Industrial sewage recovery treatment equipment

A technology for recovery and treatment of industrial sewage, applied in water/sewage treatment equipment, water/sewage treatment, water/sewage multi-stage treatment, etc., to achieve the effect of increasing the electrolysis rate and increasing the aeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

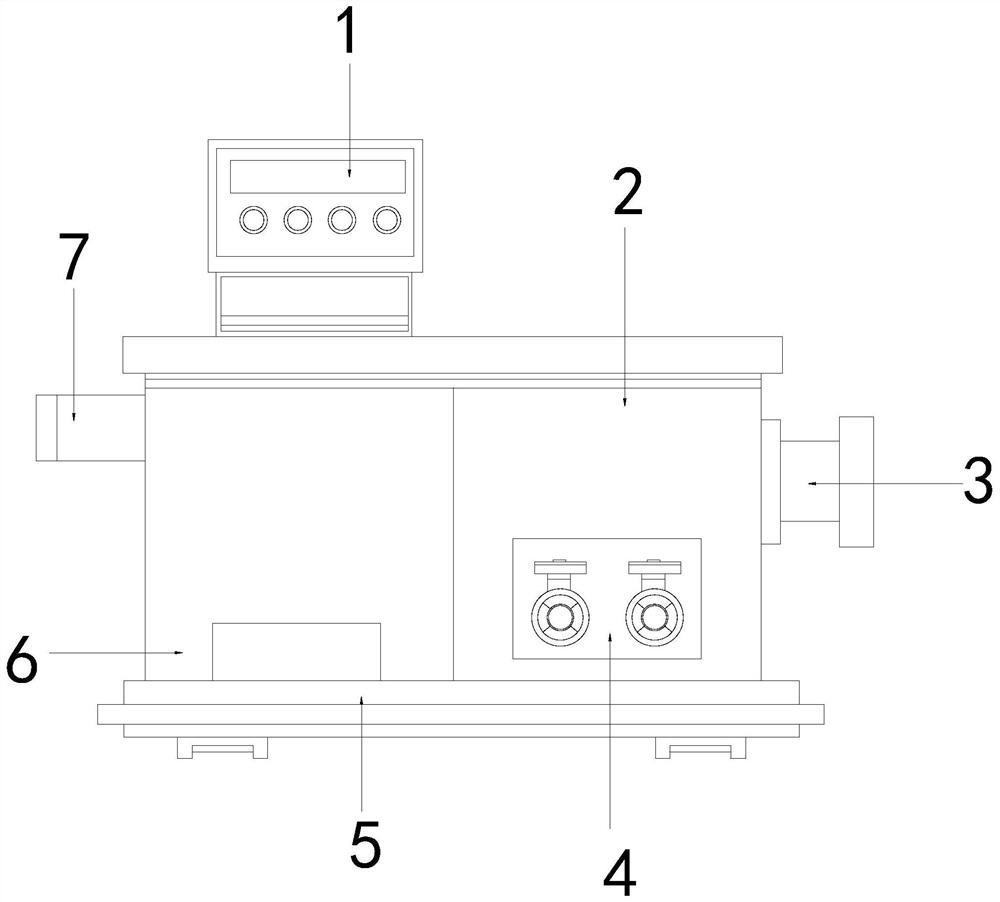

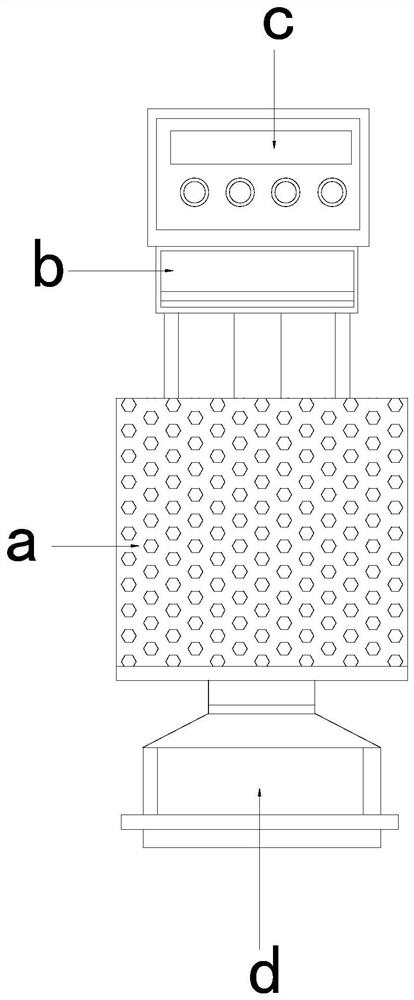

[0026] see Figure 1-Figure 3 , the present invention provides a technical solution for industrial sewage recovery and treatment equipment: its structure includes: an electrolytic frame body 1, a sedimentation tank 2, a water outlet pipe 3, a sewage pipe 4, a support base 5, a purification tank 6, and a water inlet pipe 7. The water pipe 3 is installed in the sedimentation tank 2 on the right side of the sedimentation tank 2 and is buckled. The front side of the sedimentation tank 2 is provided with a sewage pipe 4, and the left side of the sedimentation tank 2 is provided with a purification tank 6. Buckle connection, the support base 5 is provided under the purification tank 6, the electrolysis rack body 1 is arranged above the purification tank 6, the electrolysis rack body 1 is buckled with the purification tank 6, and the upper left side of the purification tank 6 is provided with The water inlet pipe 7, the electrolysis frame body 1 includes the reactor device a, the ele...

no. 2 example

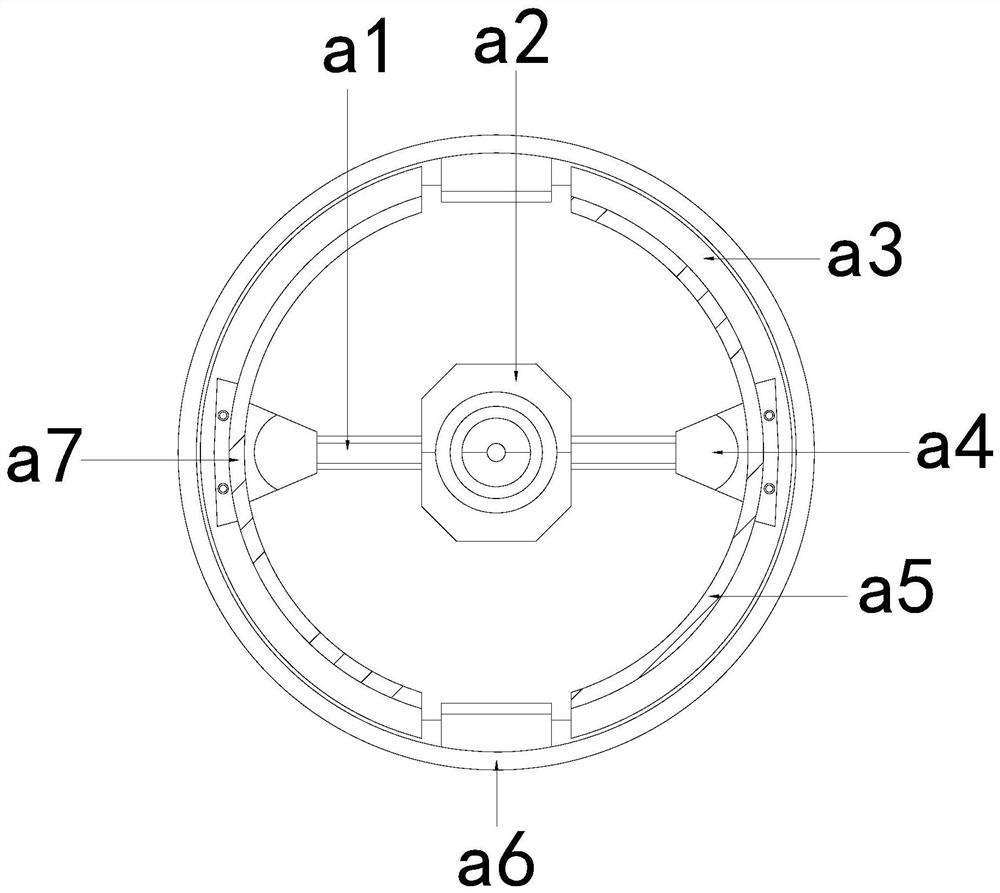

[0030] see Figure 4-Figure 6 , the present invention provides a technical solution for industrial sewage recovery and treatment equipment: its structure includes: the aeration auxiliary frame a1 includes an aeration strip a11, a linkage rod a12, a sleeve frame a13, and a loading groove a14, and the aeration strip a11 Set on the inner side of the sleeve frame a13 and fastened with the sleeve frame a13, the inner end of the sleeve frame a13 is provided with a linkage rod a12, the linkage rod a12 is locked with the sleeve frame a13, and the outer end of the sleeve frame a13 is welded with a loading recess Slot a14.

[0031] The aeration bar a11 includes a grille bushing a111 and a support inner rod a112. The grille bushing a111 is sleeved on the outer side of the support inner rod a112 and buckled with the support inner rod a112.

[0032] The scraper device a4 includes an assembly vertical plate a41, a fitting scraper a42, and a connection groove a43. An assembly riser a41 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com