Online activation method for lead-acid storage battery

A lead-acid battery, activation method technology, applied in lead-acid battery, lead-acid battery construction, secondary battery and other directions, can solve the problems of high cost, increased battery internal resistance, large side effects, etc., to maintain long-term stable operation, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

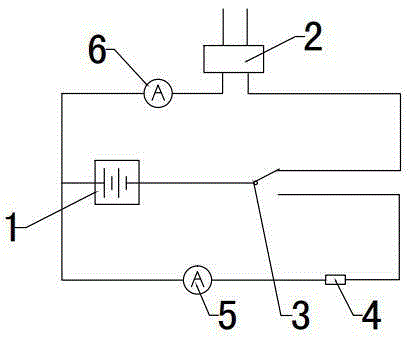

Image

Examples

Embodiment 1

[0032] On-line activation of scrap lead-acid batteries whose battery capacity is less than 80% of the rated value.

[0033] 1) Check the appearance of the battery to confirm that the battery has no broken plate, no rupture, leakage, and no bulge deformation;

[0034] 2) Open the upper cover of the battery, remove the sealing rubber cap and fill the battery with glacial acetic acid to the electrolyte, the amount of glacial acetic acid added is 1.4‰ of the total mass of the electrolyte;

[0035] 3) After resealing the battery, connect the battery to the discharger for over-discharge until the voltage of the battery is 0V;

[0036] 4) Open the upper cover of the battery again, remove the sealing rubber cap and fill the battery with active agent, the active agent is sodium sulfate, ammonium sulfate, potassium sulfate, the mass ratio of sodium sulfate, ammonium sulfate, potassium sulfate is 1:0.4:1.1 , the total amount of sodium sulfate, ammonium sulfate, and potassium sulfate is ...

Embodiment 2

[0039] On-line activation of scrap lead-acid batteries whose battery capacity is less than 60% of the rated value.

[0040] 1) Check the appearance of the battery to confirm that the battery has no broken plate, no rupture, leakage, and no bulge deformation;

[0041] 2) Open the upper cover of the battery, remove the sealing rubber cap and fill the battery with glacial acetic acid to the electrolyte, the amount of glacial acetic acid added is 1‰~3‰ of the total mass of the electrolyte;

[0042] 3) After resealing the battery, connect the battery to the discharger for over-discharge until the voltage of the battery is 0V;

[0043] 4) Open the upper cover of the battery again, remove the sealing rubber cap and fill the battery with active agent, the active agent is sodium sulfate, ammonium sulfate, potassium sulfate, the mass ratio of sodium sulfate, ammonium sulfate, potassium sulfate is 1:0.35:1.15 , the total amount of sodium sulfate, ammonium sulfate, and potassium sulfate ...

Embodiment 3

[0046] On-line activation is performed on scrap lead-acid batteries whose battery capacity is less than 90% of the rated value and new batteries whose battery capacity is at the rated value.

[0047] 1) Check the appearance of the battery to confirm that the battery has no broken plate, no rupture, leakage, and no bulge deformation;

[0048] 2) Open the upper cover of the battery, remove the sealing rubber cap and fill the battery with glacial acetic acid to the electrolyte, the amount of glacial acetic acid added is 3‰ of the total mass of the electrolyte;

[0049] 3) After resealing the battery, connect the battery to the discharger for over-discharge until the voltage of the battery is 0V;

[0050] 4) Open the upper cover of the battery again, remove the sealing rubber cap and fill the battery with active agent, the active agent is sodium sulfate, ammonium sulfate, potassium sulfate, the mass ratio of sodium sulfate, ammonium sulfate, potassium sulfate is 1:0.5:1.2 , the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com