Electroplating wastewater treatment equipment capable of recovering rare metals and operation method of electroplating wastewater treatment equipment

A rare metal, electroplating wastewater technology, applied in the electrolysis process, electrolysis components and other directions, can solve the problems of reduced electrolysis efficiency, single rare metal electrolysis, reduced wastewater treatment efficiency, etc., to facilitate electrolysis and precipitation of gold and various substances. Even and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

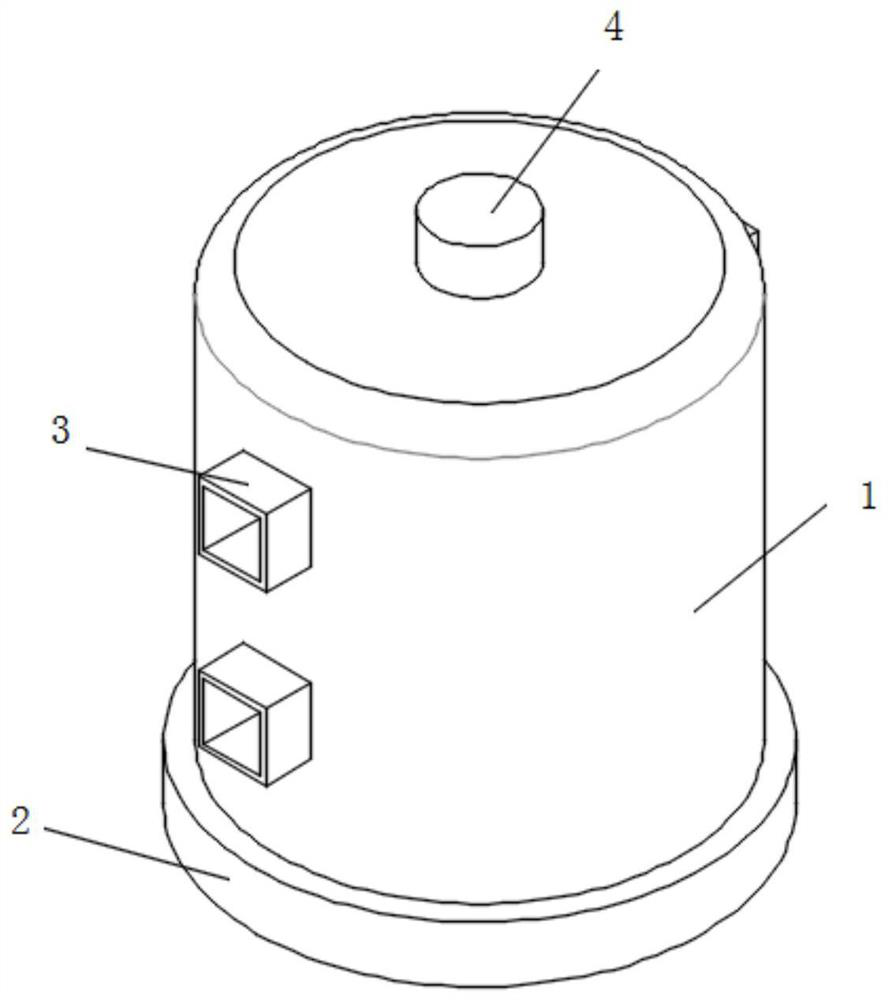

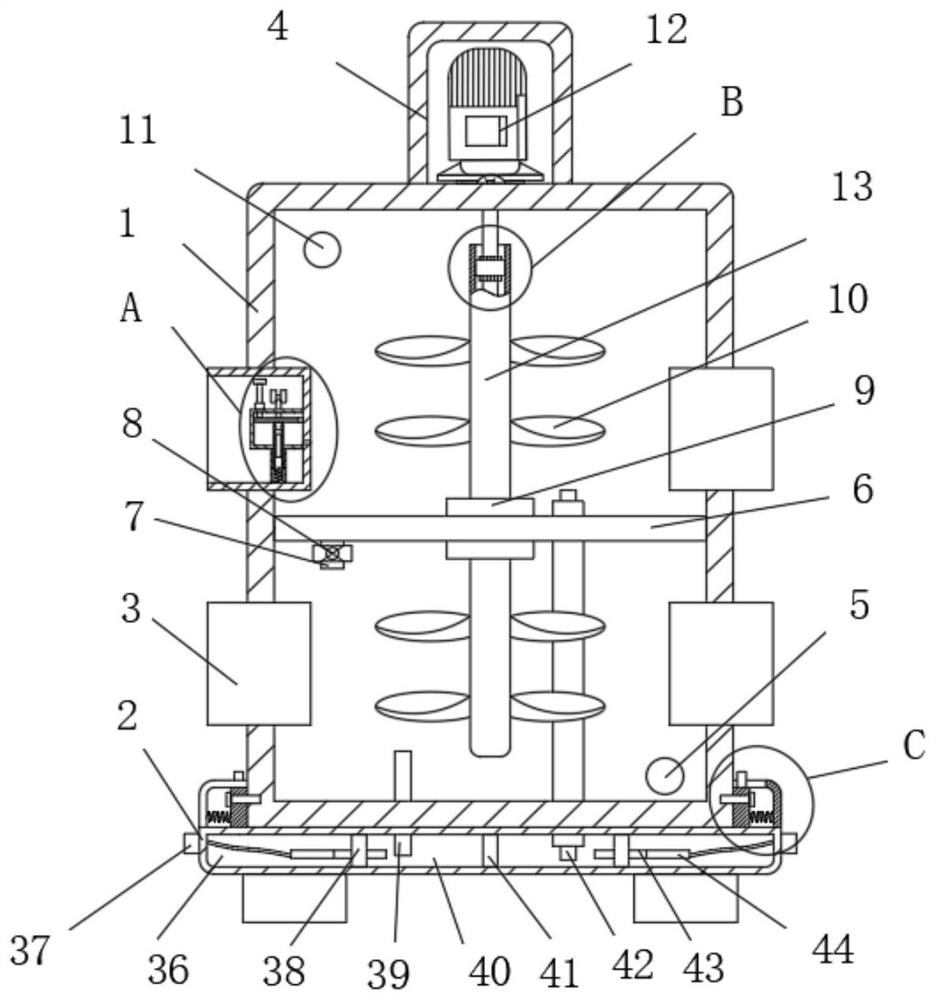

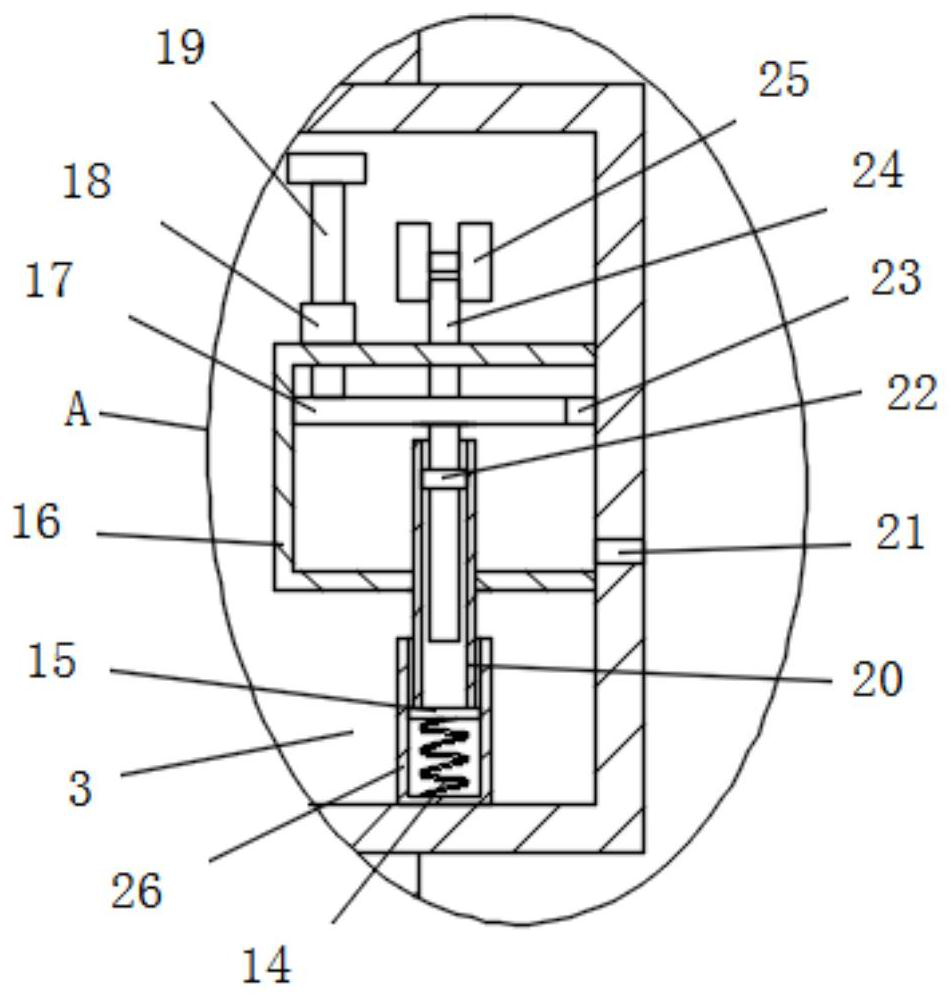

[0037] Embodiment 1: This embodiment provides electroplating wastewater treatment equipment that can recover rare metals, see Figure 1-7 Specifically, it includes a box body 1, a base 2 is fixedly installed on the lower side wall of the box body 1, a water inlet 11 is provided on the upper end side wall of the box body 1, and a water outlet is provided on the lower end side wall of the box body 1 5. A partition 6 is fixedly installed on the inner side wall of the box body 1, and a plurality of electrolytic boxes 3 are installed on the side wall of the box body 1, and the plurality of electrolytic boxes 3 are arranged symmetrically, and the partition plate 6 is arranged among the plurality of electrolytic boxes 3 Between, on the side wall of partition plate 6, water pipe 7 is installed, and solenoid valve 8 is fixedly installed on water pipe 7, and the recovery mechanism that is used to reclaim rare metal is all installed in a plurality of electrolytic tanks 3;

[0038] The re...

Embodiment 2

[0045] Embodiment two: in embodiment one, there is also the problem that electrolysis efficiency is reduced due to concentration changes around the electrode rod. Therefore, on the basis of embodiment one, this embodiment also includes:

[0046] In the present invention, a turntable 9 is fixedly installed on the side wall of the partition 6, and a rotating rod 13 is inserted in the rotating disc 9. A plurality of dials 10 are fixedly installed on the side wall of the rotating rod 13, and the side wall of the box body 1 A motor 12 is fixedly connected to the top, the output shaft of the motor 12 is installed at one end of the rotating rod 13, and the outer side of the motor 12 is provided with a protective shell 4. This structural design makes the concentration of various substances in the wastewater near the electrode rod 24 more uniform , to facilitate the electrolysis and metal precipitation work, improve the efficiency of electrolysis, increase the effect of metal precipitat...

Embodiment 3

[0048] Embodiment three: see Figure 7 , in this embodiment, the present invention also proposes the operation method of the electroplating wastewater treatment equipment that can recover rare metals, comprising the following steps:

[0049] Step 1, when performing recovery work, first insert the collection pipes 20 in the two opposite electrolytic tanks 3 into the solution phase tank 6 and seal them, then respectively insert the electrode rods 24 in the two electrolytic tanks 3 through the solution tank 16. The piston plate 17 and the connecting ring 22 are inserted into the collecting pipes 20 on both sides, and then the two electrode rods 24 are clamped by the elastic force of the tension spring 34 through the two conductive plates 25 in the corresponding clamping parts;

[0050] Step 2, then inject waste water into the tank 1 through the water inlet 11, the waste water will enter the solution tank 16 through the through hole 21, and then start the power supply in the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com