Multistage electrolysis method

An electrolysis method and electrolysis cell technology, applied in the electrolysis process, electrolysis components, electrode shape/type, etc., can solve problems such as unsuitable maintenance and troubleshooting, large depth of the cell body, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

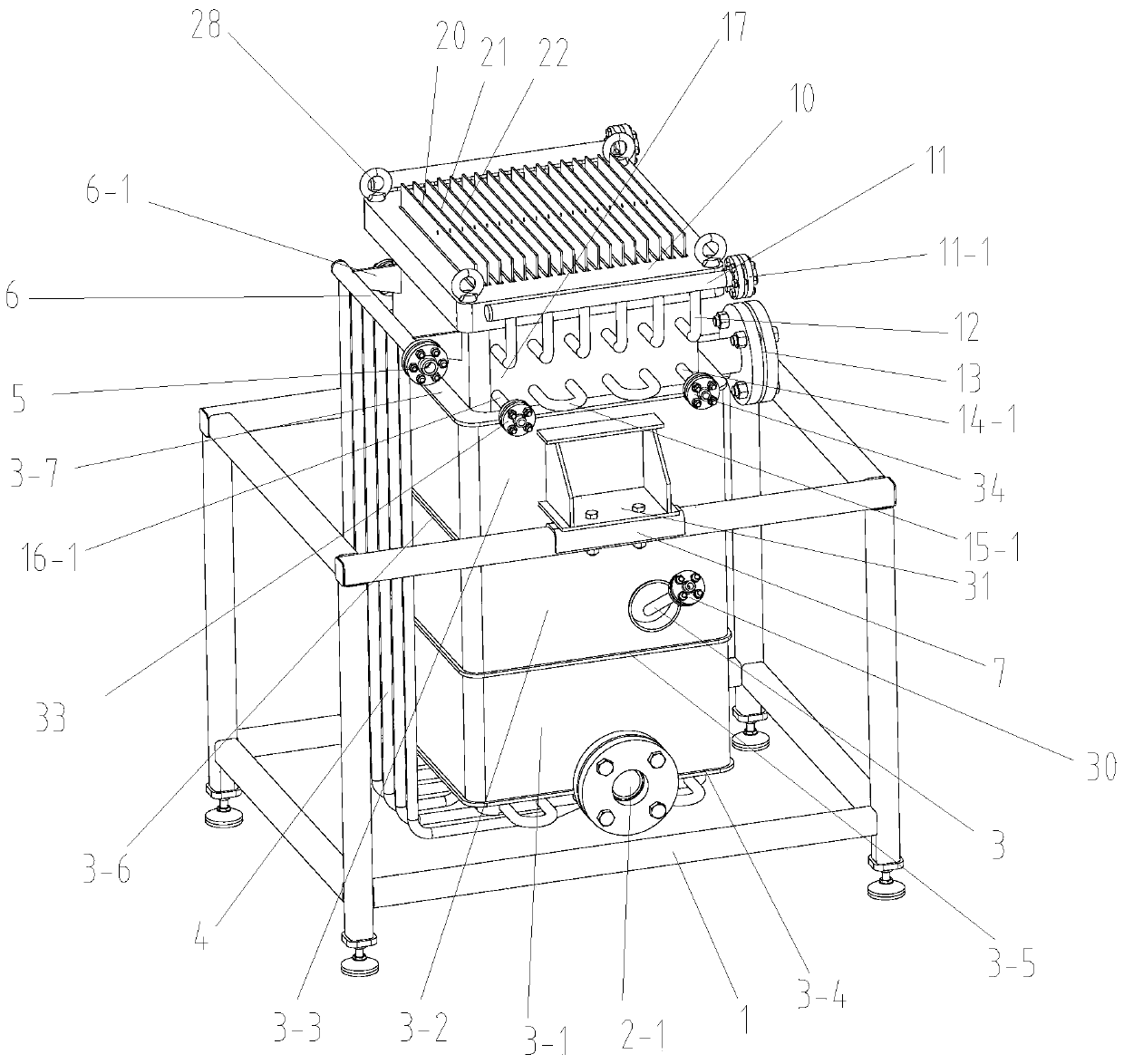

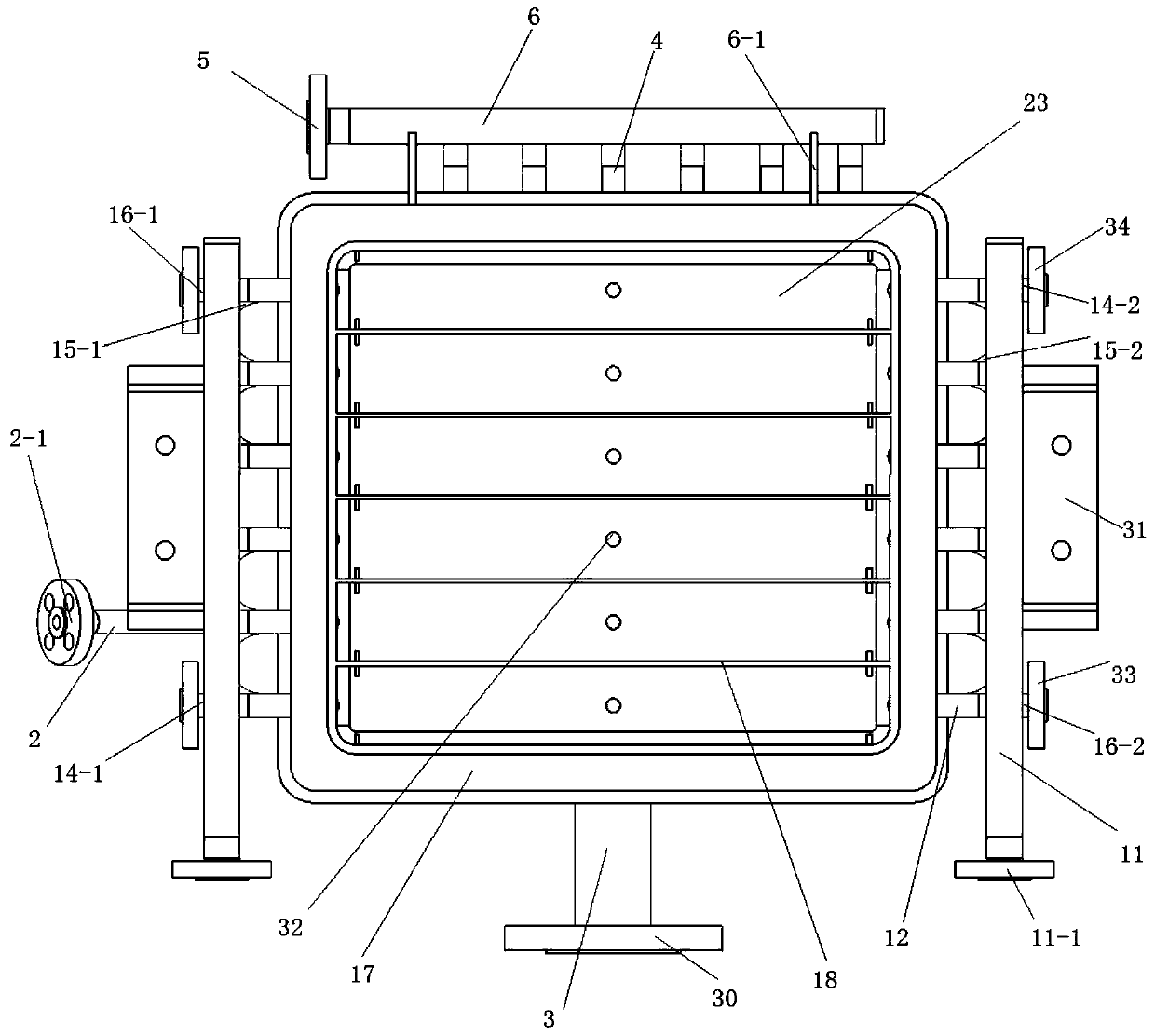

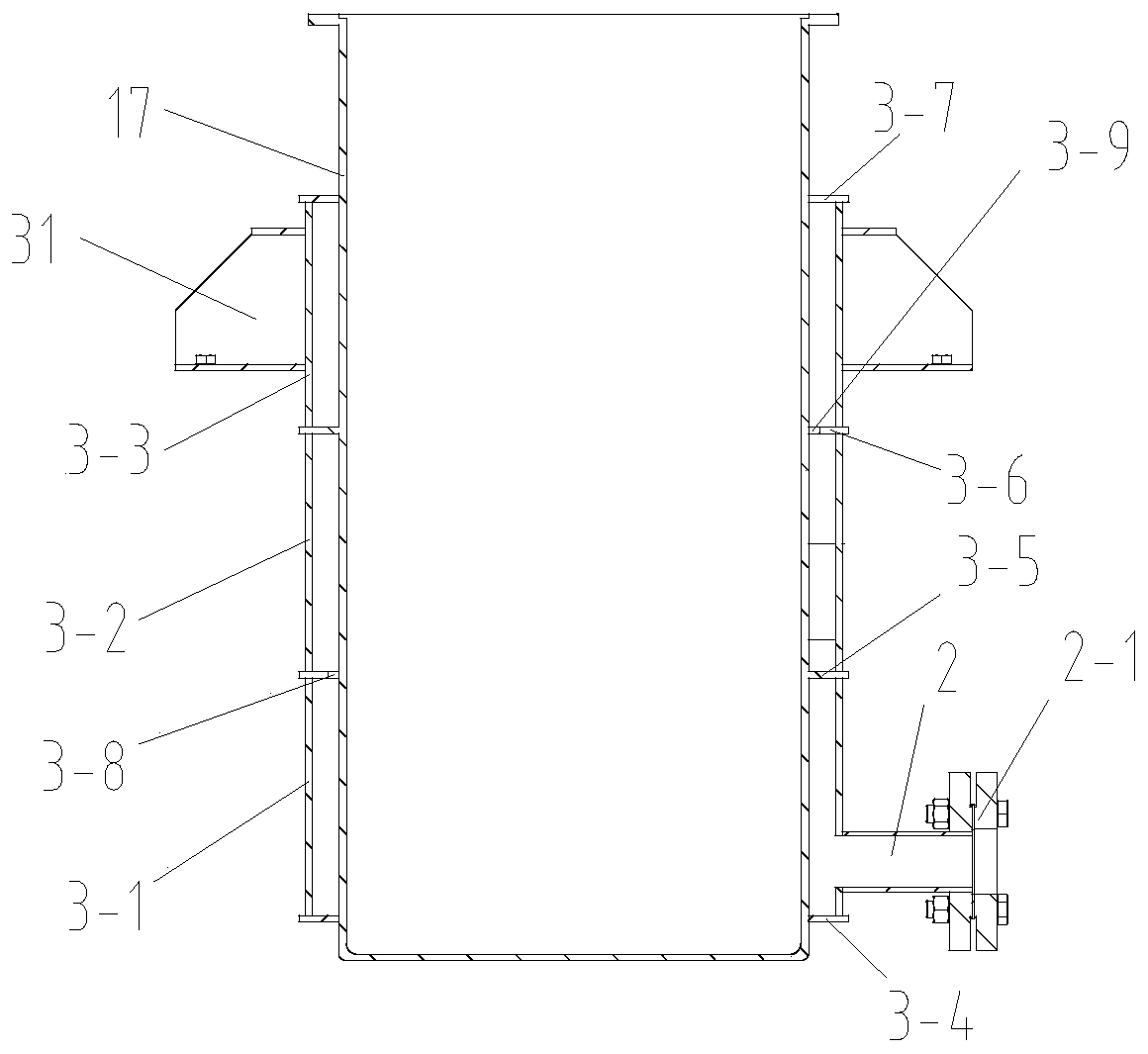

[0101] Such as figure 1 , figure 2 and Figure 14 A kind of multistage electrolysis method shown, the electrolytic cell that this electrolytic method adopts comprises support 1, the electrolytic cell mechanism that is arranged on support 1 and the cooling mechanism that surrounds on described electrolytic cell mechanism, and described electrolytic cell mechanism includes Tank body 17, two inlet and outlet parts connected to tank body 17, two exhaust parts connected to tank body 17, suction liquid parts connected to the bottom of tank body 17, and a cover plate arranged on the top of tank body 17 10, the tank body 17 is provided with a plurality of partitions 18, and the partition board 18 divides the cavity of the tank body 17 into a plurality of electrolytic cells 23, and the number of the electrolytic cells 23 is an even number;

[0102] The two liquid inlet and outlet parts are respectively the first liquid inlet and outlet parts arranged on one side of the tank body 17 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com