Cooling electrode for gallium electrolyzing

An electrode and electrode ring technology, applied in the field of gallium electrolytic recovery, can solve the problems of increased difficulty in the production of high-purity gallium, increased impurity content of metal gallium, and large pollution, so as to avoid thermal deformation or cracking, improve power utilization, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

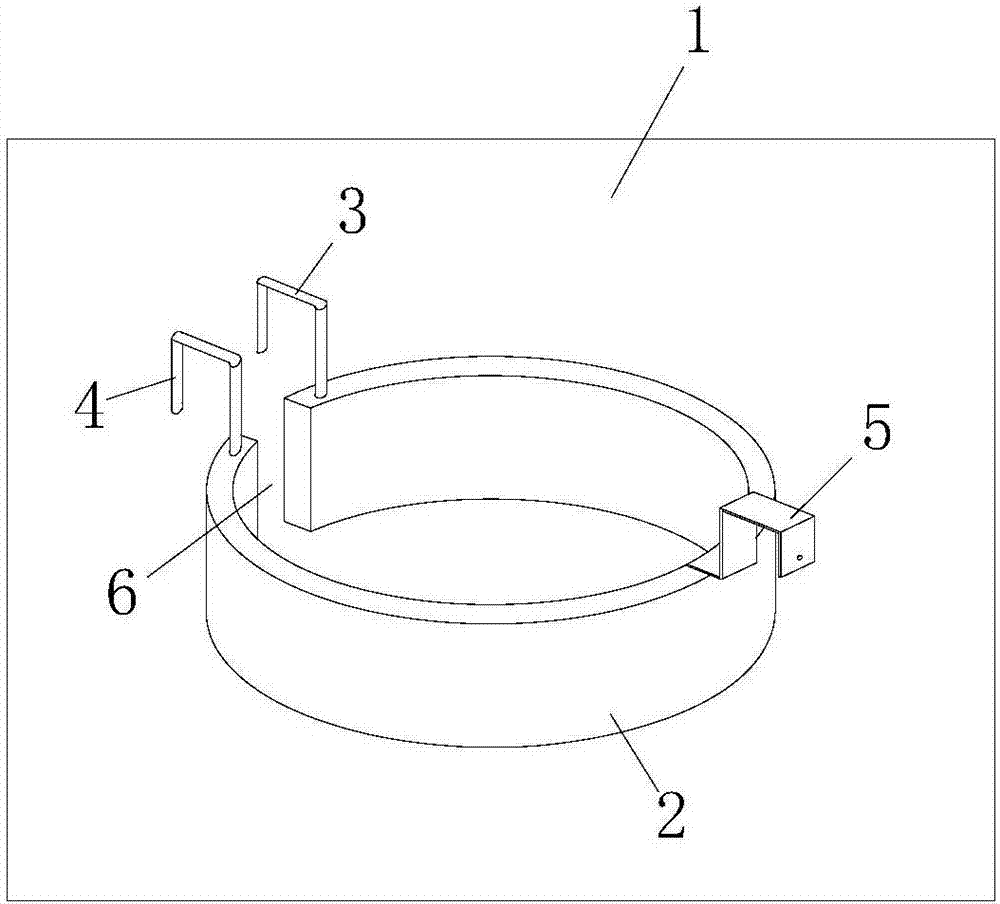

[0029] refer to figure 1 , a cooling electrode for gallium electrolysis, comprising a cathode electrode plate 1, an annular anode plate 2, a circulating water inlet 3, a circulating water outlet 4 and an electrode ring 5, the annular anode plate 2 is provided with a truncation opening 6, and the The interior of the annular anode plate 2 is hollow, and the circulating water inlet 3 and the circulating water outlet 4 are respectively arranged at the two ends of the annular anode plate 2 at the truncation opening 6, and are all communicated with the interior of the annular anode plate 2. The circulating water inlet 3. The circulating water outlet 4 is connected to the water-passing device through a pipeline. A flow regulating valve is provided on the pipeline between the water-passing device and the circulating water inlet 3. The electrode ring 5 is connected to the annular anode plate 2 and connected to the The truncation port 4 is relatively arranged.

[0030] Wherein, the mat...

Embodiment 2

[0038] Device, method are the same as embodiment 1, and different process parameter is: step 2: with above-mentioned NaGaO 2 The solution is added into the electrolytic cell as the electrolyte, and the cathode electrode plate and the annular anode plate are inserted in the electrolytic cell, and the current density is adjusted to 1500A / m 2 .

Embodiment 3

[0040] Device, method are the same as embodiment 1, and different process parameter is: step 2: with above-mentioned NaGaO 2 The solution is added into the electrolytic cell as the electrolyte, and the cathode electrode plate and the annular anode plate are inserted in the electrolytic cell, and the current density is adjusted to 1650A / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com