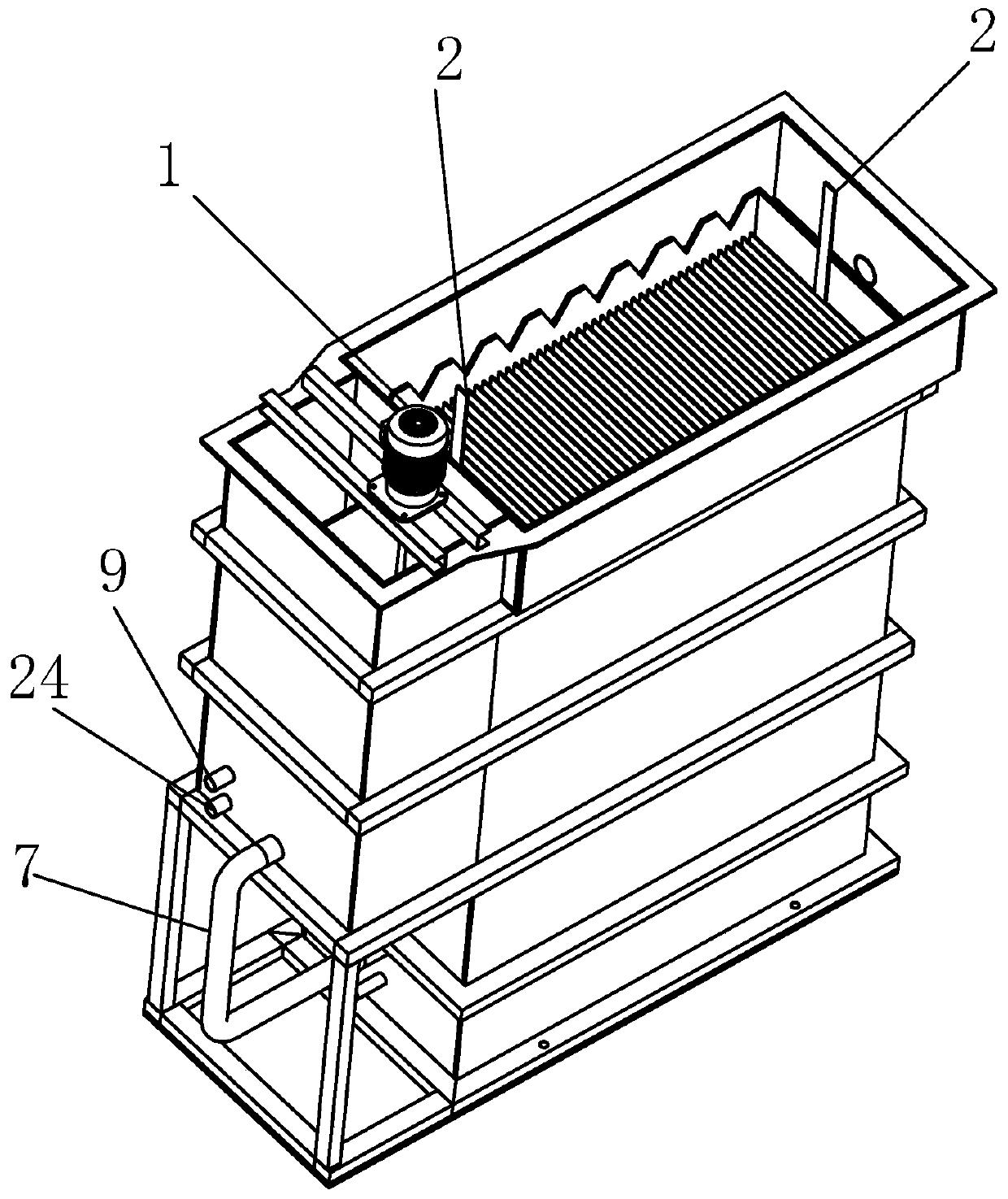

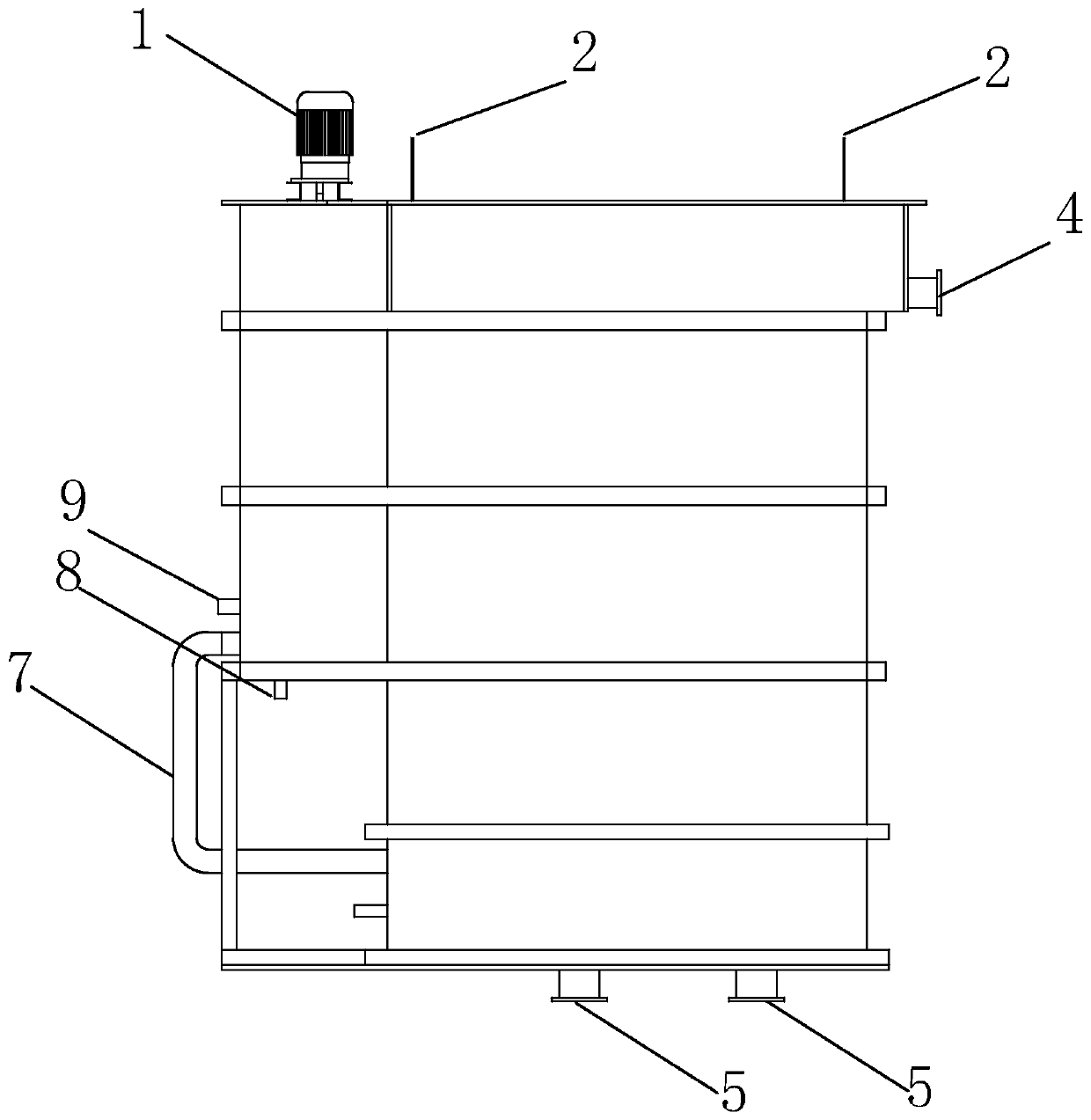

Electrochemical phosphorus removal device and phosphorus removal method

An electrochemical and electrode plate technology, applied in the field of devices for phosphorus removal using electrochemical technology, can solve the problems of substandard treatment of high-concentration phosphorus-containing sewage, large equipment footprint, and high treatment costs, avoiding electrolytic short-flow, The effect of reducing floor space and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

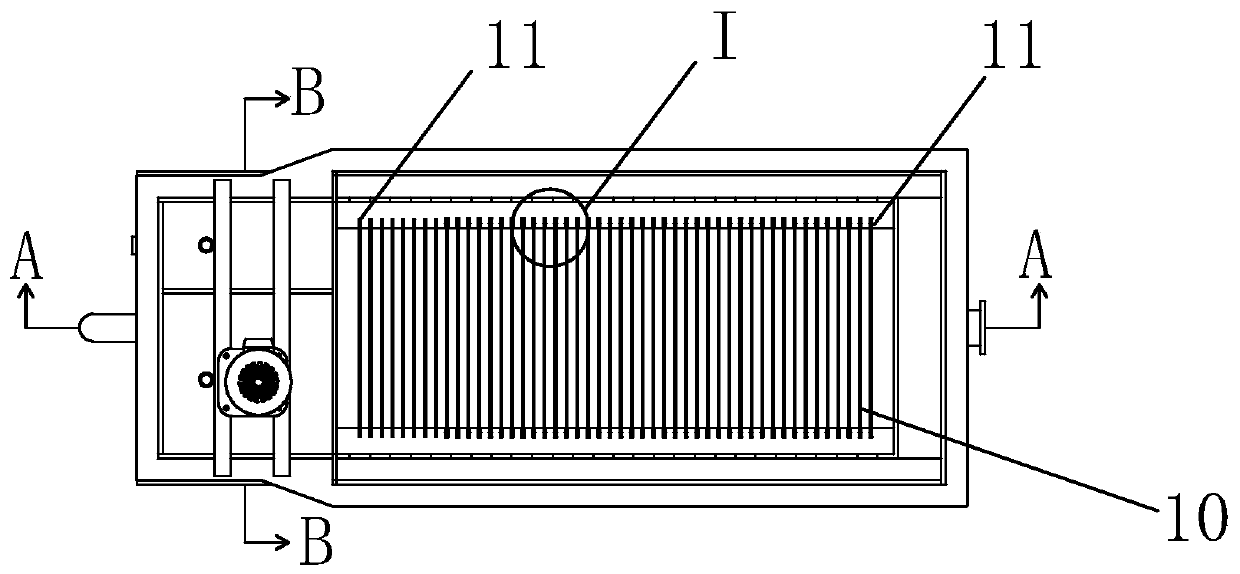

[0071] Controlled process parameters: the distance between the electrode plates is 2cm, the working voltage between the plates is 2v, the sewage electrolysis time is 30min, and the electrode water ratio is 28m 2 : 1m 3 , the current density is 50A / m 2 , its power supply is a high-frequency pulsed DC power supply, the pulse frequency is 5000Hz, and the duty ratio is 10%. 20L / (L min), the pH value of the sewage is adjusted to 8 in the secondary coagulation reaction tank.

[0072] Phosphate surface treatment wastewater containing 256mg / L of inorganic phosphorus (calculated as P) enters the primary coagulation reaction tank 20 for aeration and mixing through the water inlet 9, and the phosphorus-containing sewage after aeration and mixing enters the secondary coagulation reaction Tank 21, start the dosing system at the same time, adjust the sewage pH value to 8, stir and mix; the stirred and mixed phosphorus-containing sewage flows into the perforated pipe 17 through the connect...

Embodiment 2

[0074] Controlled process parameters: the distance between the electrode plates is 1.5cm, the working voltage between the plates is 1v, the electrolysis time is 10min, and the electrode water ratio is 28m 2 : 1m 3 , the power supply is a high-frequency pulsed DC power supply with a current density of 100A / m 2 , the pulse frequency is 20000Hz, the duty cycle is 100%, the aeration volume of the second aeration port 24 is 10L / (L min), the aeration volume of the aeration port one 23 is 40L / (L min), the second Adjust the pH value of sewage to 8 in the coagulation reaction tank.

[0075] Phosphate surface treatment wastewater containing 256mg / L of inorganic phosphorus (calculated as P) enters the primary coagulation reaction tank 20 for aeration and mixing through the water inlet 9, and the phosphorus-containing sewage after aeration and mixing enters the secondary coagulation reaction Tank 21, start the dosing system at the same time, adjust the sewage pH value to 8, stir and mix...

Embodiment 3

[0077] Controlled process parameters: the distance between the electrode plates is 4cm, the working voltage between the plates is 3v, the electrolysis time is 20min, and the electrode water ratio is 28m 2 : 1m 3 , the power supply is a high-frequency pulsed DC power supply with a current density of 100A / m 2 , the pulse frequency is 10000Hz, the duty ratio is 50%, the aeration rate of the second aeration port 24 is 15L / (L min), the aeration rate of the aeration port one 23 is 30L / (L min), the second Adjust the pH value of sewage to 9 in the coagulation reaction tank.

[0078] Phosphate surface treatment wastewater containing 256mg / L of inorganic phosphorus (calculated as P) enters the primary coagulation reaction tank 20 for aeration and mixing through the water inlet 9, and the phosphorus-containing sewage after aeration and mixing enters the secondary coagulation reaction Tank 21, start the dosing system at the same time, adjust the pH value of the sewage to 9, stir and mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com