Integrated electrolysis atomization module and atomization device

An integrated, atomized sheet technology, applied in the direction of spraying devices, water supply devices, atomized substances, etc., can solve the problem that the effectiveness of disinfection is difficult to guarantee, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

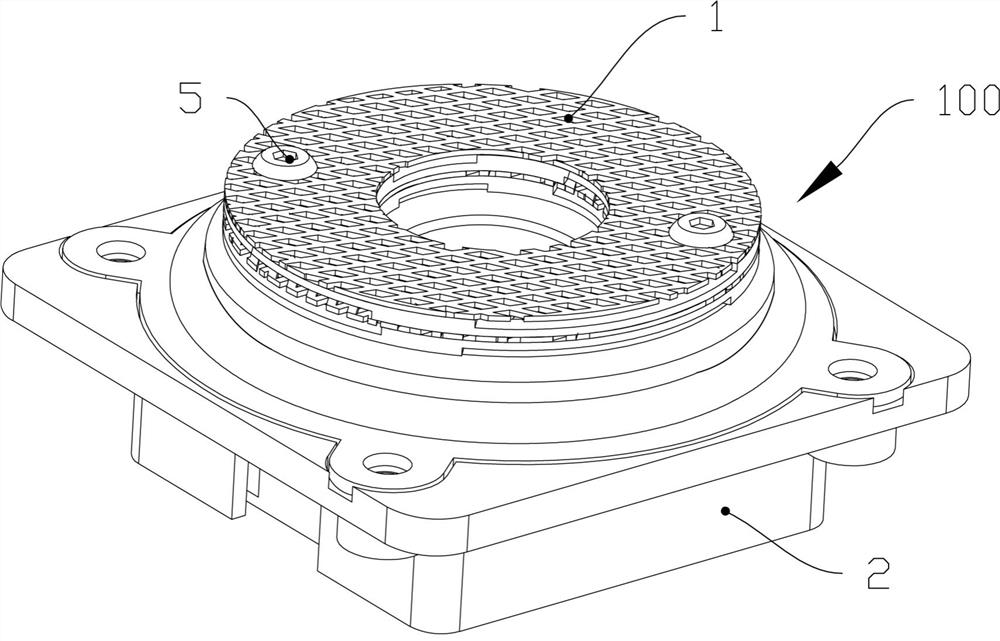

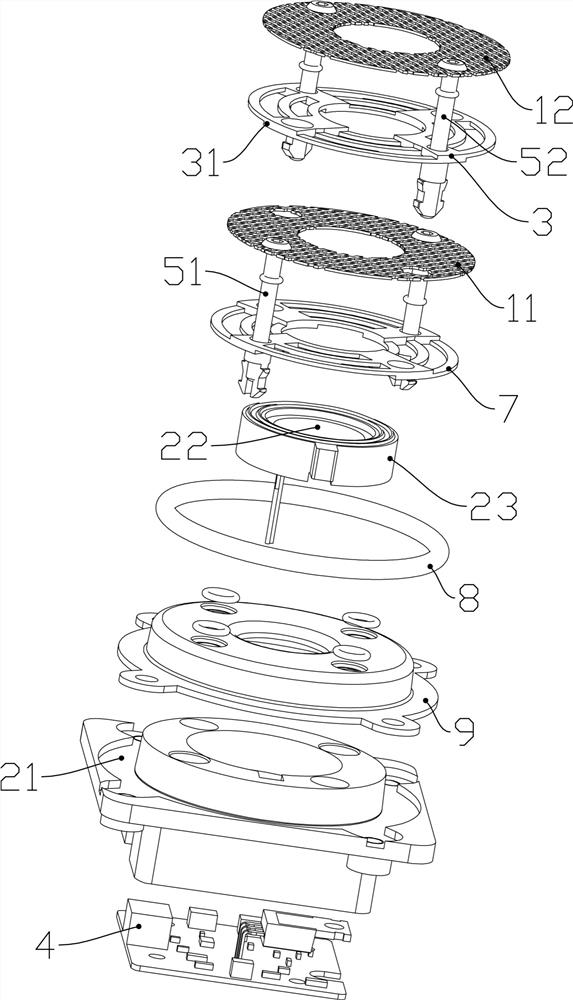

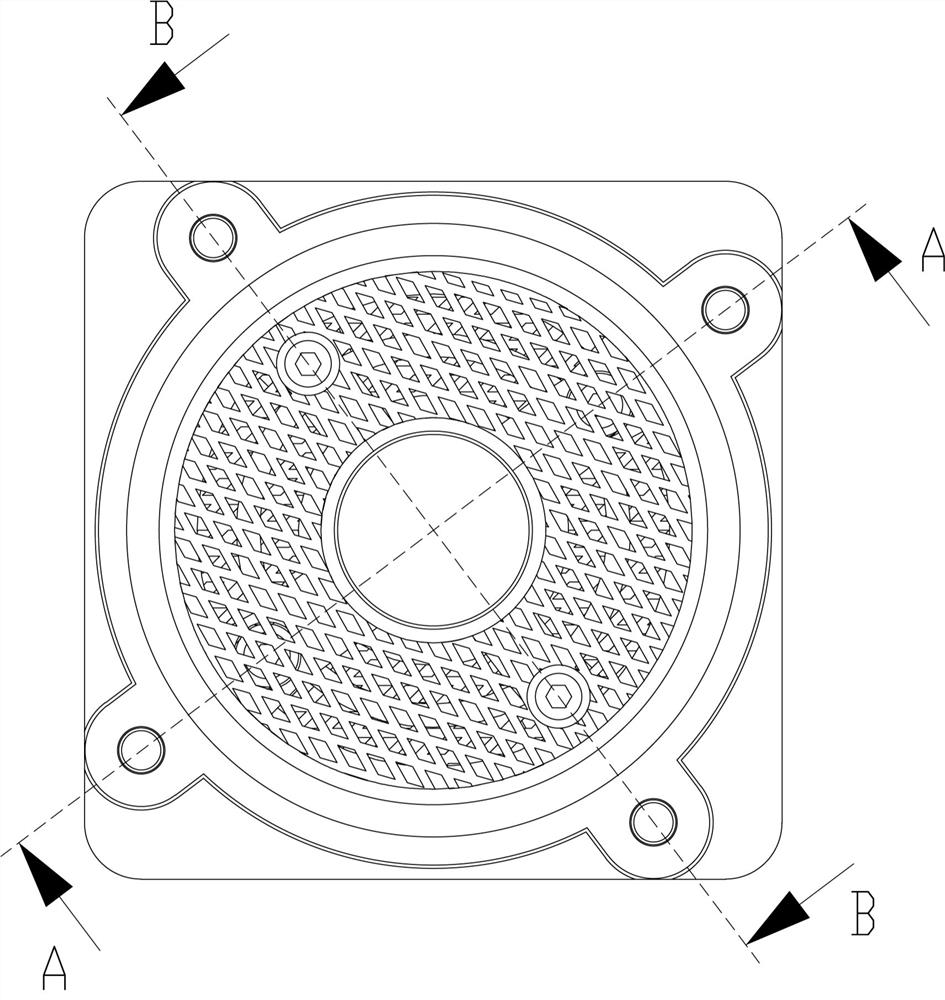

[0061] This embodiment is a specific implementation manner proposed for the flat atomizing sheet 22, such as figure 1 As shown, this embodiment discloses an integrated electrolytic atomization module 100, including an electrolysis assembly 1 and an atomization assembly 2, and the atomization assembly 2 includes a mounting base 21 and a flat mist mounted on the mounting base 21 An atomizing sheet 22, the flat atomizing sheet 22 is used to atomize the liquid above it and spray it upward. The flat atomizing sheet 22 is a component that can atomize liquids such as water through high-frequency vibration, and it is connected to a high-frequency signal drive circuit (the drive circuit can be arranged on the control circuit board 4 described below ) to produce high-frequency vibrations. When the flat atomizing sheet 22 vibrates at a high frequency, bubbles flowing upward at a high speed will be generated in the liquid above it, and the bubbles will burst due to cavitation in the proc...

Embodiment 2

[0087] Such as Figure 7As shown, this embodiment is a specific implementation of the microporous atomization sheet 22c, which discloses an integrated electrolytic atomization module, including an electrolysis component 1c and an atomization component 2c, and the atomization component 2c It includes a mounting seat 21c and a microporous atomizing sheet 22c installed on the mounting seat 21c, and the microporous atomizing sheet 22c is used to atomize the liquid inside it and spray it outward; the electrolytic assembly 1c includes At least one electrolysis electrode pair is the first electrolysis electrode 11c and the first electrolysis electrode 12c, there is an electrical isolation distance H1 between the first electrolysis electrode 11c and the first electrolysis electrode 12c, the first electrolysis electrode 11c and the first electrolysis electrode 12c An electrolysis electrode 12c is arranged inside the installation seat 21c and connected to the installation seat 21c, and ...

Embodiment 3

[0099] Such as Figure 8 As shown, this embodiment discloses an atomizing device, which is used to atomize liquid, which includes a housing chamber 6 for containing liquid, and also includes the integrated device described in Embodiment 1 or Embodiment 2 The integrated electrolytic atomization module 100, the accommodating chamber 6 has a cavity wall 61, the integrated electrolytic atomization module 100 is a component independent of the cavity wall 61, and the integrated electrolytic atomization module 100 is installed on the The cavity wall 61 is used to electrolyze and atomize the liquid in the accommodating cavity 6 . When adopting this embodiment, the integrated electrolytic atomization module 100 can be assembled first and then installed on the cavity wall 61 as an independent accessory. The atomization module 100 can be directly sold to enterprises or consumers who produce atomization devices as an accessory with electrolysis and atomization functions. Wherein, the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com