Method and device for controlling discharging power supply

A technology of discharge power supply and control method, applied in circuits, manufacturing tools, electric processing equipment, etc., can solve the problems of poor processing efficiency and large line loss of electrolytic discharge power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Now, the detailed structure of the present invention and its connections are described in conjunction with the following drawings, so as to facilitate the understanding of those skilled in the art.

[0043] Currently known EDM pulse control methods are equal-frequency machining control method and equal-energy machining control method, both of which have two operation modes of direct current (DC) and alternating current (AC). The known methods are analyzed and compared as follows:

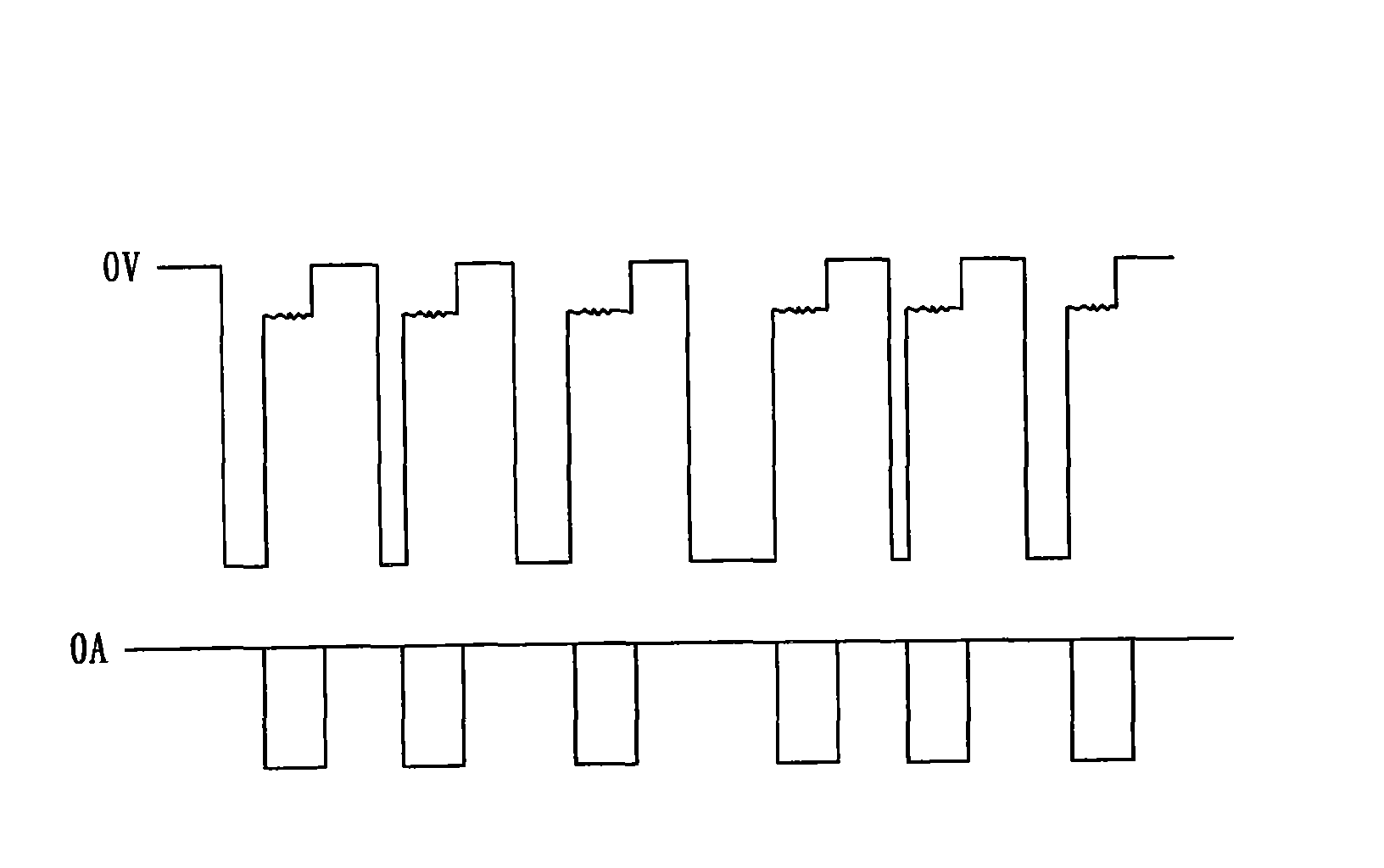

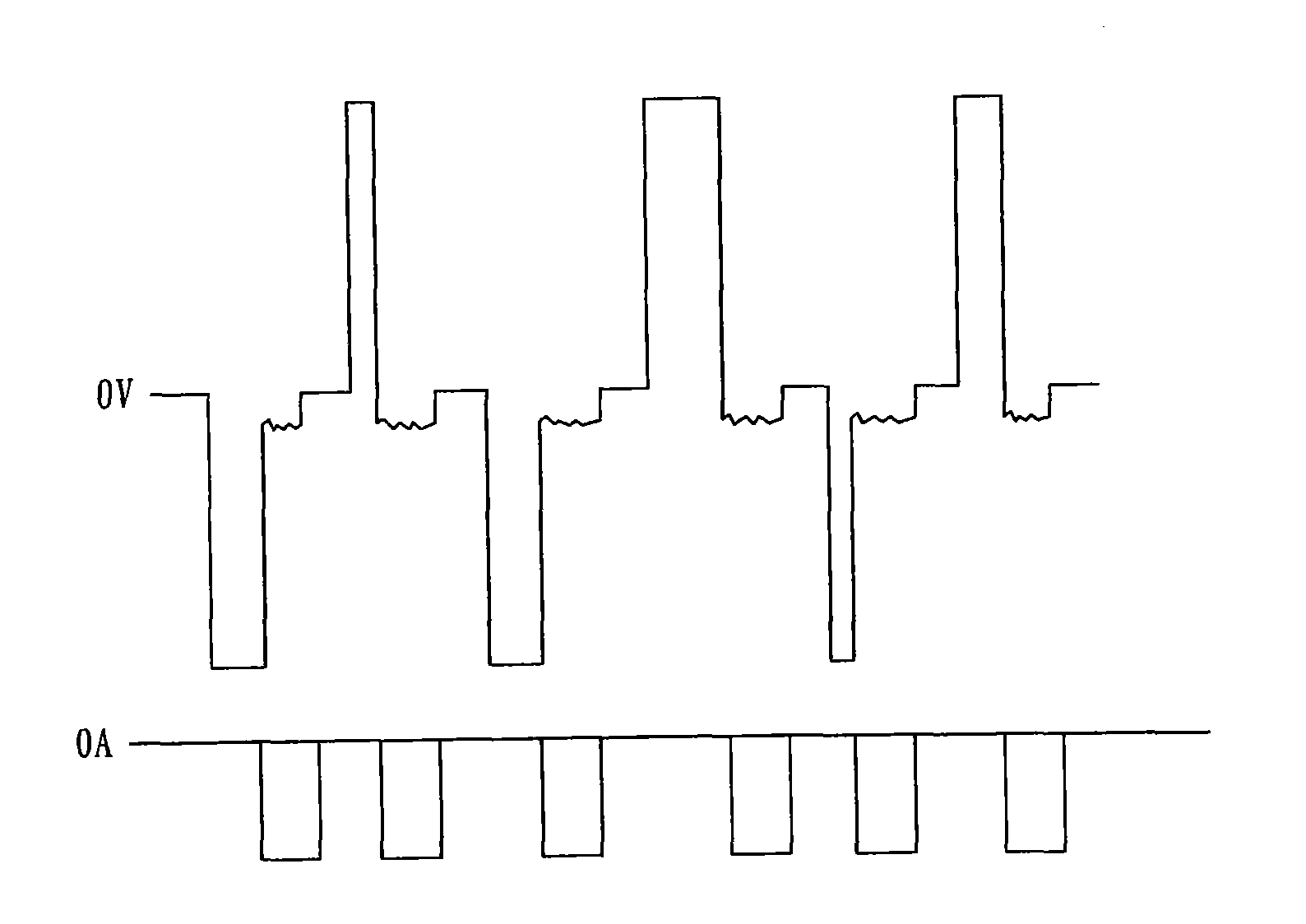

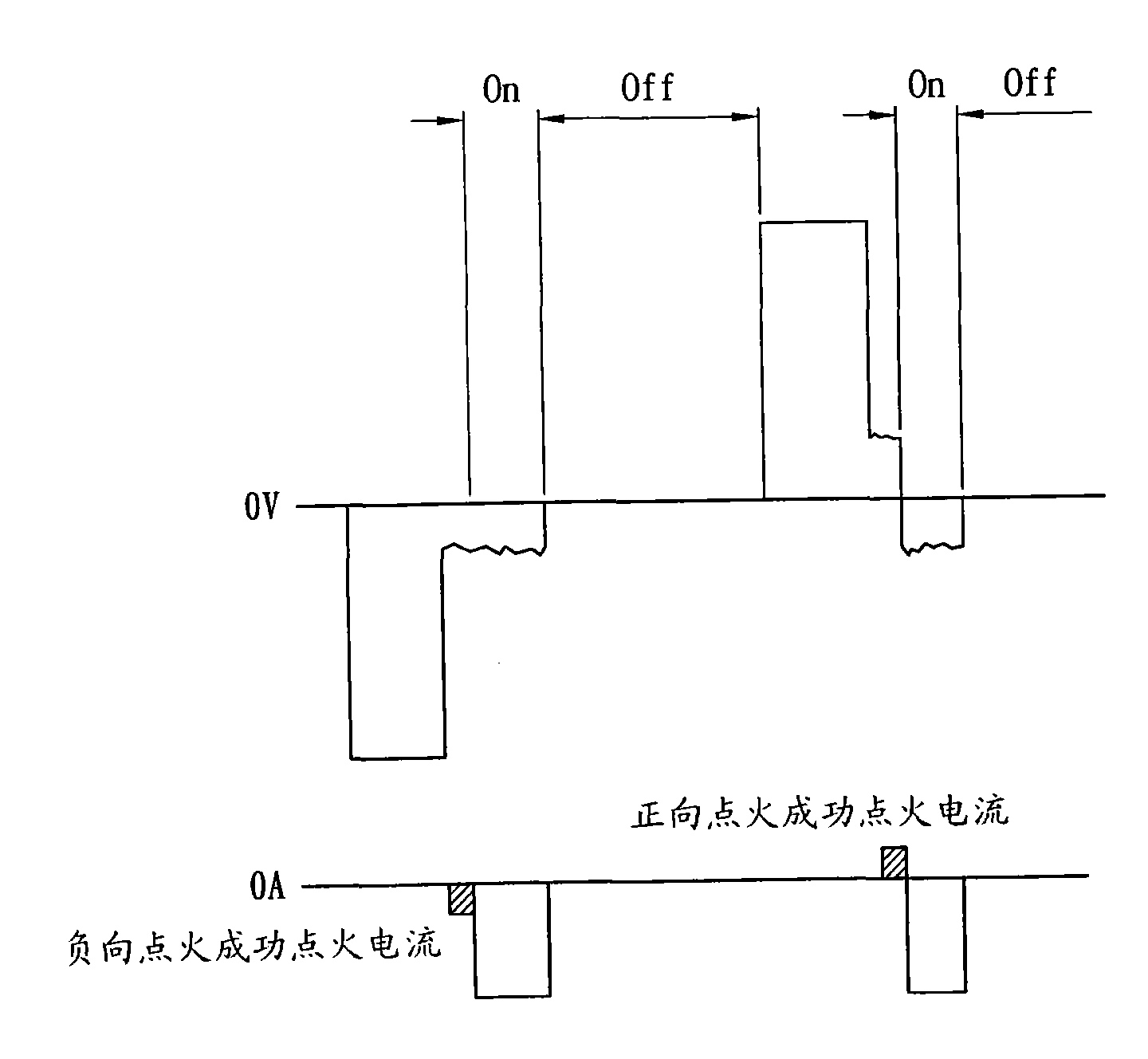

[0044] (1) Equal frequency control method: the control method uses the switch Qf to turn on and off (On time, Off time) at a fixed time, and the time can be set separately, because the time of on and off is fixed, so it is called equal frequency discharge . The advantage of this method is that the control method is simple, but because the gap state when the switch is turned on is unknown, the actual discharge time length cannot be confirmed, so the discharge energy of a single shot is not fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com