Method for preparing long-chain alkyl ammonium hydroxide by continuous electrolysis

A long-chain alkyl and ammonium hydroxide technology, which is applied in electrolysis process, electrolysis components, electrolysis organic production, etc., can solve the problems of unfavorable energy saving and industrial production, low service life of ionic membrane, slow reaction rate, etc. Achieve the effect of reducing energy consumption, avoiding loss and increasing mixing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

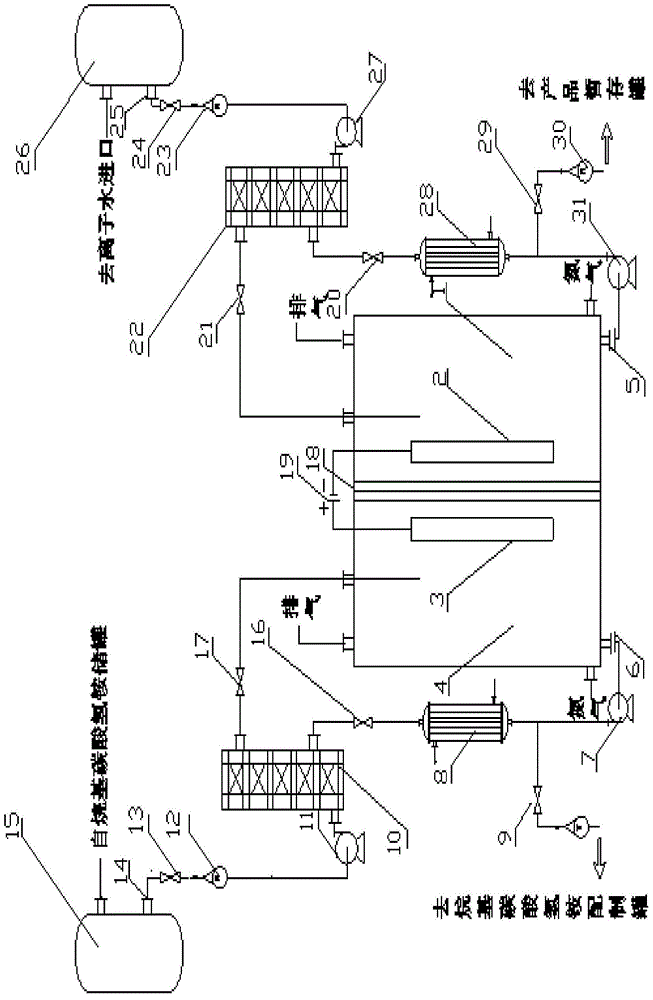

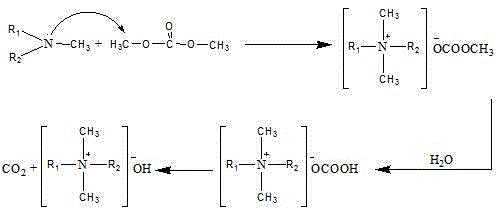

[0043] The electrolytic cell is divided into an anode electrolysis chamber 4 and a cathode electrolysis chamber 1 with an Asahi Kasei F4402 cation exchange membrane 18, and the anode electrolysis chamber and the anode circulation liquid static mixer 10, the external circulation heat exchanger 8, and the anode circulation discharge pump 7 form an anode circulation The loop, the cathode chamber, the static mixer 22 for the cathode circulating liquid, the external circulation heat exchanger 28, and the cathode circulation discharge pump 31 form the cathode circulation loop. Nitrogen gas is passed into the anode electrolysis chamber and the cathode electrolysis chamber to replace the air in the electrolysis chamber. Add 8Kg of octadecyltrimethylammonium methyl carbonate and 30Kg of water into a stirrer, and stir and react at 60°C for 1 hour to obtain octadecyltrimethylammonium bicarbonate with a concentration of 0.5mol / L aqueous solution. Add 15 L, 0.5 mol / L octadecyltrimethy...

Embodiment 2

[0045] The electrolytic cell is divided into an anode electrolysis chamber 4 and a cathode electrolysis chamber 1 with an Asahi Kasei F4403D cation exchange membrane 18, and the anode electrolysis chamber and the anode circulation liquid static mixer 10, the external circulation heat exchanger 8, and the anode circulation discharge pump 7 form an anode circulation The loop, the cathode chamber, the static mixer 22 for the cathode circulating liquid, the external circulation heat exchanger 28, and the cathode circulation discharge pump 31 form the cathode circulation loop. Nitrogen gas is passed into the anode electrolysis chamber and the cathode electrolysis chamber to replace the air in the electrolysis chamber. Add 7.4Kg of ammonium dodecyl trimethyl methyl carbonate and 25Kg of water into a stirrer, and stir and react at 50°C for 1.5h to obtain dodecyl trimethyl carbonate with a concentration of 0.65mol / L Aqueous solution of ammonium hydrogen. Add 16 L, 0.65 mol / L dodecyl...

Embodiment 3

[0047] The electrolytic cell is divided into an anode electrolysis chamber 4 and a cathode electrolysis chamber 1 with an Asahi Kasei F4602 cation exchange membrane 18, and the anode electrolysis chamber and the anode circulation liquid static mixer 10, the external circulation heat exchanger 8, and the anode circulation discharge pump 7 form an anode circulation The loop, the cathode chamber, the static mixer 22 for the cathode circulating liquid, the external circulation heat exchanger 28, and the cathode circulation discharge pump 31 form the cathode circulation loop. Nitrogen gas is passed into the anode electrolysis chamber and the cathode electrolysis chamber to replace the air in the electrolysis chamber. Add 4.5Kg ammonium octyltrimethylammonium methyl carbonate and 22Kg water into a stirrer, and stir and react at 45°C for 1.8h to prepare an aqueous solution of octyltrimethylammonium bicarbonate with a concentration of 0.7mol / L. Add 15 L, 0.7 mol / L octyltrimethylammoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com