A kind of nano engine and its method and application for providing power

An engine and nanotechnology, applied in the field of nanotechnology, can solve the problems of low kinetic energy, inability to guarantee the limited energy, activity and catalytic efficiency of nanorobots, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

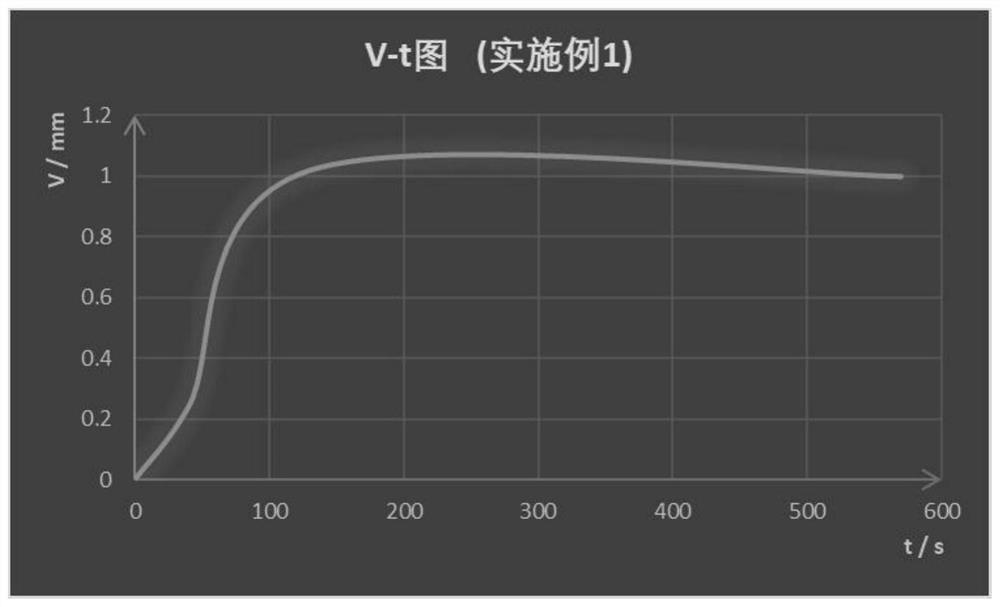

Embodiment 1

[0056] 1) The structure of the nanoengine:

[0057] The nanomotor provided in this embodiment includes a shell made of titanium dioxide, the shape of the shell is a cylinder with one end open, the wall thickness of the shell is 160 nm, the radial length of the shell is 420 nm, and the axial length is 800 nm.

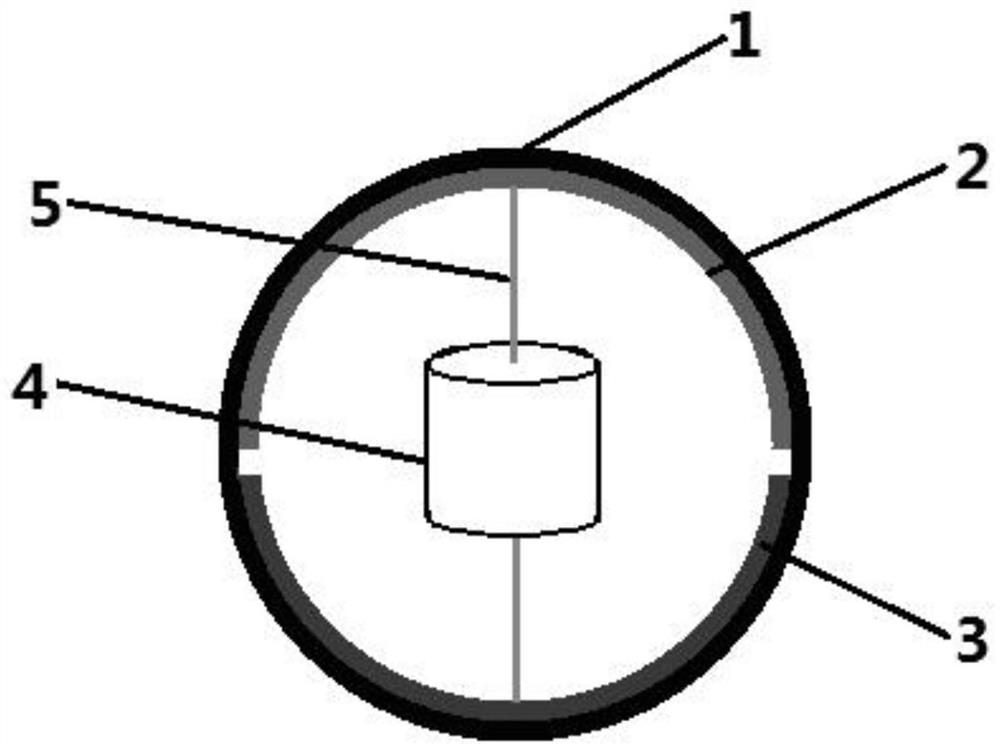

[0058] In this embodiment, the structure of the housing cavity is as follows figure 1 As shown, it includes a nickel-plated graphite layer 2 arranged on one side of the inner wall of the housing 1 along the radial direction, and an iridium oxide layer 3 arranged on the other side of the inner wall of the housing 1 along the radial direction, the nickel-plated graphite layer 2 and the iridium oxide layer 3 are symmetrically arranged, and the nickel-plated graphite layer 2 and the iridium oxide layer 3 are not in contact, the thickness of the nickel-plated graphite layer 2 and the iridium oxide layer 3 are both 30nm, and the area is 87920nm 2 . The inner cavity of the ho...

Embodiment 2

[0069] 1) The structure of the nanoengine:

[0070] The nanomotor provided in this embodiment includes a shell made of titanium dioxide, the shape of the shell is a cylinder with one end open, the wall thickness of the shell is 160 nm, the radial length of the shell is 420 nm, and the axial length is 800 nm.

[0071] In this embodiment, the structure of the housing cavity is as follows figure 1 As shown, it includes a nickel-plated graphite layer 2 arranged on one side of the inner wall of the housing 1 along the radial direction, and an iridium oxide layer 3 arranged on the other side of the inner wall of the housing 1 along the radial direction, the nickel-plated graphite layer 2 and the iridium oxide layer 3 are symmetrically arranged, and the nickel-plated graphite layer 2 and the iridium oxide layer 3 are not in contact, the thickness of the nickel-plated graphite layer 2 and the iridium oxide layer 3 are both 30nm, and the area is 87920nm 2 . The inner cavity of the ho...

Embodiment 3

[0082] 1) The structure of the nanoengine:

[0083] The nanomotor provided in this embodiment includes a shell made of titanium dioxide, the shape of the shell is a cylinder with one end open, the wall thickness of the shell is 160 nm, the radial length of the shell is 420 nm, and the axial length is 800 nm.

[0084] In this embodiment, the structure of the housing cavity is as follows figure 1 As shown, it includes a nickel-plated graphite layer 2 arranged on one side of the inner wall of the housing 1 along the radial direction, and an iridium oxide layer 3 arranged on the other side of the inner wall of the housing 1 along the radial direction, the nickel-plated graphite layer 2 and the iridium oxide layer 3 are symmetrically arranged, and the nickel-plated graphite layer 2 and the iridium oxide layer 3 are not in contact, the thickness of the nickel-plated graphite layer 2 and the iridium oxide layer 3 are both 30nm, and the area is 87920nm 2 . The inner cavity of the ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com