Plate electrode for plasma cleaning, electrode assembly and device

A technology of plasma cleaning and electrode plates, applied in the direction of cleaning methods and appliances, chemical instruments and methods, etc., to achieve the effects of good cleaning effect, high conductivity, strong hardness and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

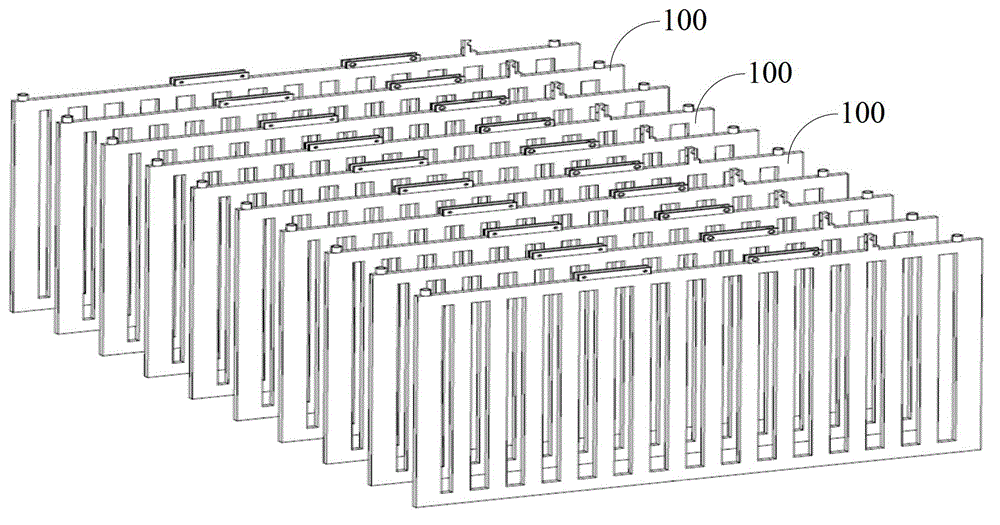

[0017] An embodiment of the present invention provides an electrode plate for plasma cleaning, which can further improve the performance of the electrode and enhance the effect of plasma cleaning. Embodiments of the present invention also provide corresponding sum electrode devices and equipment. A detailed description will be given below in conjunction with the accompanying drawings.

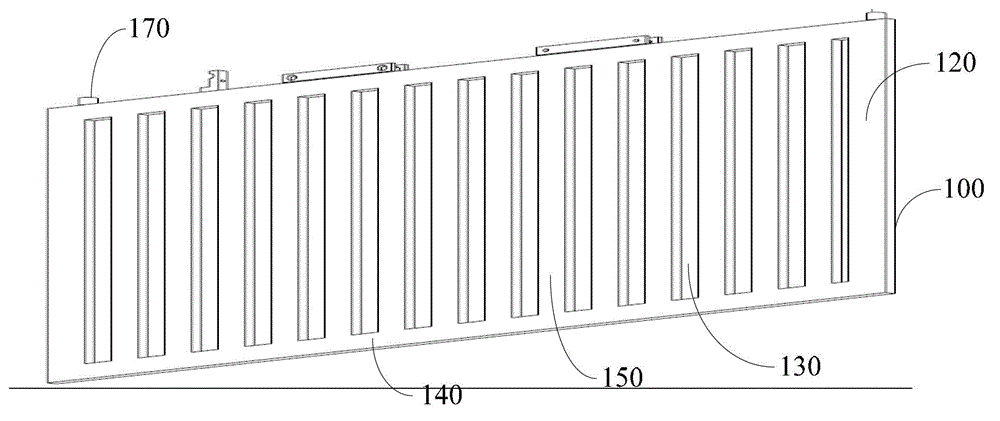

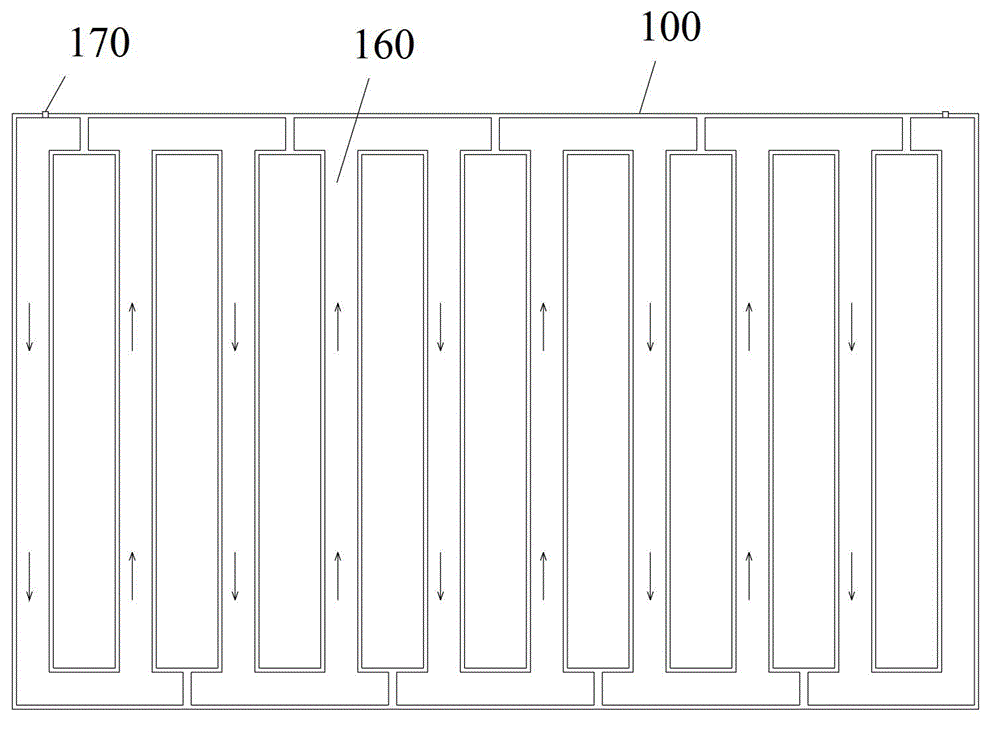

[0018] Please refer to figure 1 and figure 2 , an embodiment of the present invention provides an electrode plate for plasma cleaning.

[0019] The electrode plate 100 is made of aluminum or aluminum alloy and has a grid-like structure. The interior is hollow to form a cavity 110. The cavity 110 has two openings 170 for liquid injection and outflow respectively.

[0020] In one embodiment, the grid-like structure may be formed by opening several regularly arranged rectangular hollow grooves 130 on a rectangular sheet-shaped body 120 .

[0021] In another embodiment, the electrode plate may...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com