sulfate, 1 to 4% of magnesium chloride, 1 to 4% of ferric sulfate, 2 to 7% of ferrous sulfate, 15 to 25% of calcium sulfate, 0.01 to 0.3% of a water-retaining agent, 0.05 to 0.3% of sodium gluconate, 0 to 0.3% of an air entraining agent and 47.4 to 77.94% of water. The binder for pervious concrete provided by the invention uses inorganic substances as main components, is nontoxic, has good anti-ageing performance, can improve the strength of pervious concrete and has good water retention performance and water penetration performance; and the preparation method is simple in process, short in preparation period, low in cost and applicable to industrial production.

Owner:XIAMEN UNIV OF TECH

Online activation method for lead-acid storage battery

ActiveCN105428730ALarge capacitySolve insufficient capacityFinal product manufactureSecondary cells charging/dischargingActivation methodAcetic acid

The invention discloses an online activation method for a lead-acid storage battery and belongs to the technical field of storage battery recycling. The method is characterized by comprising the activation steps of: checking the storage battery, injecting glacial acetic acid into an electrolyte solution of the storage battery, sealing the storage battery, and over-discharging the storage battery until the voltage of the storage battery is 0V; opening the storage battery again, injecting an active agent, and adding distilled water into the storage battery until the rated electrolyte solution capacity of the storage battery is reached, wherein the total additive amount of the active agent is 0.45-0.65% of the total mass of the electrolyte solution; and sealing the storage battery again and charging the storage battery until the original rated voltage of the storage battery is reached. According to the activation method, not only can a scraped lead-acid storage battery with the battery capacity lower than a rated value be repaired but also a new battery or a slightly vulcanized lead-acid storage battery can be directly activated, and the service life of the battery can be greatly prolonged after the activation.

Owner:ZIBO VOCATIONAL INST

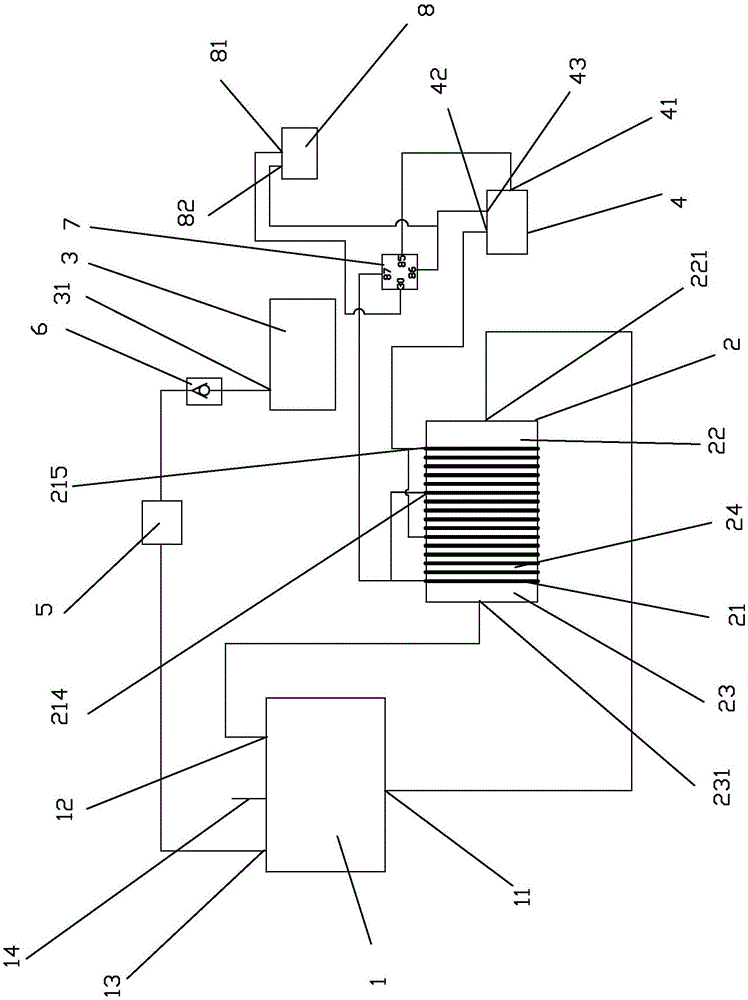

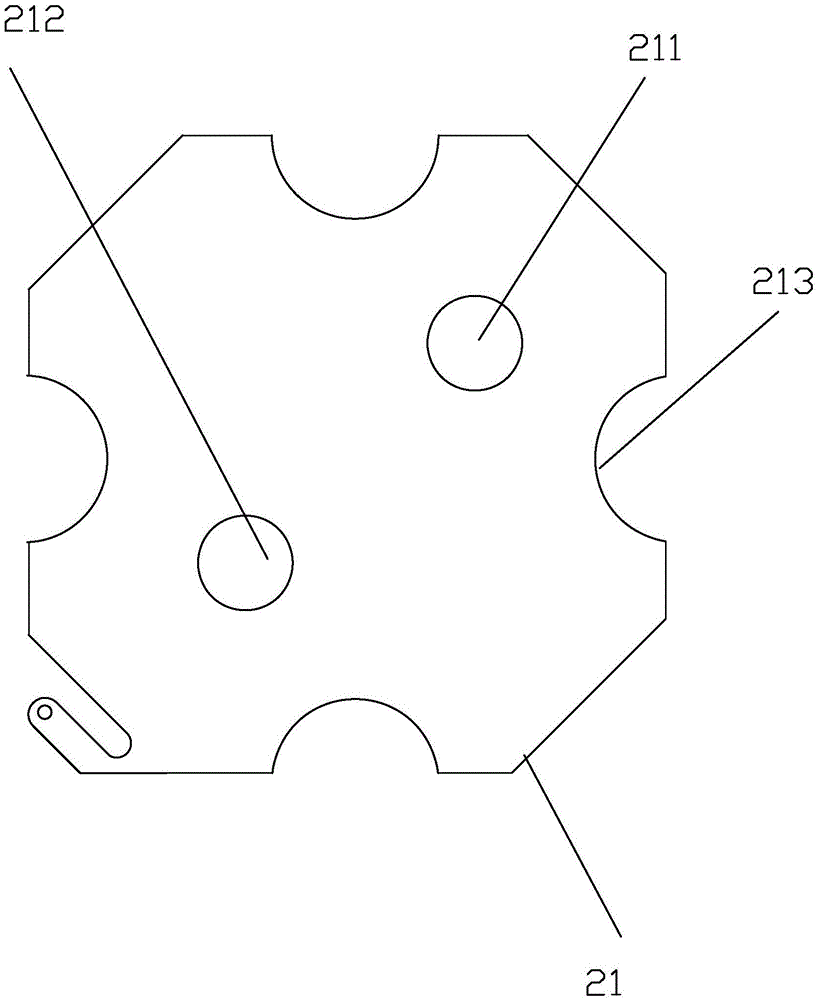

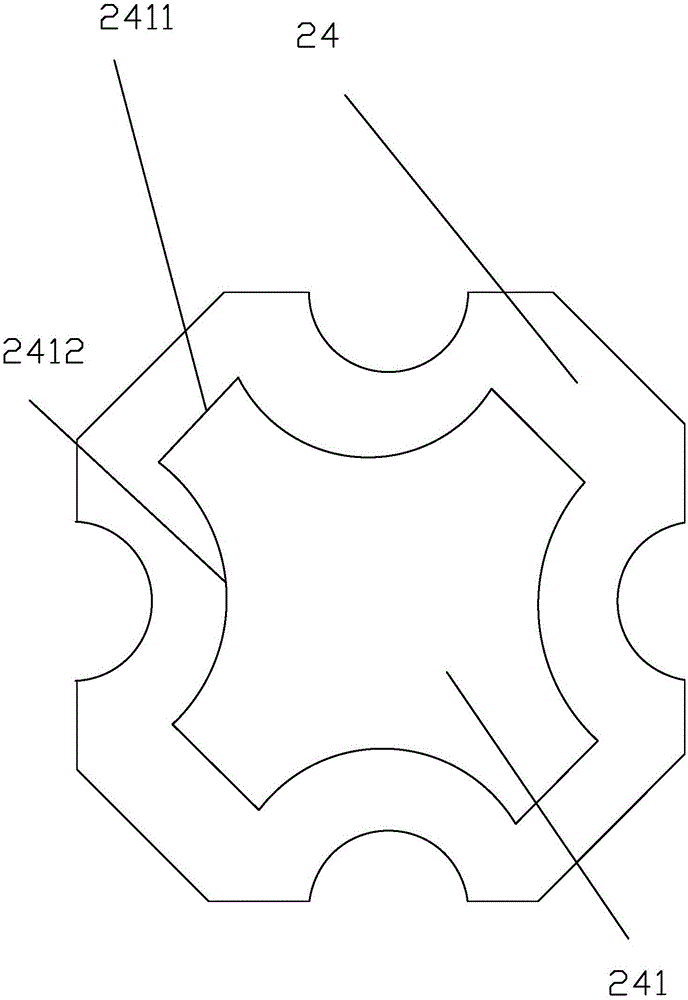

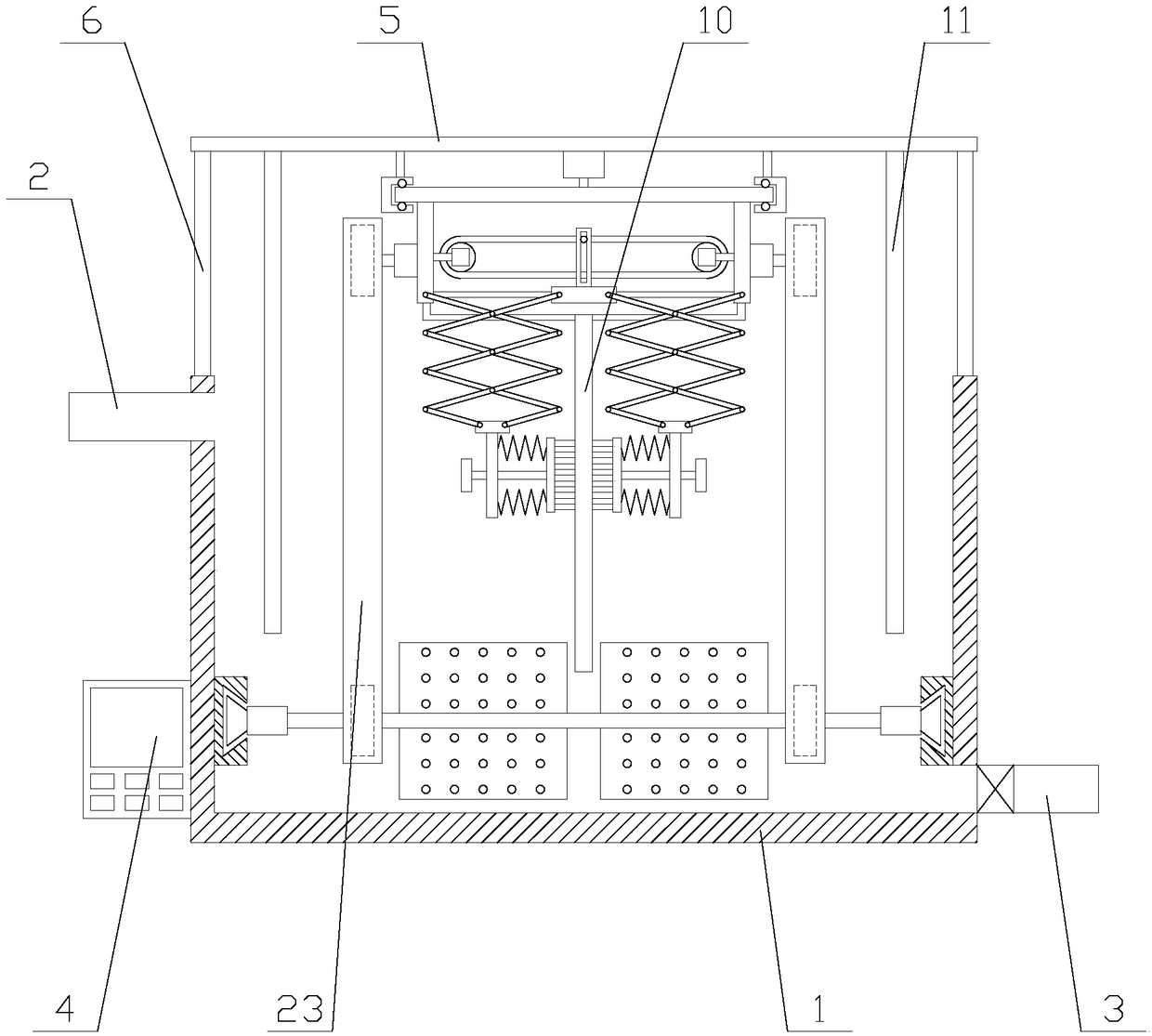

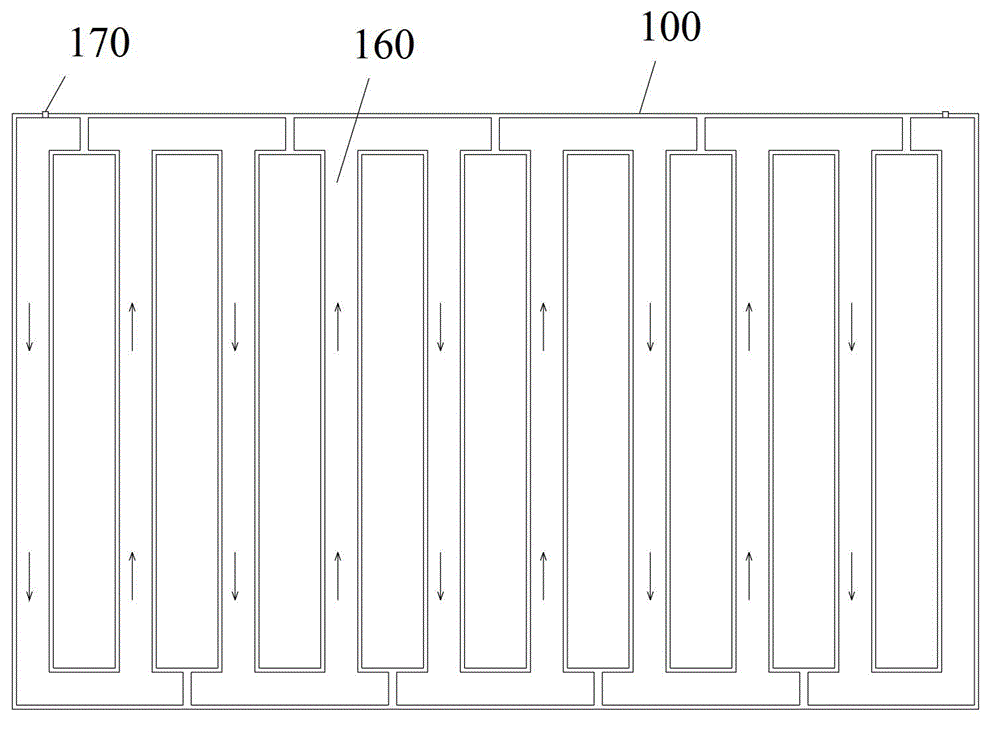

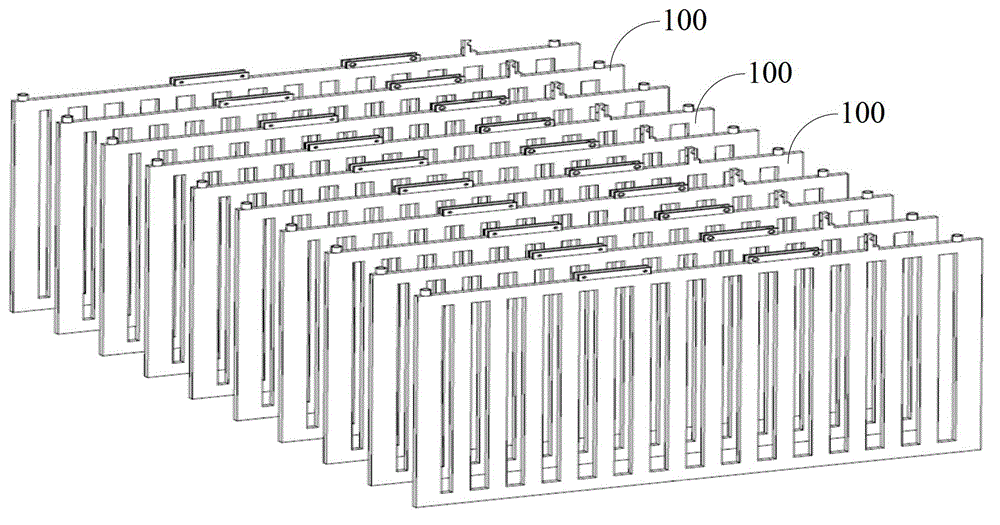

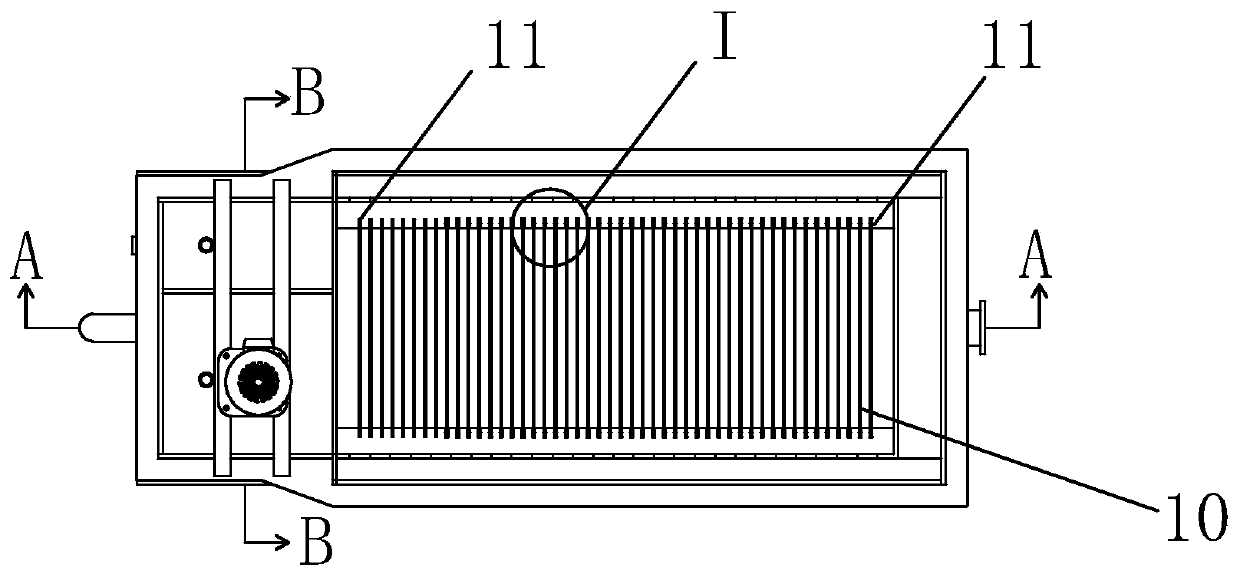

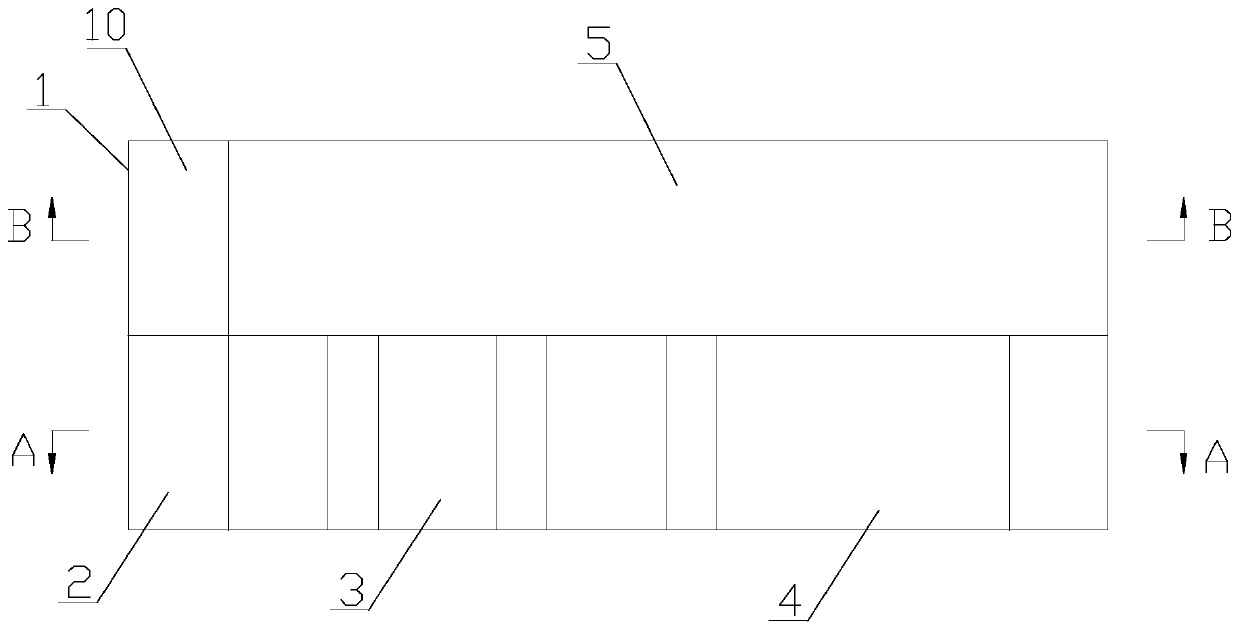

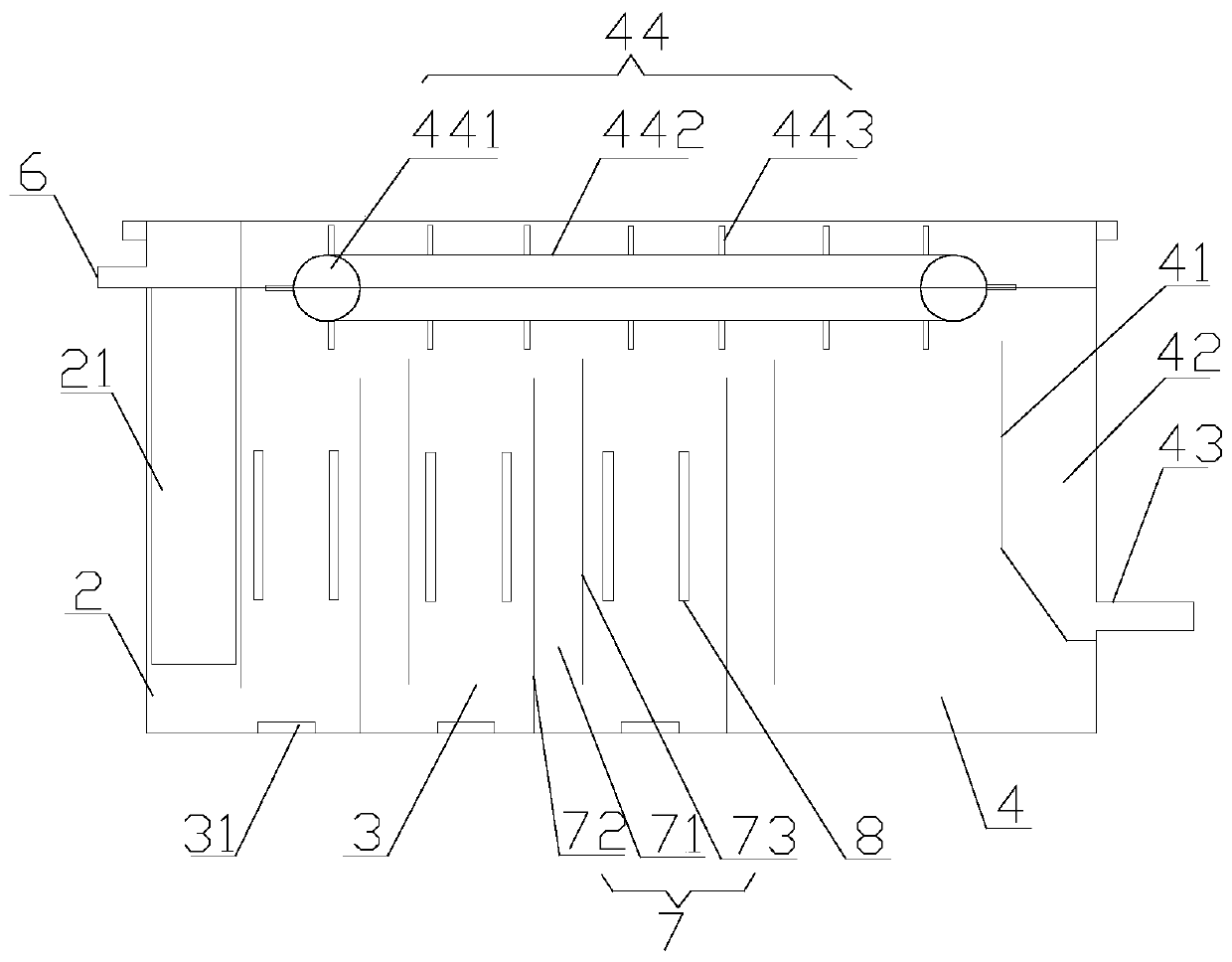

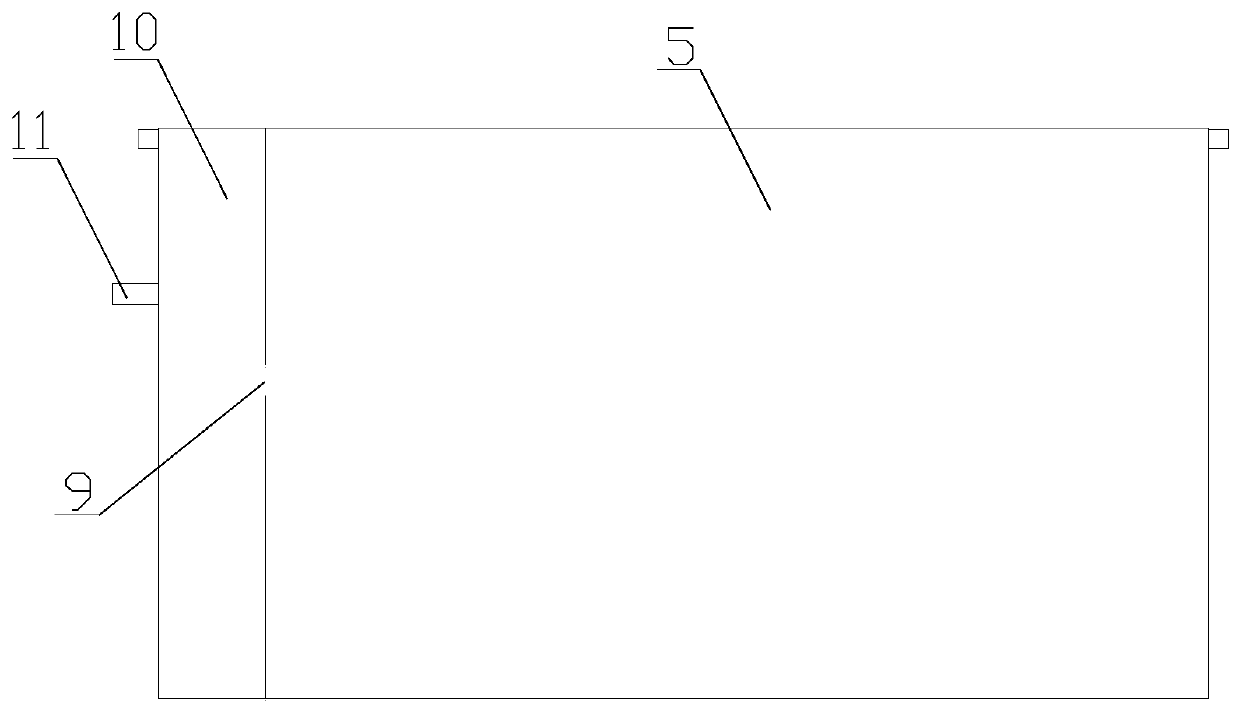

Internal circulation type electrolytic bath

PendingCN108502990AFull electrolysisEmission complianceWater/sewage treatment apparatusWater treatment multistage treatmentsSewageActuator

The invention discloses an internal circulation type electrolytic bath, and belongs to the technical field of sewage treatment. An existing processor can only intermittently treat sewage, the sewage processing efficiency is affected, sewage in an electrolytic area is low in water flow, sewage cannot be fully electrolyzed, the electrolysis efficiency is poor, and the effluent quality is poor. Accordingly, multiple electrolytic mechanisms are arranged, the sewage can continuously flow into the electrolytic mechanisms, actuators of the electrolytic mechanisms drive the sewage to surge into electrode components in pressurized cylinders, the sewage in the same electrolytic mechanism is electrolyzed repeatedly, an internal circulation type electrolysis mode is formed, when the sewage surges continuously, water electrolyzed repeatedly on the top flows into the next electrolytic mechanism from an overflow hole, cyclic electrolysis is conducted continuously again, a multistage electrolytic system is formed, and finally it is ensured that the sewage conforms to emission standard.

Owner:浙江美纳环保科技有限公司

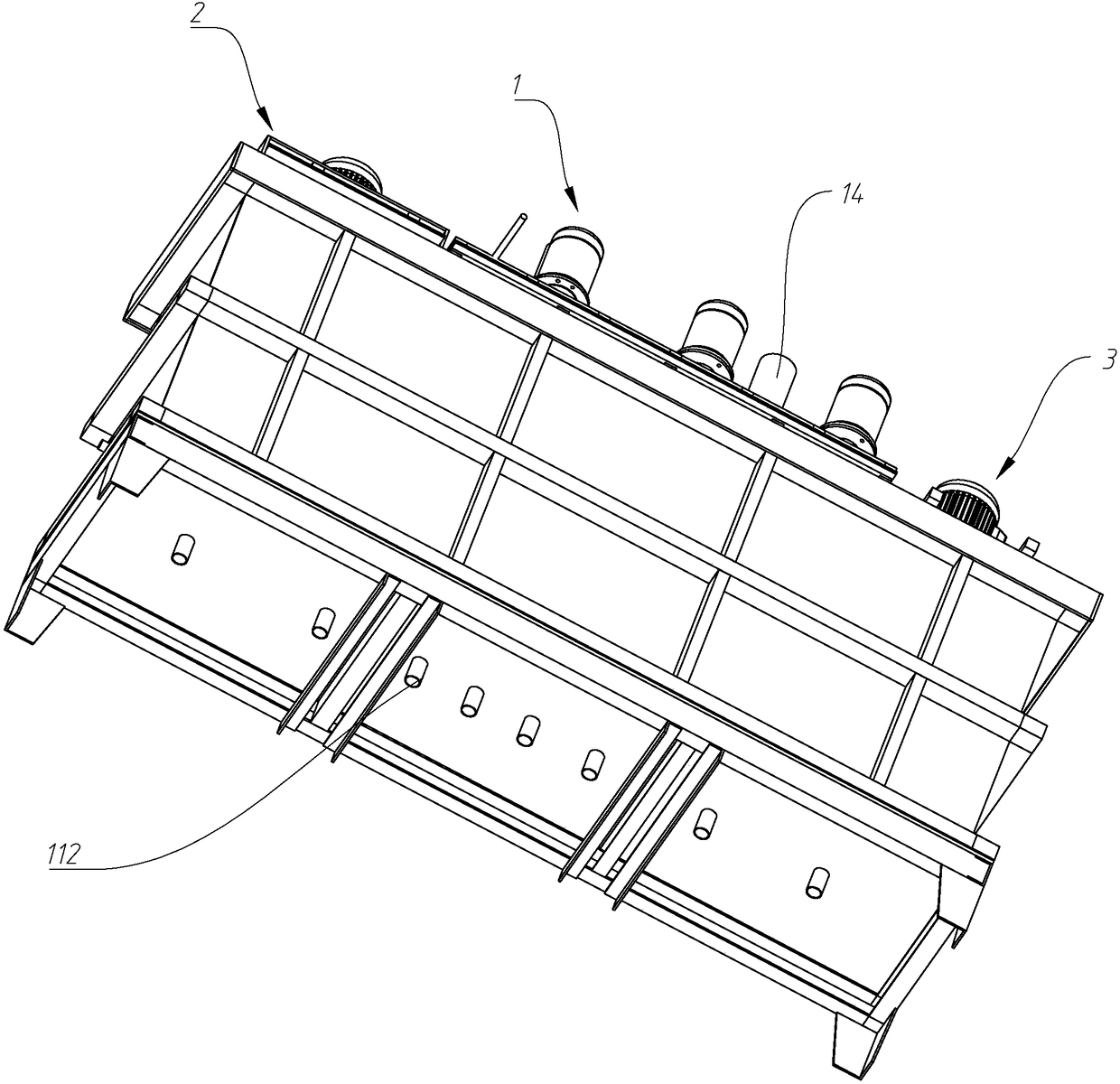

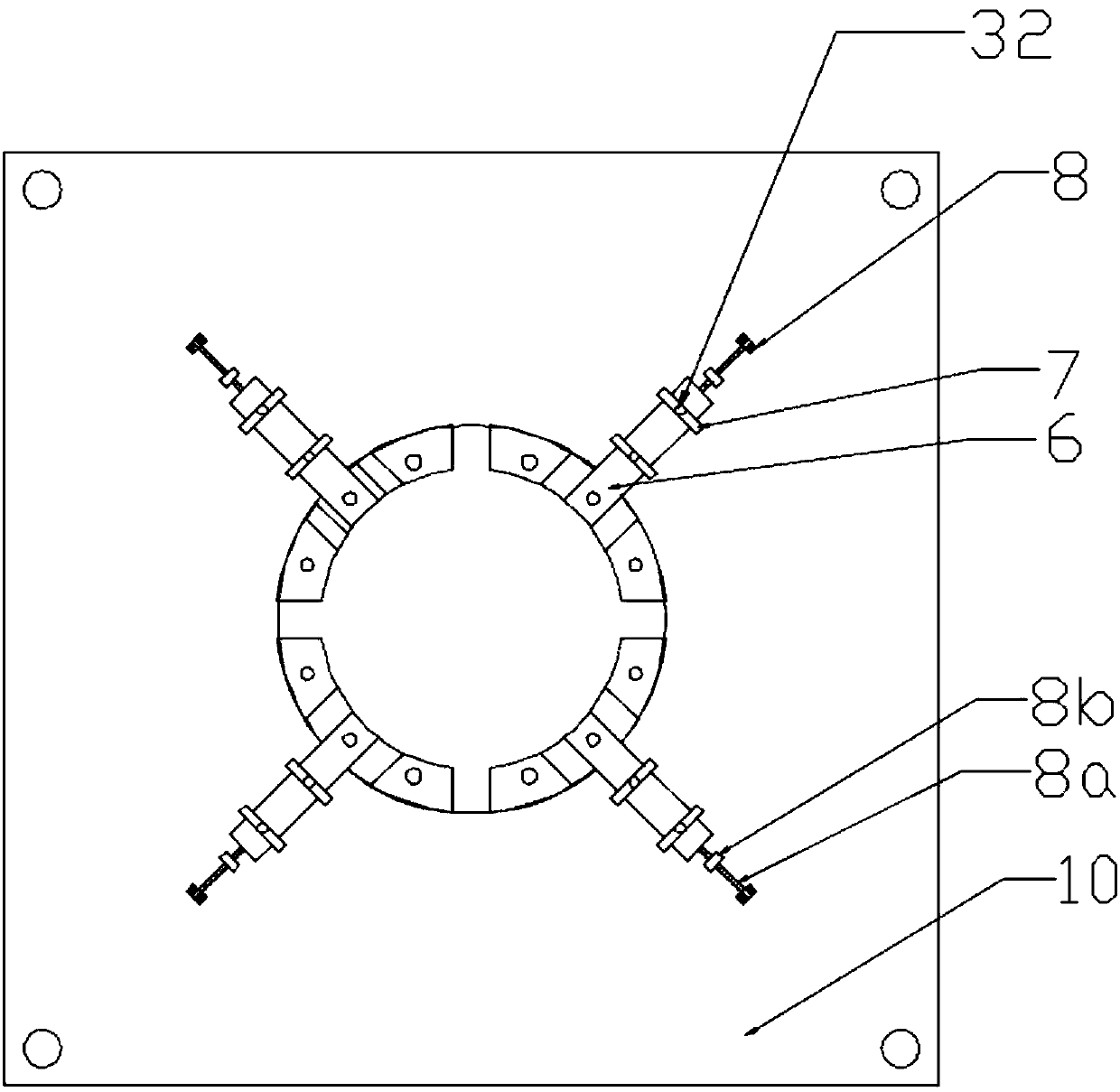

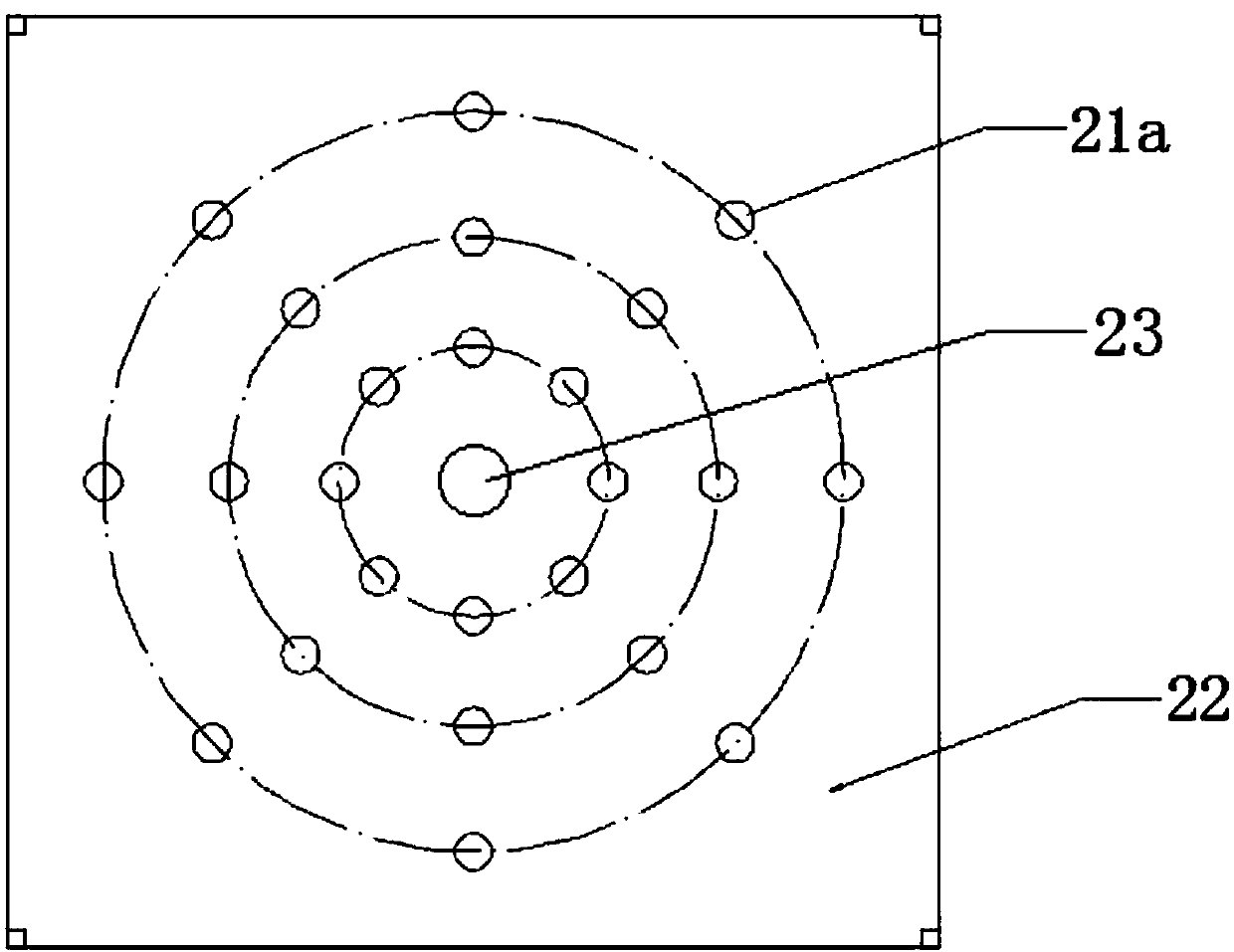

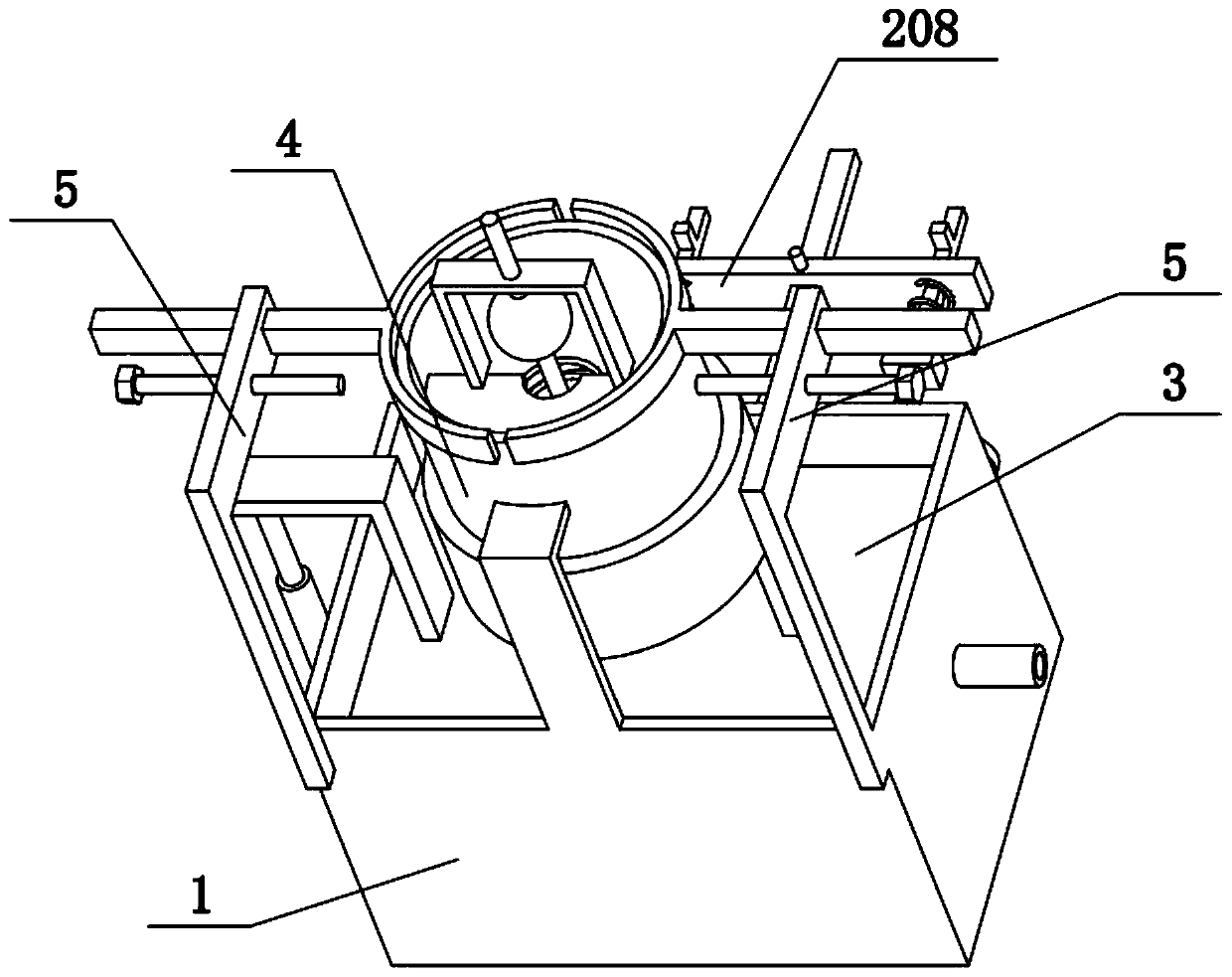

Self-rotation type electrolysis production device for producing rare earth metals element and alloy thereof

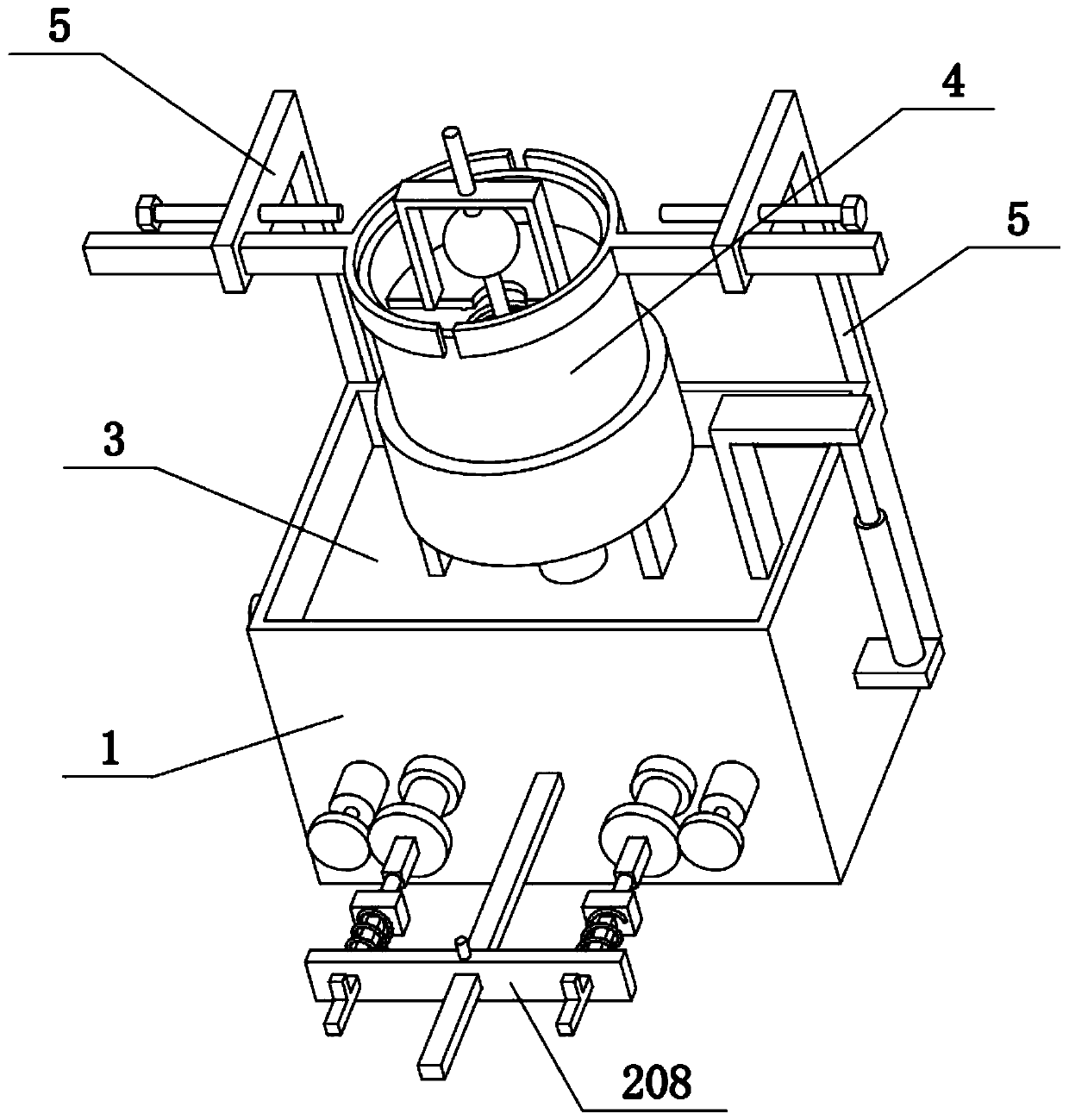

The invention discloses a self-rotation type electrolysis production device for producing a rare earth metals element and an alloy thereof. A rotational tray is arranged on the bottom of an electrolytic tank body, the rotational tray is erected on a revolving platform through a rolling connection part, and an electric motor in the revolving platform is connected with a driving shaft which is connected with the lower surface of the rotational tray; a platform plate is erected on the revolving platform through platform plate supports which are arranged at the four corners respectively, four graphite anode plates which are distributed around the inner circle of the electrolytic tank body are arranged in the electrolytic tank body, and all the graphite anode plates and an anode conduction plate are fixed together. A rotating jackscrew mechanism is arranged on the anode conduction plate, and an anode is connected with a molybdenum rod through a connection arm, wherein the molybdenum rod isvertically inserted into the electrolytic tank body. According to the self-rotation type electrolysis production device, the revolving platform can drive the electrolytic tank body to rotate, the rotation of molten salt electrolyte is achieved, and better circulation flowing of the electrolyte and the dissolution and uniform distribution of a rare earth oxide are accelerated; the space between electrodes can be changed through the rotating jackscrew mechanism, a circulating water cooling structure is beneficial for reducing the temperature of the iron platform plate, and the resistance and thepower consumption are reduced.

Owner:JIANGSU JINSHI RARE EARTH CO LTD

Anode scrap-free tandem electrolyzing device with anode material storing box

The invention provides an anode scrap-free tandem electrolyzing device with an anode material storing box, wherein the anode scrap-free tandem electrolyzing device is applied to the fields such as the electrolytic refining of metal, the electrolytic production of metal powder material, the electrolytic recovery of waste metal and the like. The anode scrap-free tandem electrolyzing device is characterized in that the anode material storing box is arranged at one side of an electrolytic bath, a metal inner box of the anode material storing box is connected with an anode plate through a conductive yoke plate, and the electrolyzed anode material is oxidized into metal ions in the box and is distributed into the electrolytic bath due to the diffusion of the ions and the circulation of electrolyte; the anode plate is made from the metal or the alloy which can not be chemically dissolved by the electrolyte, wherein the metal activity of the metal or the alloy is lower than that of the electrolyzed metal rather than the electrolyzed anode material; the electrolysis material is added from the anode material storing box and is free from the anode scrap; pole plates in the groove are connected with one another in series, and the electrolyte is isolated due to the effective combination among the anode plate, a cathode and pole plate installing notches. According to the anode scrap-free tandem electrolyzing device, the anode does not need to be changed, the anode material can be conveniently added, the anode scrap of the anode plate is unavailable, the use quantity of the anode raw material in the groove is low, and the anode scrap-free tandem electrolyzing device has the characteristics of being energy-source-saving, investment-saving, and high in production efficiency.

Owner:王惟华

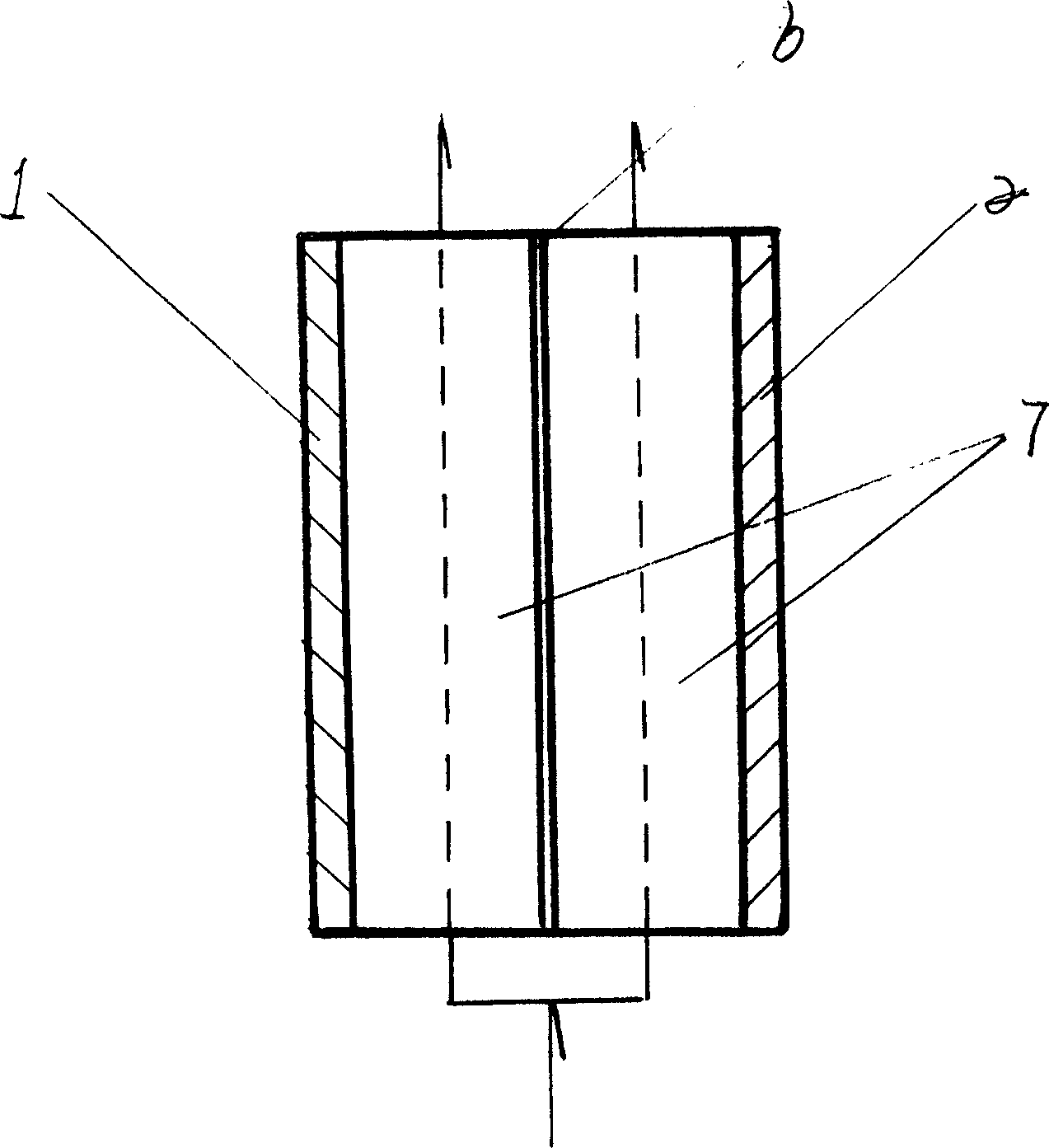

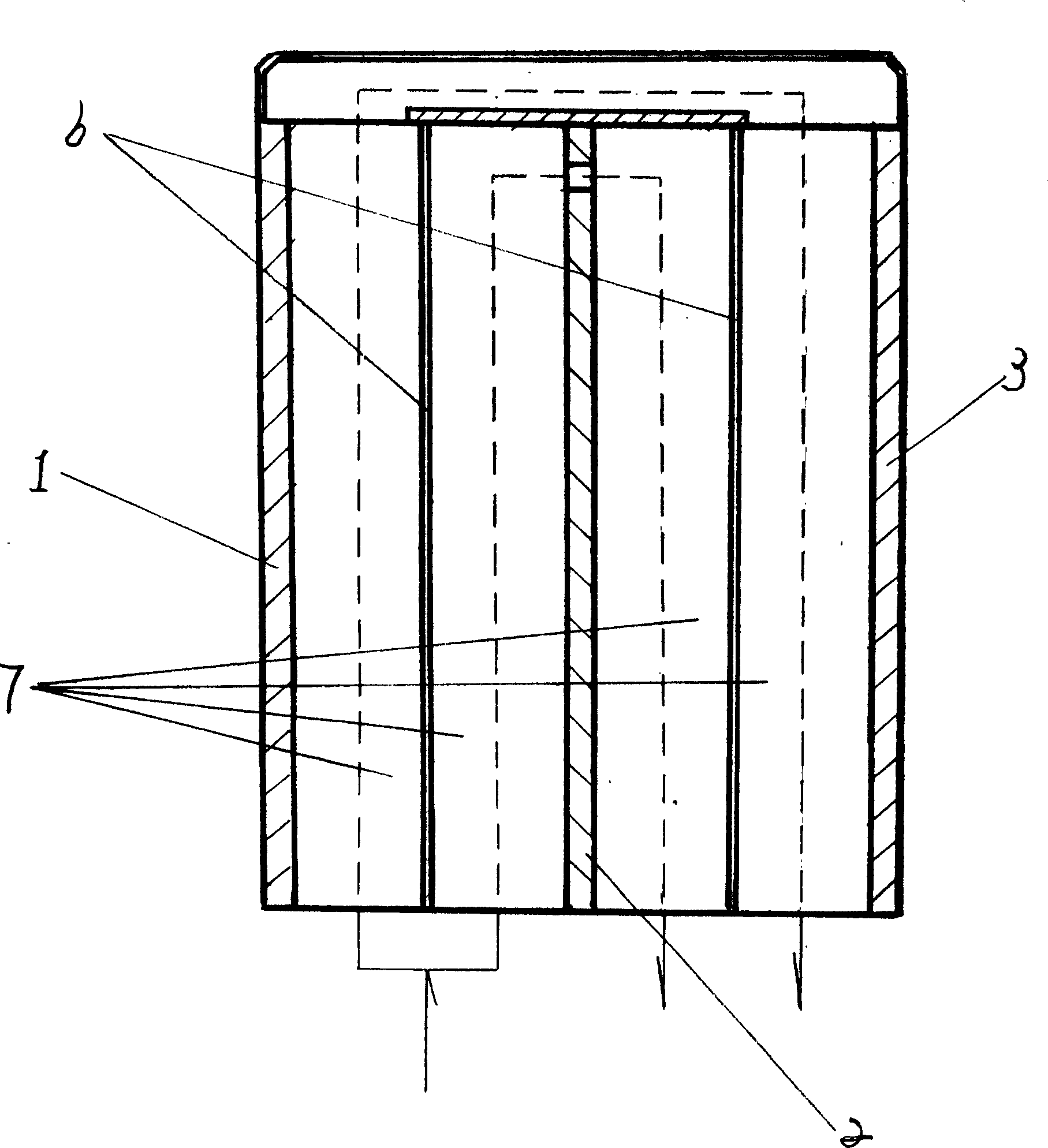

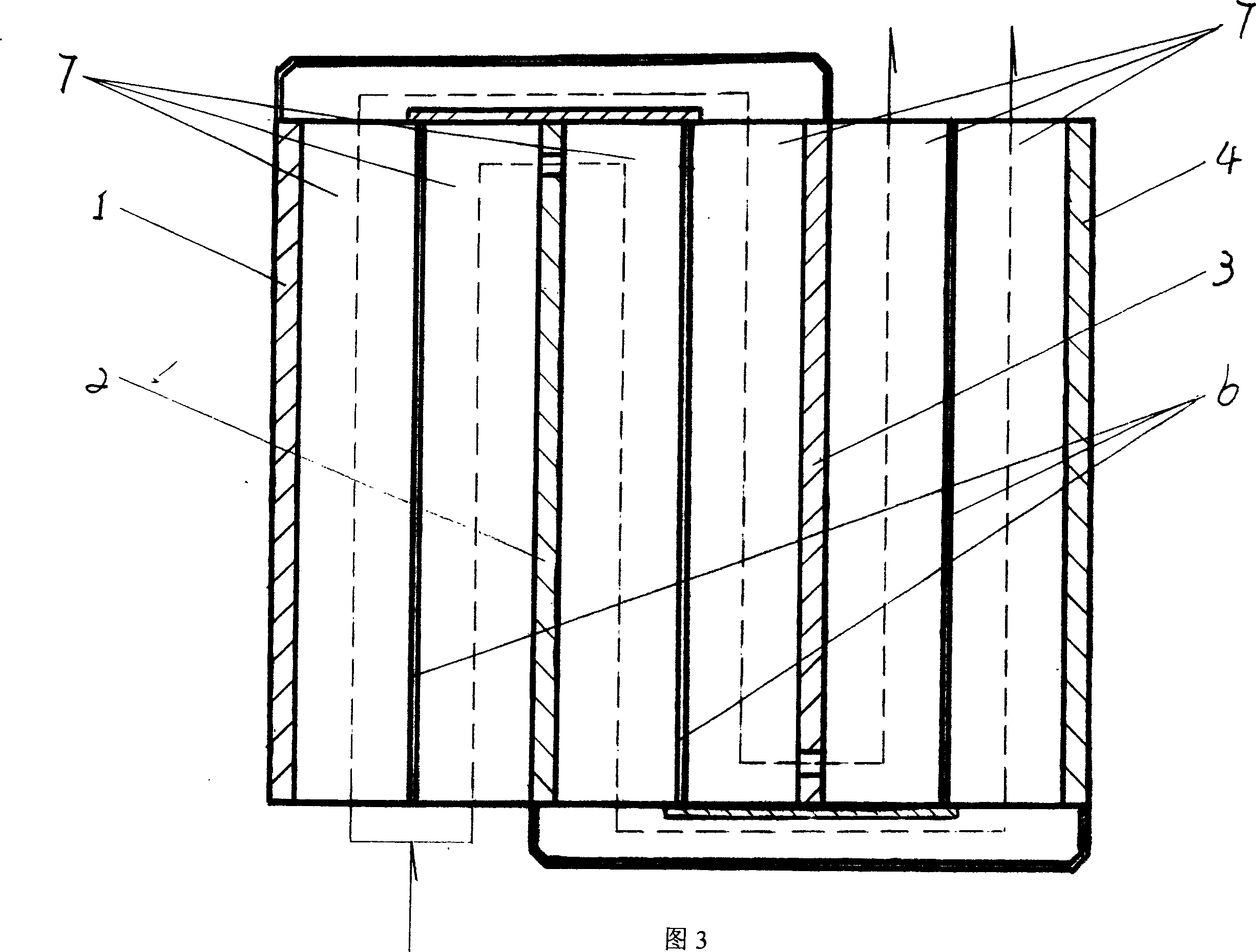

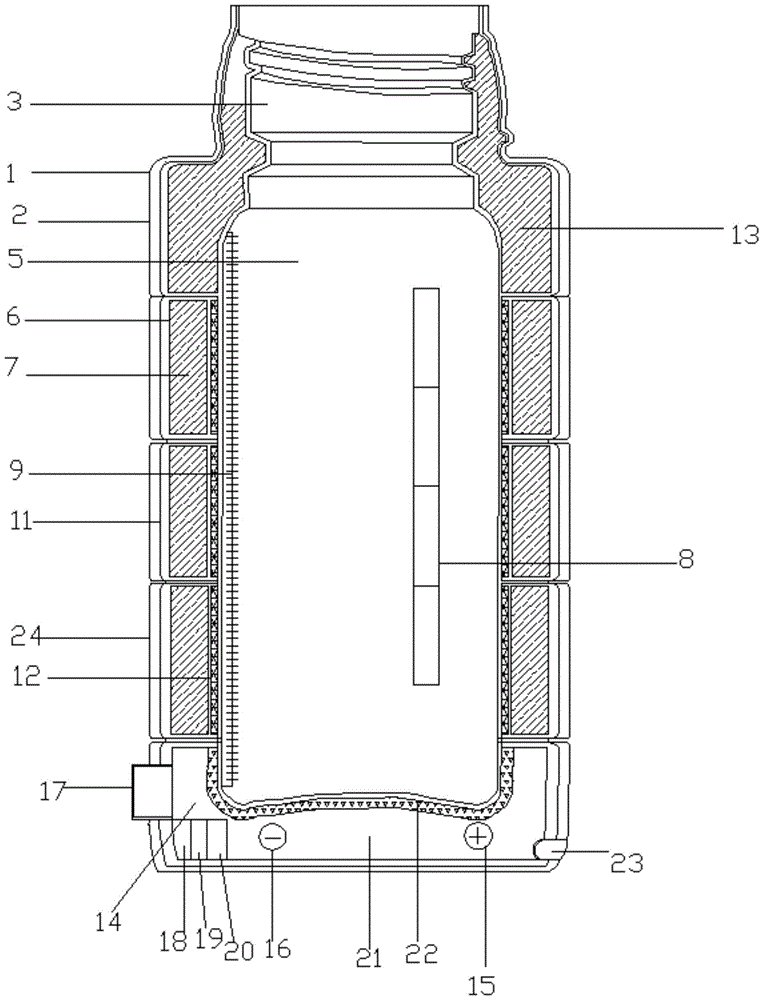

Ion water maker capable of leading magnetized water into series connection type double-layer or multi-layer electrolytic tank to be electrolyzed

InactiveCN1699190ANot easy to scaleElectrolysis process lengthenedElectrolysis componentsWater/sewage treatmentConnection typeAlkalinity

The invention discloses an ion water maker capable of leading magnetized water into series connection type double-layer or multi-layer electrolytic tank to be electrolyzed, wherein tap water is magnetized through intense magnetic field, than is conveyed into tandem double-layer or multiple-layer electrolytic tank for electrolyzation, by lengthening the electrolytic process, the electrolyzation can be more efficient. The pH of the highest alkalinity water can be 11.5, the pH of the lowest acidulous water can be 2.5.

Owner:李小鲁

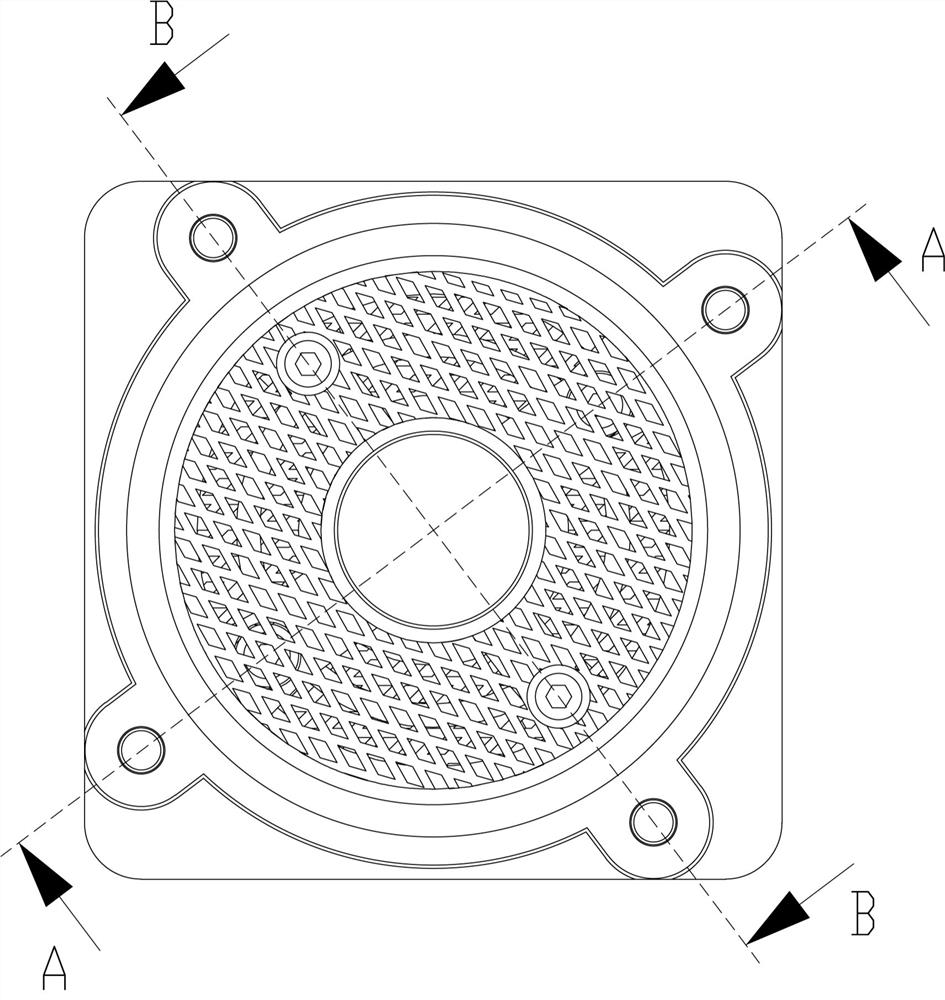

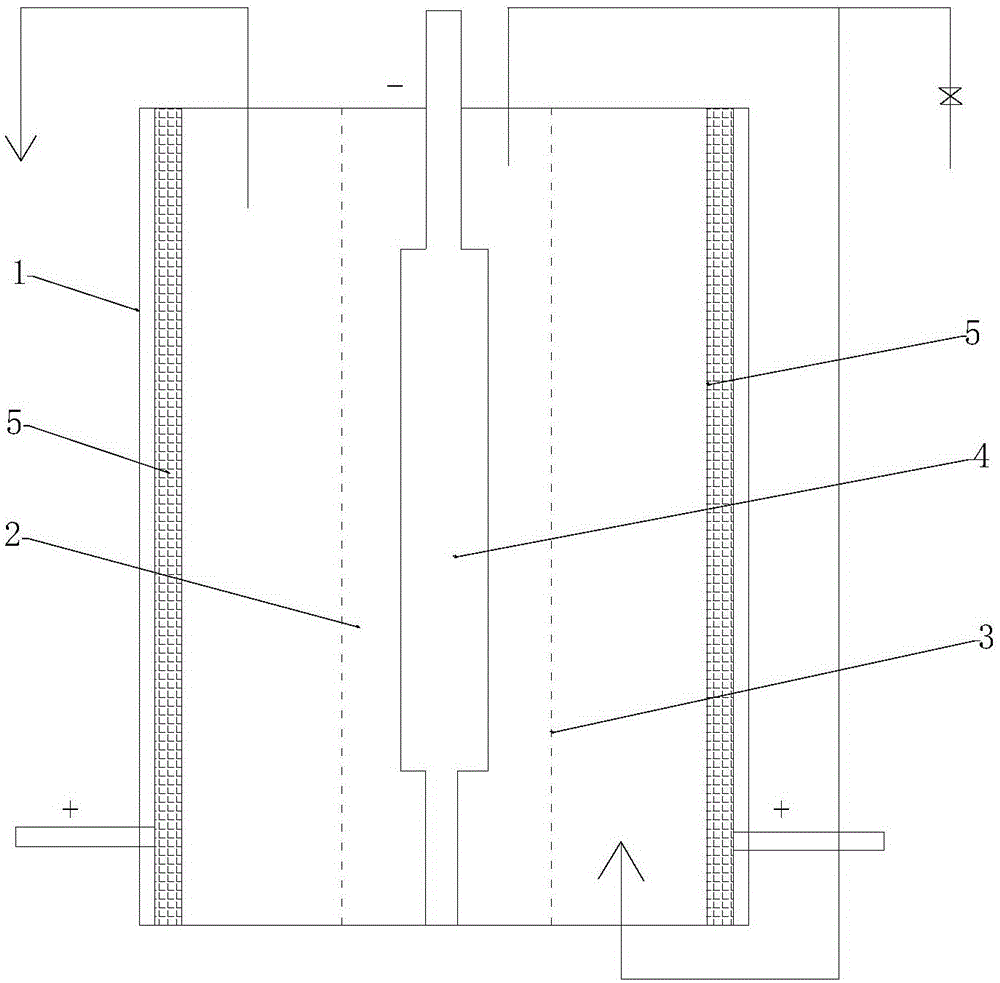

Plate electrode for plasma cleaning, electrode assembly and device

InactiveCN103934238AImprove conductivityStrong hardnessCleaning processes and apparatusElectrolysisProduct gas

The invention discloses a plate electrode for plasma cleaning. The plate electrode for plasma cleaning is made of aluminum or aluminum alloy and is of a grid structure, the plate electrode is hollow to enable an inner cavity to be formed inside the plate electrode, the inner cavity is provided with two openings, and the two openings are used for allowing liquid to be injected into the inner cavity and allowing the liquid to flow out of the inner cavity respectively. According to the plate electrode for plasma cleaning, due to the fact that the plate electrode is made of aluminum or aluminum alloy, the electrical conductivity is high, the hardness is high, and the mechanical property is good; due to the fact that the plate electrode is in the grid shape, gas can be electrolyzed more thoroughly, the whole cavity is filled with plasma generated after the gas is electrolyzed, and the cleaning effect is better; due to the fact that the plate electrode is hollow to enable the inner cavity to be formed inside the plate electrode and the inner cavity is provided with the two openings used for allowing the liquid to be injected into the inner cavity and allowing the liquid to flow out of the inner cavity respectively, clod water can be allowed to flow through the inner cavity in a circulating mode so as to cool the plate electrode, and the service life of the plate electrode is prolonged. The embodiment of the invention further provides a corresponding electrode assembly and a device.

Owner:SHENNAN CIRCUITS

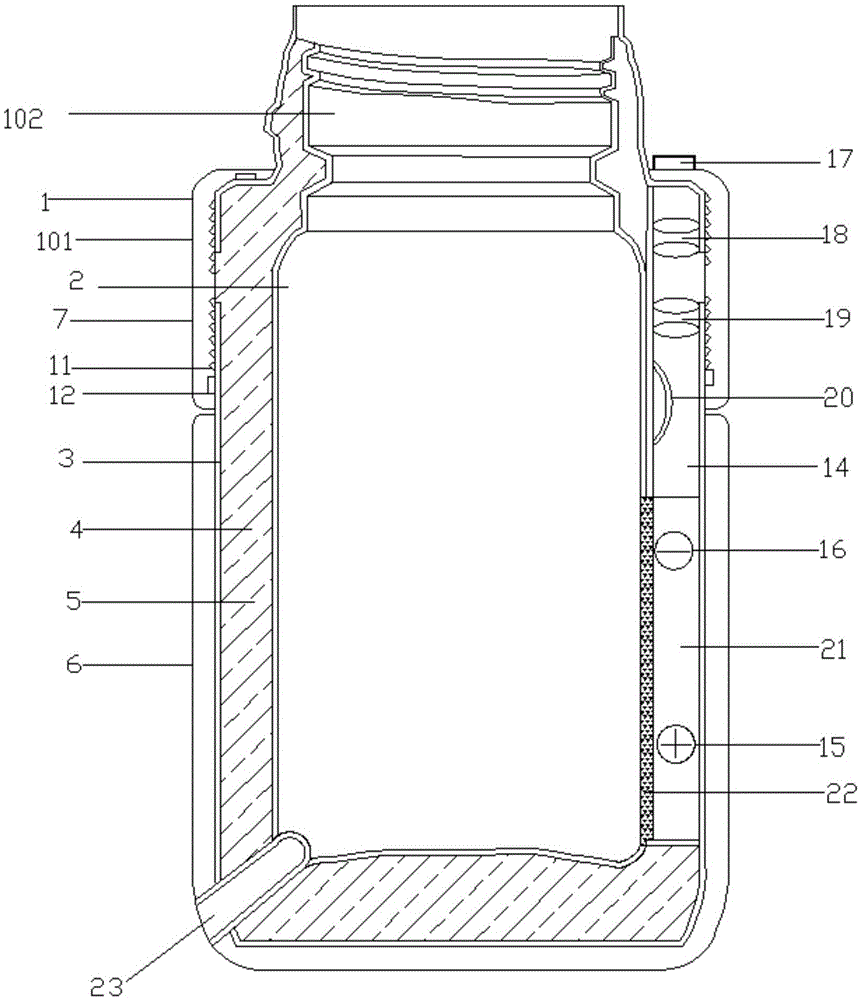

Water cup

The invention discloses a water cup, which comprises a water cup body, the water cup body includes a cup body and a cup mouth part, the cup body includes an inner bladder and an outer bladder, the outer bladder is provided with a collar, and the collar is provided with There is a sandwich cavity and a contact sheet, and a heat exchange substance is arranged in the space wrapped by the interlayer cavity and the contact sheet, and the heat exchange substance contains a solution or a liquid mixture, and negative ions are arranged at the bottom between the inner liner and the outer liner A generator, the negative ion generator can electrolyze water quality and separate positive ions or negative ions, so that the negative ions can be distributed in the drinking area. The invention has a simple structure, not only has the effect of rapidly cooling hot water, but also has the effect of slow cooling when the water temperature drops to a water temperature range suitable for the user to drink. The ring is used to regulate the water temperature of different temperatures. At the same time, the negative ion water is beneficial to the health of the human body.

Owner:SUZHOU ZZH INTPROP SERVICES

Electrolytic polishing method for aluminum alloy workpieces

The invention discloses an electrolytic polishing method for aluminum alloy workpieces. A polishing solution is prepared in an electrolytic tank and is prepared from, by mass, 55% of strong phosphoric acid with a concentration of 85%, 10% of strong phosphoric acid with a concentration of 98%, 15% of a YB-66 additive and 20% of water. During electrolytic polishing, the polishing solution is heated to reach 60 DEG C, the current density is 17-20A / dm2, and the time of electrolytic polishing lasts for 3-5 minutes. The polishing electrolytic solution used in the method can achieve a better polishing effect by being matched with the specific current density and a cathode and anode area proportion; additionally, high-frequency vibration is used in the polishing process, and accordingly, grooves of the workpieces can be fully subjected to electrolysis. The electrolytic polishing method can be used for the aluminum alloy workpieces with complicated structures and can meet a requirement for high surface smoothness.

Owner:HUZHOU QIANJIN BAOYUN MACHINERY CASTING

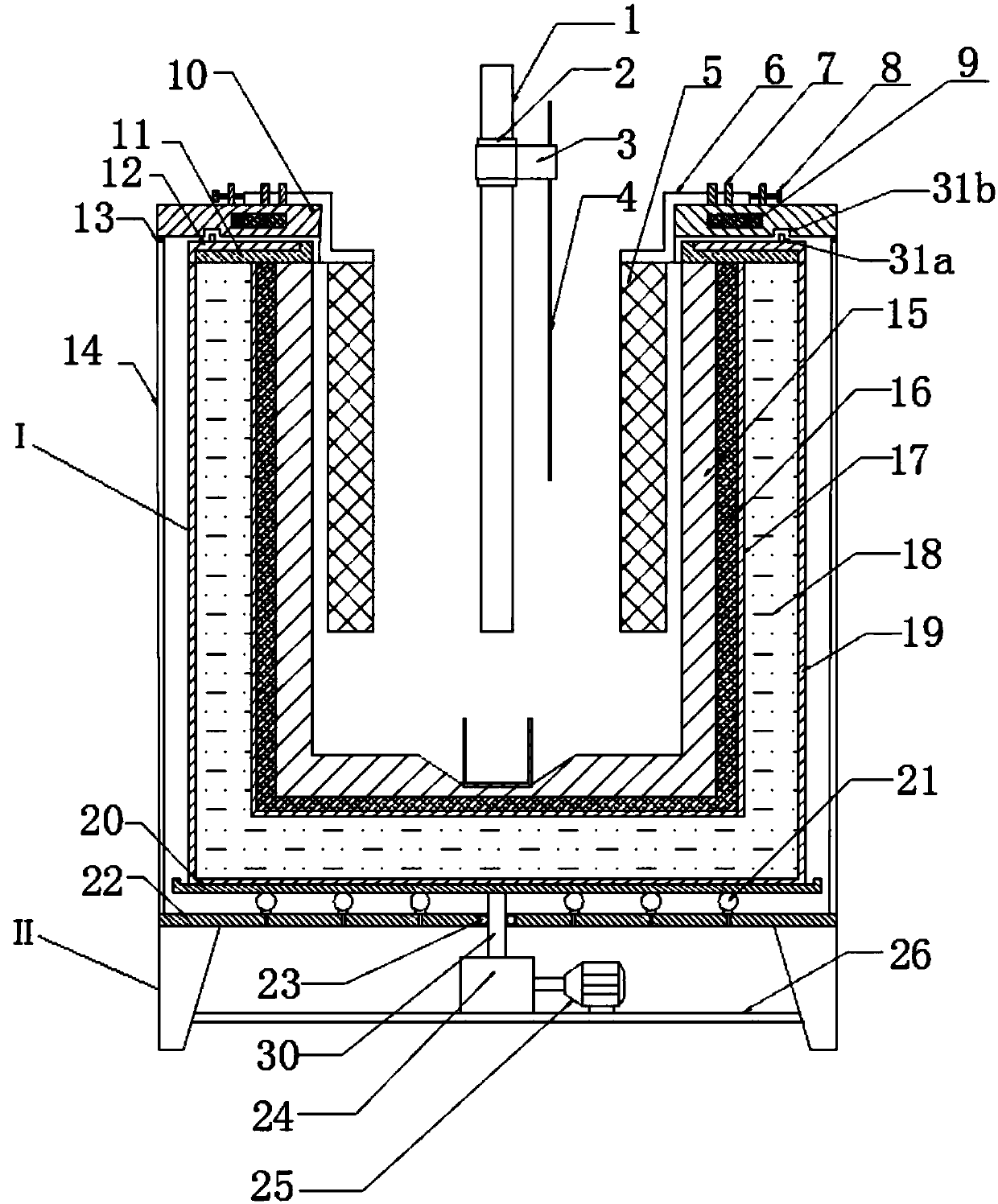

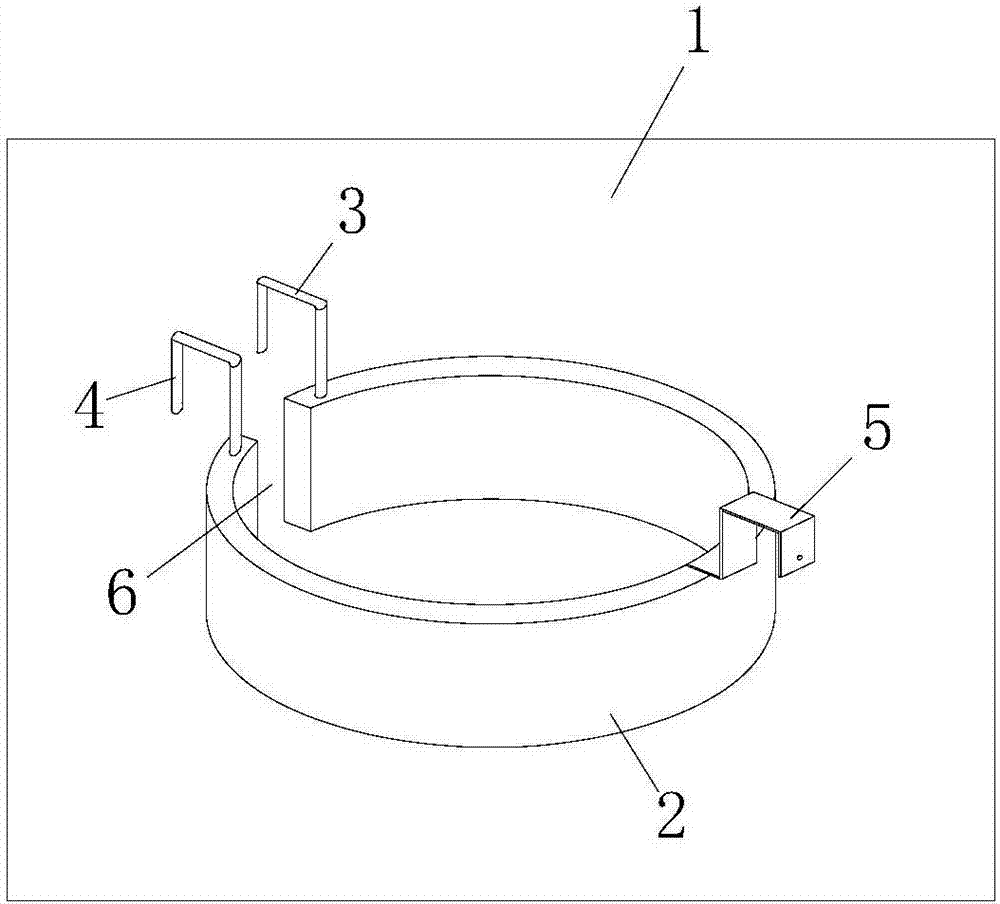

Cooling electrode for gallium electrolyzing

ActiveCN107059054AEffective control of electrolysis temperatureControl electrolysis temperaturePhotography auxillary processesProcess efficiency improvementElectrolysisEngineering

The invention discloses a cooling electrode for gallium electrolyzing. The cooling electrode comprises a cathode electrode plate, an annular anode plate, a circulation water inlet, a circulation water outlet and an electrode ring. A cut-off opening is formed in the annular anode plate, and the interior of the annular anode plate is airtight and hollow. The circulation water inlet and the circulation water outlet are formed in the positions, located at the two ends of the cut-off opening, of the annular anode plate and communicate with the interior of the annular anode plate. The circulation water inlet and the circulation water outlet communicate with a water leading device through pipelines. A flow adjusting valve is arranged on the pipeline between the water leading device and the circulation water inlet, and the electrode ring is connected with the annular anode plate and is arranged opposite to the cut-off opening. By means of the cooling electrode for gallium electrolyzing, the purity of metal gallium obtained through electrolyzing is 4 N, the electric energy utilization rate is high, the electrode plate service life is long, the production cost is low, and the production efficiency is high.

Owner:JIANGXI DEYI SEMICON TECH

Special disinfection device for animal breeding and plant cultivation

InactiveCN105645527APromote absorptionPromote growthWaste water treatment from animal husbandryWater/sewage treatment apparatusSaline waterEngineering

The invention discloses a special disinfection device for animal breeding and plant cultivation. The device comprises a water supply mechanism used for supplying water, a first control unit used for controlling the flow of the water, a saline water supply mechanism used for supplying saline water, a second control unit used for controlling the flow of the saline water, a mixing mechanism used for mixing the water and the saline water, a power supply unit and an electrolyzer. The water supply mechanism and the saline water supply mechanism are connected with the mixing mechanism which is connected with the electrolyzer. The electrolyzer is connected with the power supply unit which is used for supplying power to the electrolyzer. The first control unit is connected with the water supply mechanism. The second control unit is connected with the saline water supply mechanism. By mean of the special disinfection device, the structure is simple, and the sterilization effect is good.

Owner:FOSHAN HEALTHCARER TECH CO LTD

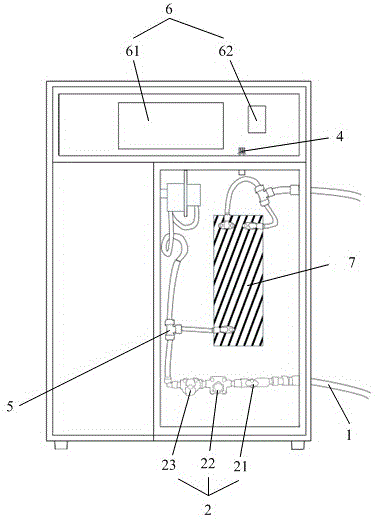

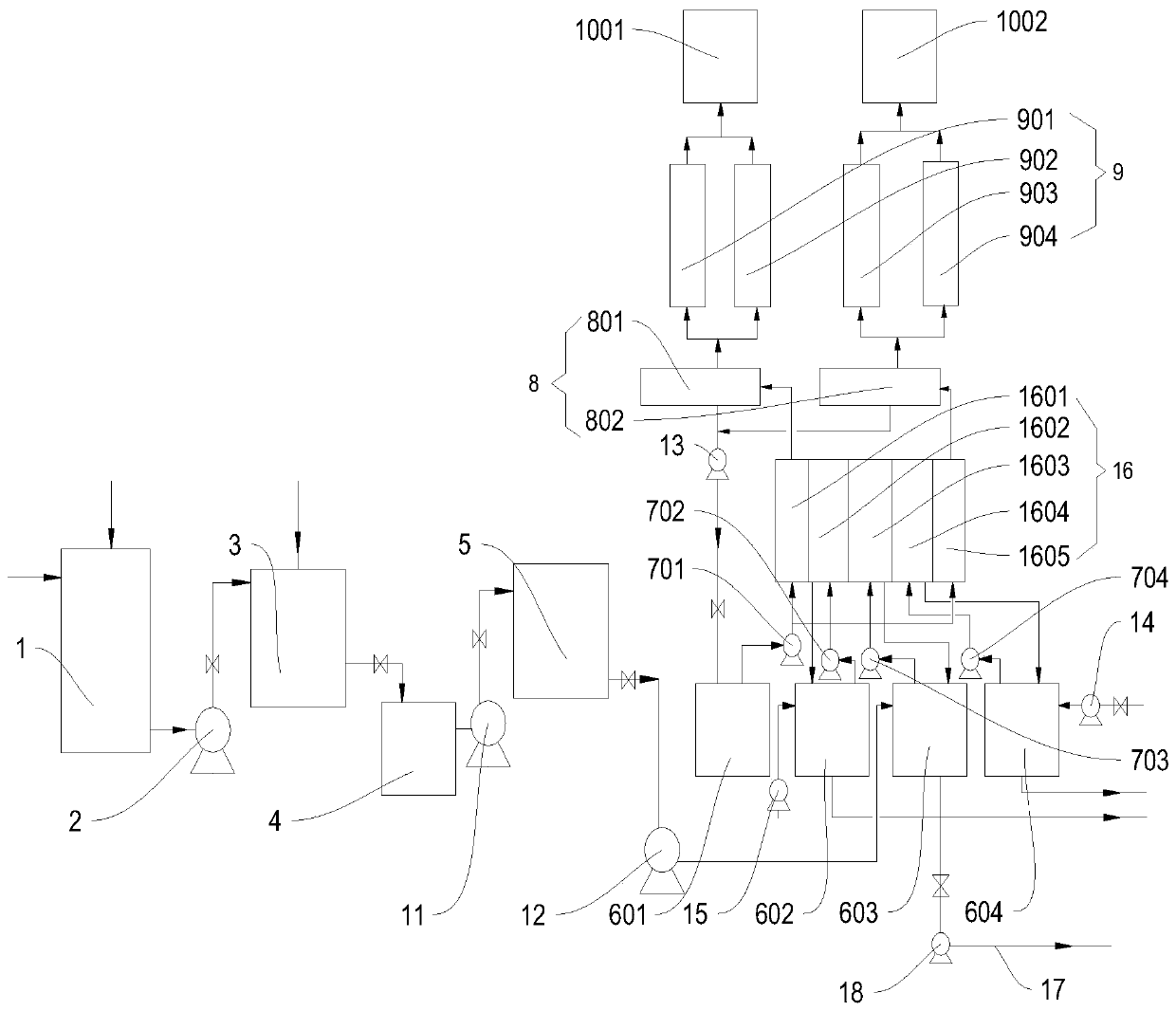

Sodium hypochlorite preparation system capable of intelligently adjusting current density

The invention discloses a sodium hypochlorite preparation system capable of intelligently adjusting current density. The invention mainly relates to the technical field of sodium hypochlorite preparation systems. The system comprises a water softening device, a molten salt tank, a plurality of electrolytic cells, a plurality of direct-current power supplies, a plurality of control modules and a plurality of monitoring unit groups, the control modules read temperature information measured by a temperature sensor, flow information measured by a flow sensor and saline water concentration measuredby a concentration meter in a polling mode through a serial port, and the control modules can control the direct-current power supplies to be switched to an optimal current density according to intelligent matching of system program information data. Parameters like salt water concentration, softened water flow and temperature in the electrolytic cells are measured and displayed in real time through the control modules, the magnitude of current required by the electrolytic reaction is judged by combining the data, and the corresponding current source is adjusted, so that the current is supplied as required, the utilization rate of the current is greatly improved, the voltage between the electrodes is reduced to the maximum extent, and the energy consumption is reduced by about 20%.

Owner:SHANDONG RIXIN ELECTRICAL EQUIP CO LTD

Electrochemical phosphorus removal device and phosphorus removal method

PendingCN111453895AInto the uniformSmall footprintWater contaminantsWaste water treatment from metallurgical processElectrolysisSludge

The invention discloses an electrochemical phosphorus removal device and a phosphorus removal method, and belongs to the technical field of environmental engineering sewage treatment. The electrochemical phosphorus removal device is sequentially provided with a reaction zone and an electrolysis zone, the reaction zone comprises two stages of coagulation reaction tanks which are separated through baffle plates, the electrolysis zone comprises a containing groove, a water distribution area, an electricity connection electrode plate and an induction electrode plate, and an overflow groove is formed in the upper part of the containing groove. The device disclosed by the invention has the advantages that the passivation of the electrode plates can be reduced, the sludge amount after sewage treatment is small, the occupied area of equipment is small, the electrode-water ratio is large, the treatment cost is low, the device can be combined with the existing phosphorus removal equipment for use, and the device is also suitable for pretreatment on high-concentration phosphorus-containing sewage.

Owner:浙江美纳环保科技有限公司

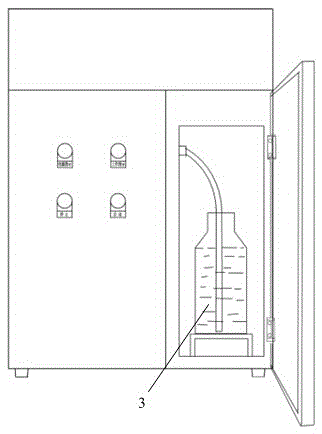

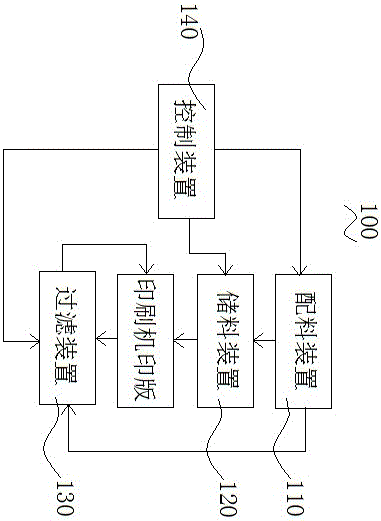

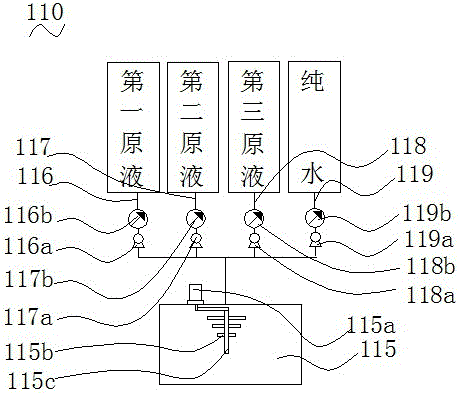

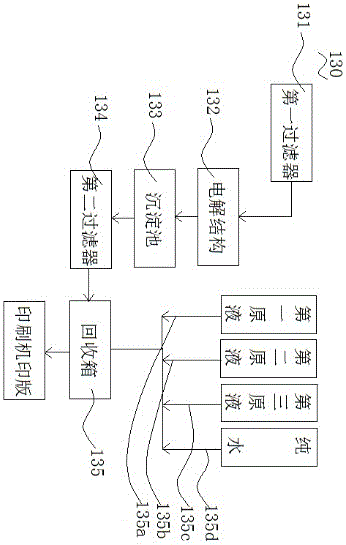

Full-automatic eco-friendly fountain solution batching system

PendingCN105690978AAchieve recyclingGuaranteed qualityRotary lithographic machinesProcess engineeringPrinting press

The invention relates to the field of printing equipment, particularly to a full-automatic eco-friendly fountain solution batching system. The full-automatic eco-friendly fountain solution batching system comprises a batching device used for preparing a fountain solution, a storage device used for storing the fountain solution, a filter device used for filtering the fountain device, and a control device used for setting parameters, wherein the control device is connected with the batching device, the storage device and the filter device for control; the batching device is connected with the storage device; an output end of the storage device is connected with a printing press printing plate; a fountain solution output end of the printing press printing plate is connected with an input end of the filter device; and an output end of the filter device is connected with a fountain solution input end of the printing press printing plate. According to the full-automatic eco-friendly fountain solution batching system, the fountain solution can be filtered and recycled, so that the production efficiency is improved, the production cost is reduced, and the environmental protection is facilitated; and besides, the batching accuracy of the fountain solution is high, and the printing effect is good.

Owner:DONGGUAN HUANAN PRINTING CO LTD

Electrochemical phosphorus removal device and phosphorus removal method

InactiveCN111018201AGuaranteed board spacingIncrease exposureMultistage water/sewage treatmentWater/sewage treatment by oxidationElectrolysisSludge

The invention discloses an electrochemical phosphorus removal device and a phosphorus removal method, and belongs to the technical field of environmental engineering sewage treatment. The electrochemical phosphorus removal device is sequentially provided with a reaction zone and an electrolysis zone, and the reaction zone comprises two stages of coagulation reaction tanks which are separated through a baffle plate; the electrolysis zone comprises an accommodating tank, a water distribution zone, a connecting electrode plate, and an induced electrode plate; and an overflow tank is arranged at the upper part of the accommodating tank. The device disclosed by the invention has the advantages that electrode plate passivation can be reduced, the sludge amount after sewage treatment is small, the equipmehnt occupied area is small, the electrode-water ratio is large, the treatment cost is low, the device can be combined with an existing phosphorus removal equipment for use, and the device isalso suitable for pretreatment of high-concentration phosphorus-containing sewage.

Owner:浙江美纳环保科技有限公司

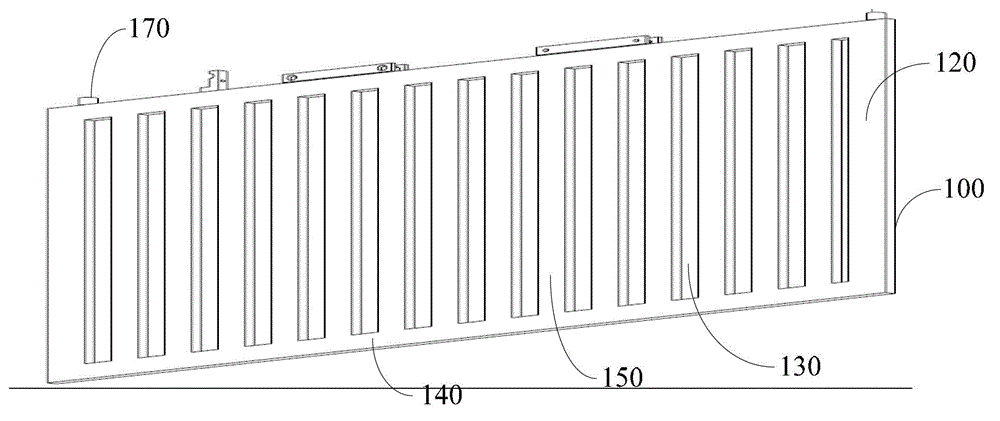

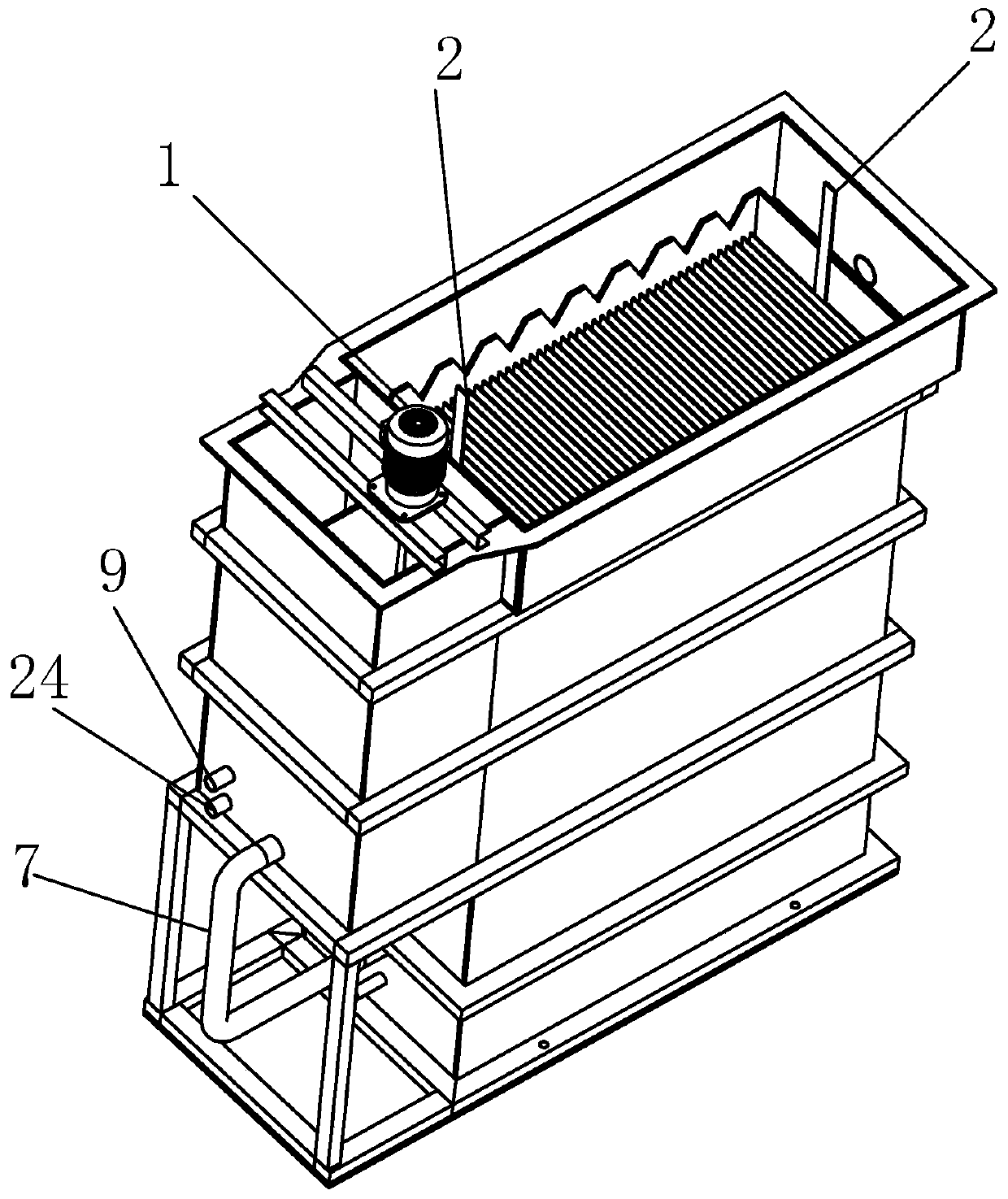

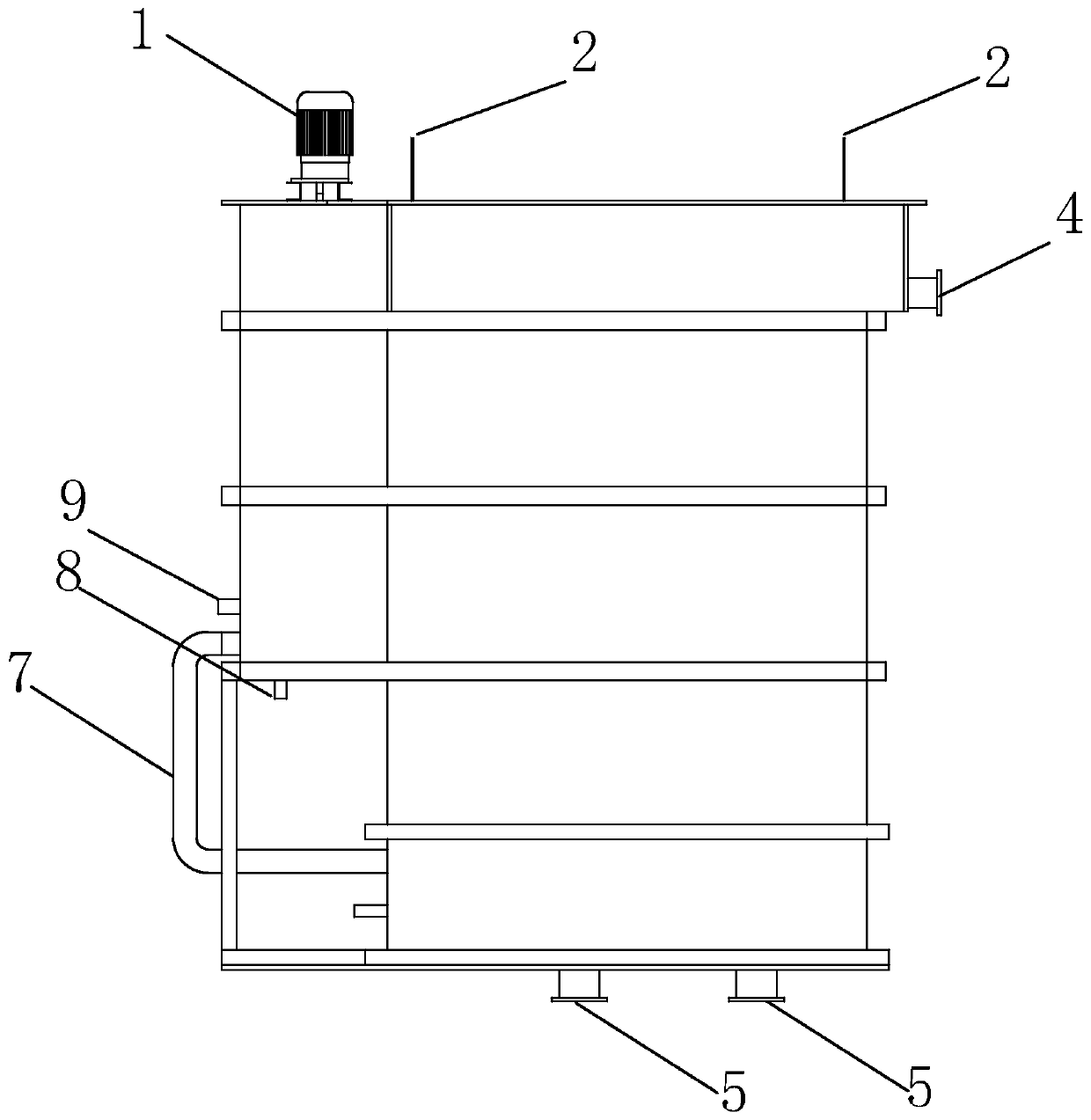

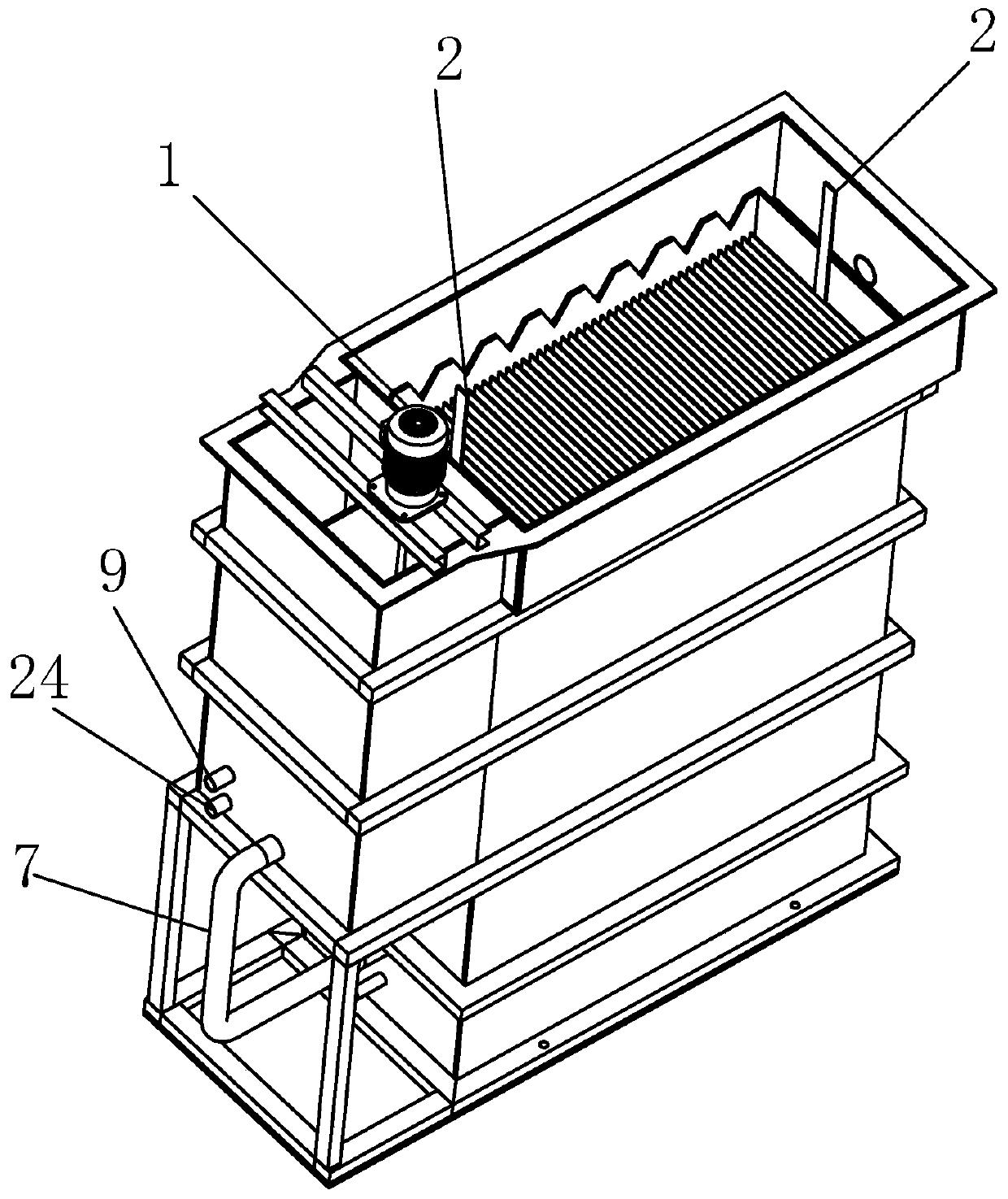

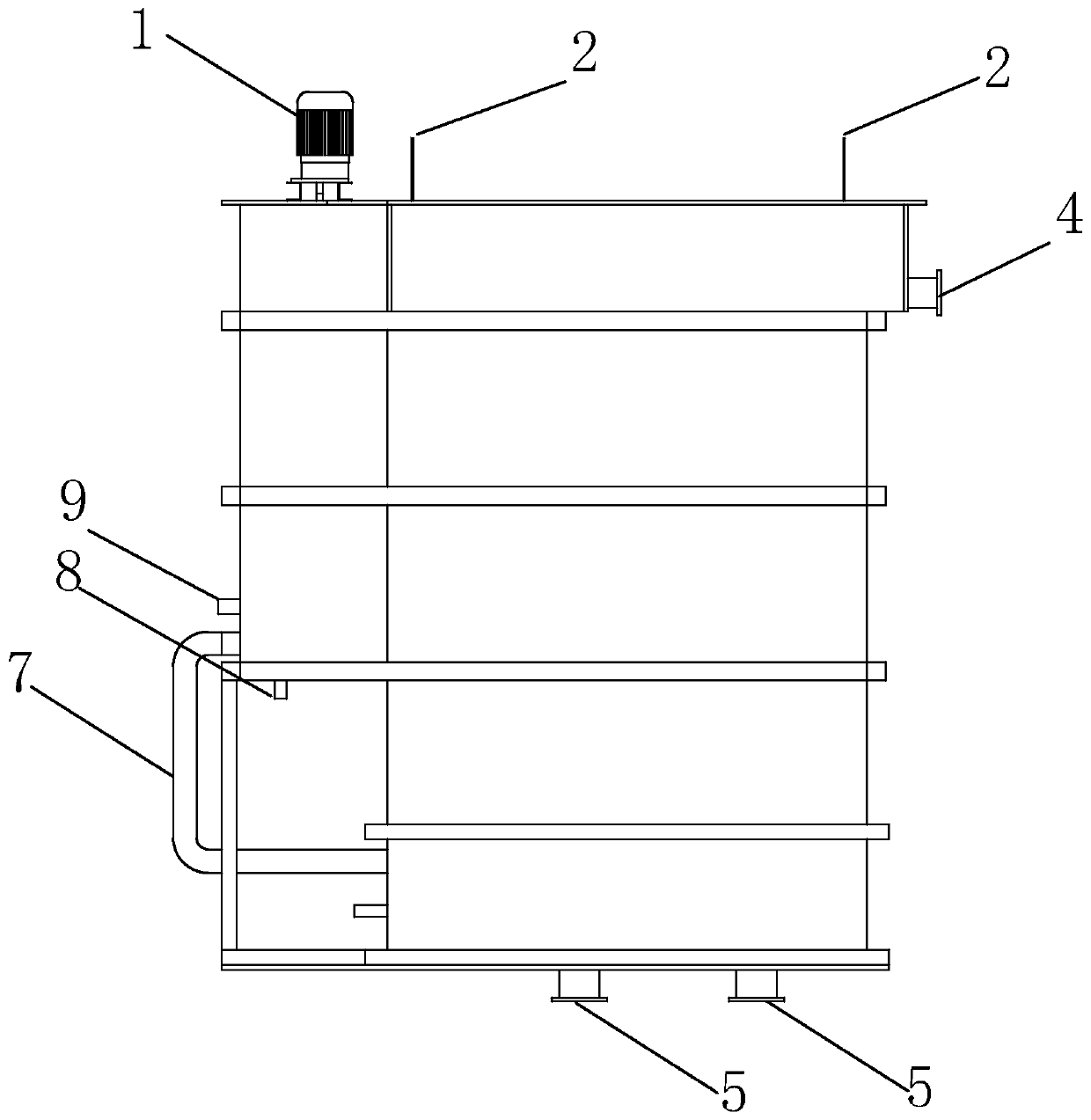

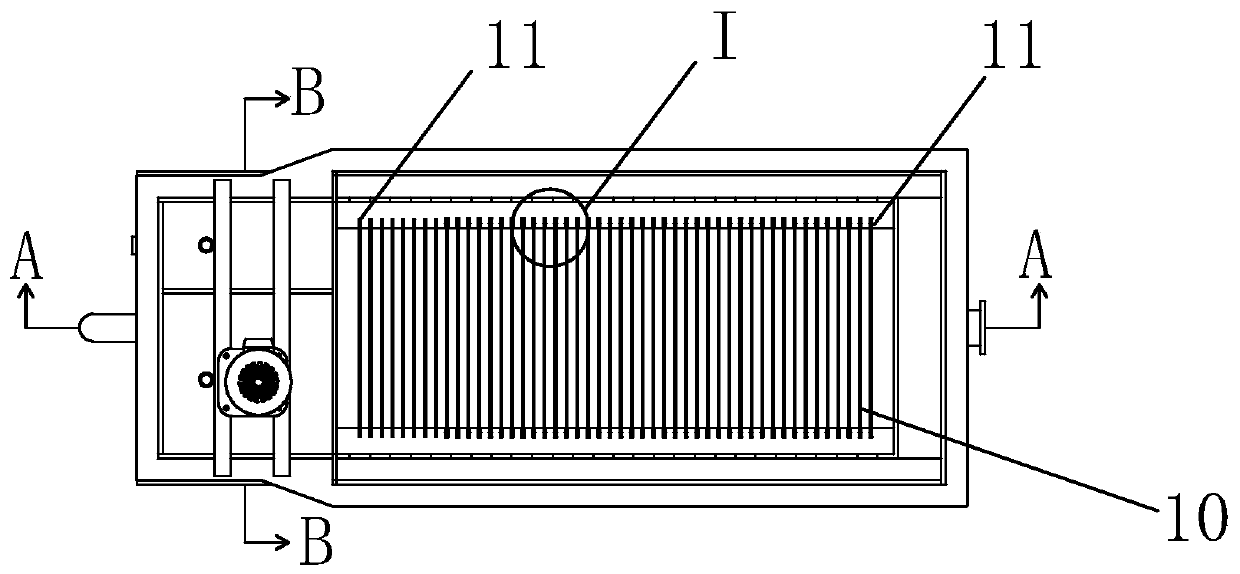

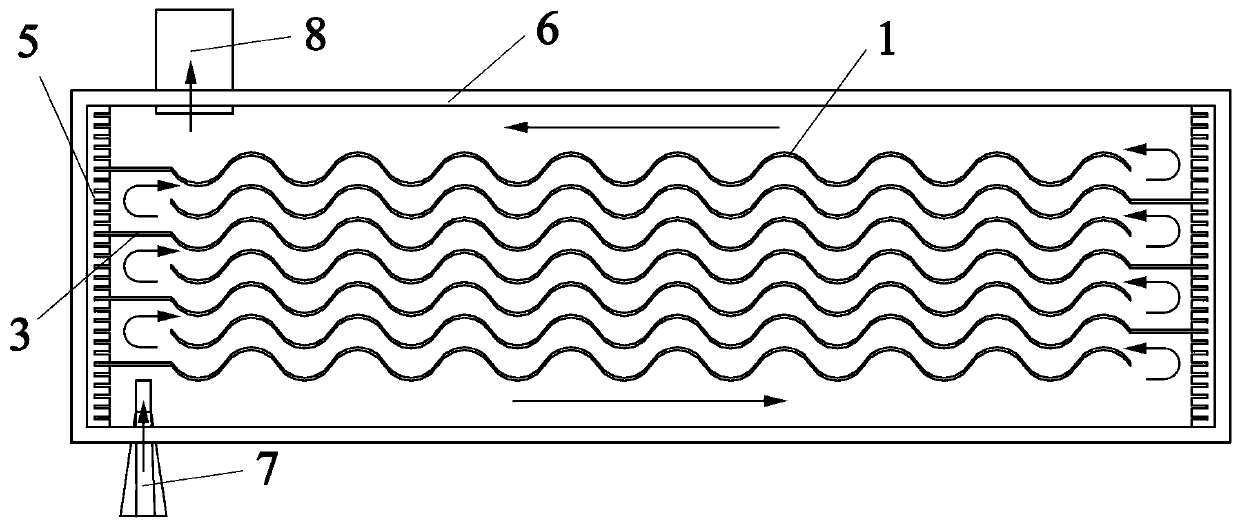

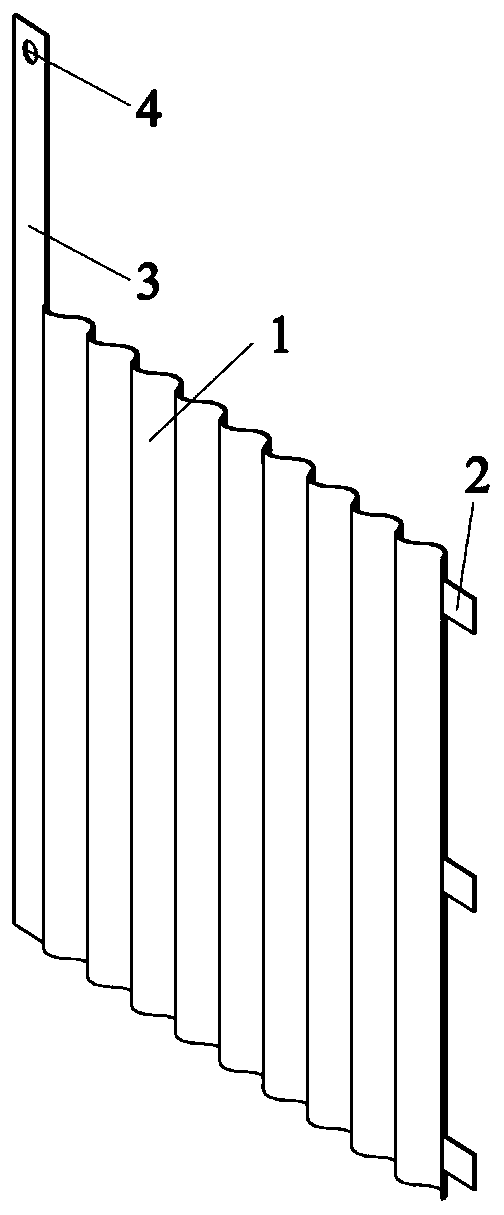

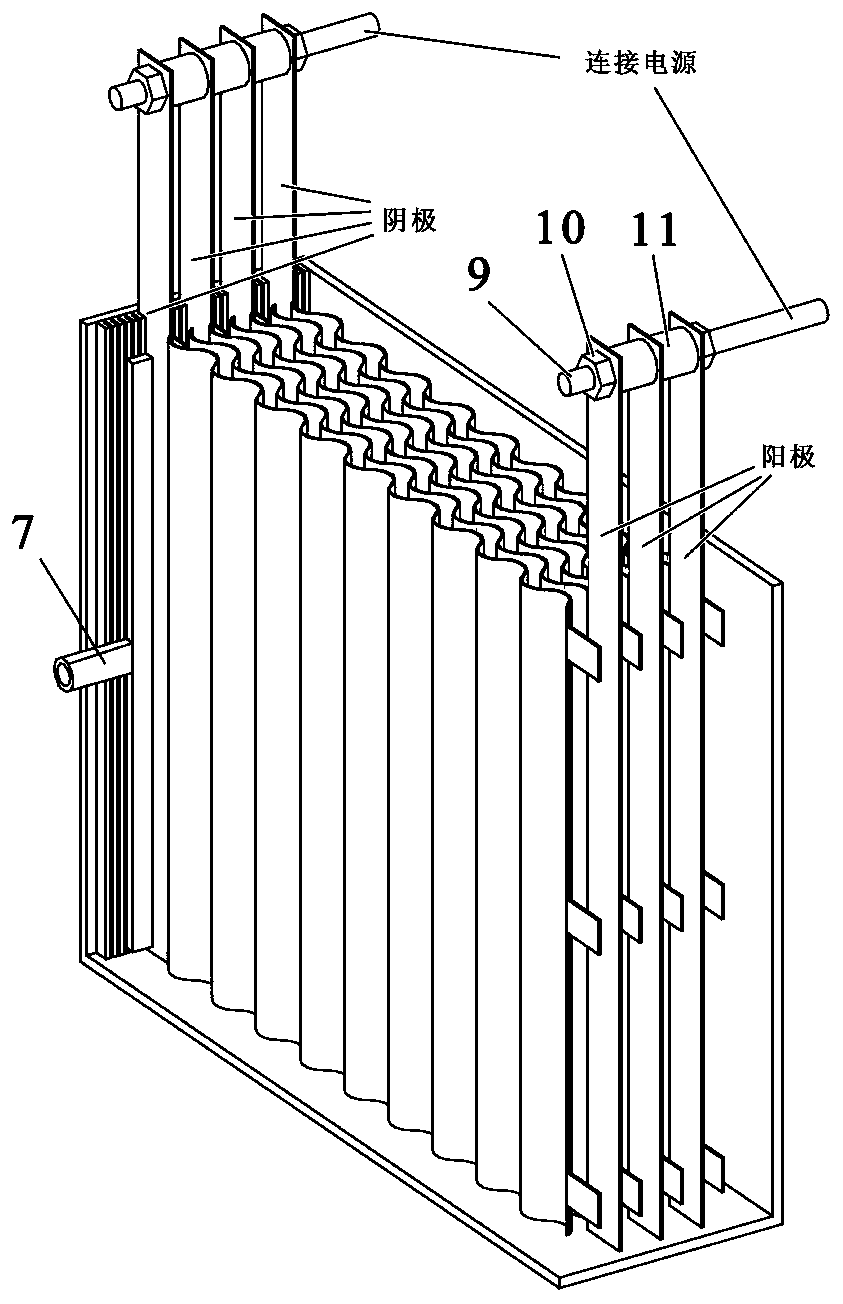

Efficient electrolyzing device for sewage treatment

PendingCN110054261AIncrease the areaImprove electrolysis efficiencyWater/sewage treatment apparatusElectricityWave shape

The invention discloses an efficient electrolyzing device for sewage treatment. The device comprises an electrode plate, an intercepting end plugboard, an overflowing end plugboard, a pole plate slot,an electrolytic cell, an inflow water uniform distributor, a water outlet, an electric conducting screw, an electric conducting nut, and an electric conducting support column. Side edges at two endsof the electrode plate are fixedly provided with the intercepting end plugboard and the overflowing end plugboard. The pole plate slot is fixed at two ends of an inner wall of the electrolytic cell. The electrode plate, the intercepting end plugboard and the overflowing end plugboard are inserted to the bottom of the electrolytic cell along the pole plate slot from top to bottom according to a mode of alternately arranging a negative electrode and a positive electrode. An upper end of the intercepting end plugboard is provided with a screw hole. The electrode plate is communicated with a powersupply through the screw hole, the electric conducting screw, the electric conducting nut and the electric conducting support column. The inflow water uniform distributor and the water outlet are installed on the electrolytic cell, and used for communicating with the interior and exterior of the electrolytic cell. The electrode plate adopts a wave shape or a break angle shape. The efficient electrolyzing device has the characteristics of adequate electrolysis, high treatment efficiency, convenient assembly and disassembly, and an adjustable electrode plate spacing distance.

Owner:桂润环境科技股份有限公司

Device and method for treating byproduct mirabilite of viscose factory

The invention belongs to the technical field of solid waste treatment processes, and particularly relates to a device and a method for treating byproduct mirabilite of a viscose factory. The device comprises a blending tank, a first delivery pump, a pH regulating tank, a settling pond, a second delivery pump, a filter, bipolar membrane electrodialysis equipment, a third delivery pump, an alkali chamber storage tank, a salt chamber storage tank, an acid chamber storage tank, a second reflux pump, a third reflux pump, a fourth reflux pump, a sixth delivery pump and a dirt discharge pipeline, wherein the settling pond is arranged below the pH regulating tank. The method for treating mirabilite comprises the following steps: mixing mirabilite and soft water in a dissolving pool, removing impurities from the mixed solution through the impurity removal operation of the pH regulating tank, the settling pond and the filter, electrolyzing by using the bipolar membrane electrodialysis equipment,and completing the treatment of the sodium sulfate of the filtrate in the salt chamber when the electric conductivity of the filtrate in the salt chamber of the bipolar membrane electrodialysis equipment is less than or equal to 20 mS / cm, so that the emission standard is reached.

Owner:阿拉尔市中泰纺织科技有限公司 +1

Temperature-controllable cup

The invention discloses a temperature-controllable cup. The cup comprises a cup body, wherein the cup body comprises an inner container and an outer container, the space formed between the inner container and the outer container is an interlayer, a heat exchange substance is arranged in the interlayer and comprises a solution or liquid mixture, a lantern ring is arranged on the outer wall of the outer container and connected with the outer container and a casing, the cup body and the casing can be dismounted and separated or connected into a whole, and an anion generator is arranged in the interlayer and can electrolyze common water into anionic water. The cup is simple in structure, plays a role in quickly cooling hot water and has a slow cooling role when the water temperature is decreased to be suitable for drinking by users, meanwhile, the casing and the outer container can be dismounted and separated, the water temperature can be increased or decreased quickly and conveniently, the users can use water at the suitable and ideal temperature, and clean water beneficial to health is provided for the users.

Owner:SUZHOU ZZH INTPROP SERVICES

Electric flocculation oil-water separator

PendingCN110734173AFull electrolysisImprove processing efficiencyFatty/oily/floating substances removal devicesTreatment involving filtrationElectrolysisElectro flocculation

The invention relates to the field of water treatment, in particular to an electric flocculation oil-water separator. The electric flocculation oil-water separator comprises a box body; the box body is divided into a filter chamber, an electrolysis chamber, a water purification chamber and a settling chamber by partition plates; a separator water inlet is formed in the upper part of the filter chamber; the bottom of the electrolysis chamber is communicated with the bottom of the filter chamber; a plurality of double-layer partition plates are arranged in the filter chamber and divide the filter chamber into a plurality of electrolysis chamber units, and a pair of electrodes is arranged between every pair of electrolysis chamber units; a flow channel is formed between the two partition plates of each double-layer partition plate, and the adjacent electrolysis chamber units are communicated through a corresponding flow channel; the flow channels are vertically distributed, a flow channelwater inlet is formed in the upper end of each flow channel, and a flow channel water outlet is formed in the lower end of the flow channel; the bottoms of the water purification chamber and the electrolysis chamber are communicated; the bottoms of the settling chamber and the water purification chamber are communicated, and a settling chamber water outlet is formed in the upper part of the settling chamber. An S-shaped circulation path is formed in the electrolysis chamber, so that swill can be fully electrolyzed, and the water treatment efficiency is improved.

Owner:北京丰舜通环保科技有限公司

Disinfectant and preparation method thereof

InactiveCN106577740AImprove the bactericidal effectFull electrolysisBiocideElectrolysis componentsHypochloriteDisinfectant

The invention relates to a disinfectant and a preparation method thereof. The disinfectant per liter contains 410 mg-430 mg of hypochlorite, 35 mg-45 mg of hypochlorous acid, 12 mg-15 mg of chlorate, 3,700 mg-3,900 mg of chloride, 0-10 mg of perchlorate, 0.034-0.036 mg of hydroxide and the balance of water. The disinfectant is good in disinfection and sterilization effect, and particularly can be used for disinfecting containers.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

A kind of permeable concrete gel agent and preparation method thereof

The invention provides a pervious concrete gelling agent and a preparation method thereof, and relates to the field of constructional materials. The gelling agent is prepared from the following components in percentage by weight: 3.5%-5.5% of ammonium sulfate, 2%-4% of sodium sulfate, 0.5%-2% of magnesium chloride, 0.5%-2% of potassium sulfate, 0.15%-0.4% of sodium silicate, 1%-3% of poly-ferric sulfate, 20%-30% of calcium sulfate, 0.15%-0.4% of sodium gluconate, 0.1%-0.4% of a water retention agent and 52.3%-70% of water. The gelling agent is capable of improving the pervious water retention property of concrete in the premise of ensuring the physical indexes of roads, and improving the compression strength, wear resistance and the like of cement. The gelling agent contains a large amount of metal ions, thus being helpful to sufficiently electrolyze effective ions in the cement, accelerate hydration reaction of the cement, form a network-shaped crystal structure and enhance the intensity of pervious concrete. The preparation method of the gelling agent is simple, short in period, low in cost and suitable for industrialized production.

Owner:XIAMEN UNIV OF TECH +1

A device for producing sodium hypochlorite by electrolysis of seawater with light energy

The invention relates to a device for preparing sodium hypochlorite by electrolyzing seawater with light energy, and belongs to the technical fields of sodium hypochlorite preparation device and light energy utilization. The electrolytic cell is a closed container, the cathode and the anode are respectively fixedly arranged in the electrolytic cell, the cathode is located at the upper part of the electrolytic cell, the anode is located at the lower part of the electrolytic cell, and the diaphragm is arranged laterally between the cathode and the anode. The invention designs a device for preparing sodium hypochlorite by electrolyzing seawater by photovoltaic power generation to realize energy saving and emission reduction and electrolyzing seawater to produce sodium hypochlorite; relying on solar panel power generation to provide the power consumed by the electrolytic cell, making full use of natural energy, clean and pollution-free, and protecting the surrounding area Environment; the hydrogen obtained from electrolysis provides the energy required for seawater evaporation and concentration for fuel combustion, making full use of resources and ingenious design; the concentration of ions contained in seawater after evaporation and concentration increases the conductivity to achieve the purpose of fully electrolyzing sodium chloride, improving Electrolysis efficiency.

Owner:山东和创智云环保装备有限公司

Hydrogen chloride preparation process and system

ActiveCN111519203AFull electrolysisChange electrode positionCellsHydrogen chloride preparationElectrolysisHydrogen chloride

The invention relates to the field of hydrogen chloride preparation, in particular to a hydrogen chloride preparation process and a system. The method for preparing hydrogen chloride by the hydrogen chloride preparation system comprises the following steps: S1, adding sodium chloride and water into a reaction box, respectively electrifying two metal columns as a positive electrode and a negative electrode, and electrolyzing the sodium chloride and an aqueous solution to generate sodium hydroxide, hydrogen and chlorine; S2, rotating the two gear rings to correspondingly drive the two rotary drums and the two L-shaped plastic columns to rotate, and then changing the positions of the electrodes in the electrolysis process; S3, when the reaction box is filled with hydrogen and chlorine, extruding the hydrogen and the chlorine out of the gas outlet pipe, igniting the extruded hydrogen and chlorine by an igniter, and then generating hydrogen chloride gas; and S4, ejecting the blocking ball upwards by the hydrogen chloride gas in the sleeve , then opening the gas outlet hole, after the hydrogen chloride gas reaches the upper portion of the fixed cylinder, sleeving the upper end of the fixed cylinder with a collecting bag, and collecting the hydrogen chloride gas.

Owner:SHANDONG RIKE PLASTIC RUBBER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com