Self-rotation type electrolysis production device for producing rare earth metals element and alloy thereof

A technology for rare earth metals and production equipment, applied in the field of electrolysis, can solve the problems of insufficient circulating flow of molten salt electrolyte, uneven distribution of rare earth oxides, and shortening the service life of the tank, so as to improve the utilization rate of raw materials, avoid the formation of slag, improve the The effect of operating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

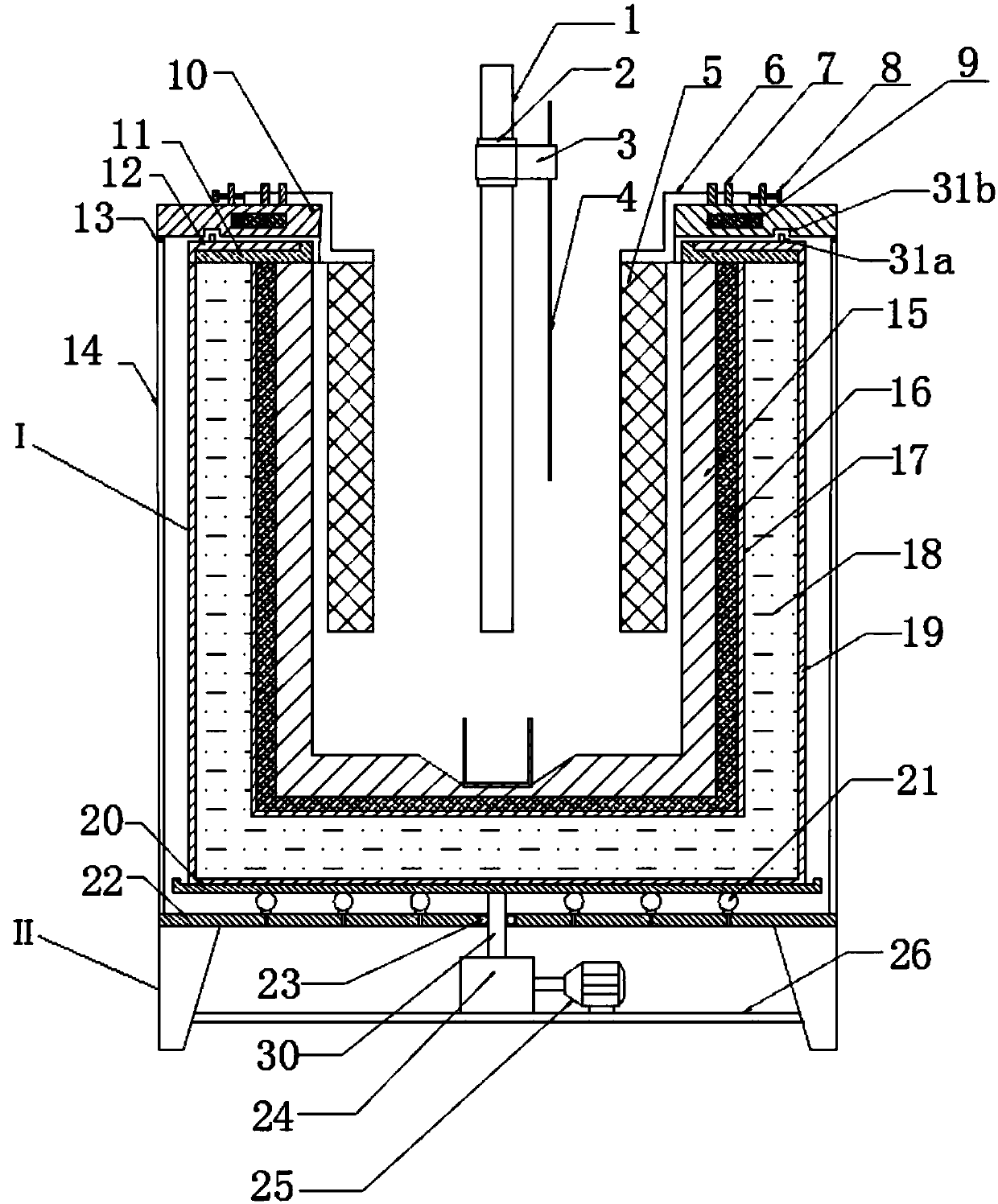

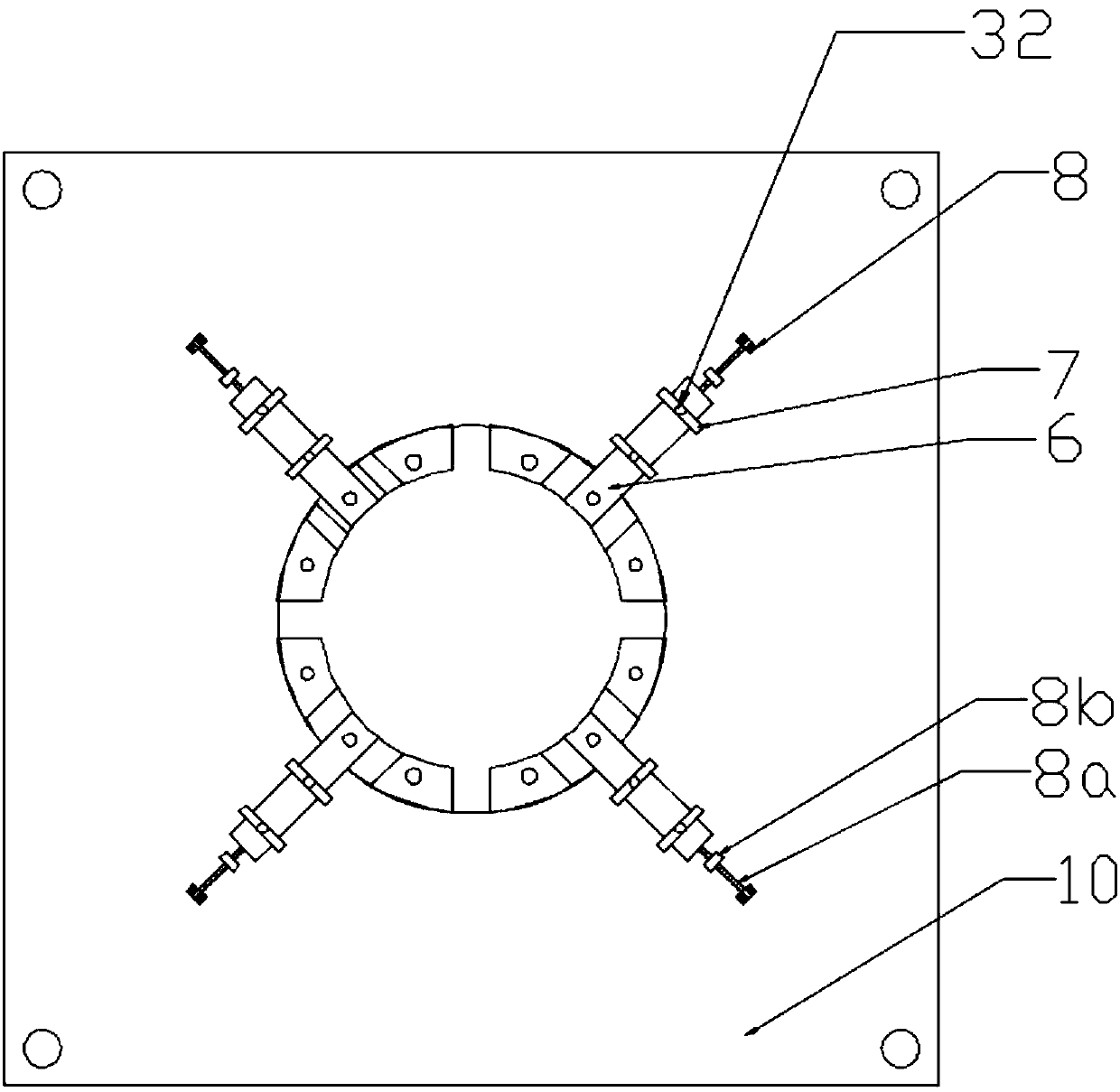

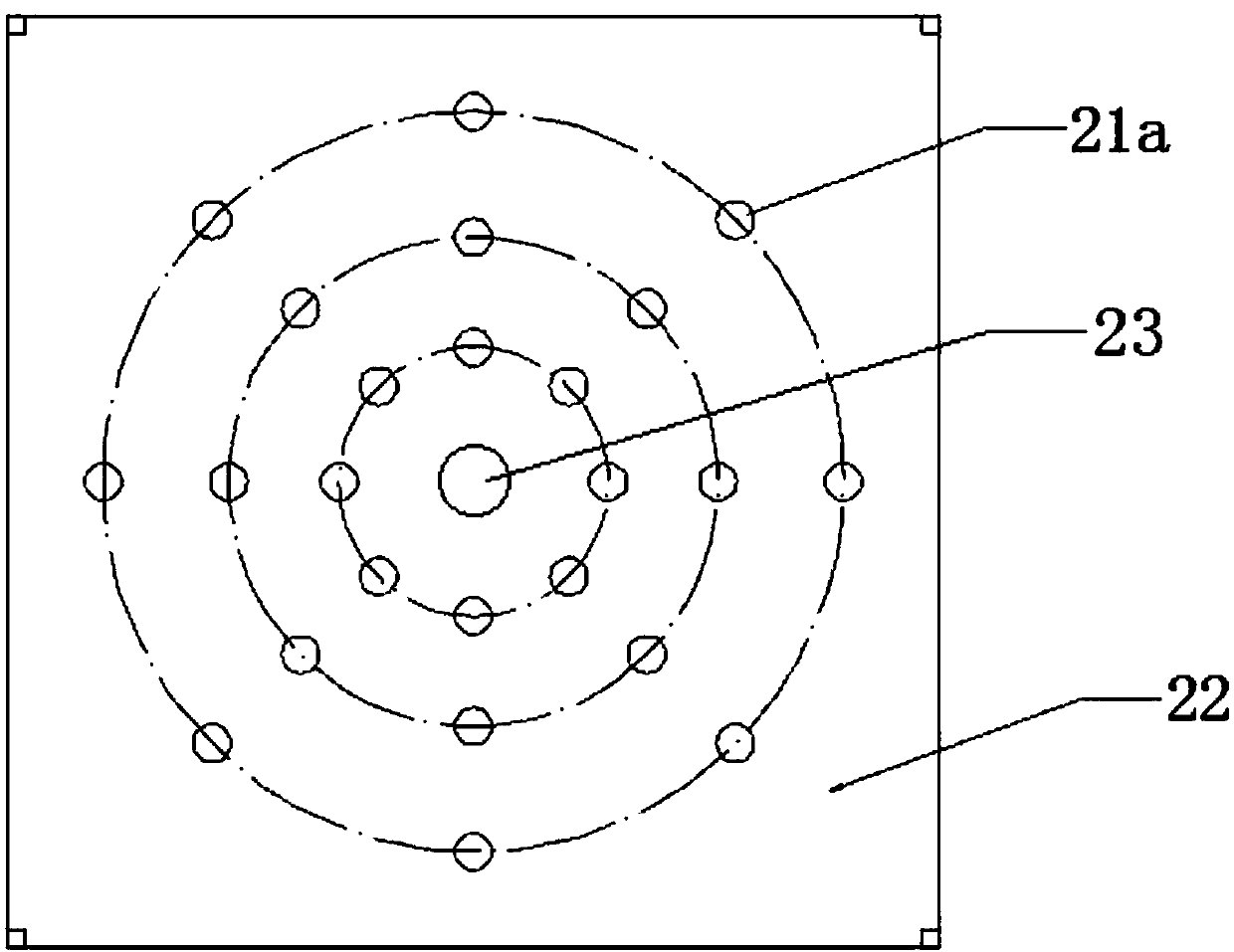

[0025] As shown in the figure, a self-rotating electrolytic production equipment for producing rare earth metal elemental substances and their alloys includes an electrolytic cell body I, a platen 10, and a cathode 1 vertically inserted into the electrolytic cell body I. The bottom of the electrolytic cell body I is provided with Rotating tray 20, said rotating tray 20 is erected on the rotary platform II through rolling connection parts, said rotary platform II includes a load-bearing plate 22 arranged in parallel up and down and a fixed mounting plate 26, and said fixed mounting plate 26 is provided with a motor 25 , the output shaft of the motor 25 is connected to the drive shaft 30 that vertically passes through the central through hole 23 of the bearing plate 22 and is connected to the lower surface of the rotary tray 20; The multi-ring bearing group on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com