Device and method for treating byproduct mirabilite of viscose factory

A technology of by-products and viscose factories, which is applied in the field of equipment for processing the by-product of viscose factory Glauber's salt, which can solve the problem that Yuanming powder cannot be processed, and achieve the effect of maintaining conductivity and avoiding interference

Inactive Publication Date: 2020-03-24

阿拉尔市中泰纺织科技有限公司 +1

View PDF26 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Affected by the decrease in market demand, a large amount of sodium sulfate was piled up in the viscose fiber factory and could not be processed, which brought great pressure on environmental protection and sales

[0004] Therefore lack a kind of device and method thereof that can effectively process a large amount of byproduct Glauber's salt of viscose factory

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0065]The difference from Example 1 is that in the specific treatment process of Glauber's salt, Glauber's salt and soft water are added into the dissolution tank 1 at a mass ratio of 1:5 to obtain a mixed solution.

Embodiment 3

[0067] In the specific treatment process of Glauber's salt, in step A, add Glauber's salt and soft water into the dissolution tank 1 according to the mass ratio of 1:7.8 to obtain a mixed solution.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

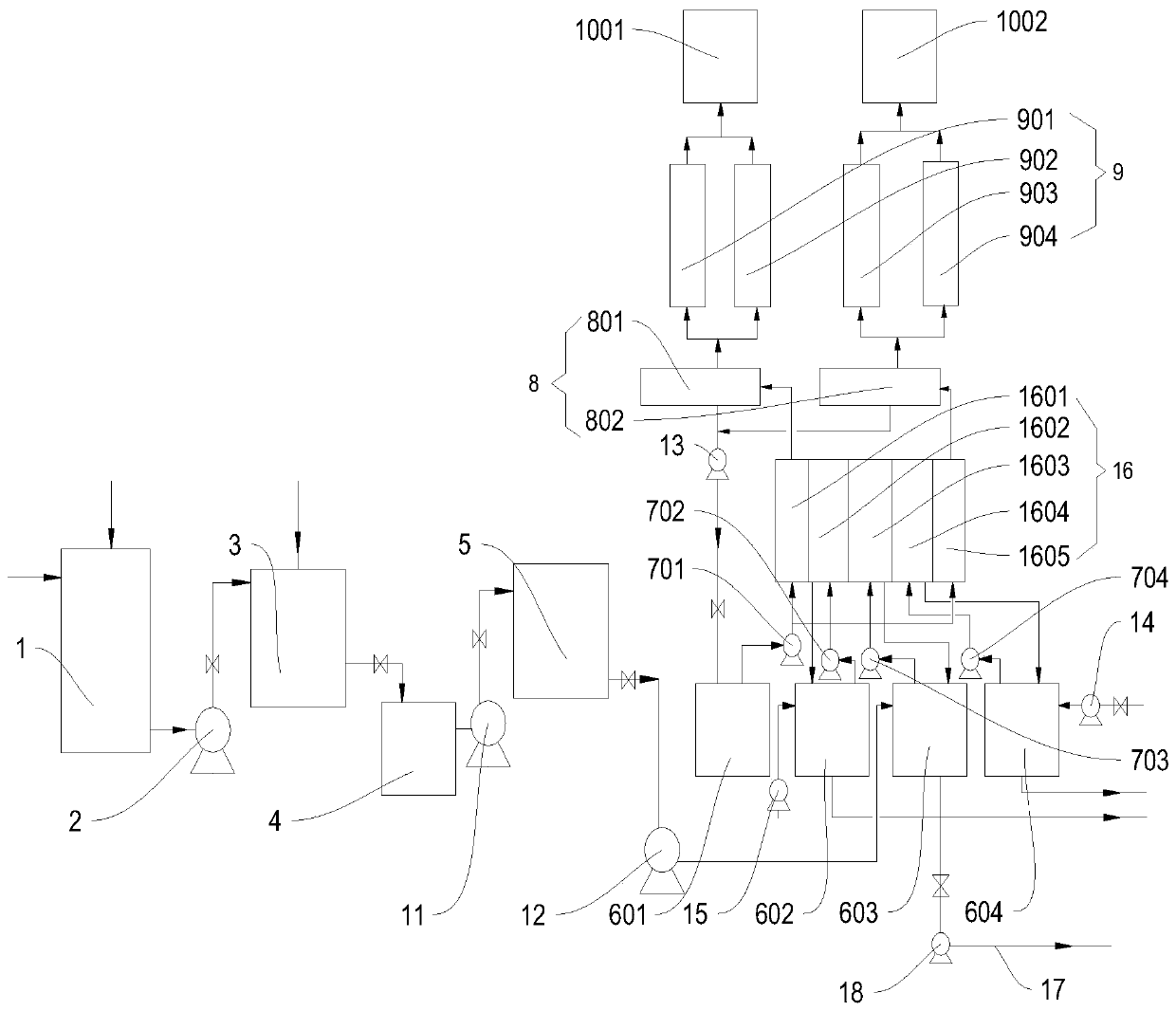

The invention belongs to the technical field of solid waste treatment processes, and particularly relates to a device and a method for treating byproduct mirabilite of a viscose factory. The device comprises a blending tank, a first delivery pump, a pH regulating tank, a settling pond, a second delivery pump, a filter, bipolar membrane electrodialysis equipment, a third delivery pump, an alkali chamber storage tank, a salt chamber storage tank, an acid chamber storage tank, a second reflux pump, a third reflux pump, a fourth reflux pump, a sixth delivery pump and a dirt discharge pipeline, wherein the settling pond is arranged below the pH regulating tank. The method for treating mirabilite comprises the following steps: mixing mirabilite and soft water in a dissolving pool, removing impurities from the mixed solution through the impurity removal operation of the pH regulating tank, the settling pond and the filter, electrolyzing by using the bipolar membrane electrodialysis equipment,and completing the treatment of the sodium sulfate of the filtrate in the salt chamber when the electric conductivity of the filtrate in the salt chamber of the bipolar membrane electrodialysis equipment is less than or equal to 20 mS / cm, so that the emission standard is reached.

Description

technical field [0001] The invention belongs to the technical field of solid waste treatment technology, and in particular relates to a device and method for treating mirabilite, a by-product of a viscose factory. Background technique [0002] Glauber's salt is a sulfate mineral Glauber's salt family Glauber's salt, mainly containing hydrous sodium sulfate (Na 2 SO 4 10H 2 O). In the production of viscose fiber, a large amount of thenardite will be produced incidentally. The specific production process is that the viscose solution is ejected from the spinneret and contacts the coagulation bath, so that the viscose solution reacts chemically with the sulfuric acid in the coagulation bath to produce sodium sulfate. As the production progresses, the sulfuric acid content in the coagulation bath decreases and the sodium sulfate content increases. Therefore, the coagulation bath needs to separate out the excess sodium sulfate in the form of cold crystallization, and then ret...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C25B1/16C25B1/22C25B9/06C25B9/17

CPCC25B1/16C25B1/22C25B9/19

Inventor 陈捷王彦波谭瀚茗靳琰张珂静何凡吴宏辉王静吴鹏亮罗书磊郑贤江李长福周恩年游延贺陶思远马盼飞张辉

Owner 阿拉尔市中泰纺织科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com