Method for extracting and recovering Cr(III) from high acid solution

A recovery method and solution technology, applied in the field of extraction and recovery of Cr in a high-acid solution, can solve the problems of large sulfuric acid consumption, small processing capacity, cumbersome management, etc., achieve good reproducibility and stability, reduce reagent consumption, The effect of simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The method for the electrolysis of Cr(III) of the present embodiment is carried out according to the following steps:

[0033] (1) Place the anion membrane at the interface of the double-cell electrolytic cell, fix the ion membrane and the electrolytic cell by a flat clip, the catholyte is 150ml with a volume fraction of 10-30% sulfuric acid solution, and the anode is 150ml of real pickling waste ;

[0034] (2) Place two cut 7cm×2cm×0.2cm lead plate electrodes in the anode and cathode electrolytic cells respectively; Under the condition of 9V, the electrolysis experiment was carried out for 4h, and Cr(III) could be oxidized to Cr(Ⅵ) after electrolysis;

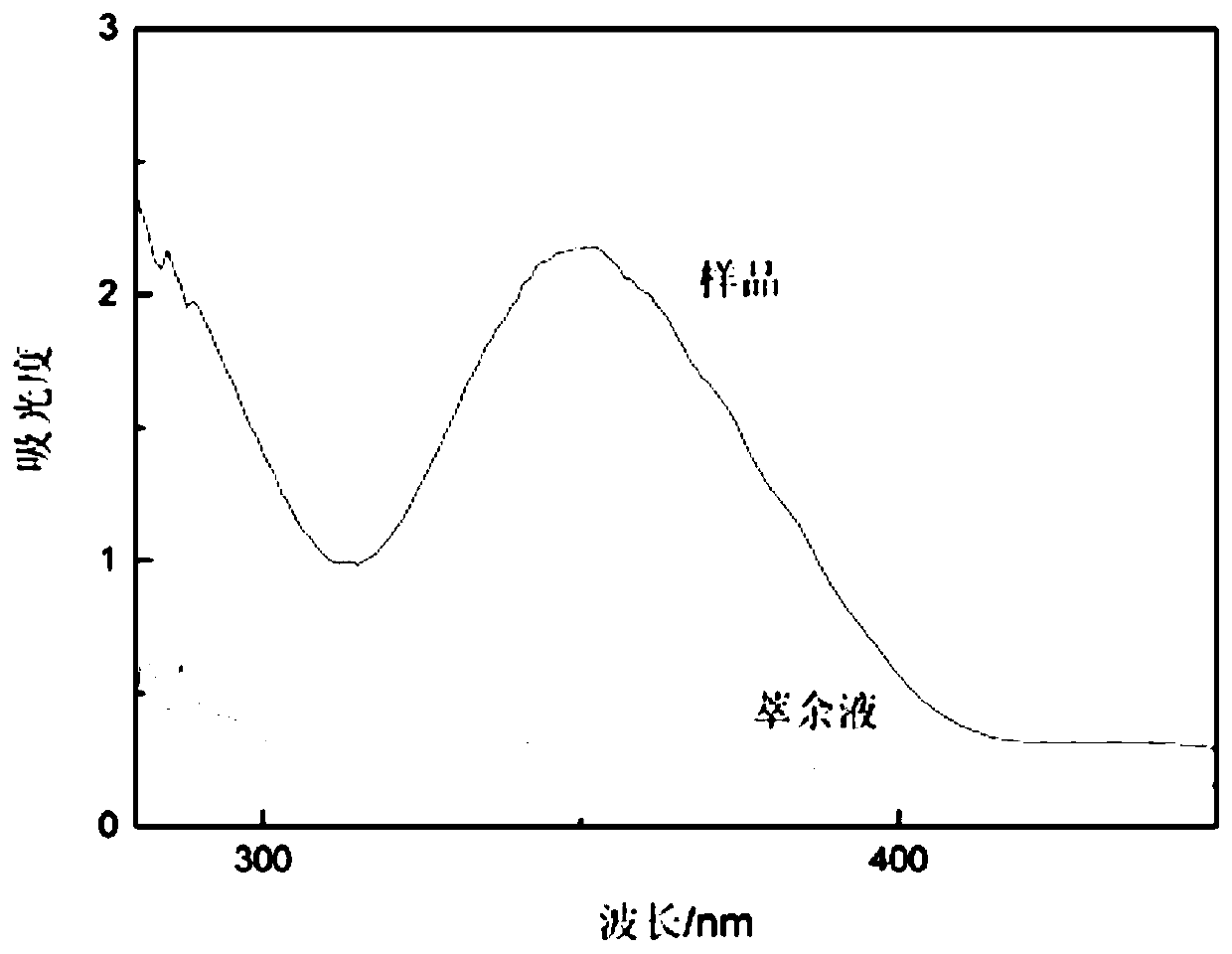

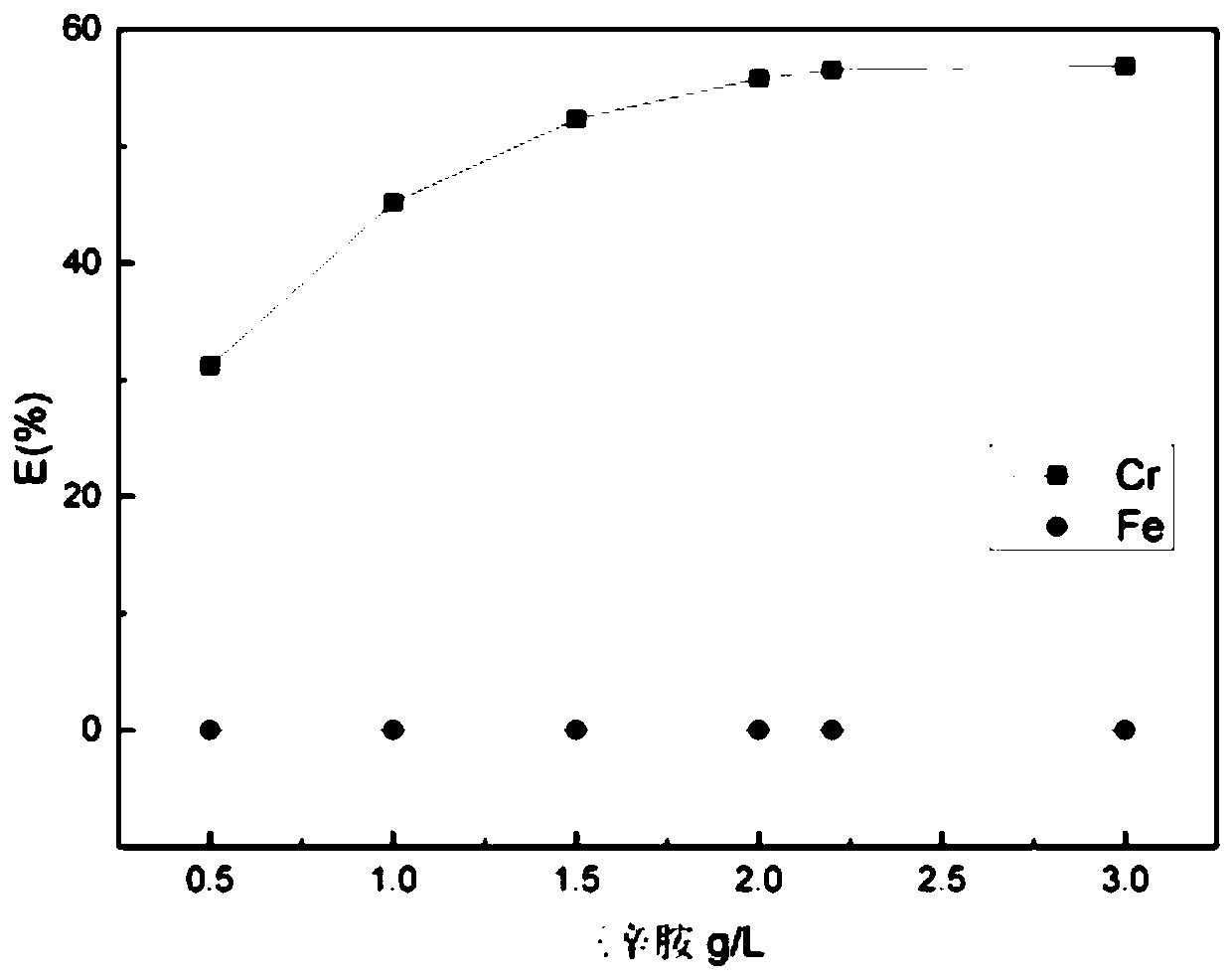

[0035] (3) Take 10ml of solution after electrolysis, add 10ml of extractant tri-n-octylamine solution with diluent n-amyl alcohol as solvent, the concentration of extractant is three times of Cr(III) in the initial pickling waste liquid, at constant temperature Stir in a water bath for 10 minutes, and then use a UV-vi...

Embodiment 2

[0045] For the method for electrolyzing Cr(III) in this embodiment, the steps refer to Example 1, and the electrolysis time is 8 hours.

Embodiment 3

[0047] For the method for electrolyzing Cr(III) in this embodiment, the steps refer to Example 1, and the electrolysis time is 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com