Patents

Literature

40results about How to "Increase the rate of electrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

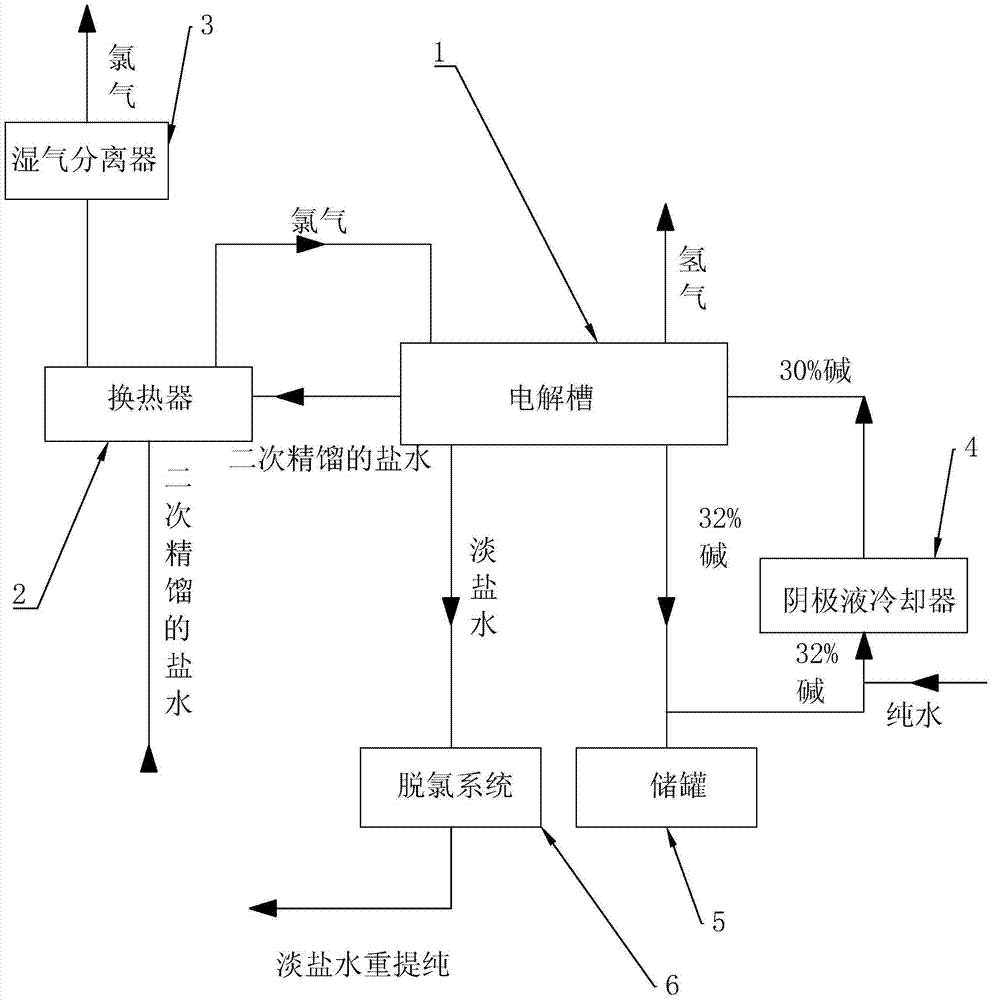

Process for producing alkali

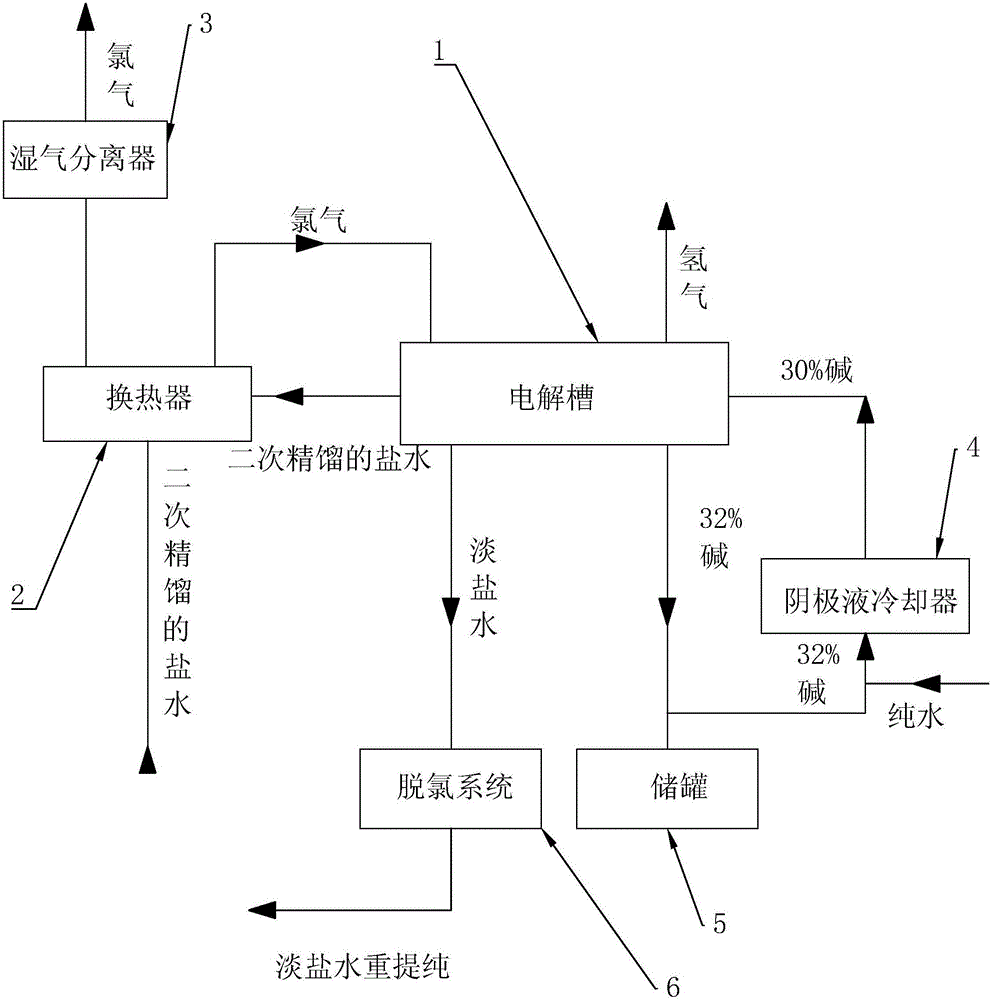

The invention relates to a process for producing alkali. The process comprises the following steps: a, secondary refined brine is preheated through a heat exchanger and enters an anode chamber of an electrolytic bath; when the current reaches 5KA, acid is added into the anode chamber; b, chlorine generated by electrolysis is used for preheating the secondary refined brine through the heat exchanger, so that the temperature of the secondary refined brine reaches 55 DEG C; c, part of alkali with the concentration being 32+ / -0.5 percent exhausted from a cathode chamber is mixed with a moderate amount of pure water to generate alkali with the concentration being 30+ / -0.5 percent, and the alkali with the concentration being 30+ / -0.5 percent enters the cathode chamber and is electrolyzed in the cathode chamber to generate hydrogen; d, the temperature of the electrolytic bath in the whole electrolytic reaction process is regulated and controlled to 85-87 through a cathode liquor cooler; e, when the concentration of cathode liquor achieves 2+ / -0.5 percent, the cathode liquor is exhausted from the cathode chamber; after the cathode liquor passes through the cathode liquor cooler, part of the cathode liquor is reused into the cathode chamber, and part of the cathode liquor is output to a storage tank. The process reduces energy waste, is beneficial to quickly exhausting the generated gas, increases the production rate of alkali, and improves the conductivity of liquor.

Owner:ZHEJIANG OCEANKING DEVELOPMENT CO LTD

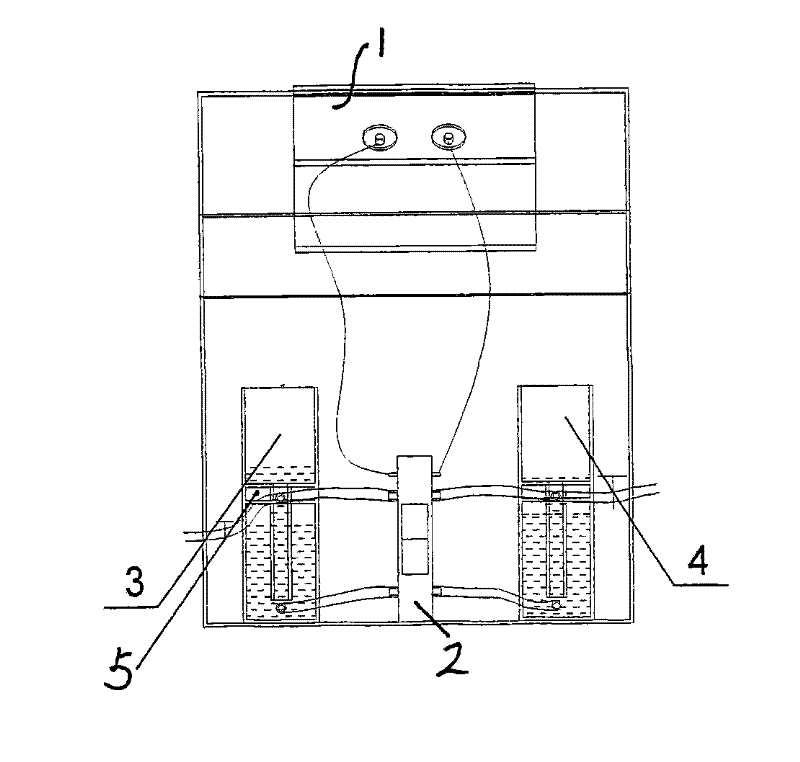

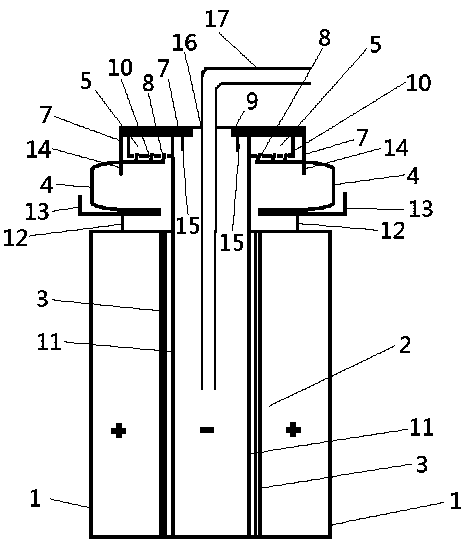

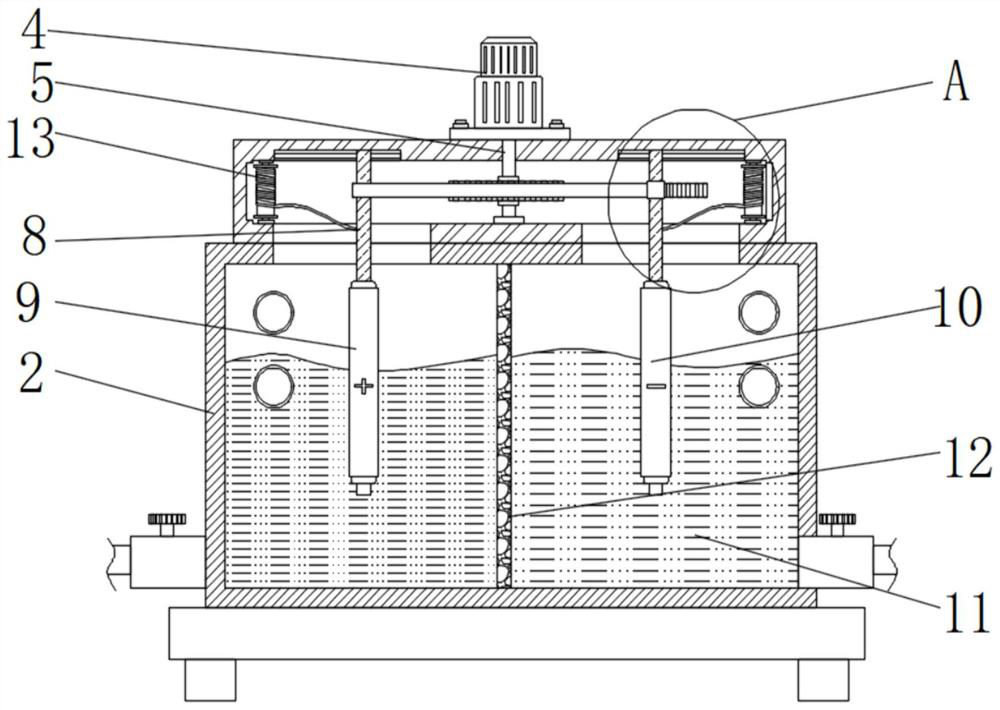

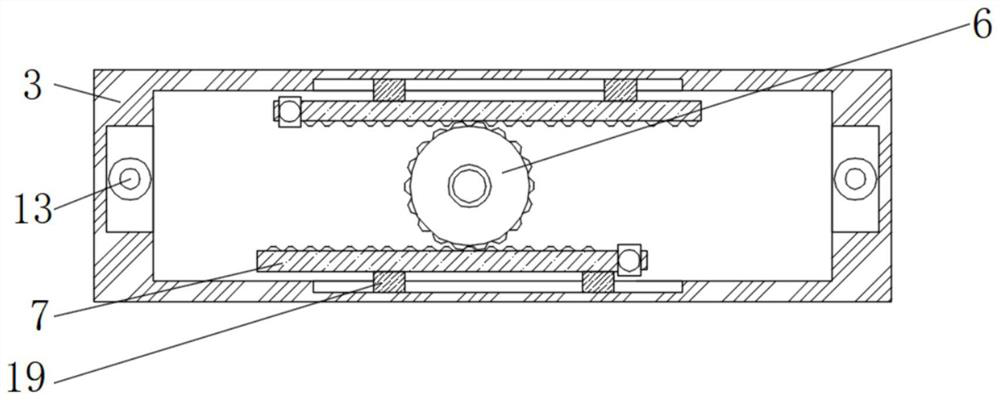

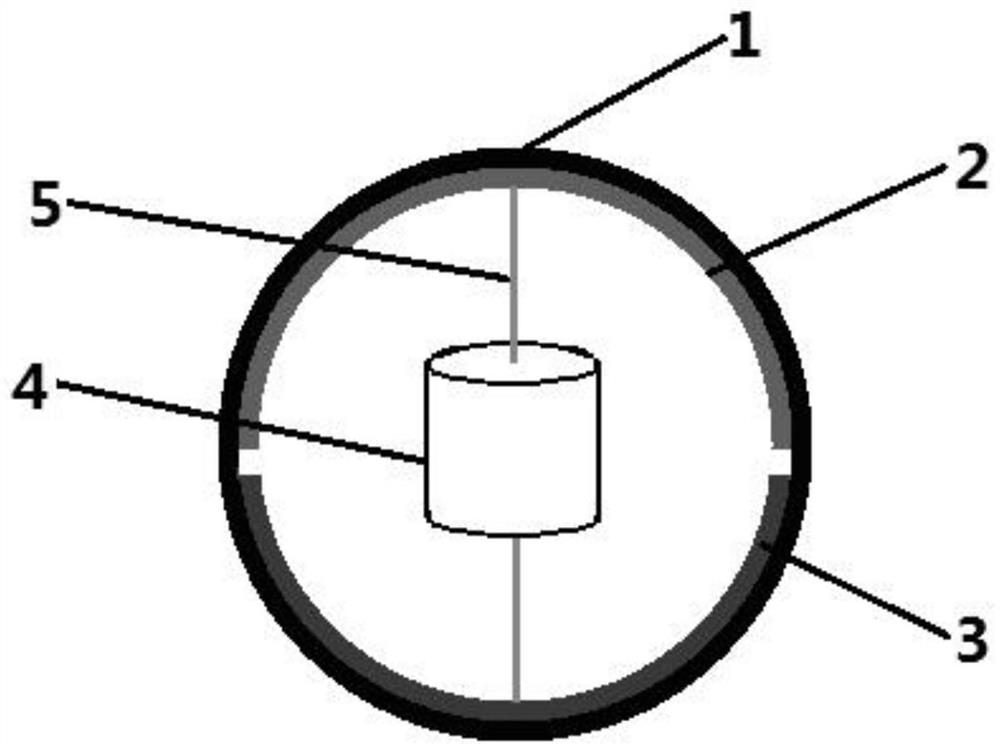

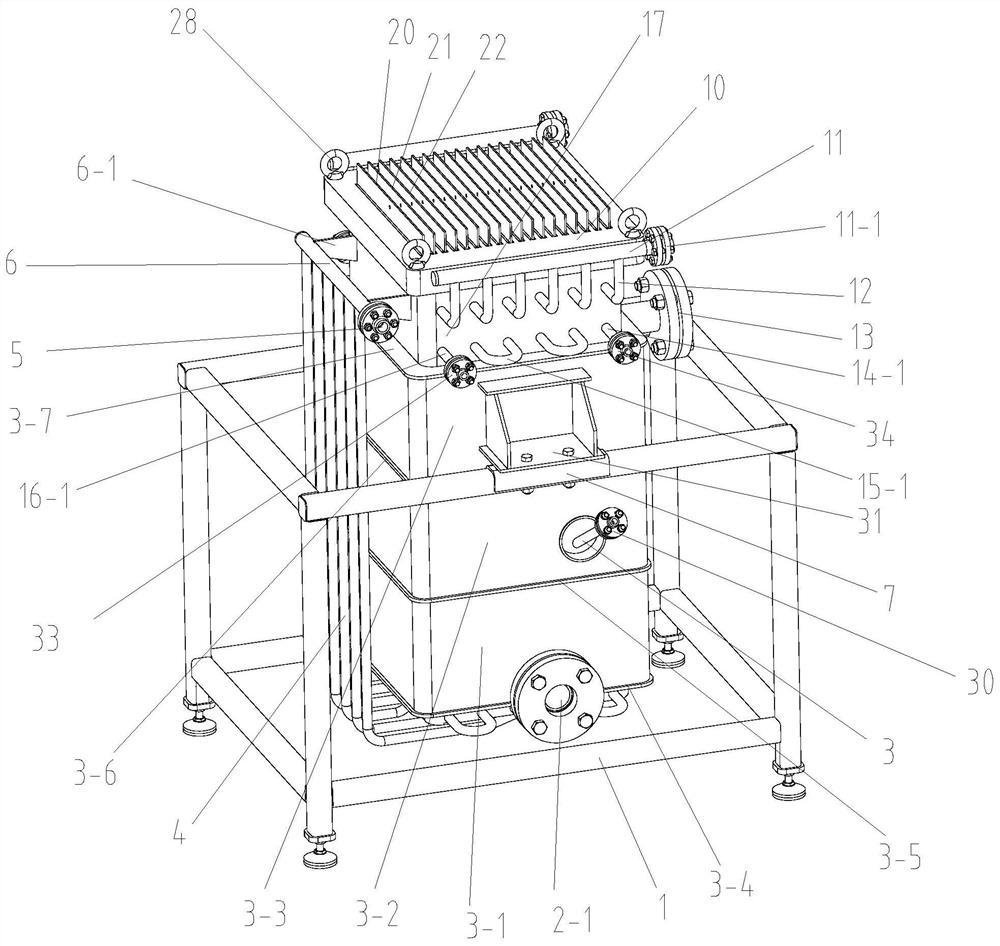

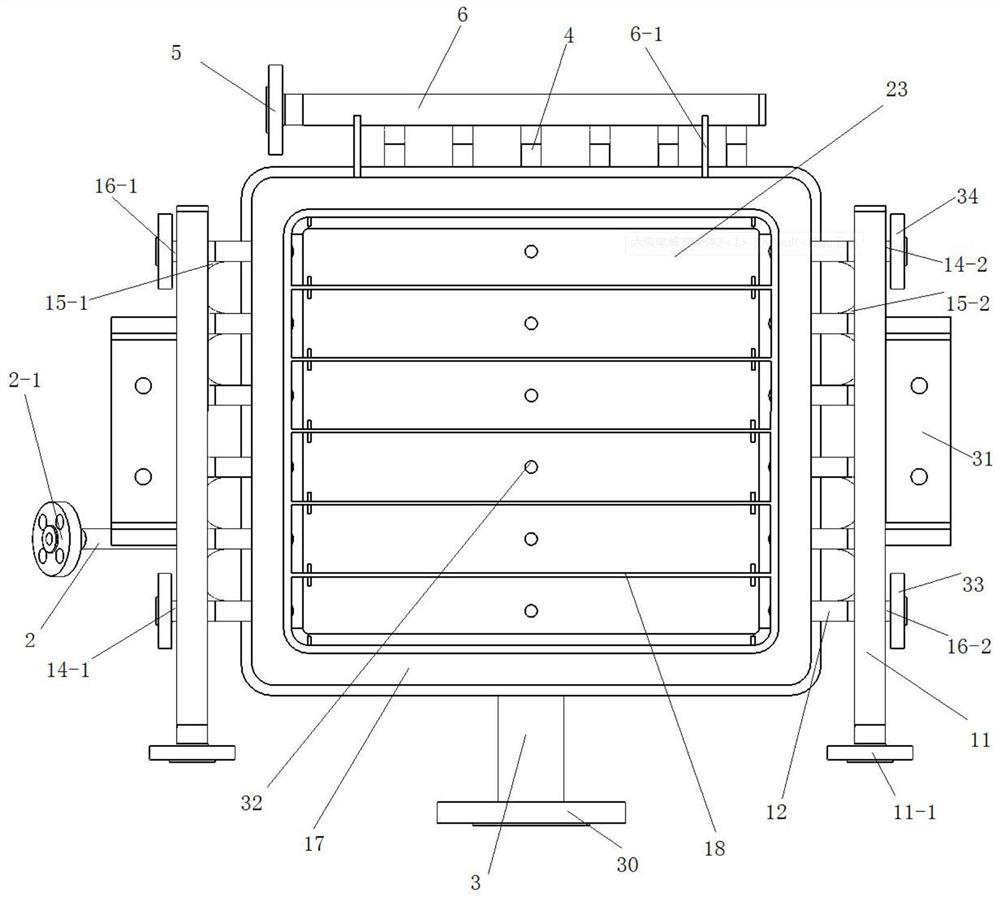

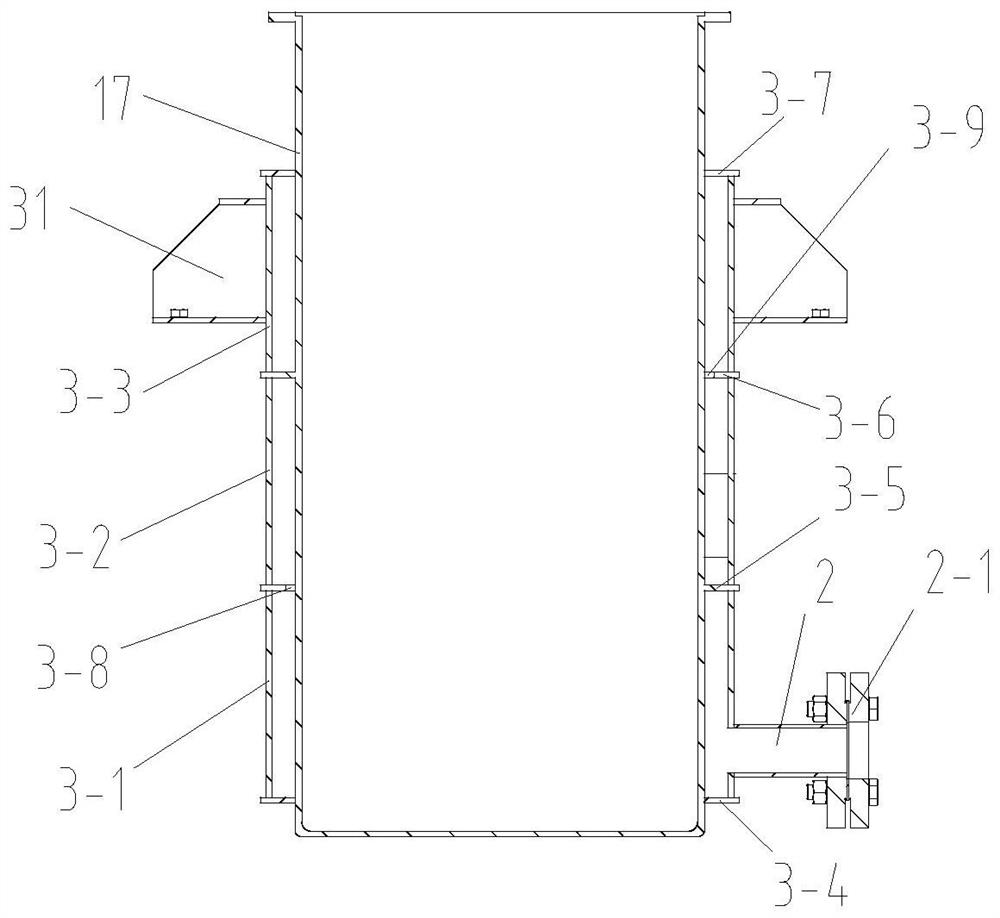

Double-reaction-electrode water half-electrolysis device

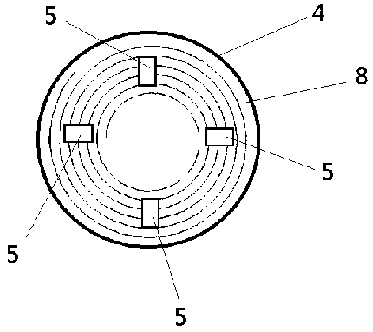

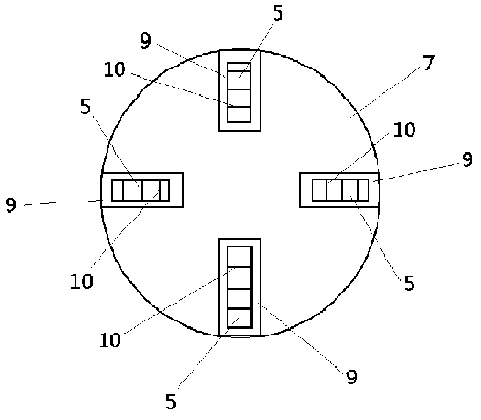

ActiveCN109898092ALow installation costIncrease the rate of electrolysisCellsElectrodesCapacitanceCurrent collector

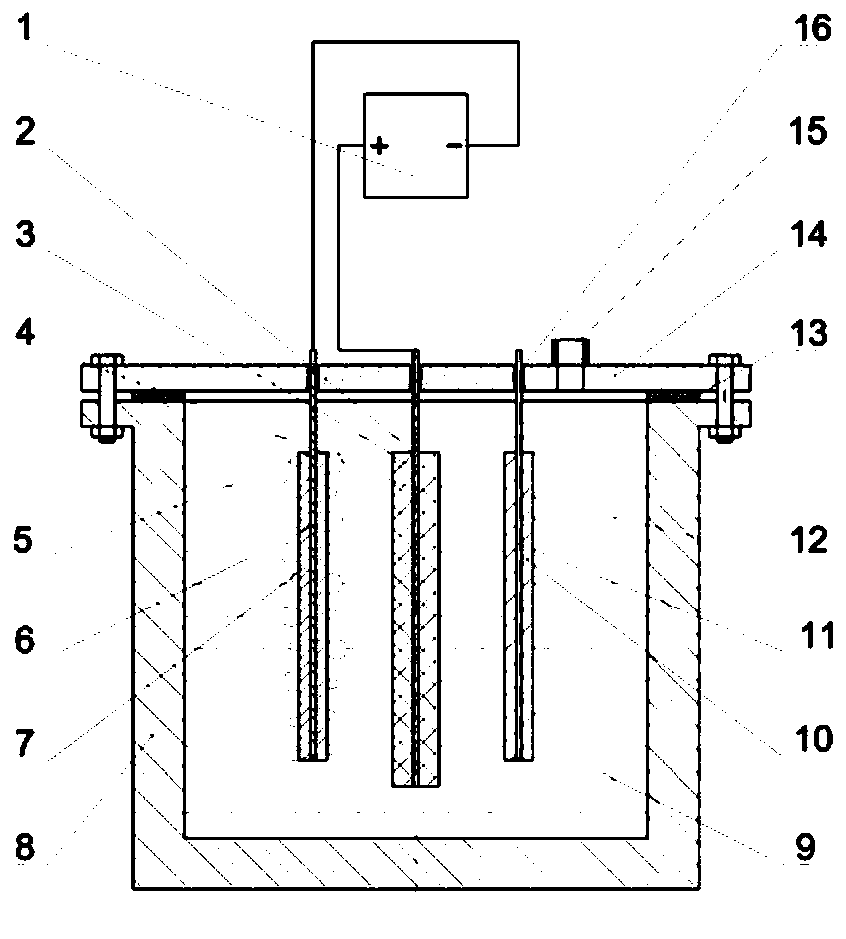

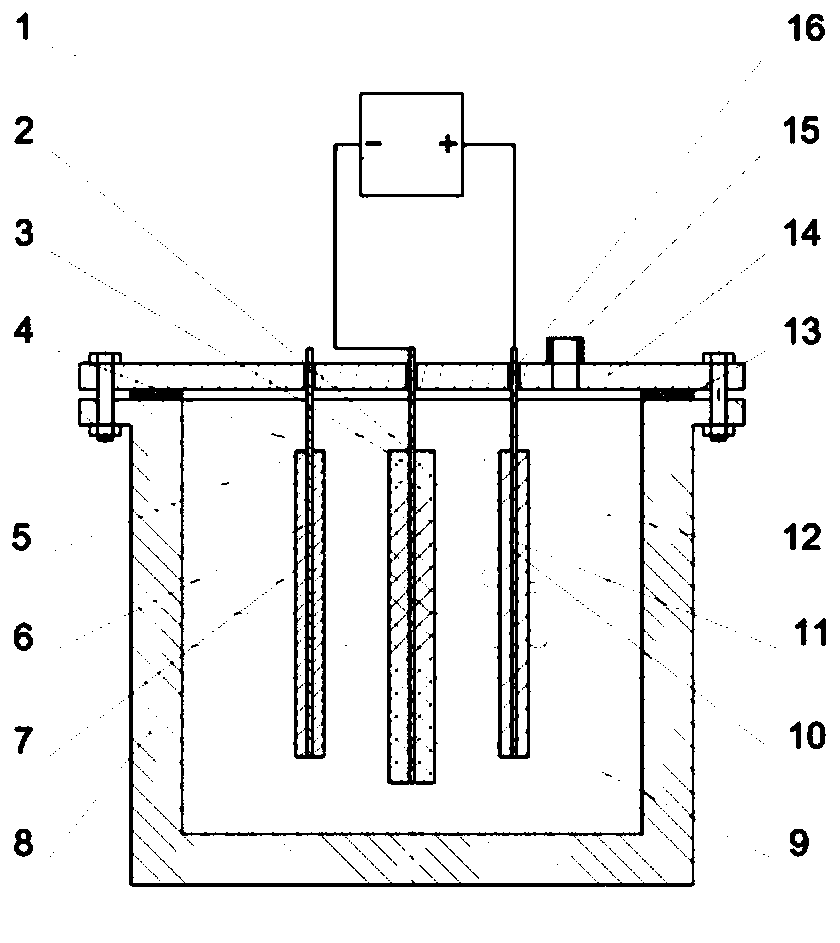

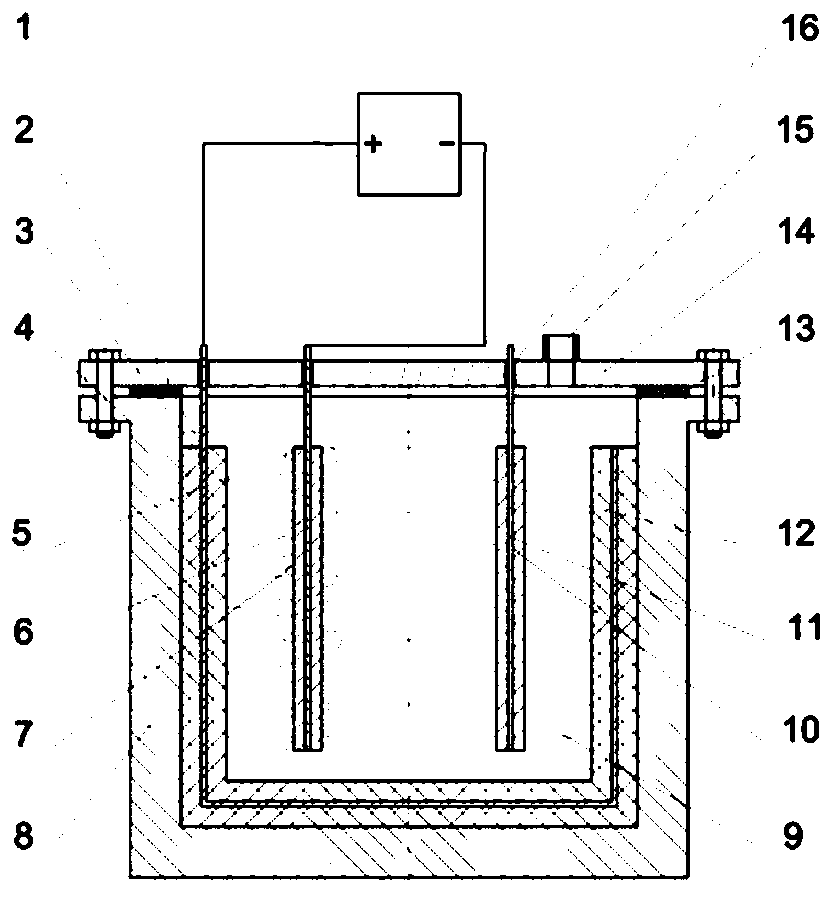

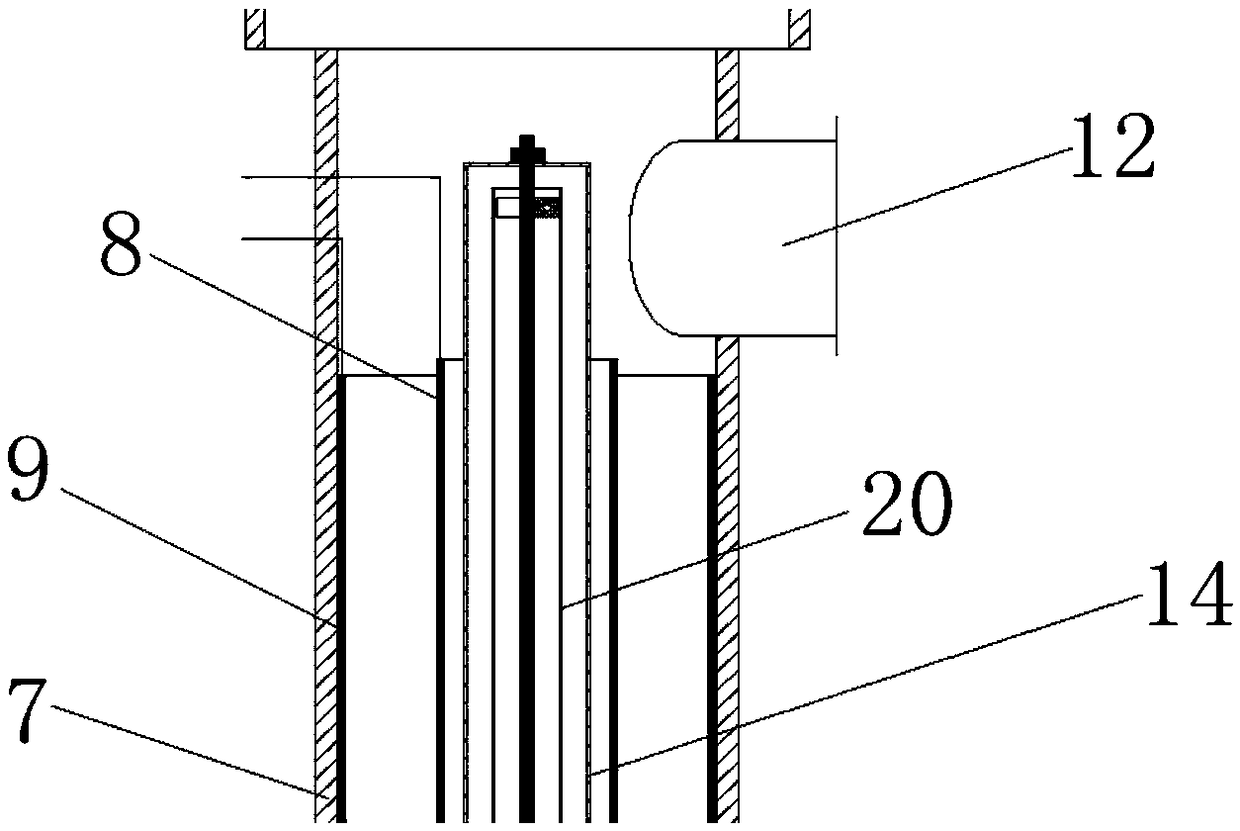

The invention concretely relates to a double-reaction-electrode water half-electrolysis device. The device is characterized in that a reaction electrode I (5) and a reaction electrode II (10) in an electrolytic tank (8) are located at two sides or the other side of a capacitor electrode (2); or the capacitor electrode (2) is laid on the inner wall and the bottom of the electrolytic tank (8), the electrolytic tank (8) provided with the capacitor electrode (2) is filled with an electrolyte (9), and the reaction electrode I (5) and the reaction electrode II (10) are located in the electrolyte (9). A current collector I (3) is connected with the positive electrode of a power supply (1), a current collector II (6) is connected with the negative electrode of the power supply (1), and hydrogen isevolved on a reaction electrode body I (7); or the current collector I (3) is connected with the negative electrode of the power supply (1), a current collector III (11) is connected with the positive electrode of the power supply (1), and oxygen is evolved on a reaction electrode body II (12). The device has the characteristics of avoiding of gas mixing, reduction of the device cost, increase ofthe electrolysis rate and significant reduction of the energy consumption for electrolysis.

Owner:WUHAN UNIV OF SCI & TECH

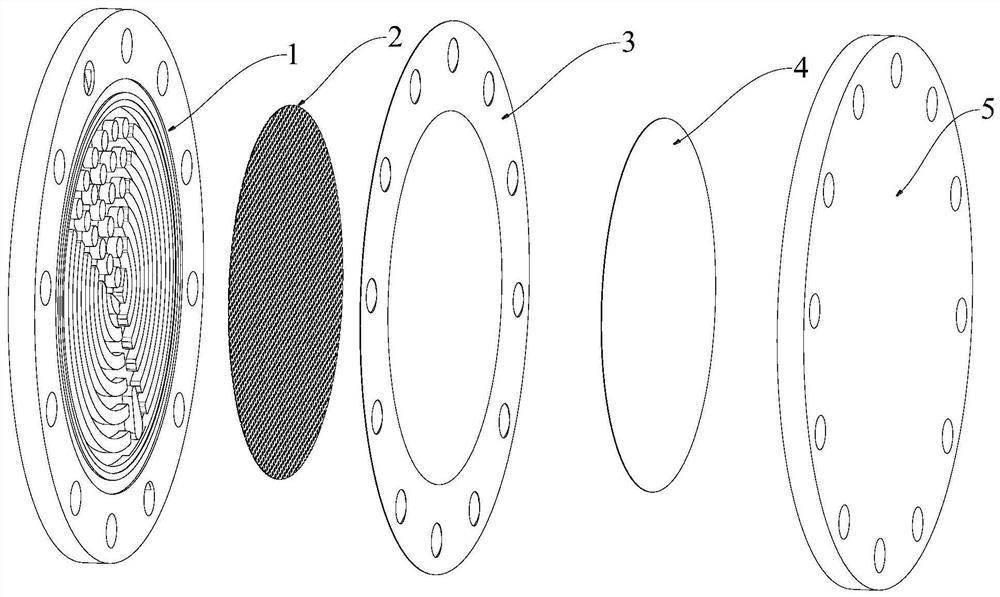

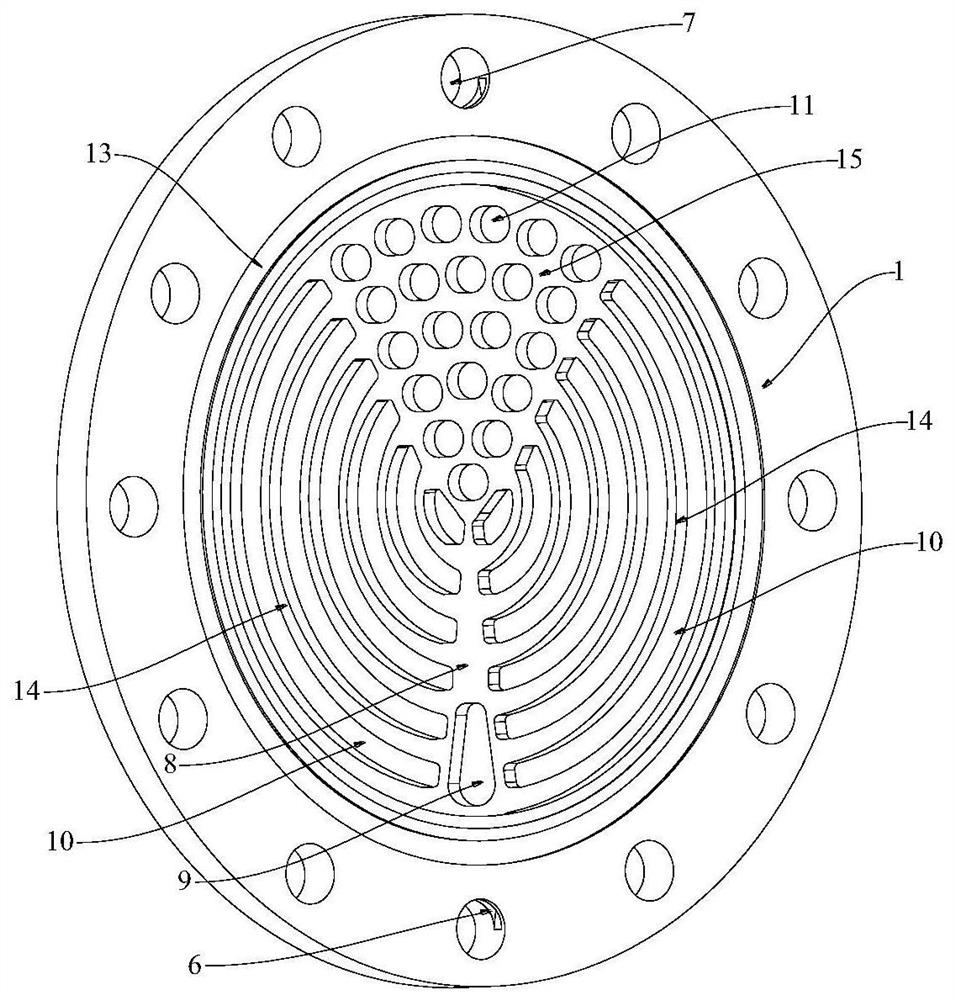

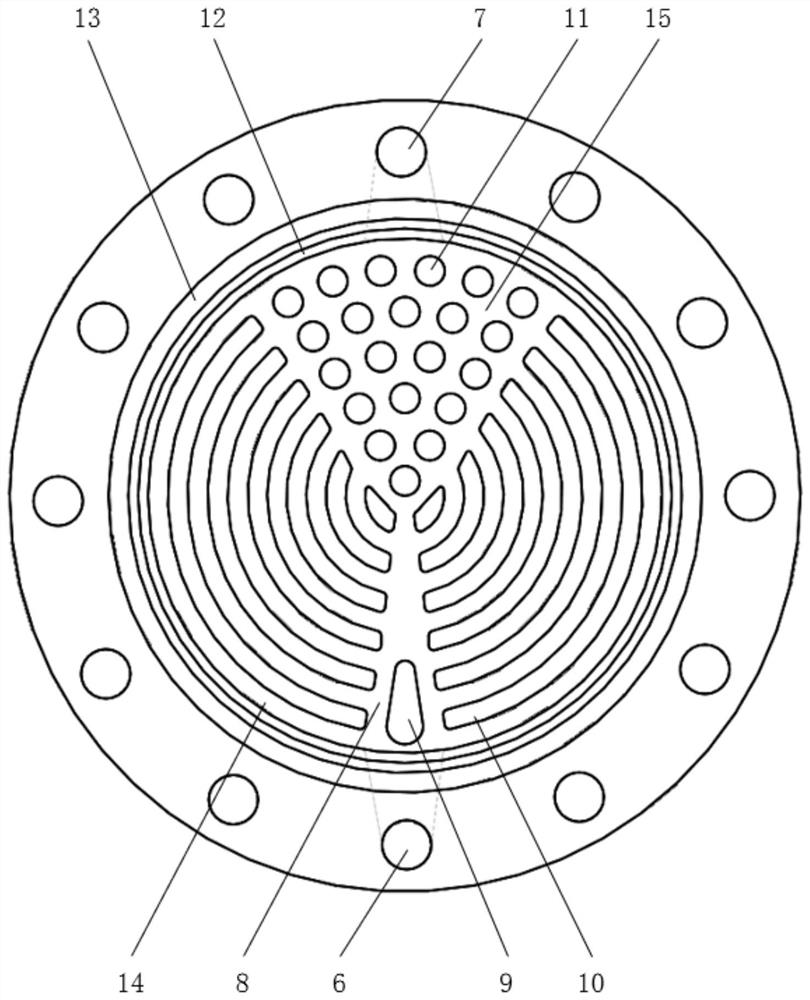

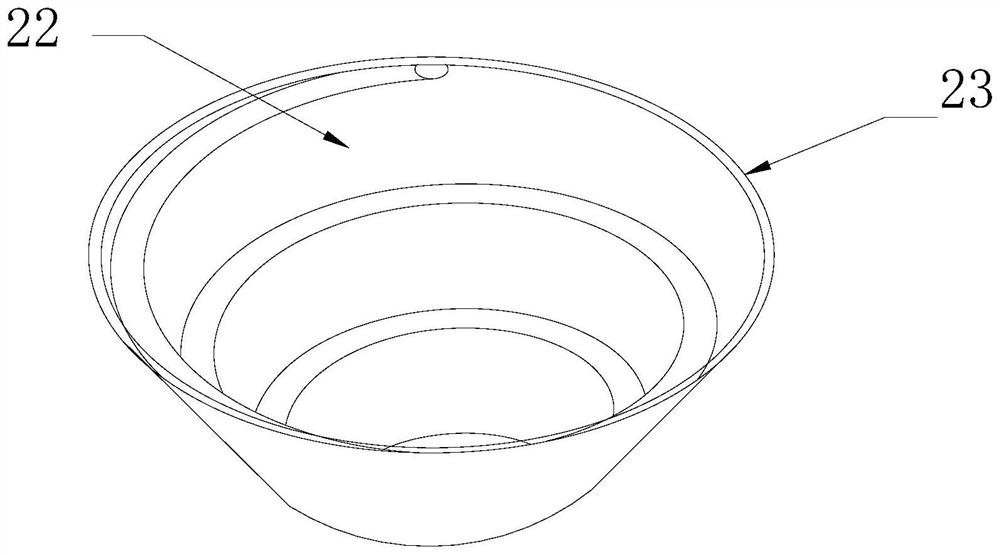

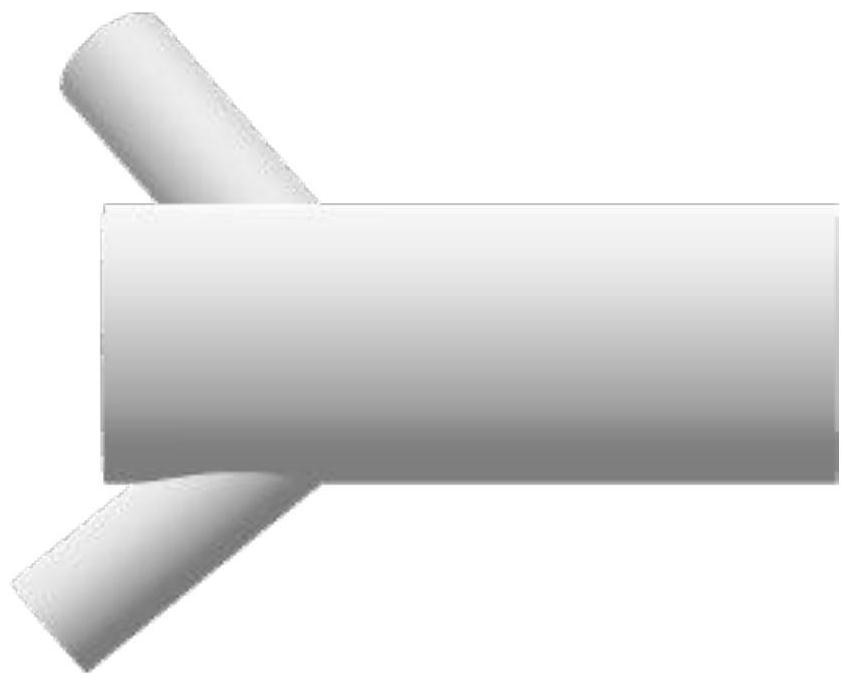

Proton exchange membrane water electrolyser structure and anode plate

The invention discloses a proton exchange membrane water electrolyser structure and an anode plate. The proton exchange membrane water electrolyser structure comprises the anode plate, an anode diffusion layer, a CCM membrane electrode, a cathode diffusion layer and a cathode plate. The anode plate comprises a fluid distribution area, an arc flow channel reaction area and a dotted flow field reaction area; and an anode plate fluid distribution area is an arc-shaped stepped flow field area which is gradually reduced from two sides to the circle center, an ellipse-like distribution structure is arranged in the middle of the area, the part, close to a water inlet, of the anode plate is an arc-shaped flow channel reaction area, and a flow field tail end area is a dot-shaped flow field reaction area. According to the invention, uniform diffusion of reaction water in each flow channel after entering a flow field is ensured by arranging the ellipse-like distribution structure in a fluid distribution area; the flow resistance of reaction water is reduced through an arc-shaped flow channel of the arc-shaped flow field, and the transmission efficiency of the reaction water is improved; and through the dot-matrix type structure of the dot-shaped flow field, formation of bubble plugs is reduced, the mass transfer capacity of reaction water is enhanced, and then the performance of the electrolytic cell is improved.

Owner:WUHAN UNIV OF TECH

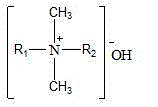

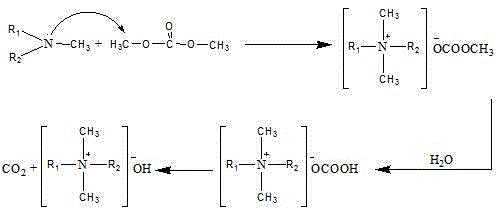

Method for preparing long-chain alkyl ammonium hydroxide by continuous electrolysis

ActiveCN104313634AInhibit side effectsHigh purityElectrolysis componentsElectrolytic organic productionHigh concentrationElectrolysis

The invention relates to a method for preparing long-chain alkyl ammonium hydroxide by continuous electrolysis. The method comprises the following steps: forming a circulation loop by virtue of an anode compartment, an anode static mixer, a heat exchanger and an anode circulating pump; forming a circulation loop by virtue of a cathode compartment, a cathode static mixer, a heat exchanger and a cathode circulating pump; carrying out electrolysis under a certain electrolytic condition; opening an anode charging pump while the electrolytic rate is gradually reduced; mixing a high concentration alkyl ammonium hydrogen carbonate aqueous solution and a low concentration anode liquid in an anode storage tank by virtue of the static mixer and feeding into the anode compartment to maintain the concentration of the anode compartment so as to ensure a relatively high electrolytic rate; and when the cathode liquid reaches a certain concentration, conveying the alkyl ammonium hydrogen carbonate aqueous solution to a product temporary storage tank by virtue of the cathode circulating pump. The method provided by the invention has the advantages of being free of pollution in the preparation process, low in cost and high in product impurity and can be continuously and industrially produced.

Owner:CHINA RES INST OF DAILY CHEM IND

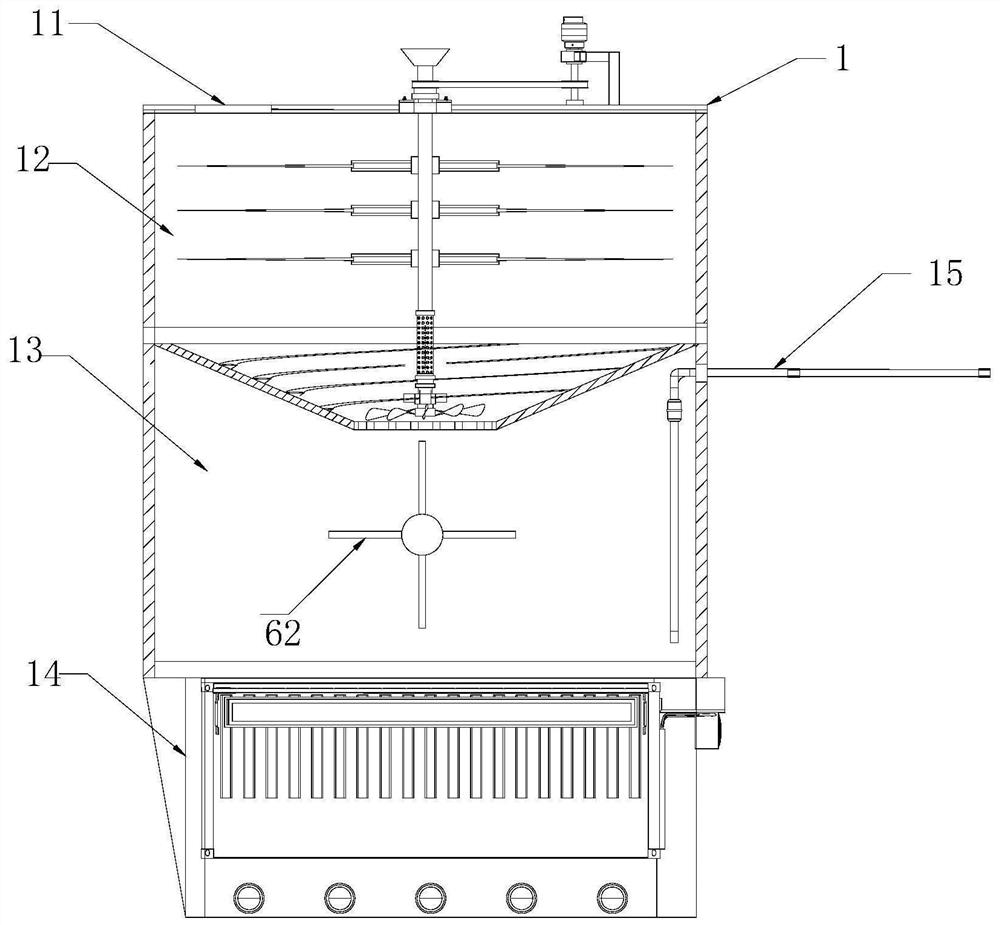

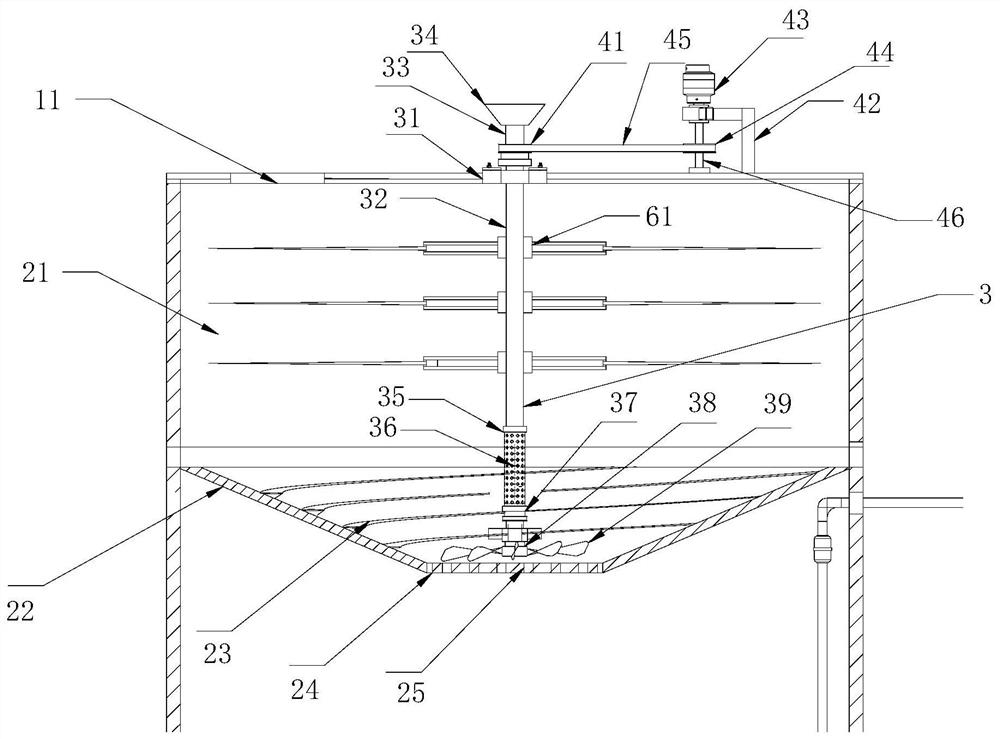

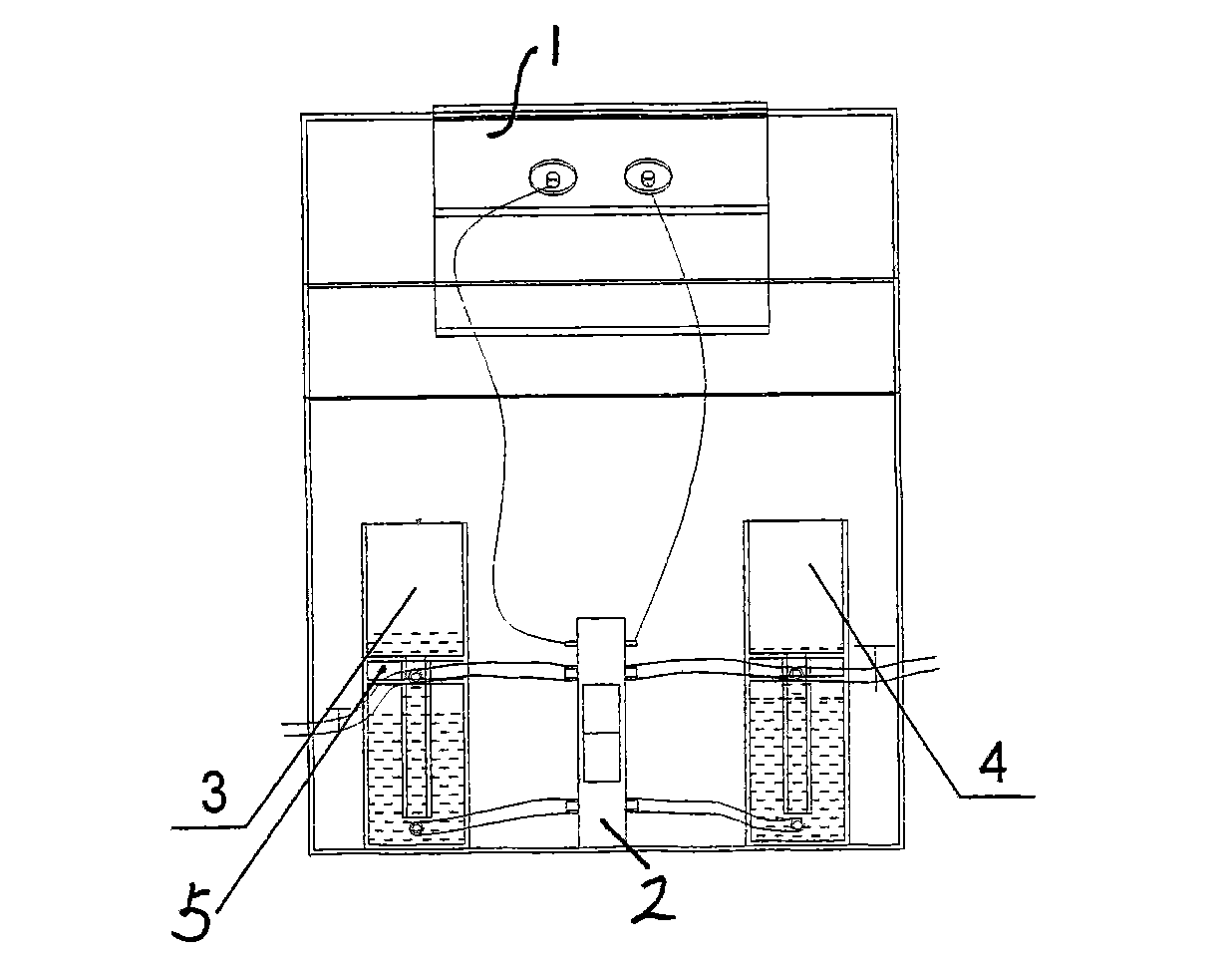

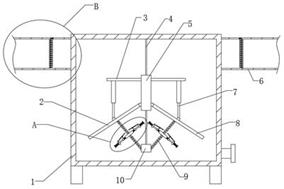

Sewage treatment device and sewage treatment method beneficial to rapid dissolution of sprinkled materials

InactiveCN112174397AImprove the mixing effectIt acts as a material bufferTransportation and packagingMixersWater flowEngineering

The invention relates to the field of sewage treatment, in particular to a sewage treatment device and method beneficial to rapid dissolution of sprinkled materials. The sewage treatment device comprises a water treatment compartment, a feeding cavity, a reaction cavity and a precipitation cavity are formed in the water treatment compartment, the feeding cavity is divided into a feeding space anda conveying space, and the conveying space is integrally designed to be of an inverted-bucket-shaped structure; the diameter of an inner cavity of the conveying space is gradually decreased, a water conveying net plate is arranged at the bottom of the conveying space, a plurality of water conveying holes are formed in the water conveying net plate, a spiral track groove is formed in the inner wallof the conveying space, and a center line pipe shaft is installed in the feeding cavity and installed in the water treatment compartment through a supporting bearing. The center line pipe shaft is ofan inner hollow structure and comprises a stirring section, an outer edge section and a material conveying section. Vortex water flowing in a clockwise rotating mode or an anticlockwise rotating modeis formed in the conveying space, and then the mixing effect of sewage and a flocculating agent is accelerated.

Owner:赵山歌

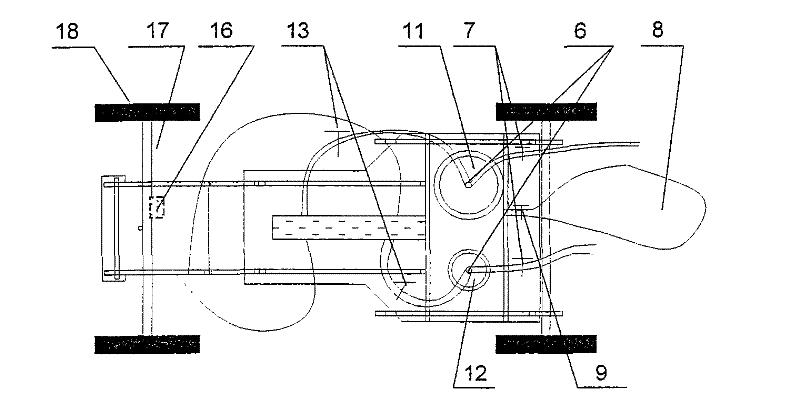

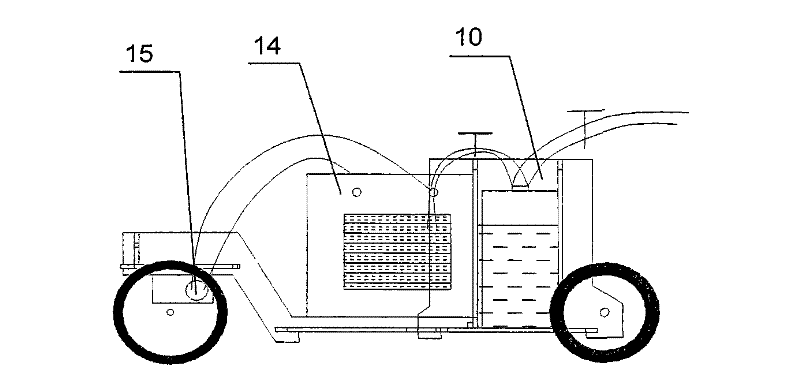

Light-hydrogen-electricity fuel cell automobile model

ActiveCN101570145ALow costImprove energy conversion efficiencyFuel cell controlVehicular energy storageElectricitySolar hydrogen

The invention discloses a light-hydrogen-electricity fuel cell automobile model, which comprises a fuel cell automobile powered by a proton exchange membrane fuel cell; and a proton exchange membrane of the proton exchange membrane fuel cell is connected with hydrogen and oxygen storage devices which are arranged on the fuel cell automobile and supplied with hydrogen and oxygen by a solar hydrogen production device. The automobile model has the advantages of environmental protection, energy conservation, high utilization ratio of fuel, zero emission and zero pollution.

Owner:南通江海港建设工程有限公司

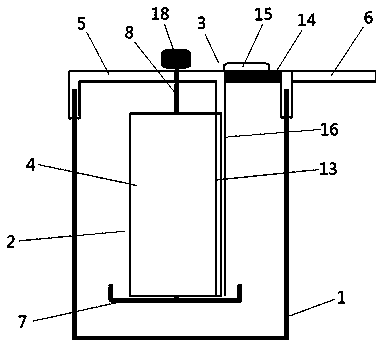

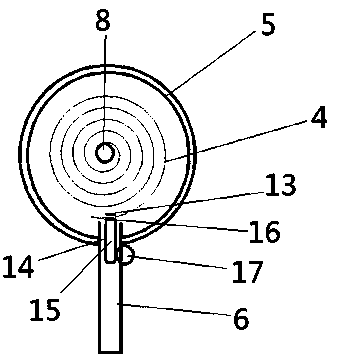

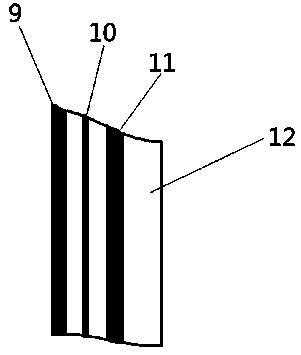

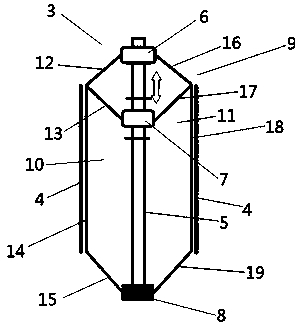

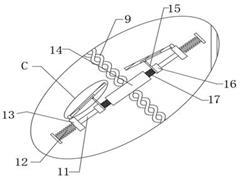

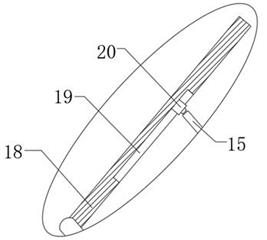

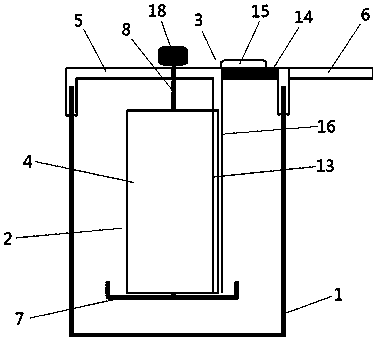

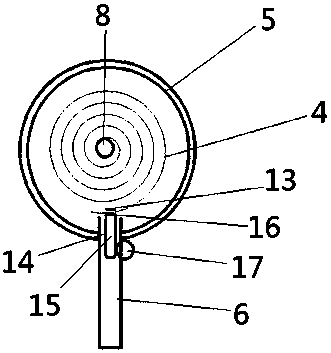

Adjustable ozone electrolysis generator assembly

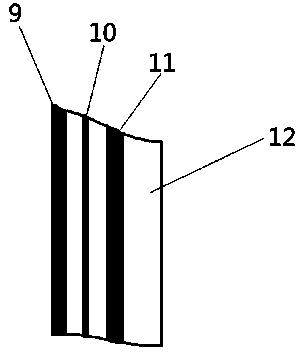

ActiveCN108796541ASmall electrolysis rateIncrease contact areaCellsElectrode shape/formsElectrolysisCathode

The invention relates to an adjustable ozone electrolysis generator assembly. A flexible deformable material is adopted for preparing an anode catalyst membrane plate, a PEM membrane, a cathode catalyst membrane plate and a cathode water bag, the anode catalyst membrane plate, the PEM membrane, the cathode catalyst membrane plate and the cathode water bad are made through integrated packaging, electric deformation of the anode catalyst membrane plate, the PEM membrane, the cathode catalyst membrane plate and the cathode water bag in a spiral electrode assembly can occur synchronously, the spiral electrode assembly is spirally coiled to be cylindrical in a cylindrical anode water trough, a spiral loosening control device is further disposed, the spiral electrode assembly is tightly wound ona vertical shaft in an initial state and has a spiral removing stress and trend, part of the spiral electrode assembly is subjected to spiral removing or tightening under the action of self stress through the spiral loosening control device, thus the electrolysis reaction contact area is increased or decreased, and then the adjustment of electrolysis rate of the ozone preparation process is achieved.

Owner:中氧科技(广州)有限公司

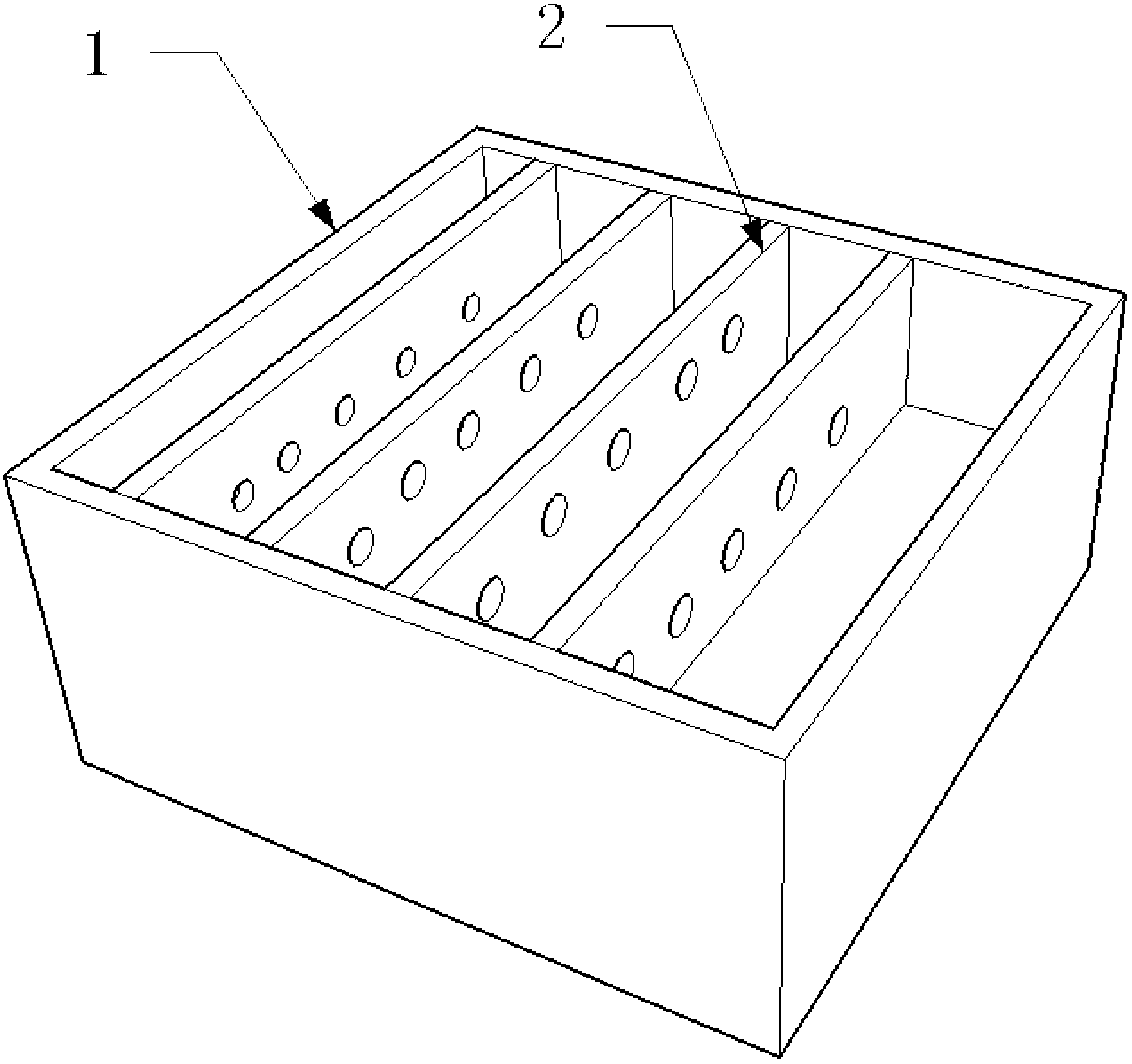

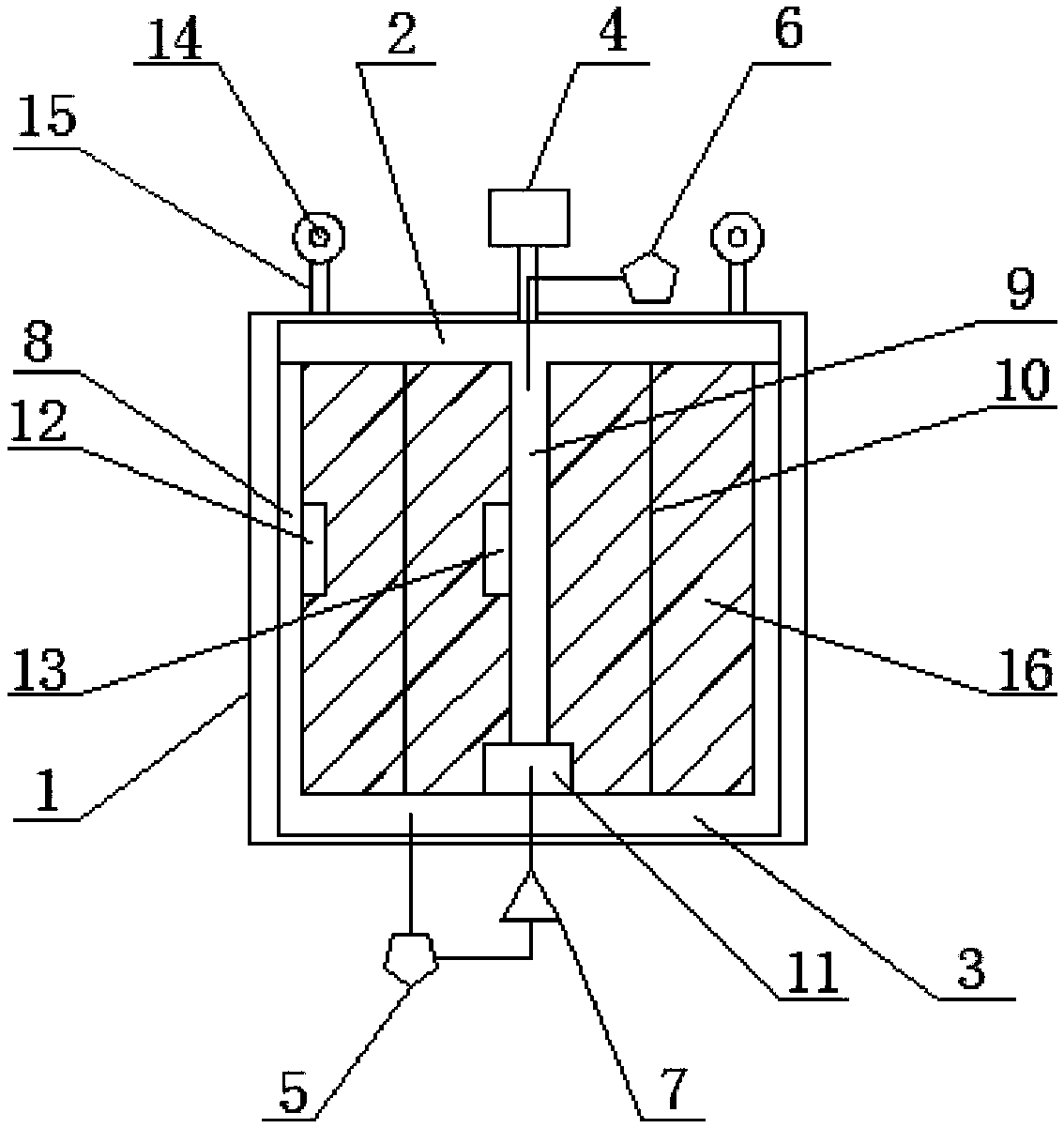

Novel electrolytic tank

InactiveCN102849827APrevent inflowIncrease the rate of electrolysisWater/sewage treatmentElectricityElectrolysis

The invention discloses a novel electrolytic tank which comprises an electrolytic tank body, electrode plates and a power supply device, wherein the electrode plates are arranged in the electrolytic tank body, and are connected with the power supply device; in the concrete embodiment, the plurality of electrode plates are available; every two electrode plates are parallel to each other; the electrode plates are arranged in parallel; the polarities of the two sides of each electrode plate are opposite to each other; and the electrode plates are respectively provided with at least one through hole, so that a liquid can conveniently flow through the electrode plates. In order to guarantee the safety of the novel electrolytic tank, an insulating layer is arranged on the outer wall of the electrolytic tank body, and a protection resistance wire is arranged between the power supply device and the electrode plates.

Owner:天津莱特化工有限公司

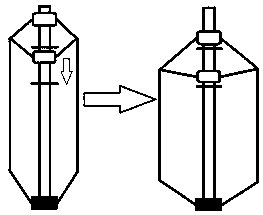

An electrolysis preparation device for ozone

ActiveCN108930049AChange in expansionReduce the degree of expansionCellsElectrode shape/formsElectrolysisEngineering

The invention relates to an electrolysis preparation device for ozone. An anode catalyst membrane plate, a cathode catalyst membrane plate and a PEM membrane in an electrolysis electrode assembly alladopt elastic deformable materials. An electrolysis generator adjusting device is provided and includes a vertical shaft, an adjusting slide block, a supporting slide block, a fixing block and adjusting frames. Adjusting bars and a plurality of pull bars are disposed in each adjusting frame, and are movably hinged to the adjusting slide block and the supporting slide block on the vertical shaft. Aplurality of the adjusting frames are disposed at the periphery direction of the vertical shaft and encircle to form a cylindric shape. The left and right adjusting bars are pushed to move up and down, thus pushing each pull bar hinged with the adjusting bars in the corresponding adjusting frame so that the electrolysis electrode assembly tightly covering the cylindric shape formed by the plurality of adjusting frames is thereupon deformed elastically to a certain degree, and the ozone preparation speed is increased.

Owner:中氧科技(广州)有限公司

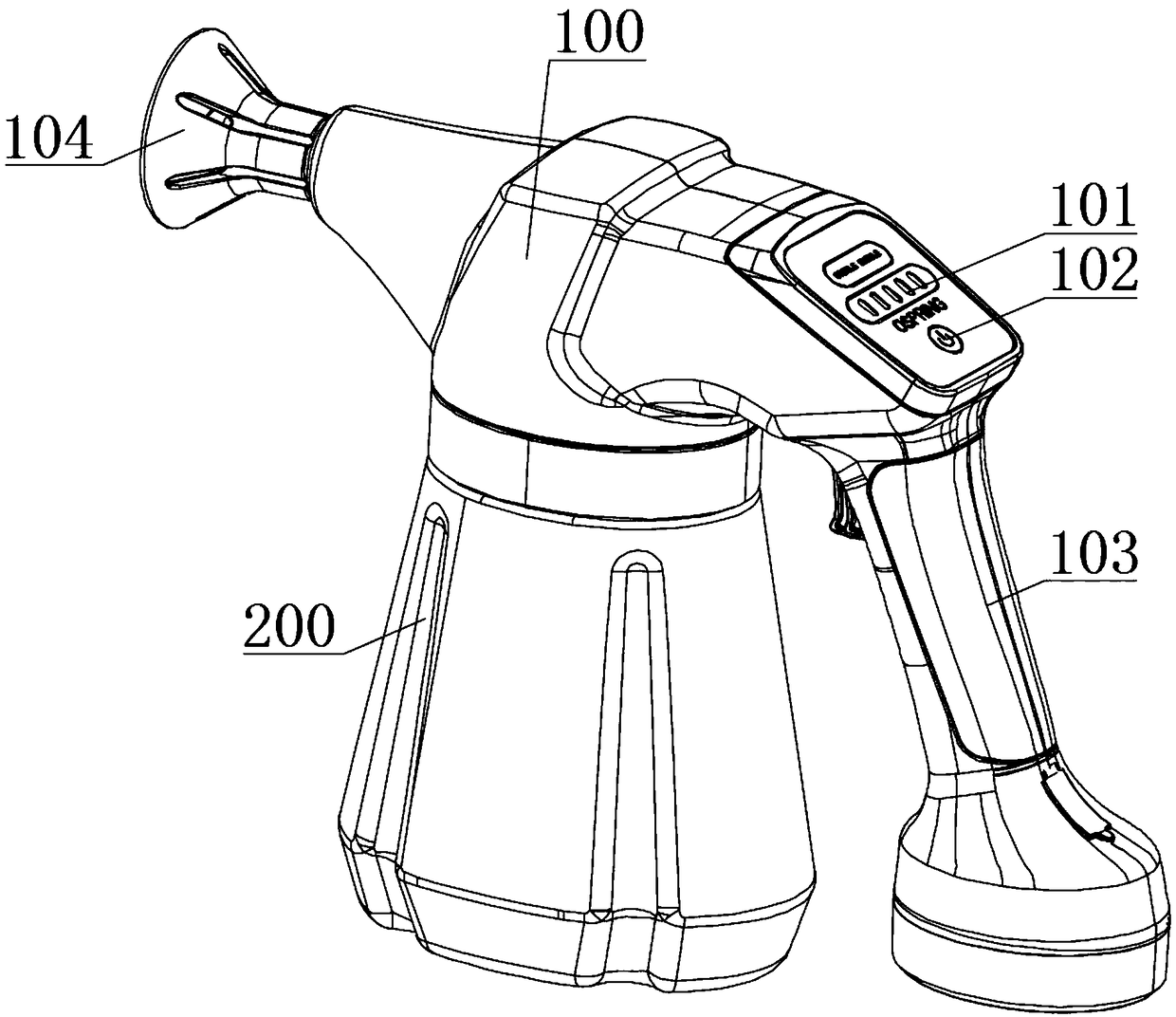

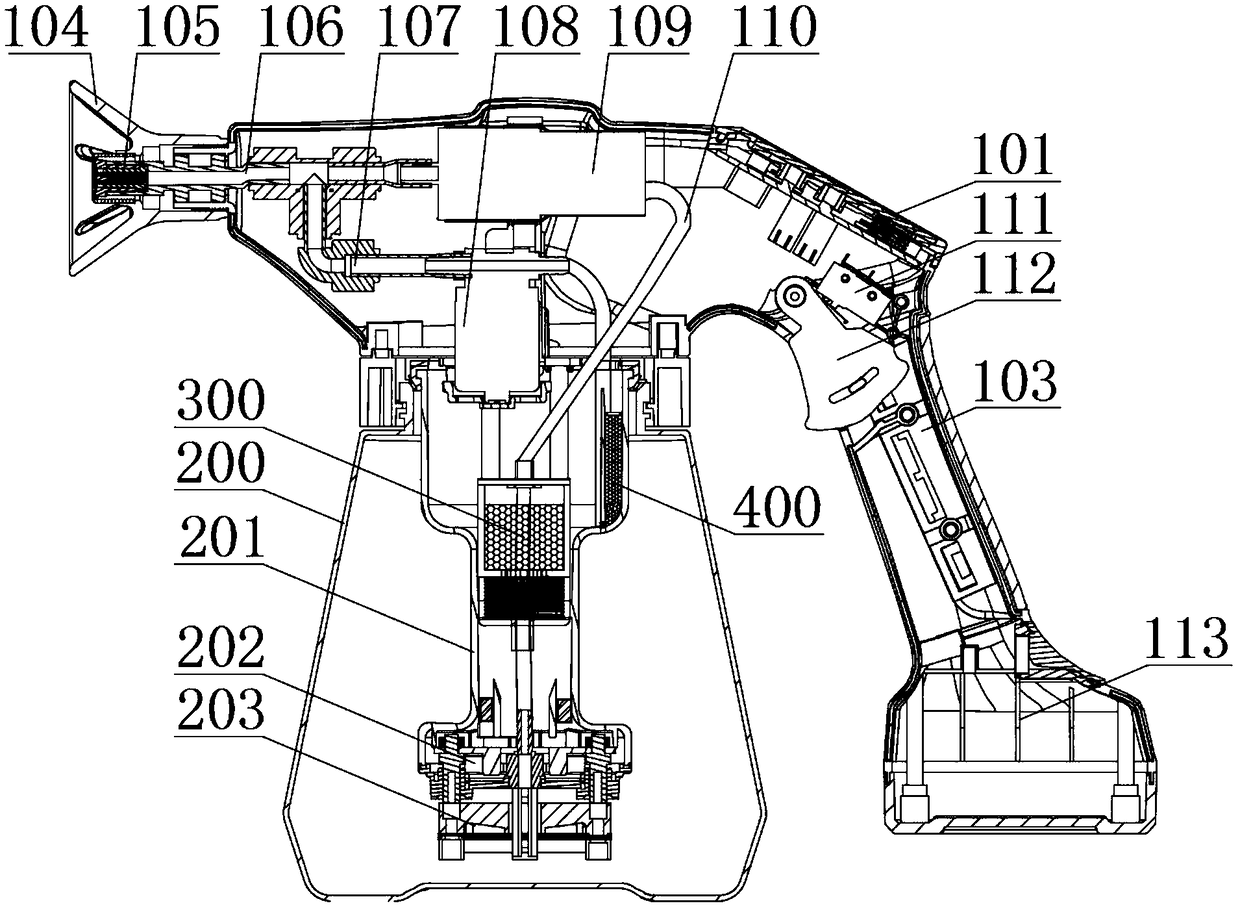

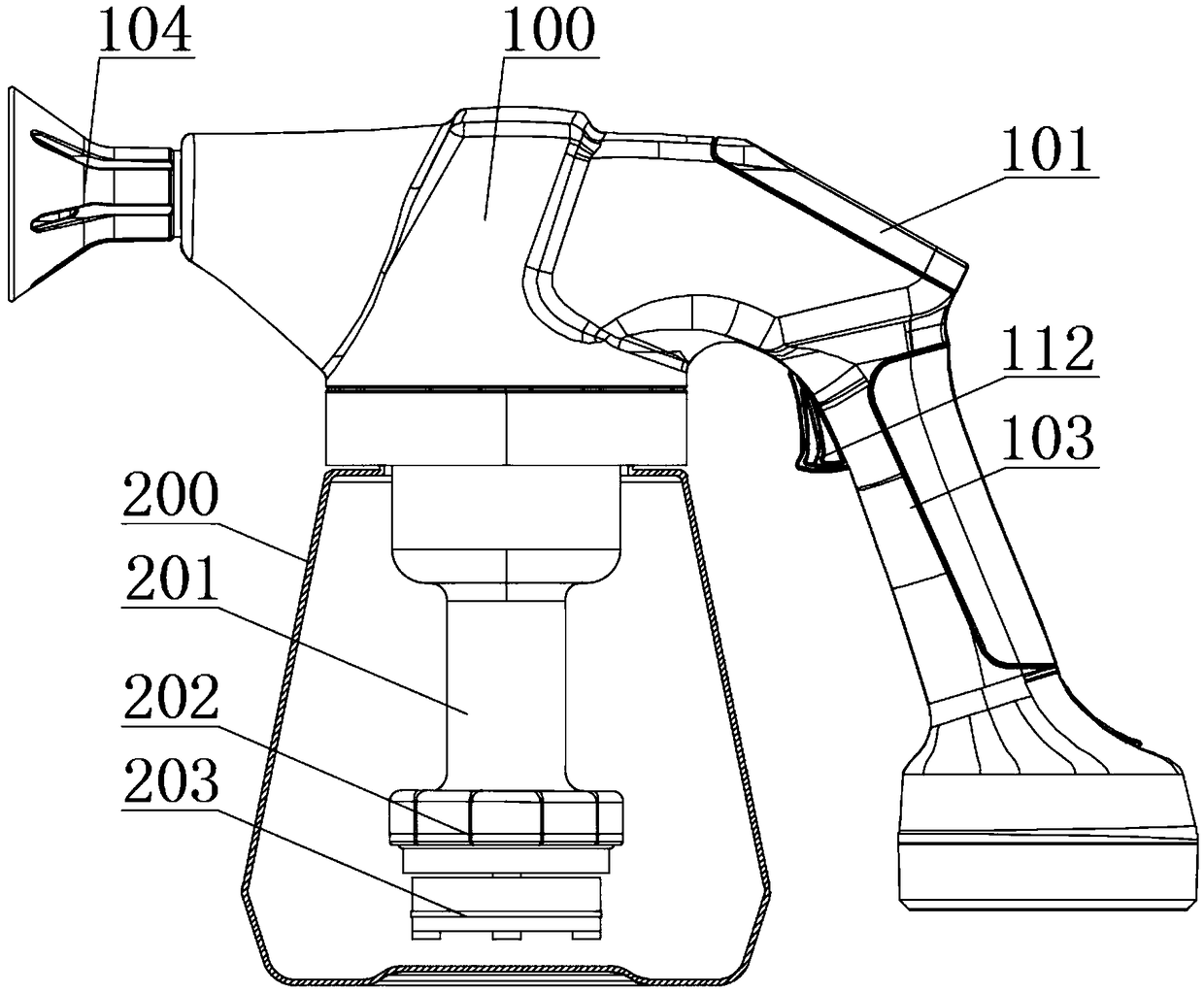

Multifunctional high-efficiency electrolytic water spray kettle for air purification

InactiveCN109340943AIncrease the degree of fragranceIncrease the rate of electrolysisGas treatmentMechanical apparatusUser needsElectrolysis

The invention discloses a multifunctional high-efficiency electrolytic water spray kettle for air purification. The multifunctional high-efficiency electrolytic water spray kettle comprises a kettle body, an electrolytic core and a spray head, wherein electrode modules are arranged at the bottom of the electrolysis core through screws; the spray head further comprises a control screen, a nozzle, awater pump and a handle, wherein a button switch is further arranged in the middle of the control screen, a secondary battery is further arranged in one end of the handle, a trigger switch is furtherarranged at one end, far away from the secondary battery, inside the handle, the electrode modules are arranged at the bottom of the electrolysis core through screws, and the electrode modules can befixedly connected through screws, so that when a user needs to increase the electrolytic rate, other electrode modules are additionally arranged at the bottom of the electrode modules, and the electrode modules can be effectively improved; and a perfume cavity is formed in the electrolytic core, so that the fragrance of water in a water return pipe can be carried into the interior of the kettle body when passing through the perfume cavity, the sprayed water mist has the fragrance, and the indoor air fragrance degree can be increased.

Owner:FUJIAN OSPRING TECH & DEV

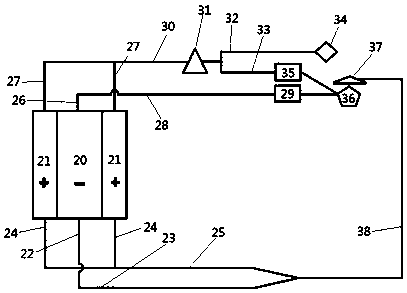

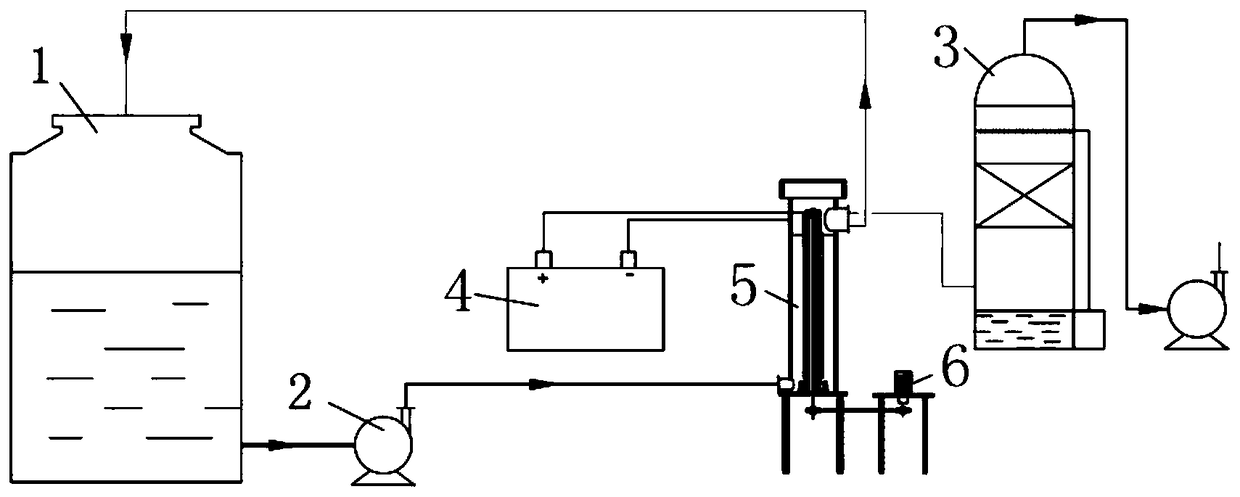

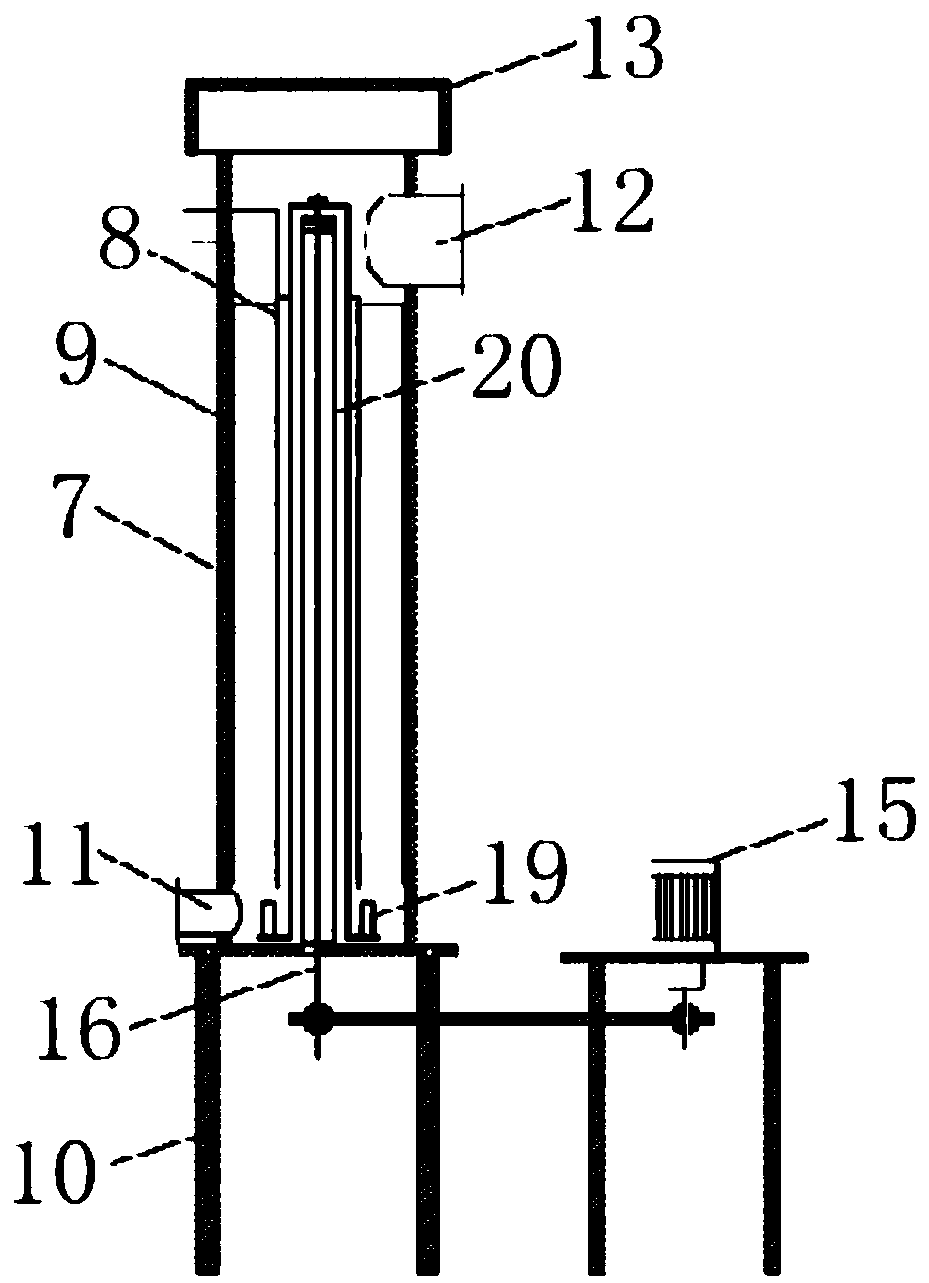

Electrolysis system device and method for electrolyzing copper

InactiveCN108950599AImprove electrolysis efficiencyQuality improvementElectrolysis componentsPhotography auxillary processesElectrolysisEngineering

The invention provides an electrolysis system device and a method for electrolyzing copper. The electrolysis system device comprises a solution storage device, a circulation mechanism, an electrolysismechanism and a recycling mechanism, wherein the solution storage device, the circulation mechanism, the electrolysis mechanism and the recycling mechanism are connected in sequence. The solution storage device is connected with the electrolysis mechanism, the electrolysis mechanism comprises a power supply device, an electrolysis device and a stirring device, and the electrolysis device is respectively connected with the power supply device and the stirring device. According to the electrolysis system device and the method for electrolyzing copper, the electric energy is used for electrolyzing and recycling copper in a copper-containing solution so that the electrolysis rate can be effectively increased; and waste gas generated in the electrolysis process can be absorbed by the recyclingmechanism, the situation that the waste gas is mixed in the solution and reacts with metal again is avoided, and the quality of the metal obtained through electrolytic recovery can be greatly improved.

Owner:苏碧云

Multistage electrolysis method

ActiveCN111074287AThe method steps are simpleReasonable designCellsElectrode shape/formsElectrolytic agentPhysical chemistry

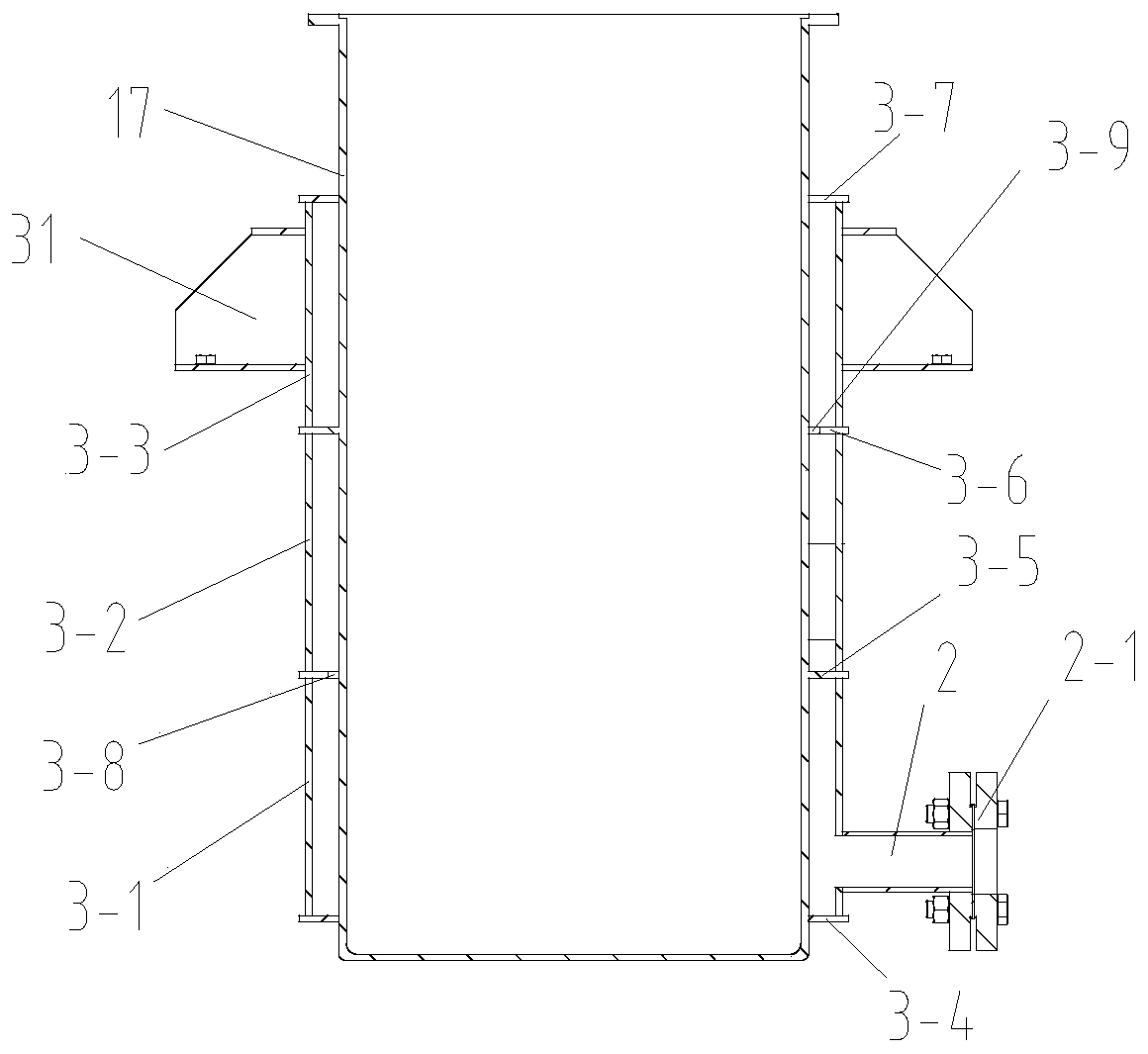

The invention discloses a multistage electrolysis method. The method comprises the following steps: 1, assembling an electrode plate mechanism; 2, installing a guide plate; 3, connecting the electrodeplate mechanism with a cell body; 4, injecting an electrolyte; and 5, electrolyzing the hexavalent uranium solution to form a tetravalent uranium solution. The method is simple in step, reasonable indesign and low in cost, the electrolysis process is convenient to operate, the hexavalent uranium solution forms the tetravalent uranium solution through multi-stage electrolysis, multiple electrodeplates are isolated and completely isolated from the wall plate of the electrolytic cell, short circuit of the electrode plates is avoided, and safety and reliability are high.

Owner:CHINA NUCLEAR POWER ENG CO LTD

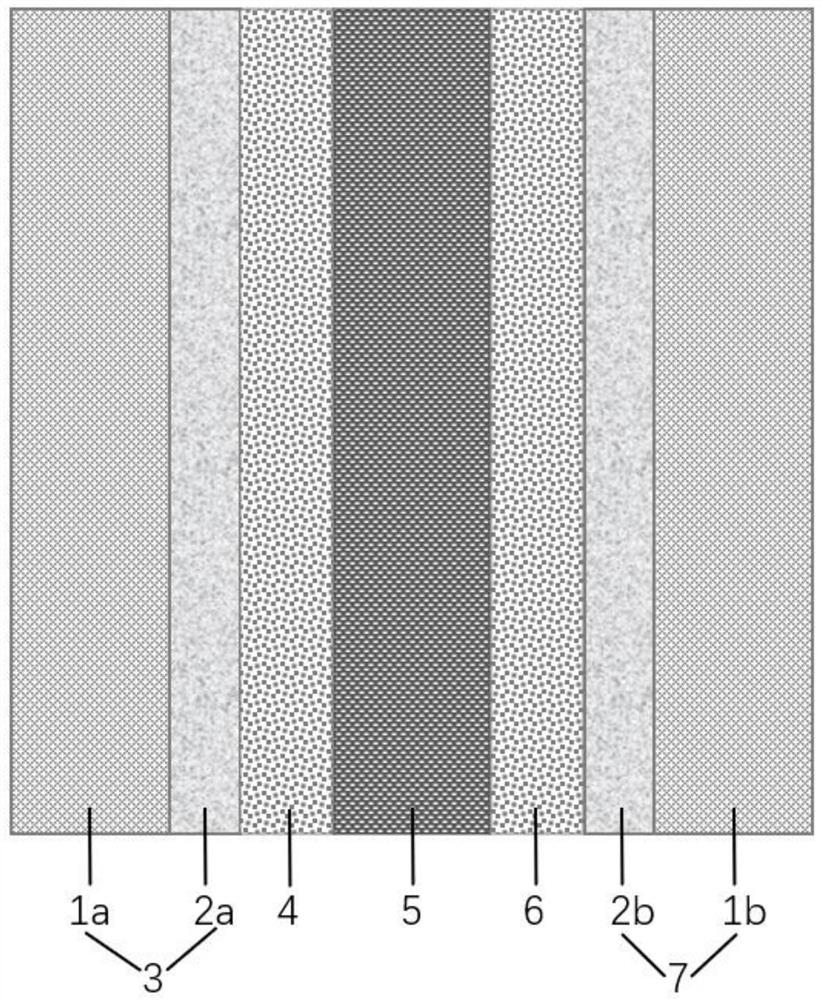

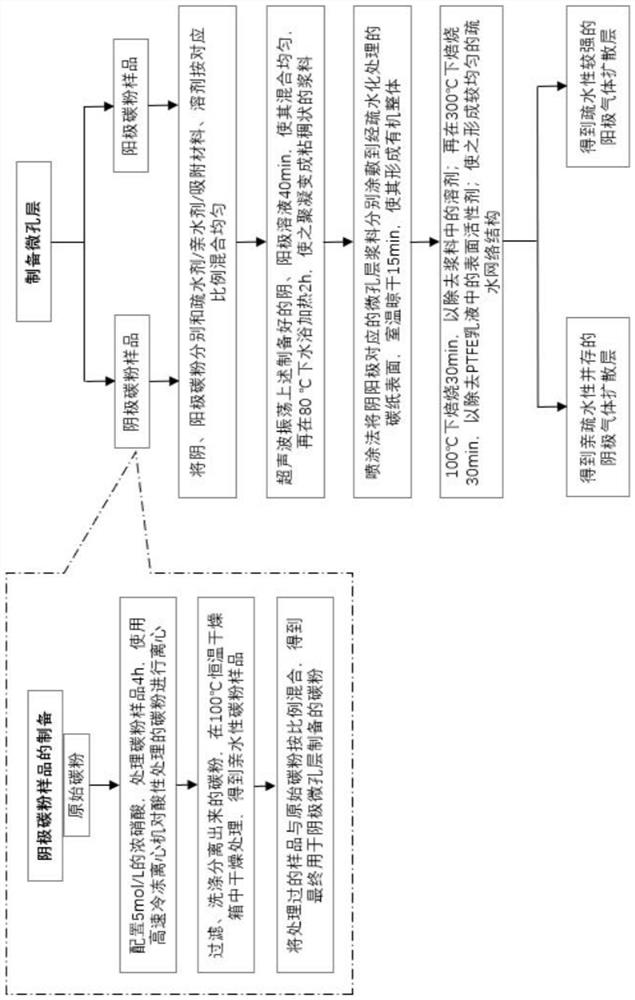

Gas diffusion layer structure of electrochemical oxygen generator membrane electrode and preparation method

PendingCN114164444AIncrease the rate of electrolysisImprove gas diffusivityElectrodesPorous substrateElectrolysis

The invention discloses a gas diffusion layer structure of an electrochemical oxygenerator membrane electrode and a preparation method, the gas diffusion layer structure comprises a cathode gas diffusion layer and an anode gas diffusion layer, the cathode gas diffusion layer comprises a cathode conductive porous substrate layer and a cathode microporous layer arranged at the inner side of the cathode conductive porous substrate layer; the anode gas diffusion layer comprises an anode conductive porous substrate layer and an anode microporous layer arranged on the inner side of the anode conductive porous substrate layer, the anode microporous layer comprises carbon particles and a binder, and the cathode microporous layer comprises carbon particles, a binder, a water absorbent and an adsorption material. Compared with the prior art, the electrochemical oxygen generator has the advantages that the conductivity is good, the hydrophilic and hydrophobic properties of the cathode gas diffusion layer and the anode gas diffusion layer are different, the gas diffusion performance and the water management performance of the electrochemical oxygen generator are improved, the water-gas distribution performance of the cathode gas diffusion layer and the anode gas diffusion layer is optimized, the electrolysis rate of the anode side water is further improved, and the electrochemical oxygen generator is more stable. And oxygen can be stably produced under the condition of low humidity.

Owner:江西德合医疗器械有限公司

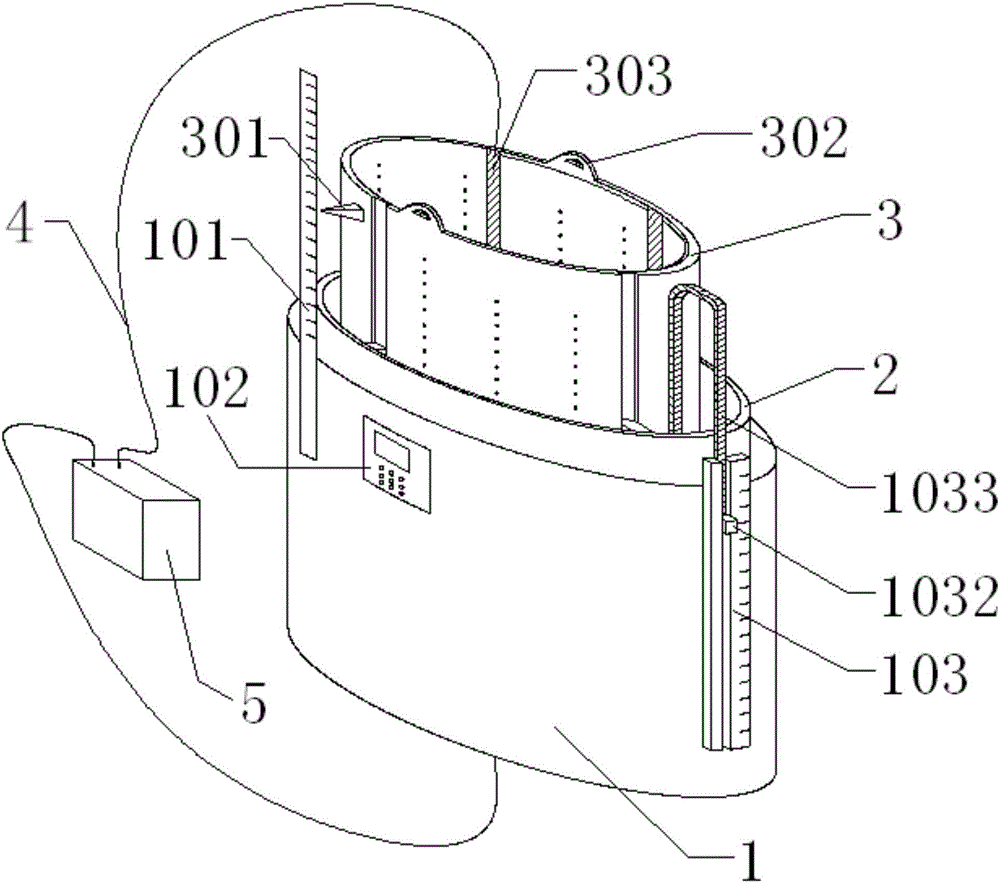

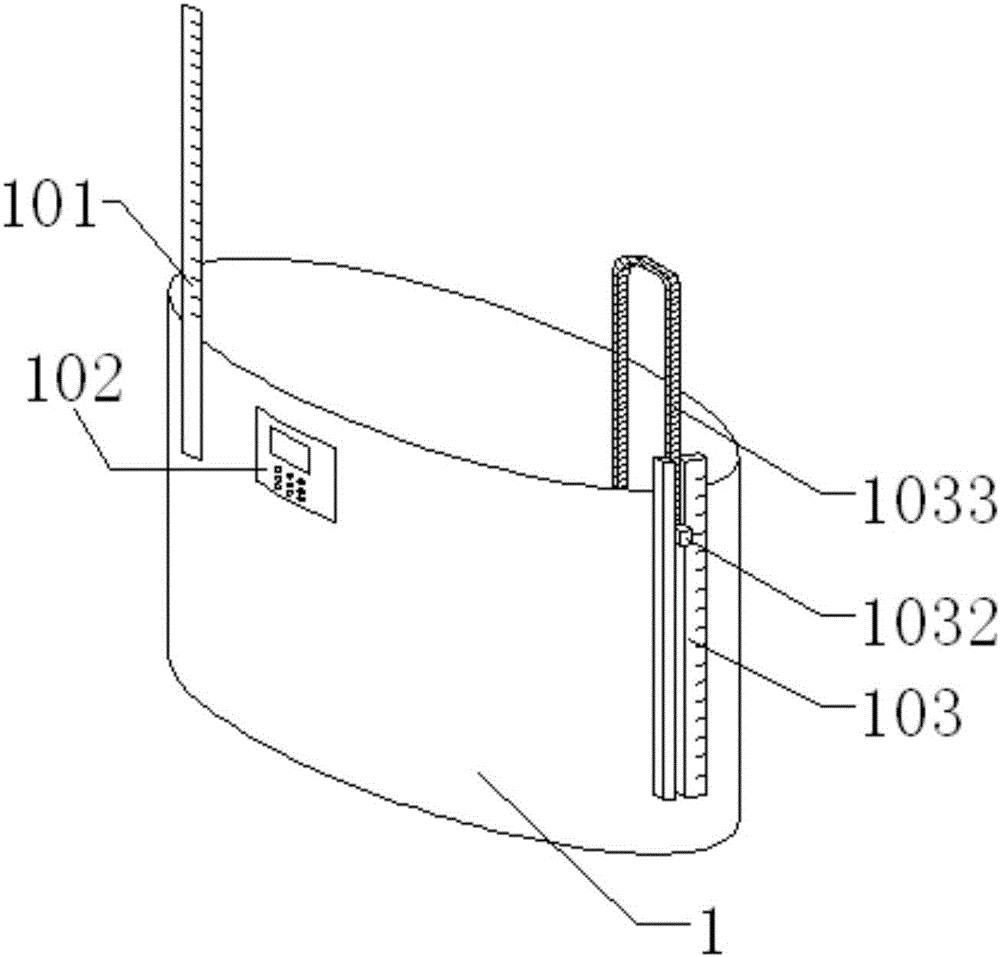

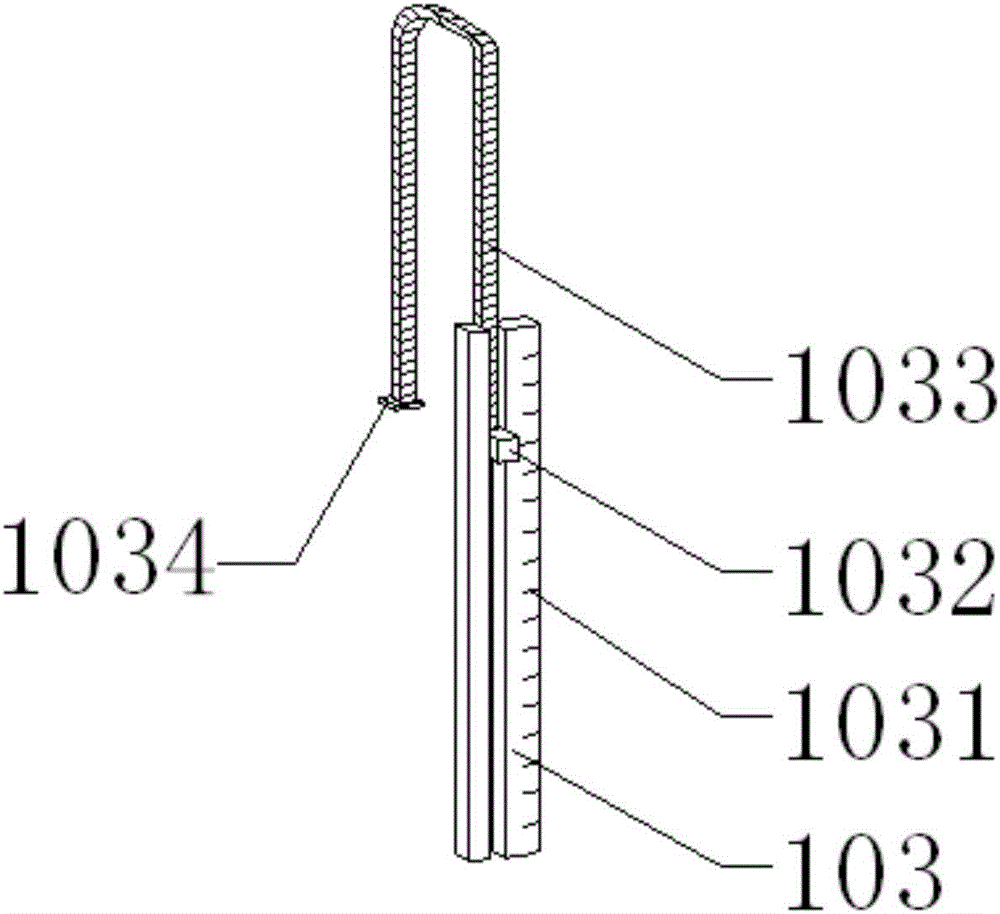

Weak acid electrolyzed water generator capable of improving water outlet stability

PendingCN113428946AIncrease the rate of electrolysisNot blockedSpecific water treatment objectivesTreatment involving filtrationThermodynamicsElectrolysed water

The invention discloses a weak acid electrolyzed water generator capable of improving the water outlet stability, which comprises an electrolysis tank, wherein the inner wall of the electrolysis tank is fixedly connected with a first fixing block and a second fixing block, the outer walls of the upper portions of the two sides of the first fixing block are fixedly connected with fixing plates correspondingly, an anode plate and a cathode plate are hinged to the outer walls of the lower portions of the two sides of the first fixing block correspondingly, waterproof electric push rods are arranged between the anode plate and the fixing plate and between the cathode plate and the fixing plate, elastic winding ropes are arranged between the anode plate and the second fixing block and between the cathode plate and the second fixing block, rotating discs are arranged on the outer walls of the elastic winding ropes, a plurality of sliding rods are fixedly connected to the outer wall of the rotating disc, a first balancing weight, a second balancing weight and a sliding plate are sequentially and slidably connected to the outer wall of each sliding rod, and the sliding plate is fixedly connected with the second balancing weight. According to the invention, the solution around the anode plate and the cathode plate can generate turbulent flow, so that the solution ceaselessly flows to the vicinity of the anode plate and the cathode plate, and the electrolysis rate is greatly accelerated.

Owner:安徽聚鹏装备科技有限公司

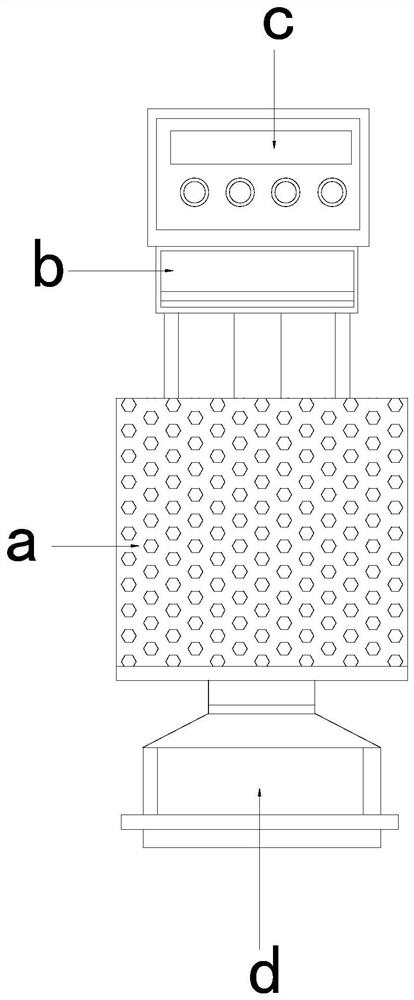

Porous medium auxiliary molten salt electrolysis metal refining device

ActiveCN106702435AImprove refining effectAvoid affecting the effect of useCellsElectrolysisMetal device

The invention discloses a porous medium auxiliary molten salt electrolysis metal refining device, and belongs to the field of molten salt electrolysis metal refining devices. The device comprises a shell, an outer barrel and an inner barrel, wherein a through hole is formed in a barrel body of the inner barrel; an electrode is fixed on the inner wall of the inner barrel; the inner barrel is positioned in the outer barrel; a heating device is arranged on the outer side of the outer barrel; and the outer barrel is positioned in the shell. Multiple cylindrical projections are arranged on the inner wall of the through hole; lattices are arranged on the end surfaces of two ends of the through hole; and the radius of the end surfaces of two ends of the through hole is smaller than the radius of the cross section of the middle part of the through hole. The device aims to overcome the defect of incapability of smoothly performing electrolysis refining due to incapability of fixing electrolytes between crude metal and refined metal with close densities in the molten salt electrolysis refining of metal melts in the prior art, realizes fixation of the electrolytes between the crude metal and the refined metal with close densities, widens the application range of a molten salt electrolysis refining technology, and improves the metal refining effect.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Light-hydrogen-electricity fuel cell automobile model

ActiveCN101570145BLow costImprove energy conversion efficiencyFuel cell controlVehicular energy storageElectricityProton

The invention discloses a light-hydrogen-electricity fuel cell automobile model, which comprises a fuel cell automobile powered by a proton exchange membrane fuel cell; and a proton exchange membrane of the proton exchange membrane fuel cell is connected with hydrogen and oxygen storage devices which are arranged on the fuel cell automobile and supplied with hydrogen and oxygen by a solar hydrogenproduction device. The automobile model has the advantages of environmental protection, energy conservation, high utilization ratio of fuel, zero emission and zero pollution.

Owner:南通江海港建设工程有限公司

A speed-adjustable ozone electrolysis preparation device

The invention relates to a speed-adjustable ozone electrolysis preparation device. The present invention uses an electrolytic generator adjusting device, and by means of the adjusting device, the diameter of the cylinder surrounded by several adjusting rods becomes larger, so that the electrolytic electrode assembly covered on the outside of the cylinder undergoes a certain elastic deformation , so that the electrolysis electrode assembly can be expanded, so that the contact area with the electrolyte increases, thereby increasing the electrolysis rate, thereby increasing the ozone production rate; turning the rotating screw in the opposite direction makes the electrolysis electrode assembly retract, reducing the electrolysis rate. The contact area reduces the electrode rate; thereby realizing the adjustment and control of the efficiency of ozone electrolysis.

Owner:中氧科技(广州)有限公司

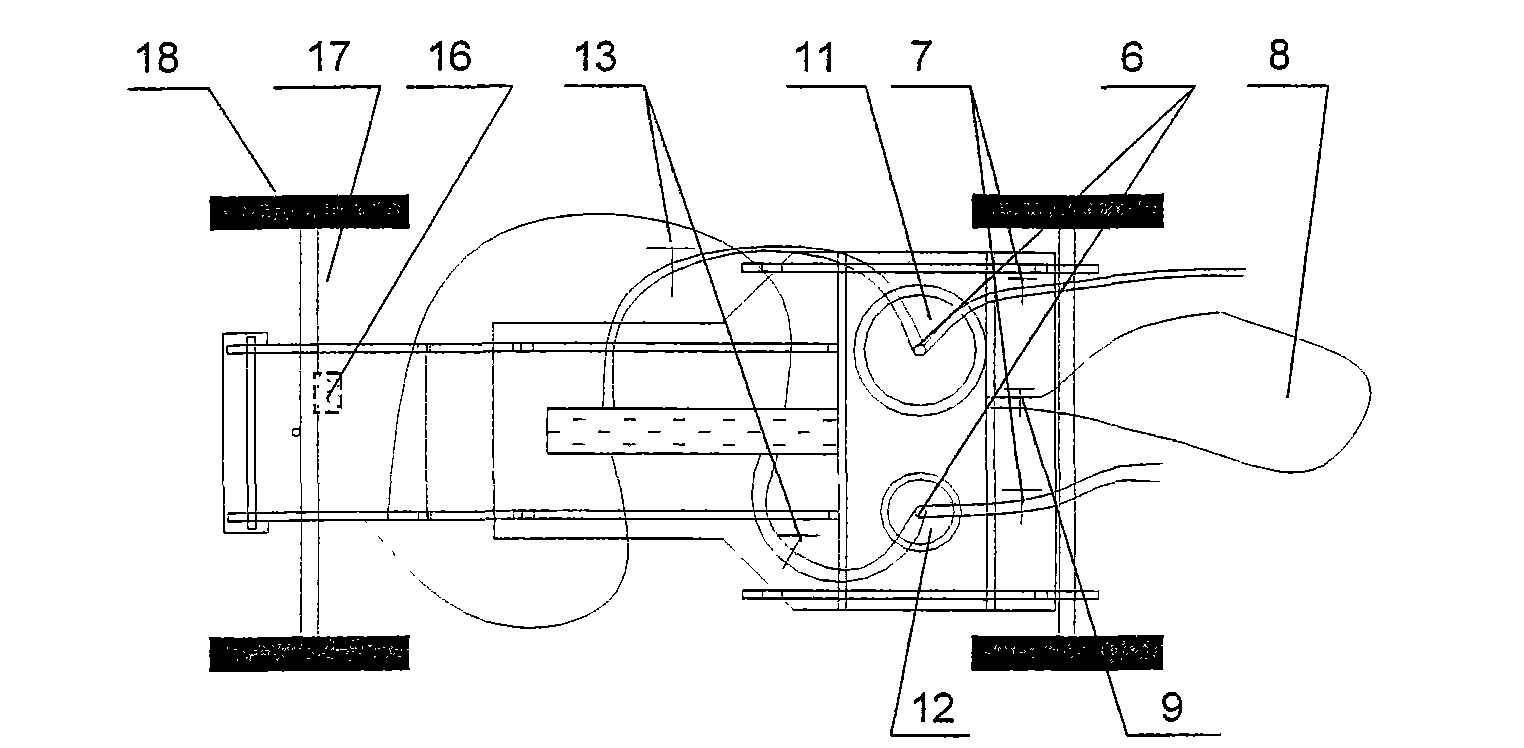

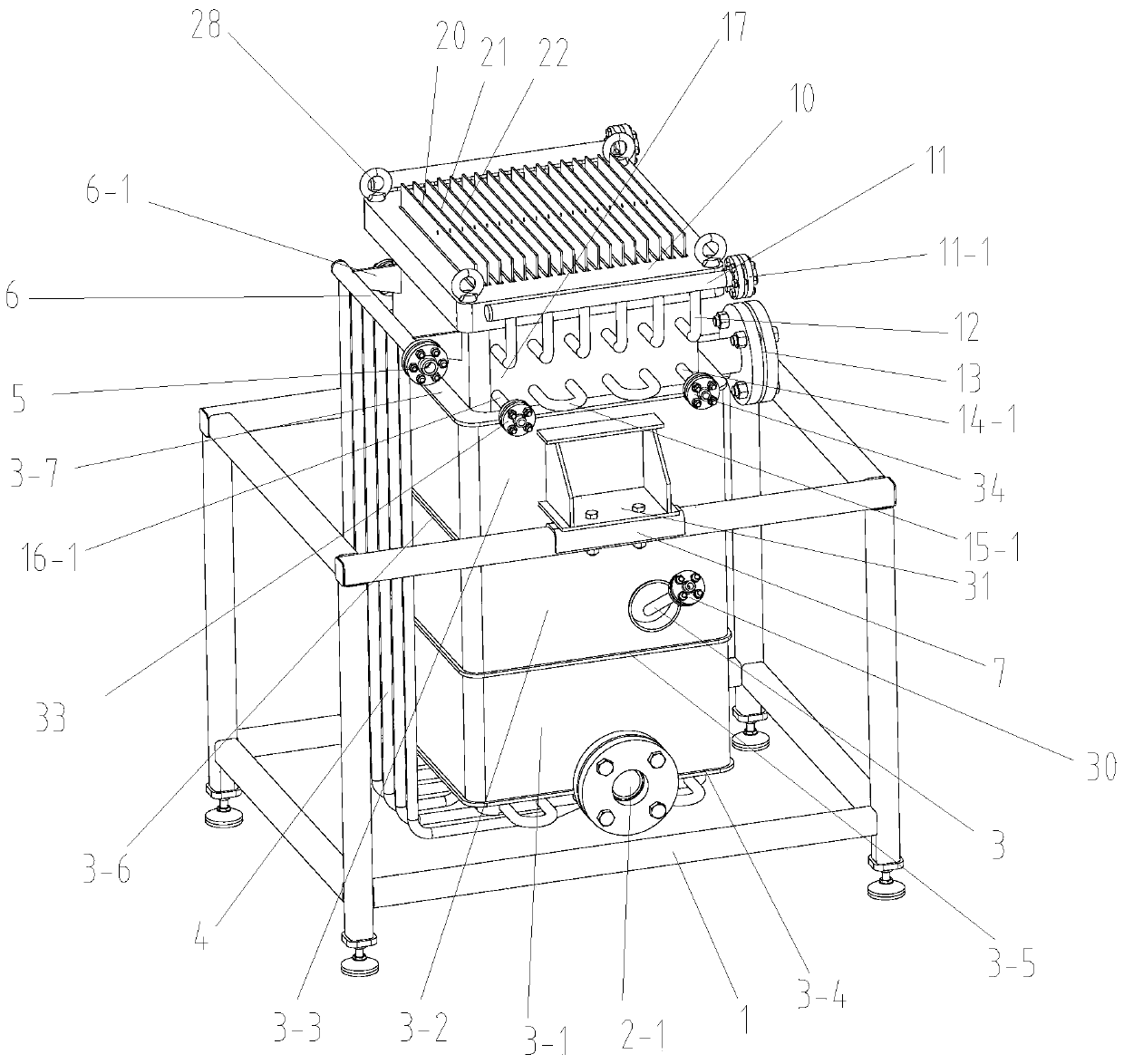

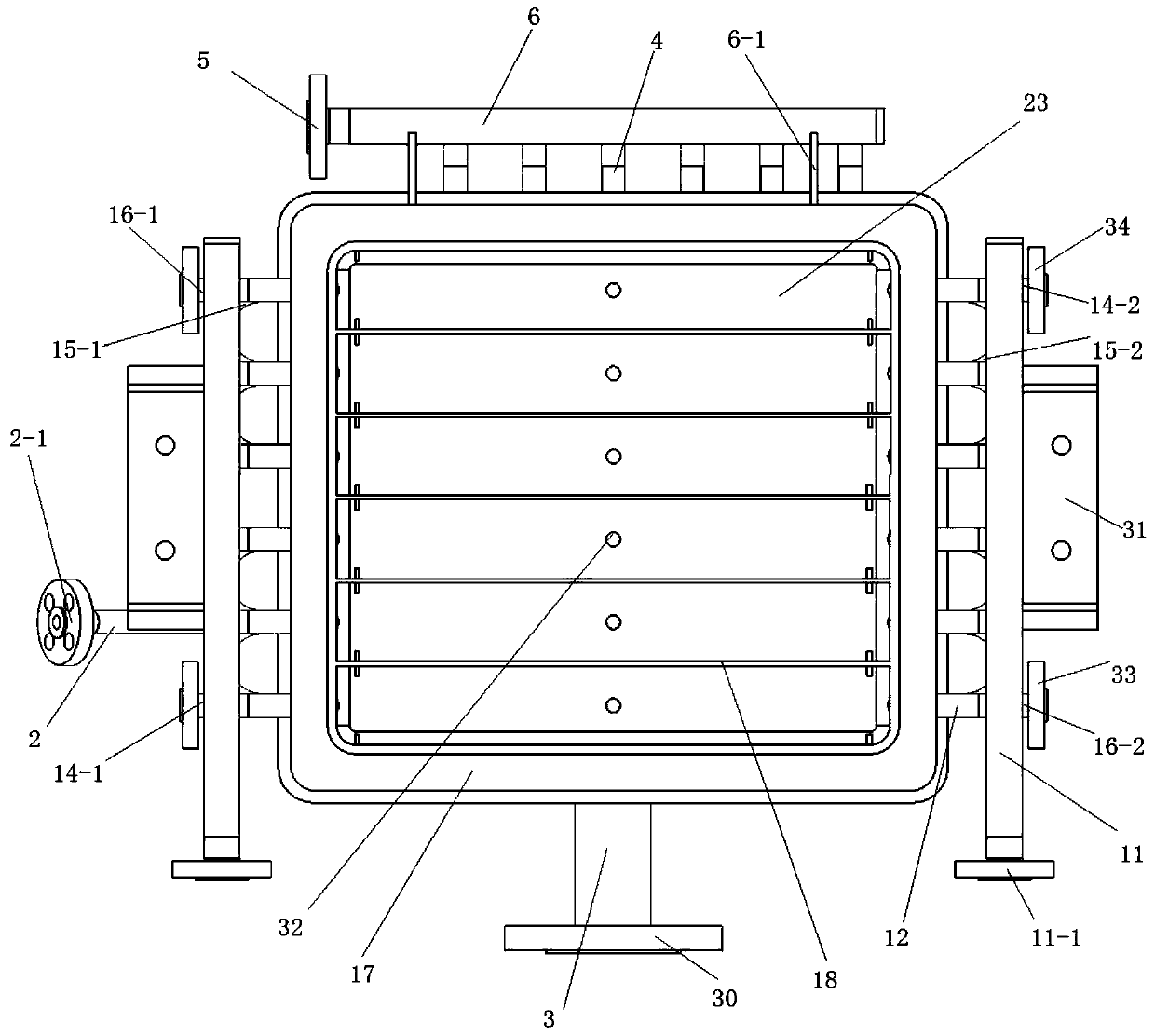

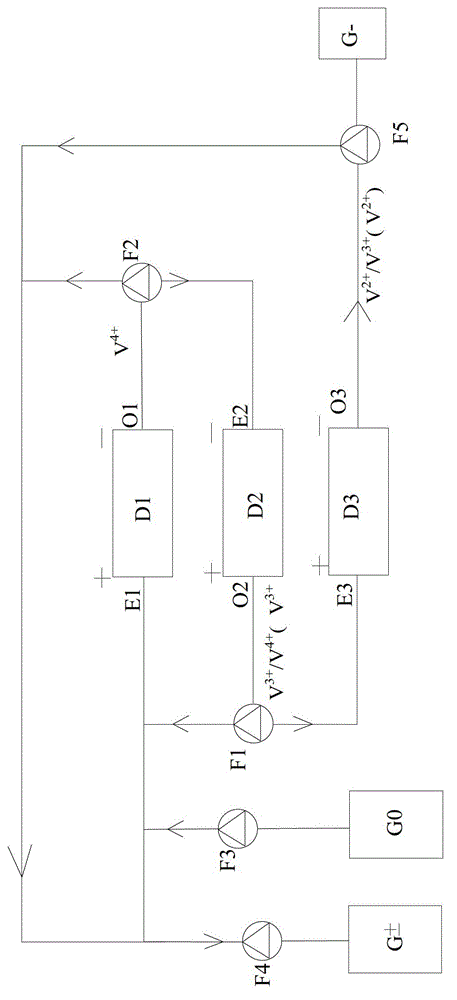

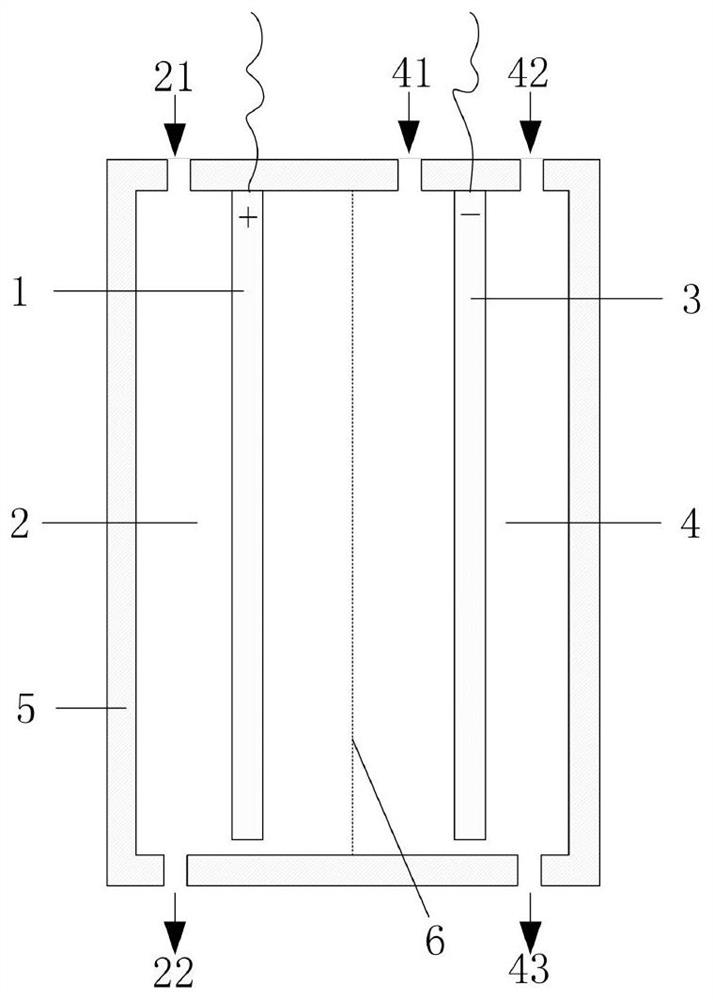

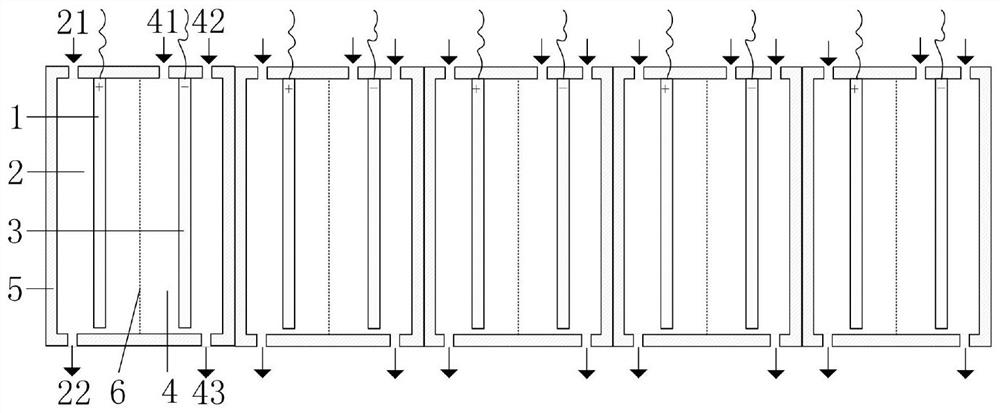

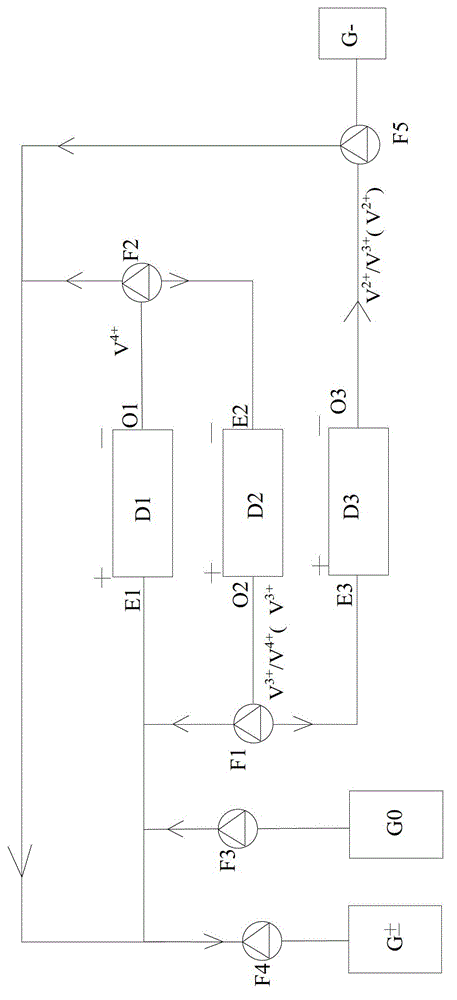

Electrolytic system and electrolytic method for preparing vanadium cell fluid

ActiveCN102978647AIncrease the rate of electrolysisThe operation method of electrolysis is simpleCellsLead-acid accumulatorsState of chargeElectrolytic cell

The invention relates to an electrolytic system for preparing a vanadium cell fluid, and the electrolytic system comprises a first electrolytic tank (D1), a second electrolytic tank (D2) and a third electrolytic tank (D3) all of which are connected in series orderly, and further comprises a first valve switching valve (F1) which is arranged between the second electrolytic tank (D2) and the third electrolytic tank (D3) and selectively communicated to the inlet (E1) of the first electrolytic tank (D1) and a first reservoir (G+ / -), a second valve switching valve (F2) which is arranged between the first electrolytic tank (D1) and the second electrolytic tank (D2) and selectively communicated to the inlet (E1) of the first electrolytic tank (D1), a third valve switching valve (F3) which is arranged between a second reservoir (G0) and the inlet (E1) of the first electrolytic tank (D1), and a fourth valve switching valve (F4) which is arranged between the first reservoir (G+ / -) and the inlet (E1) of the first electrolytic tank (D1). The outlet of the third electrolytic tank (D3) is communicated to the inlet of the first electrolytic tank (D1). The invention further relates to an electrolytic method. The device provided by the invention is capable of preparing the electrolyte through continuous electrolysis, improving the electrolytic rate and preparing the electrolytes of different states of charge simultaneously according to requirements.

Owner:湖南汇锋高新能源有限公司

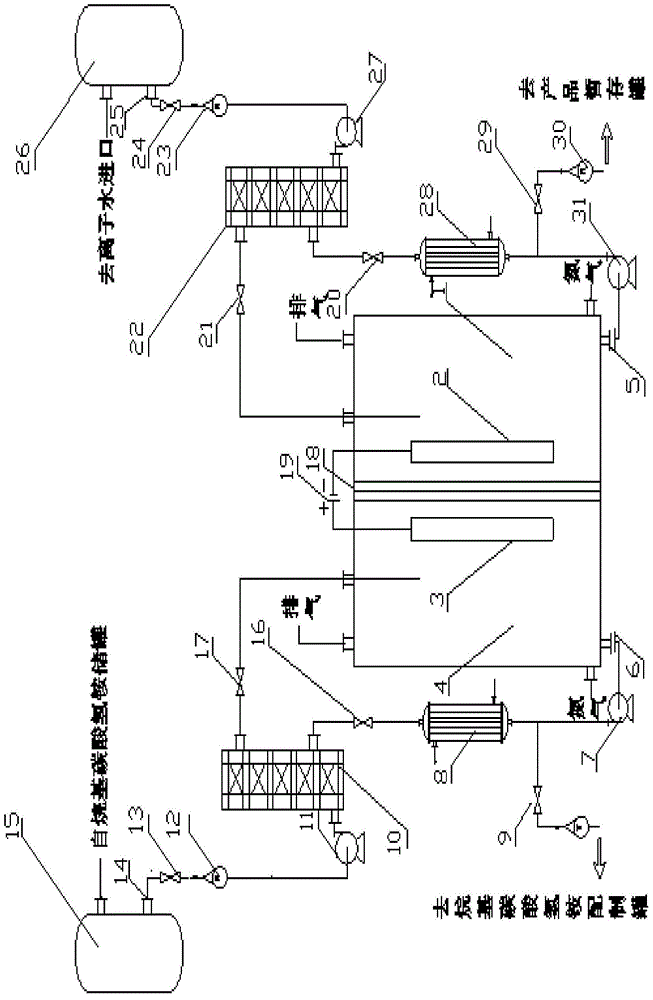

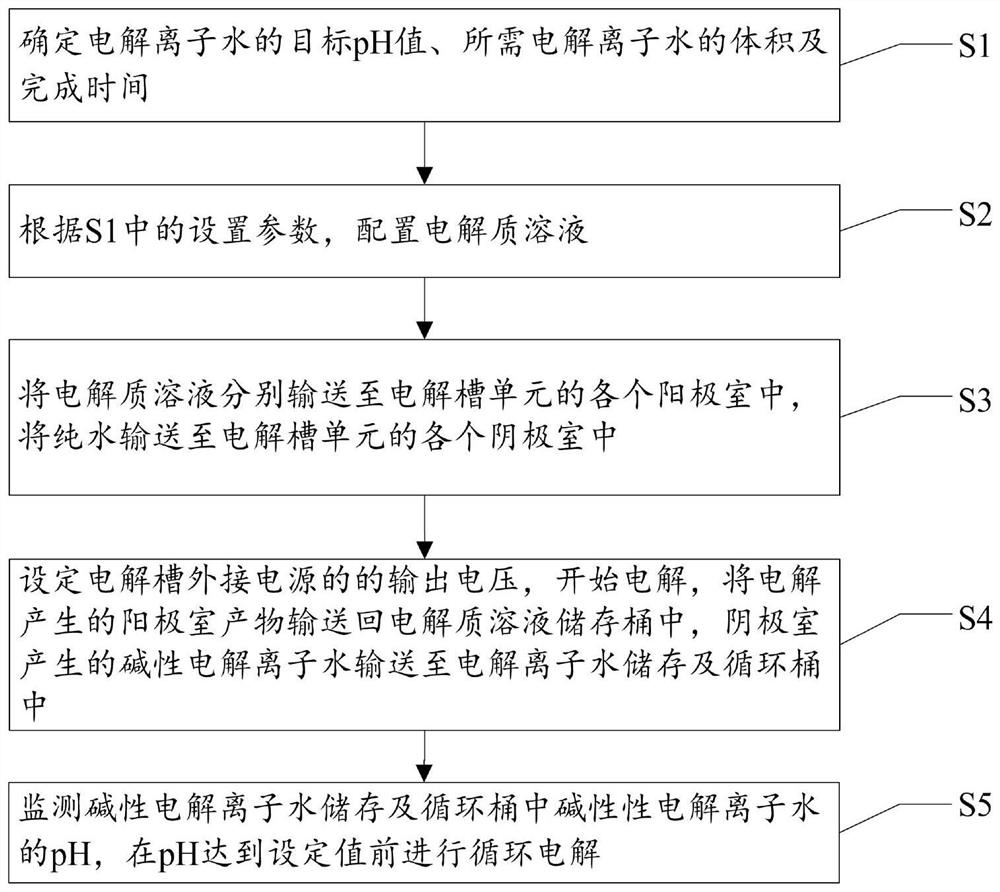

Method and equipment for preparing alkaline electrolysis ionized water with adjustable pH value

PendingCN114394652ASpeed up the rate of electrolysisImprove preparation efficiencyWater/sewage treatmentAnodeAnalytical chemistry

The invention discloses a preparation method and equipment of alkaline electrolysis ionized water with an adjustable pH value. The preparation method comprises the following steps: setting a target pH value, the amount of required electrolysis ionized water and the completion time; preparing an electrolyte solution according to related setting parameters; respectively conveying the electrolyte solution into each anode chamber of the electrolysis unit by using a water pump, and simultaneously conveying pure water into each cathode chamber of the electrolysis unit; the output voltage of an external power supply of the electrolytic bath is set, electrolysis is started, an anode chamber product generated by electrolysis is conveyed back to an electrolyte solution storage barrel, and alkaline electrolysis ionized water generated by a cathode chamber is conveyed to an alkaline electrolysis ionized water storage and circulation barrel; and the pH value of the alkaline electrolysis ionized water in the alkaline electrolysis ionized water storage and circulation barrel is monitored, and circulation electrolysis is carried out before the pH value reaches a set value. The preparation method of the alkaline electrolysis ionized water has high efficiency, the pH value, the preparation amount and the completion time are controllable and adjustable, and the degree of dependence on manpower is small.

Owner:中领水净科技(深圳)有限公司

An adjustable ozone electrolysis generator assembly

ActiveCN108796541BSmall electrolysis rateIncrease contact areaCellsElectrode shape/formsElectrolysisDecomposition

The invention relates to an adjustable ozone electrolysis generator assembly. The invention adopts flexible and deformable materials to prepare the anode catalyst membrane, PEM membrane, cathode catalyst membrane and cathode water bag, and integrates the anode catalyst membrane, PEM membrane, cathode catalyst membrane and cathode water bag into an integrated packaging preparation, the spiral electrode The anode catalyst membrane plate, PEM membrane, cathode catalyst membrane plate and cathode water bag in the assembly can be elastically deformed synchronously, and the spiral electrode assembly is spirally coiled in a cylindrical anode water tank to form a cylinder, and a screw loosening control device is also set , the spiral electrode assembly is tightly wound on the vertical shaft in the initial state, which itself has a unwinding stress and a tendency to unwind, and the spiral electrode assembly can be uncoiled or uncoiled under the action of its own stress through the uncoiling control device. A part is tightened so that the contact area for the electrolytic reaction increases or decreases, thereby realizing the adjustment of the electrolysis rate during the ozone preparation process.

Owner:中氧科技(广州)有限公司

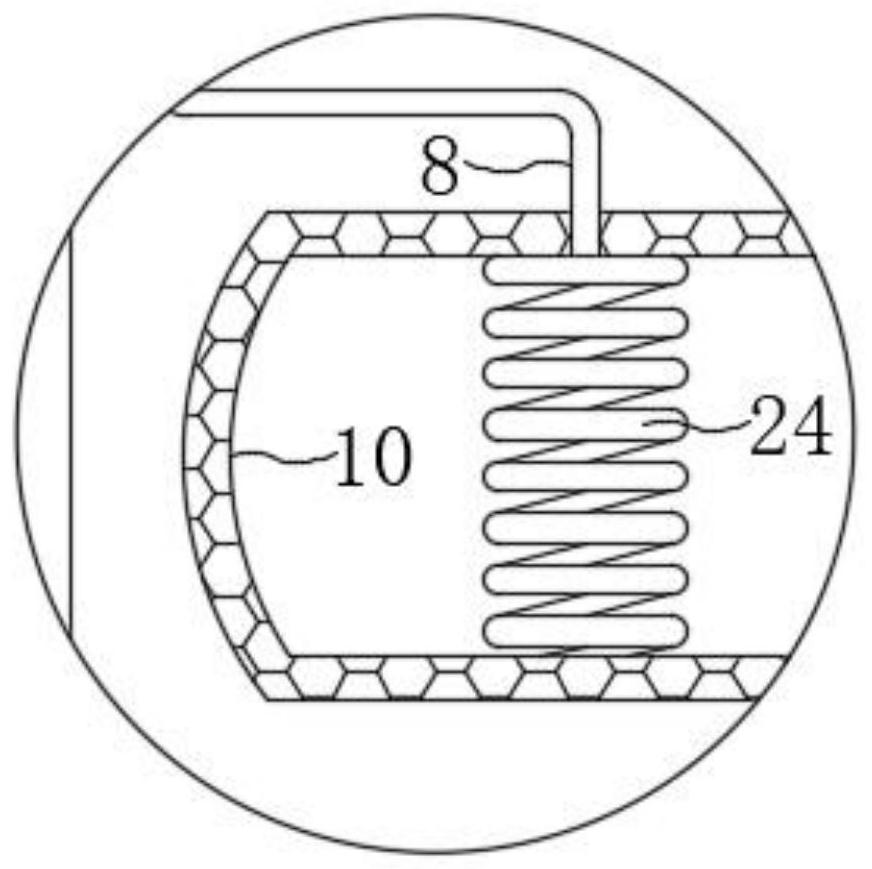

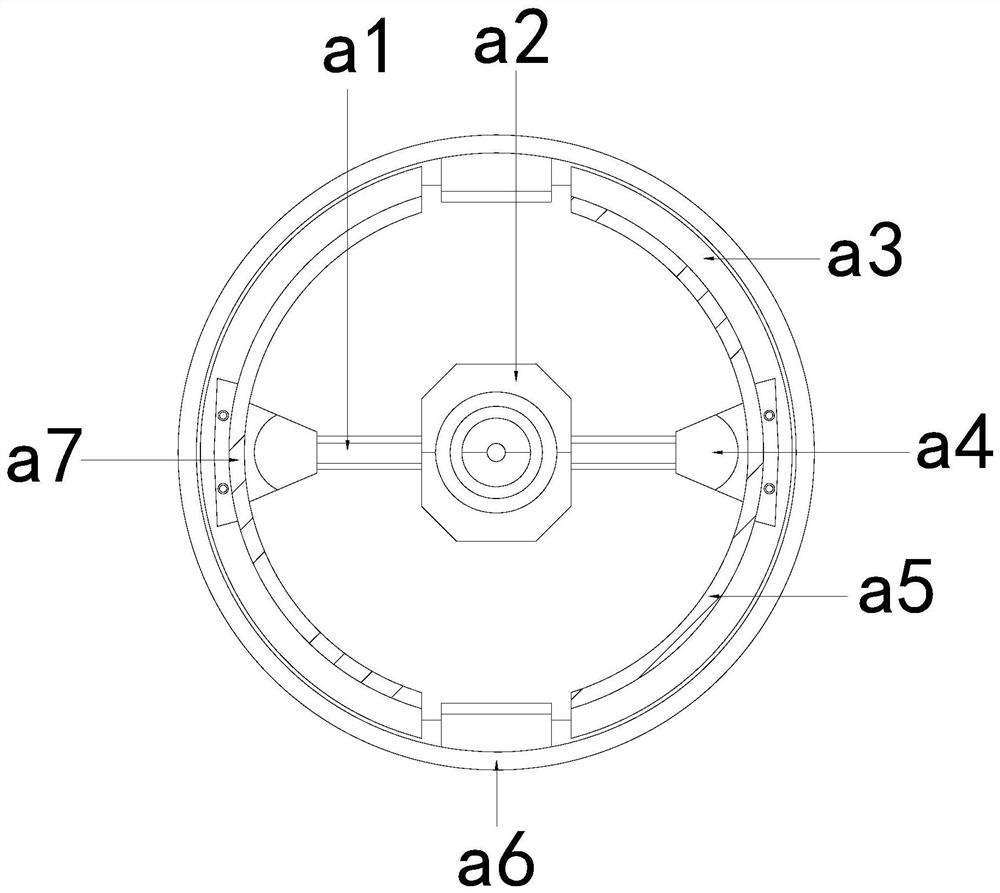

Efficient ion-exchange membrane electrolyzer

InactiveCN109750315AIncrease the rate of electrolysisTemperature controlCellsVoltage swingIon-exchange membranes

The invention relates to an efficient ion-exchange membrane electrolyzer. The efficient ion-exchange membrane electrolyzer comprises a cylindrical insulating electrolyzer shell, an annular anode plateand a cylindrical cathode plate and is characterized in that the cathode plate is located inside the anode plate; the top in the electrolyzer shell is provided with a conductive circular cover plate,and the bottom in the electrolyzer shell is provided with a conductive circular bottom plate; the cathode plate is integrally connected with the cover plate, and the anode plate is integrally connected with the bottom plate; a temperature control device is further connected to the electrolyzer shell; the cover plate and the bottom plate are respectively connected with a first power supply and a second power supply; particle electrodes are filled between the anode plate and the cathode plate; an ion-exchange membrane is further arranged between the cathode plate and the anode plate. The efficient ion-exchange membrane electrolyzer has the advantages that electrolysis speed and electrolysis rate can be increased; voltage swing can be prevented by controlling temperature in the electrolyzer;the electrolyzer is simple in structure, easy to manufacture and convenient to carry.

Owner:丹阳市日晟工业设备有限公司

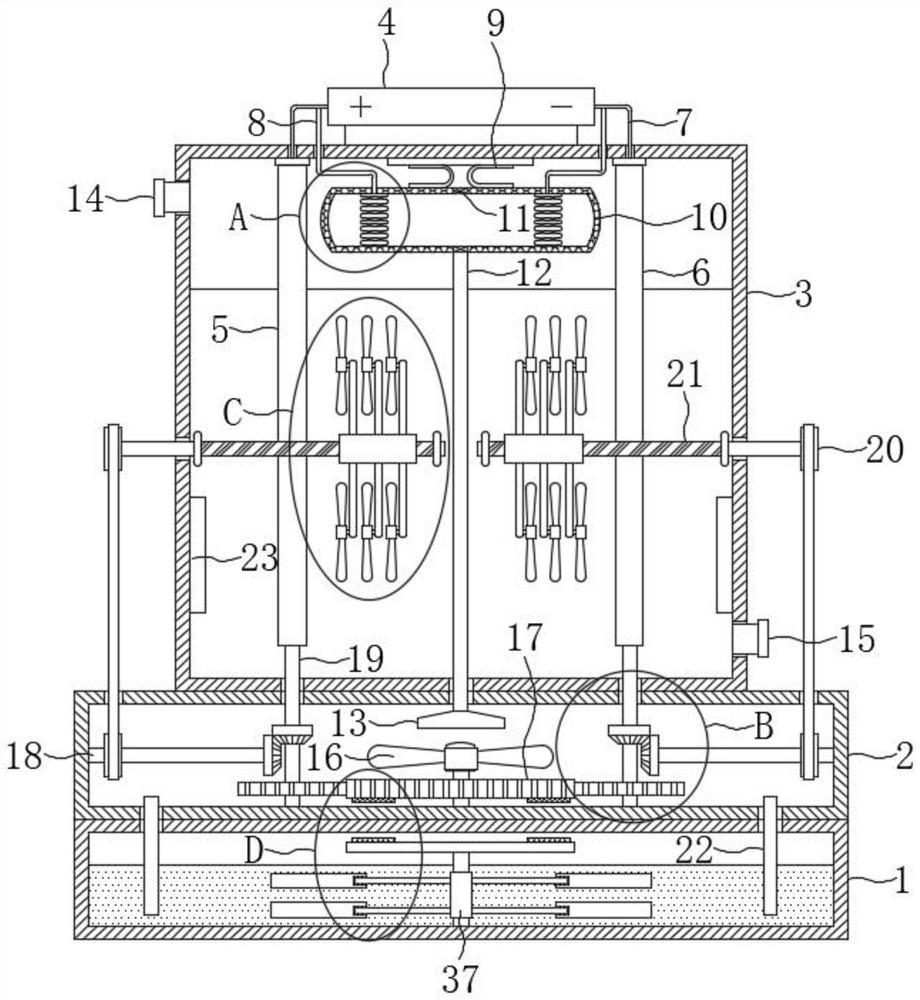

Hydrogen-rich and oxygen-rich water making machine

InactiveCN113321272AIncrease the rate of electrolysis andFast manufacturingGas treatmentLiquid degasificationAnodeGas supply

The invention discloses a hydrogen-rich and oxygen-rich water making machine which comprises a liquid storage box, a power box fixedly connected to the upper end of the liquid storage box and a making box fixedly connected to the upper end of the power box. A power source box is fixedly installed at the upper end of the making box. An anode bar and a cathode bar are symmetrically and rotationally connected between the inner bottom and the inner top of the making box through power connection terminals. The anode bar and the cathode bar are respectively coupled with the anode and the cathode of the power source box through main wires. By arranging a gas supply mechanism, a first driving mechanism, a second driving mechanism and the like, the moving speed of ions in a water body can be increased, the electrolysis rate and the hydrogen-rich and oxygen-rich water making speed can be increased, chlorine can be precipitated, the hydrogen-rich and oxygen-rich water is prevented from containing too much chlorine, the chlorine produced through electrolysis is continuously absorbed and removed, excessive contact between water and the precipitated chlorine is avoided, the chlorine can be degraded, and pollution to the air environment caused by direct emission of the chlorine is avoided.

Owner:郭亮

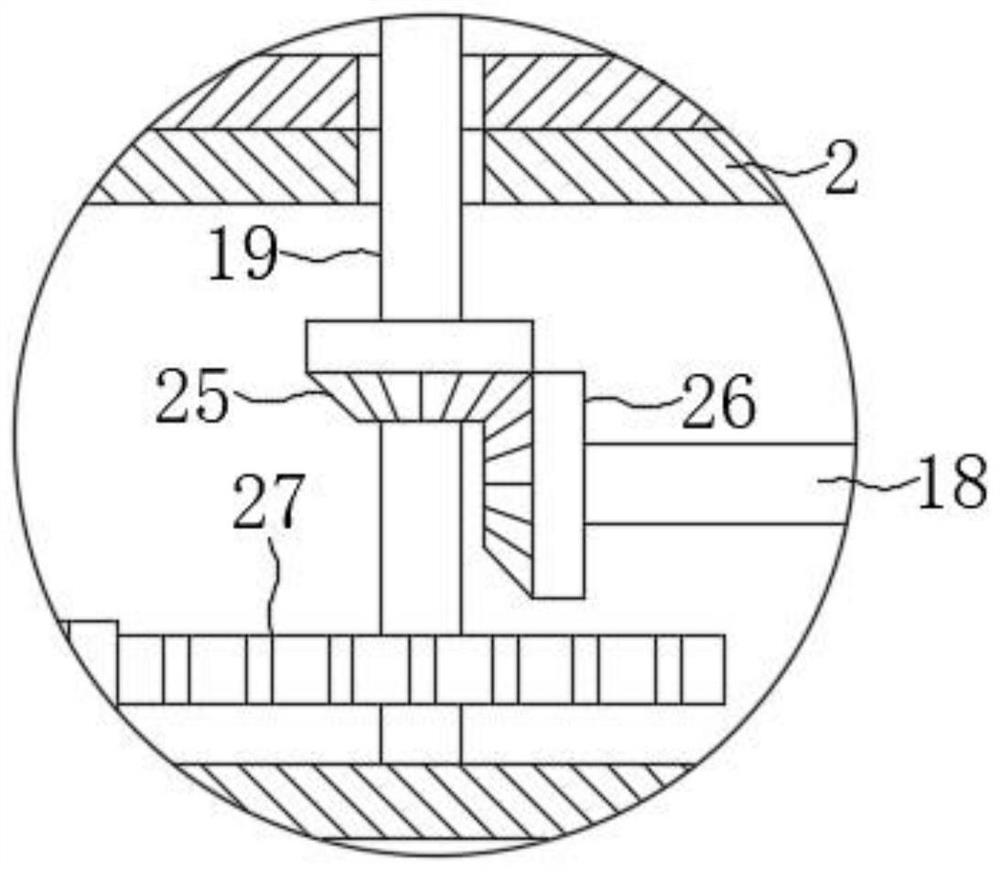

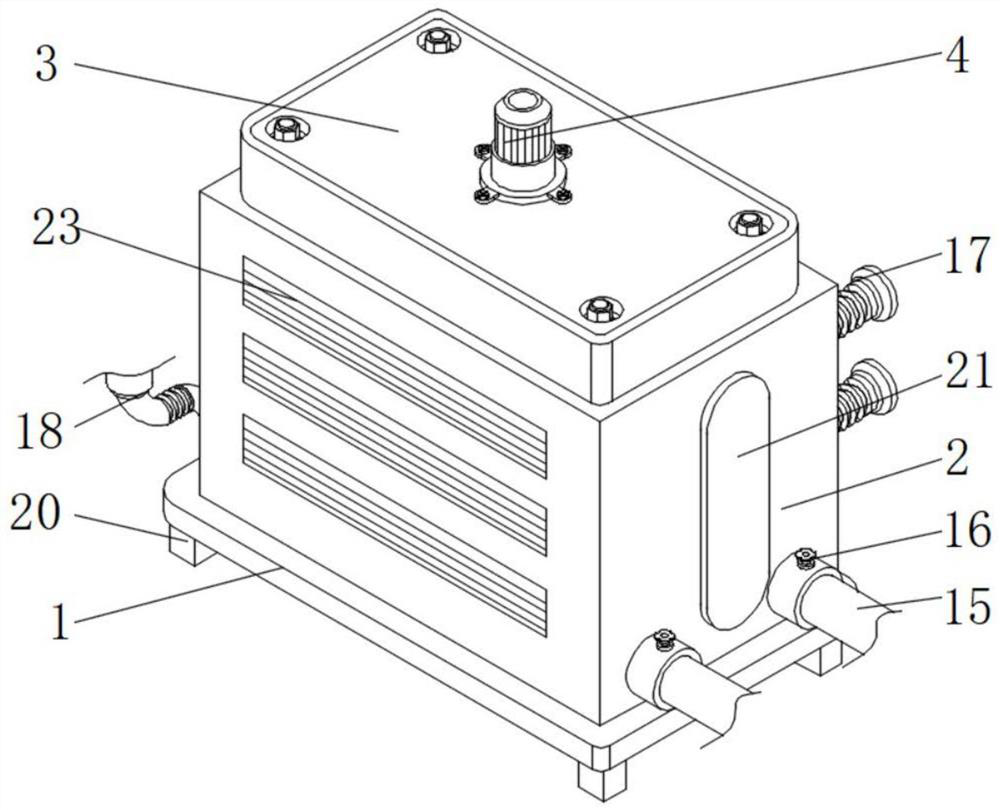

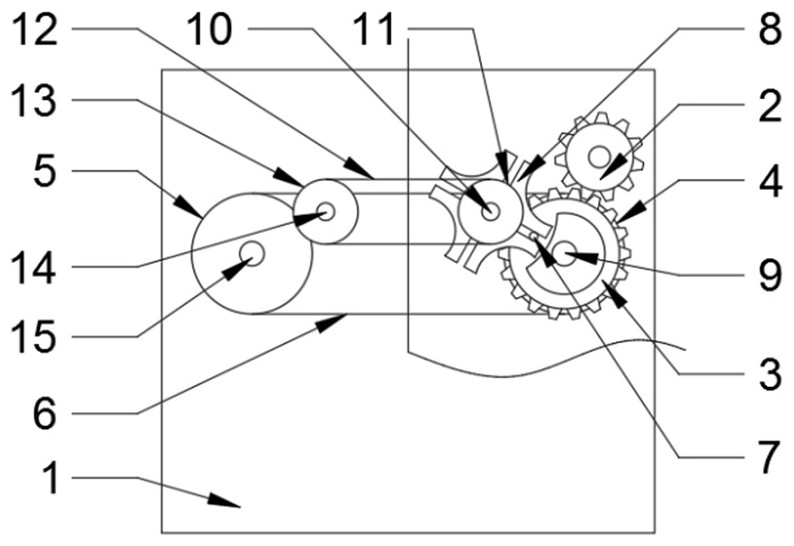

Device for controlling reaction speed in chlorine production

PendingCN113005479AIncrease production rateIncrease distanceElectrolysis componentsElectrical conductorGear wheel

The invention relates to the technical field of chlorine, and discloses a device for controlling reaction speed in chlorine production, the device comprises a base, the upper surface of the base is fixedly connected with a reaction box, and the upper surface of the reaction box is fixedly connected with a shell. According to the device for controlling the reaction speed in chlorine production, through the arrangement of the motor, the transmission rod, the gear, the toothed plate, the conductive rod and other structures, the motor is started to drive the gear to rotate forwards, the gear drives the conductive rod to move through the toothed plate, the distance between the positive electrode rod and the negative electrode rod can be increased, the length of the conductor is reduced, resistance can be reduced and current can be increased, the electrolysis rate of the solution and the production rate of chlorine are improved; in a similar way, the motor is started to drive a gear to rotate reversely, and the distance between the positive pole rod and the negative pole rod is reduced, so that the chlorine production rate can be reduced, the chlorine production rate can be effectively controlled by the device, and the device is convenient to use by workers; and the practicability of the device is enhanced.

Owner:SHANDONG LONGSHENGHE CHEM CO LTD

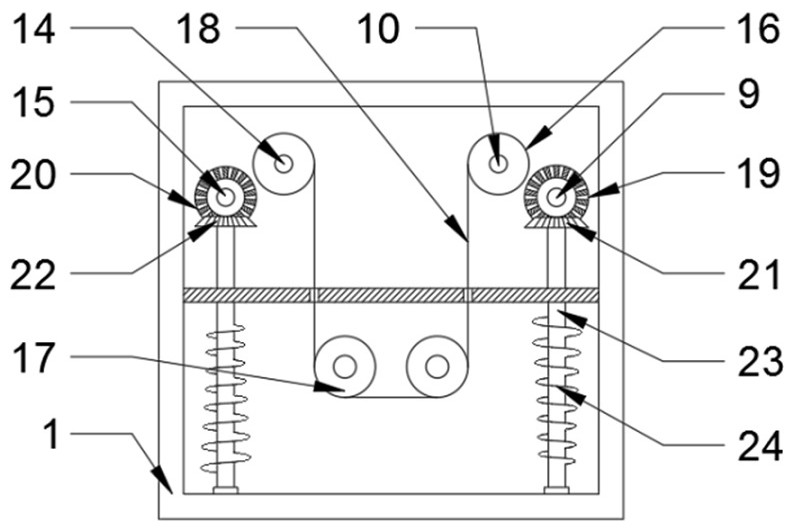

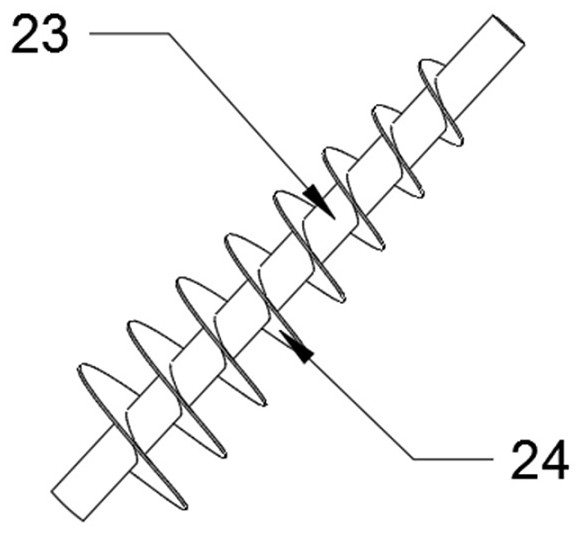

Low-voltage anode foil corrosion device for electrolytic capacitor

PendingCN113684527AIncrease the rate of electrolysisImprove processing efficiencyElectrolysis componentsCorrosionAnode

The invention relates to the technical field of low-voltage anode foil processing, in particular to a low-voltage anode foil corrosion device for an electrolytic capacitor. The low-voltage anode foil corrosion device for the electrolytic capacitor comprises a corrosion box which is internally and rotatably connected with a stirring mechanism; a first transmission mechanism rotationally connected with the stirring mechanism; a feeding mechanism rotationally connected to the interior of the corrosion box; and a second transmission mechanism rotationally connected with the first transmission mechanism. By means of the device, sediment can be effectively prevented from appearing at the bottom of the corrosion box, the electrolysis rate of the foil in the corrosion box can be increased, the machining efficiency of the foil is improved, the whole machining circulation process can be smoother, and energy waste is avoided; and the effect of further improving the processing rate of the foil can be achieved through the fact that the foil enters the corrosion box in a timed and quantitative mode.

Owner:益阳市锦汇电子有限公司

A kind of nano engine and its method and application for providing power

ActiveCN111663149BIncrease the rate of electrolysisSufficient and stable powerCellsPiezoelectric/electrostriction/magnetostriction machinesElectrolytic agentEngineering

The invention belongs to the field of nanometer science and technology, and in particular relates to a nanometer engine and its power supply method and application. The nanomotor provided by the invention comprises: a shell provided with an opening, the first area of the inner wall of the shell has a nickel-plated graphite layer, and the second area has an iridium oxide layer; and a power supply assembly. The nanomotor provided by the invention uses the nickel-plated graphite layer as the cathode substrate and the iridium oxide layer as the anode substrate, has a high electrolysis rate for water molecules, and can provide sufficient and stable power through electrolysis of water molecules. The method for providing power by a nano-engine provided by the present invention includes the following steps: placing the above-mentioned nano-motor in an electrolyte, and the nano-motor electrolyzes water molecules in the electrolyte in the inner cavity of the housing to generate bubbles to provide driving force. The invention uses the hydrogen and oxygen produced by the electrolysis of water molecules as the power of the nano engine, and the rate of bubbles generated by the electrolysis of water molecules is easy to control, which can provide sufficient kinetic energy for the nano engine.

Owner:湖南早晨纳米机器人有限公司

Industrial sewage recovery treatment equipment

InactiveCN112875942AIncrease the rate of electrolysisGood adhesionSpecific water treatment objectivesWater contaminantsElectrolysisWastewater

The invention discloses industrial sewage recovery treatment equipment which structurally comprises an electrolysis frame machine body, a sedimentation tank, a water outlet pipe, a sewage discharge pipe, a supporting base, a purification tank and a water inlet pipe. When the eqiupment is in use, through an electrolysis frame mechanism, in the industrial sewage treatment process, the equipment can solve the problems that heavy metal ions, a part of oil and suspended matter in wastewater can be attached to the outer wall of a steel plate to form a layer of thicker scale, the service life of the steel plate is indirectly influenced, and meanwhile, and the cleaning is more troublesome due to the particularity of the position of the scale. Through cooperation of a middle shaft bracket and a connecting motor cylinder, an aeration auxiliary frame can be driven to swing, thus the aeration effect can be increased and the electrolysis efficiency of sewage can be indirectly increased. Meanwhile, in the process, a specific scraping strip device can form a contact scraping effect on the inner walls of arc-shaped electrified titanium plates on the two sides, so that redundant impurities are not easily attached to the inner walls of the electrified titanium plates, and more convenience is achieved.

Owner:泉州早稻云信息科技有限公司

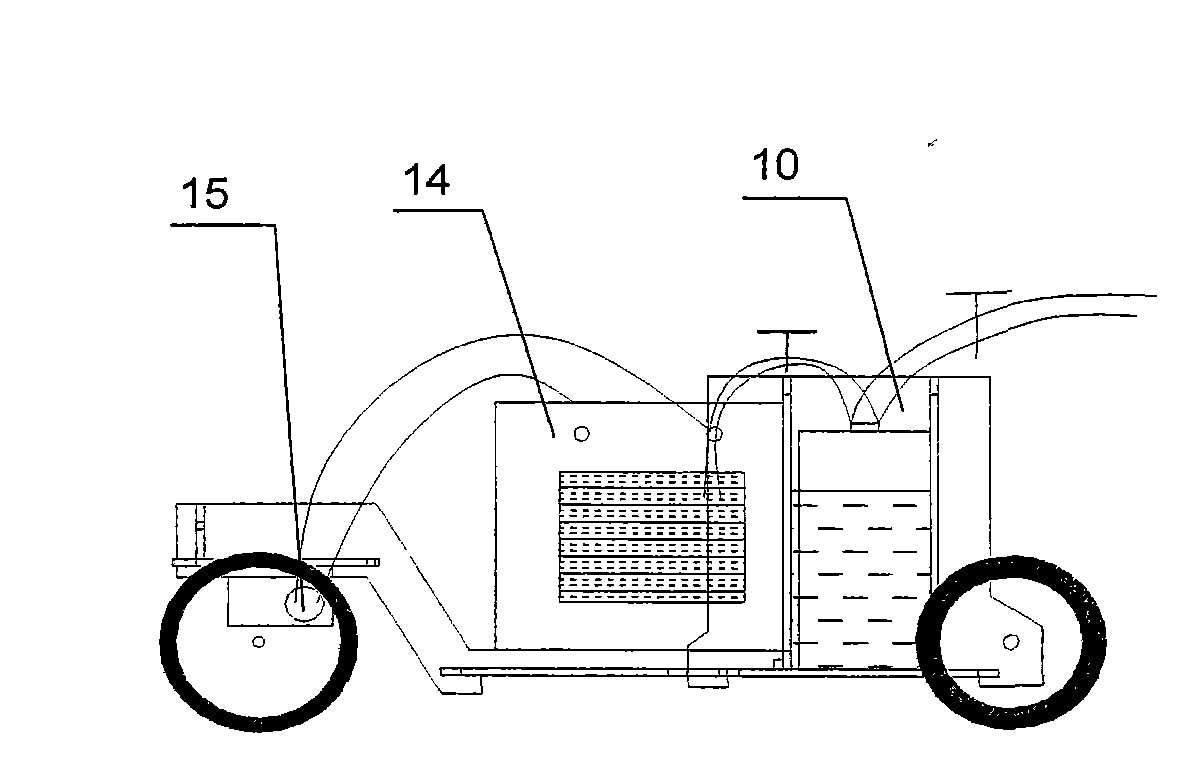

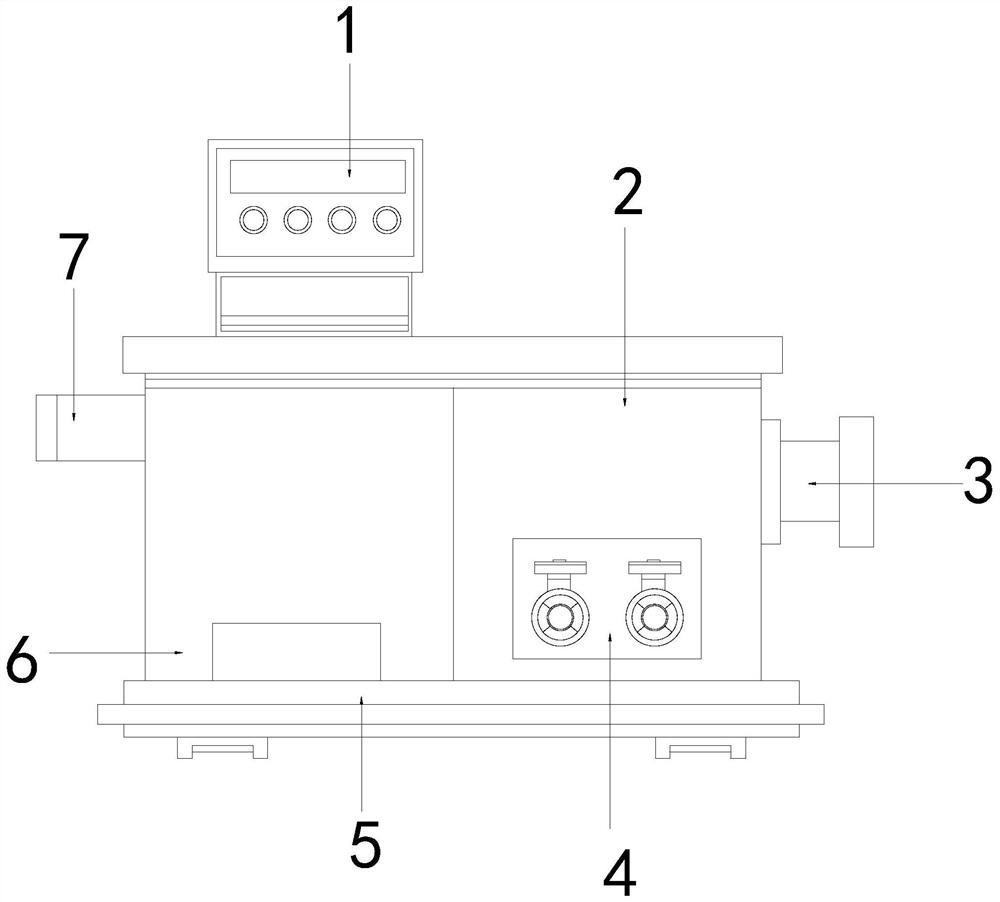

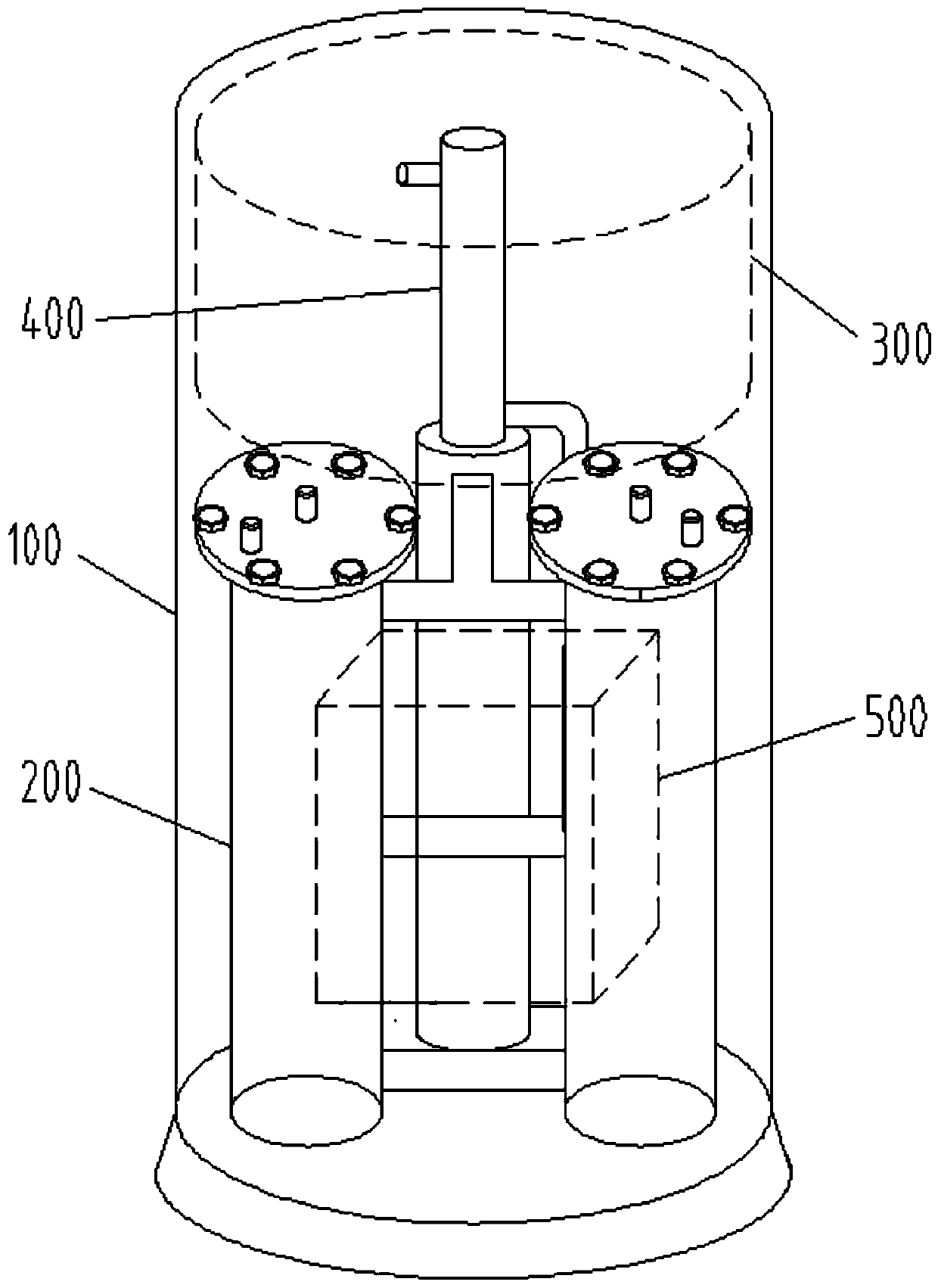

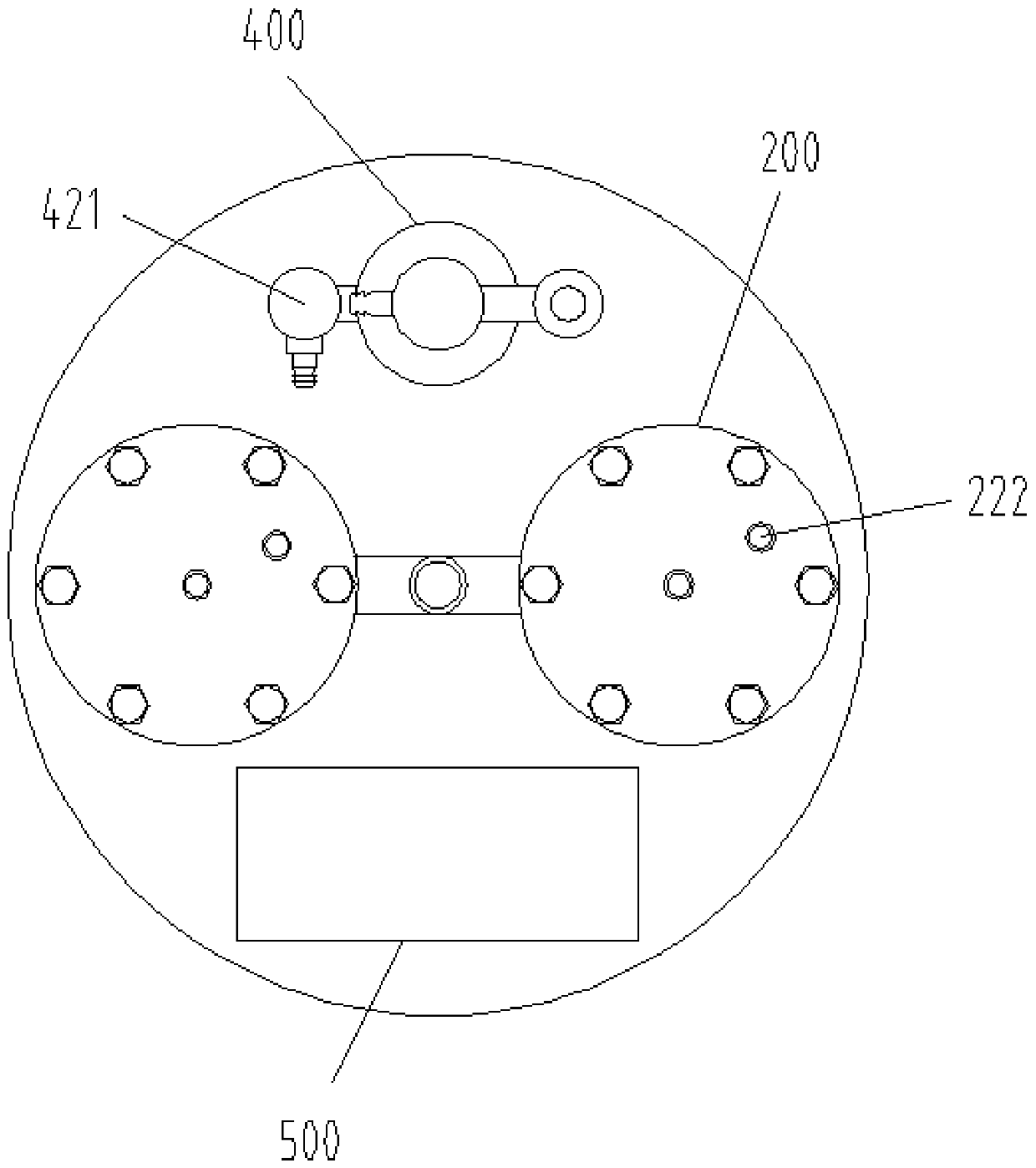

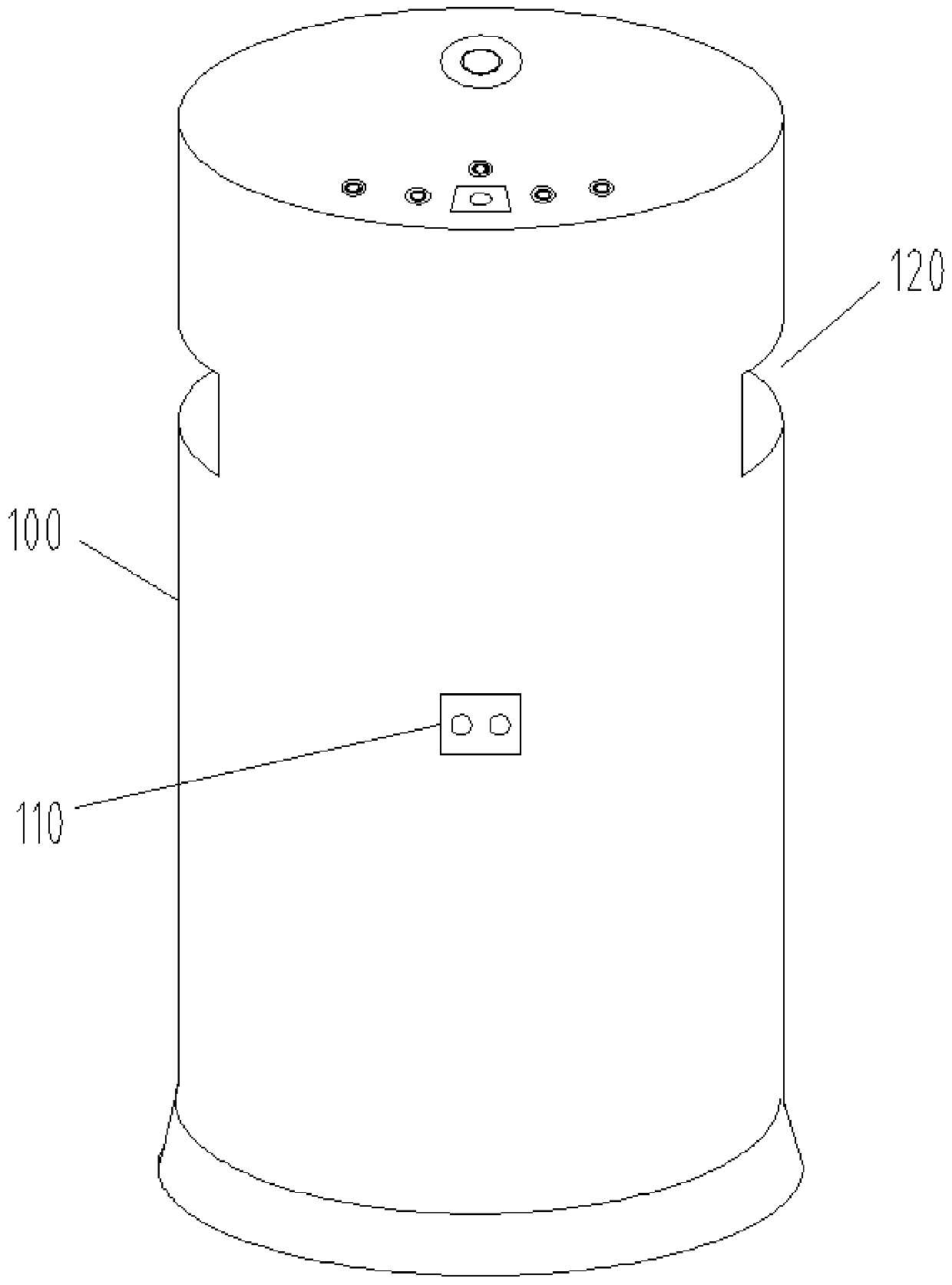

Environmentally-friendly generating equipment for household hydrogen source

The invention provides environmentally-friendly generating equipment for a household hydrogen source, and relates to the technical field of hydrogen preparation devices. The equipment comprises an outer shell, and electrolysis cylinders for generating hydrogen, a water tank for supplying water to the electrolysis cylinders, a water sealing device for isolating back fire and an electrical box are installed in the outer shell; each electrolysis cylinder is provided with a liquid injecting pipe and gas outlet pipes, the water tank is connected with the electrolysis cylinders through the liquid injecting pipe, and the water sealing device is provided with gas inlet nozzles connected with the gas outlet pipes; and a power source indicator light for displaying that power supply of a power sourceis normal, a water tank warning light for reminding that a liquid level in the water tank is too low, an electrolyte warning light for reminding that an electrolyte liquid level is too low, a water sealing warning light for reminding that a water sealing liquid level is too low and an air pressure abnormity light for reminding that air pressure change in the electrolysis cylinders is abnormal areinstalled at the top of the outer shell. According to the equipment provided by the invention, the water sealing device is arranged, so that the equipment plays a role in preventing fire back; and various warning lights are arranged, so that the equipment can remind workers to supplement an electrolyte and a water sealing liquid in time; therefore, the generating equipment for the household hydrogen source can be used safely and normally.

Owner:九江市盟祥联轴器有限公司

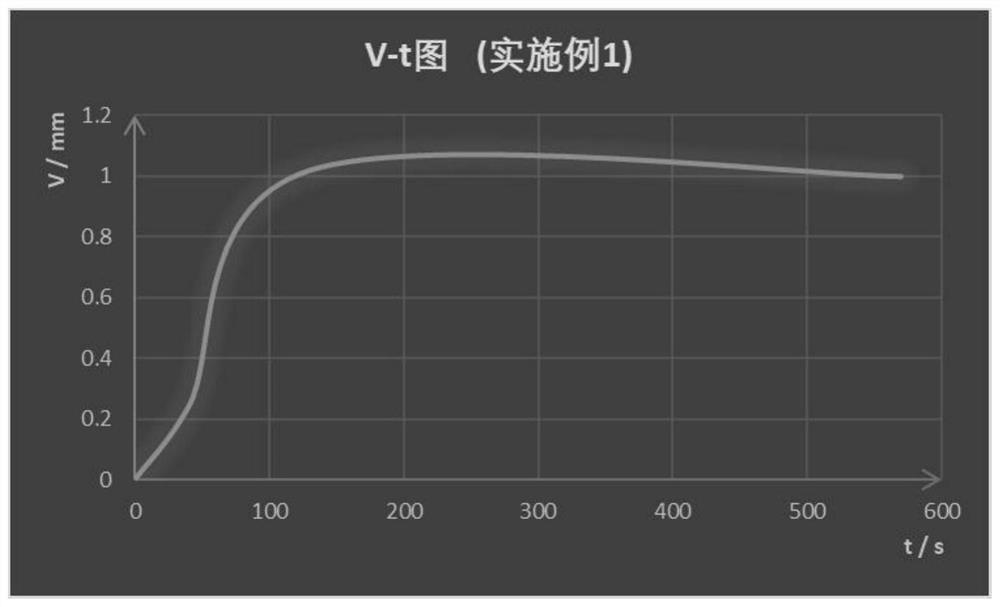

A kind of alkali production process

ActiveCN105154910BReduce wasteReduce solubilityElectrolysis componentsProduction rateTemperature control

A production process of alkali, the steps are as follows: a. Secondary refined brine enters the anode chamber of the electrolytic cell through heat exchanger preheating. When the current reaches 5KA, acid is started to be added to the anode chamber. b. The chlorine gas produced by electrolysis passes through the heat exchanger to preheat the secondary refined brine, so that the temperature of the secondary refined brine reaches 55°C. c. Part of the 32±0.5% concentration of alkali discharged from the cathode chamber is mixed with an appropriate amount of pure water to make a 30±0.5% concentration of alkali into the cathode chamber, where hydrogen is electrolyzed in the cathode chamber. d. The temperature control of the electrolytic cell in the whole electrolytic reaction process is adjusted and controlled at 85-87° C. through the catholyte cooler. e. When the concentration of the electrode catholyte solution reaches 32±0.5%, it will be discharged from the cathode chamber. After passing through the catholyte cooler, part of it will be reused in the cathode chamber, and part will be output to the storage tank. The invention reduces the waste of energy, facilitates the rapid discharge of the generated gas, and improves the productivity of the alkali and the conductivity of the solution.

Owner:ZHEJIANG OCEANKING DEVELOPMENT CO LTD

A kind of multistage electrolysis method

ActiveCN111074287BThe method steps are simpleReasonable designCellsElectrode shape/formsElectrolytic agentUranium

The invention discloses a multi-stage electrolysis method. The method comprises the following steps: 1. assembly of an electrode plate mechanism; 2. installation of a deflector; 3. connection of the electrode plate mechanism and a tank body; Five, electrolysis of hexavalent uranium solution to form tetravalent uranium solution. The method of the invention has simple steps, reasonable design and low cost, and the electrolysis process is convenient to operate. The hexavalent uranium solution is formed into a tetravalent uranium solution through multi-stage electrolysis. Plate short circuit, high safety and reliability.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Electrolytic system and electrolytic method for preparing vanadium cell fluid

ActiveCN102978647BQuick restoreIncrease the rate of electrolysisCellsLead-acid accumulatorsElectrolytic agentBiochemical engineering

The invention relates to an electrolytic system for preparing a vanadium cell fluid, and the electrolytic system comprises a first electrolytic tank (D1), a second electrolytic tank (D2) and a third electrolytic tank (D3) all of which are connected in series orderly, and further comprises a first valve switching valve (F1) which is arranged between the second electrolytic tank (D2) and the third electrolytic tank (D3) and selectively communicated to the inlet (E1) of the first electrolytic tank (D1) and a first reservoir (G+ / -), a second valve switching valve (F2) which is arranged between the first electrolytic tank (D1) and the second electrolytic tank (D2) and selectively communicated to the inlet (E1) of the first electrolytic tank (D1), a third valve switching valve (F3) which is arranged between a second reservoir (G0) and the inlet (E1) of the first electrolytic tank (D1), and a fourth valve switching valve (F4) which is arranged between the first reservoir (G+ / -) and the inlet (E1) of the first electrolytic tank (D1). The outlet of the third electrolytic tank (D3) is communicated to the inlet of the first electrolytic tank (D1). The invention further relates to an electrolytic method. The device provided by the invention is capable of preparing the electrolyte through continuous electrolysis, improving the electrolytic rate and preparing the electrolytes of different states of charge simultaneously according to requirements.

Owner:湖南汇锋高新能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com