Efficient electrolyzing device for sewage treatment

An electrolysis device and sewage treatment technology, applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., can solve problems such as uneven electrode plate spacing, complicated maintenance process, and electrode plate deformation , to achieve the effect of improving electrolysis efficiency, enhancing electrolysis effect and avoiding short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

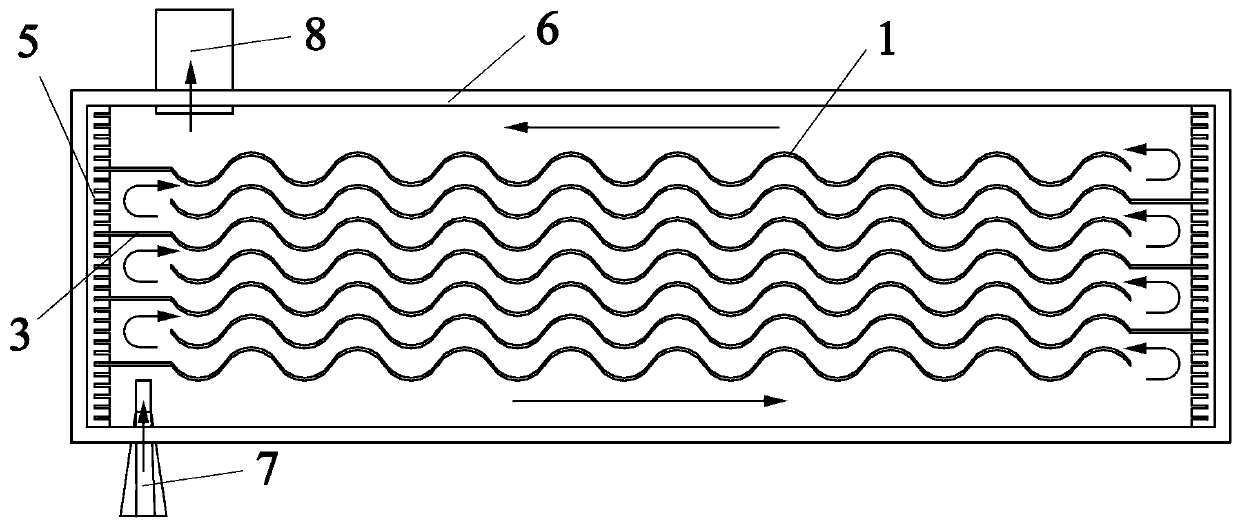

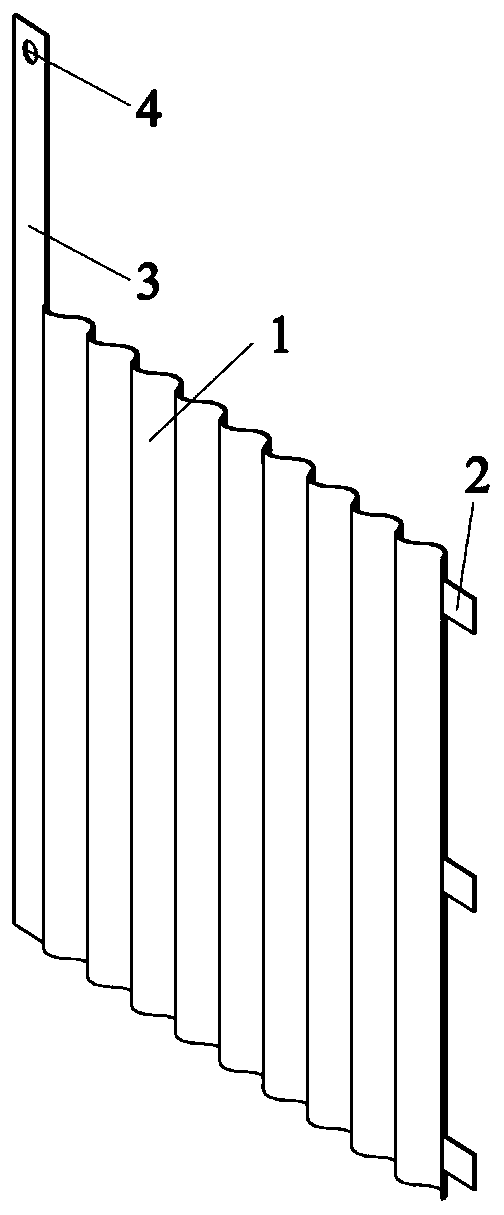

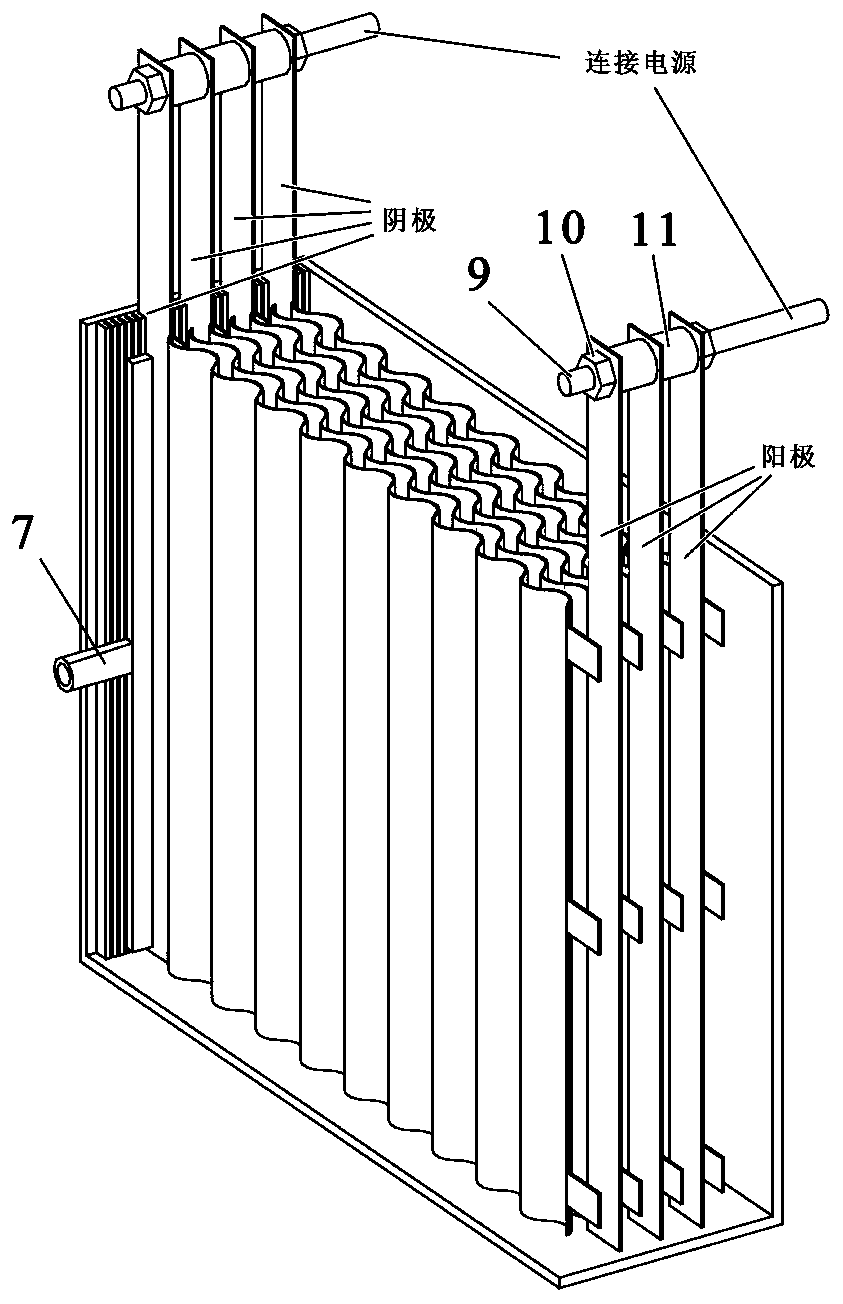

Embodiment 1

[0035]This embodiment provides a high-efficiency electrolysis device for sewage treatment, including an electrode plate 1, a flow-end insert plate 2, a cut-off end insert plate 3, a plate slot 5, an electrolytic cell 6, and a water inlet uniform distributor 7 , Conductive screw rod 9, conductive nut 10, conductive support column 11. The electrode plate 1 adopts a wave-shaped structure, and the sides of both ends are respectively fixed by welding or bolts to the cut-off end plate 3 and the flow-through end plate 2, wherein the bottom end of the cut-off end plate 3 is flush with the bottom end of the electrode plate 1, The top of the intercepting end plate 3 is higher than the top of the electrode plate 1 by 3 diameters of the screw hole 4; the single electrode plate 1 is provided with three overcurrent end plates 2, and the total height is 1 / 4 of the height of the electrode plate 1. Pole plate slot 5 is a hard insulating material, and 2 pole plate slots 5 are respectively fixed...

Embodiment 2

[0040] Figure 5 Schematic diagram of the top view structure designed for the angled structure electrode plate, Figure 6 Schematic diagram of the top view structure designed for large and small wave structure electrode plates. The electrode plate 1 with the angled structure is easier to process, and is easy to clean and maintain. The large and small wave structure can form an electrolysis process in which one side of the electrode plate is uniform voltage and the other side is pulse voltage, which can be applied to the treatment of special sewage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com