Patents

Literature

32results about How to "Improve gas diffusivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid electrolyte, membrane and electrode assembly, and fuel cell

InactiveUS20060280983A1Improve ionic conductivityImprove gas diffusivityCosmetic preparationsElectrolyte holding meansFuel cellsSulfur

A solid electrolyte having an aromatic ring in a main chain, wherein a sulfonic acid group bonds to the aromatic ring via a linking group containing a sulfur atom. The solid electrolyte exhibits a high ion conductivity.

Owner:FUJIFILM HLDG CORP +1

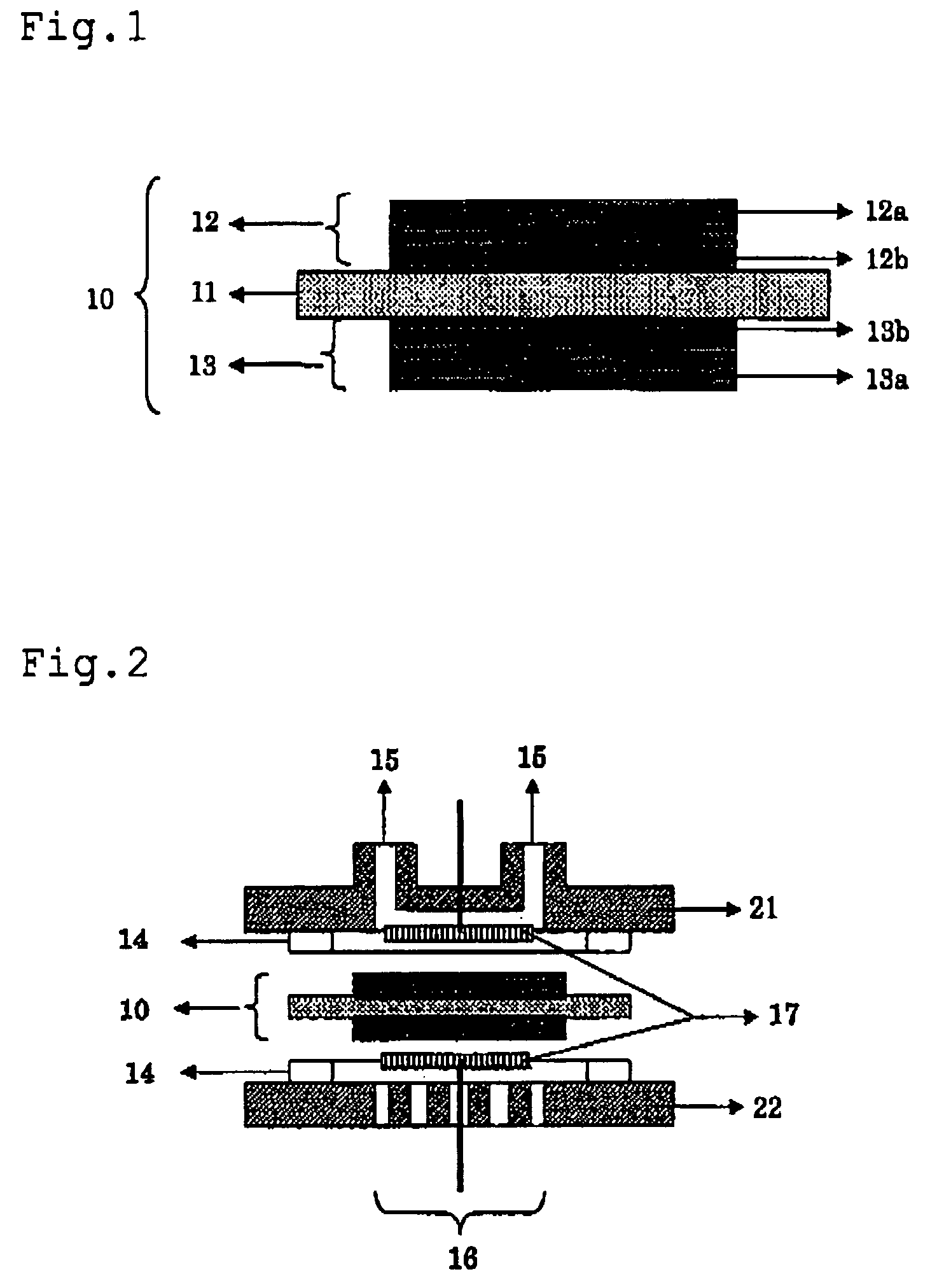

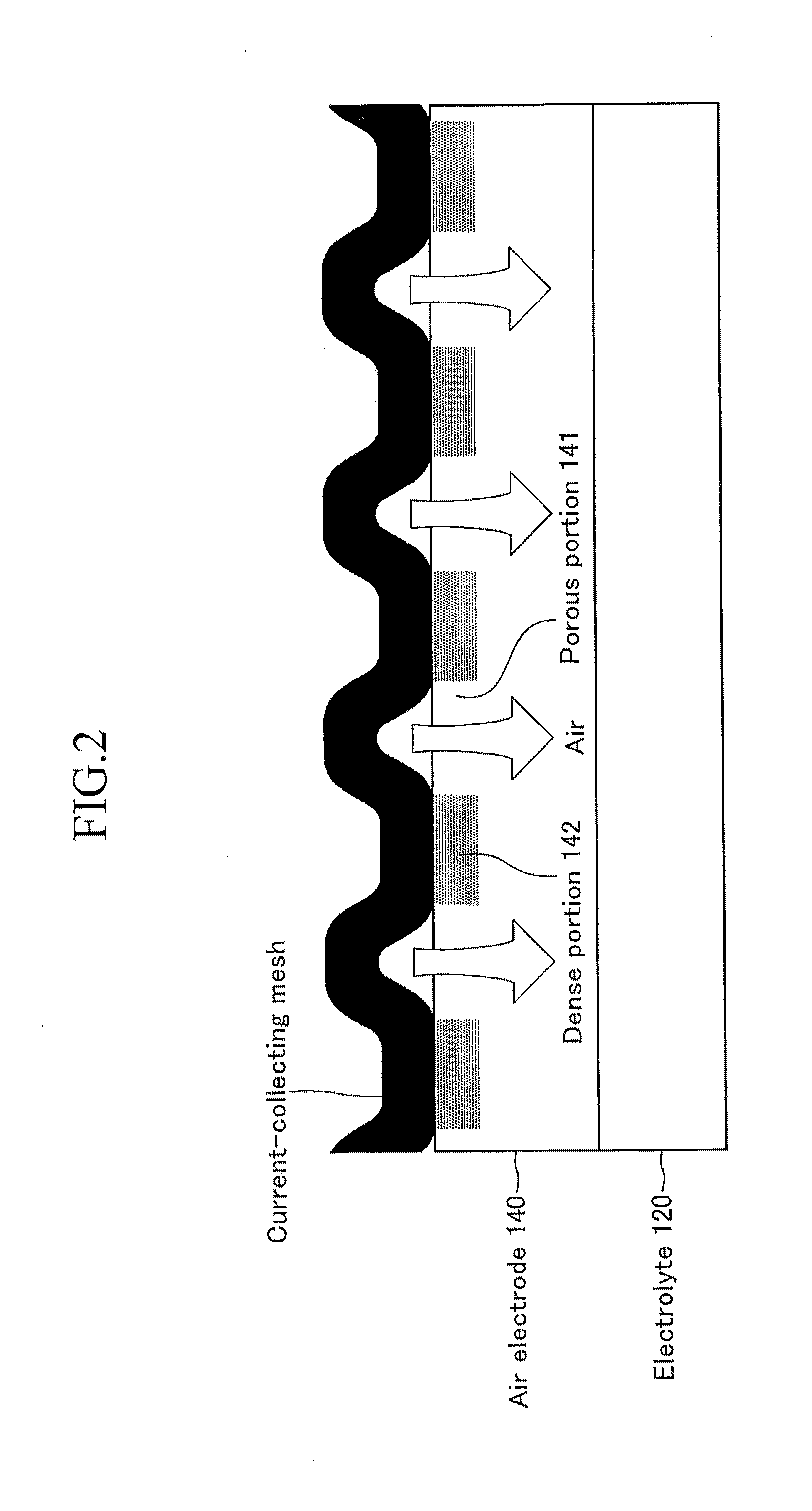

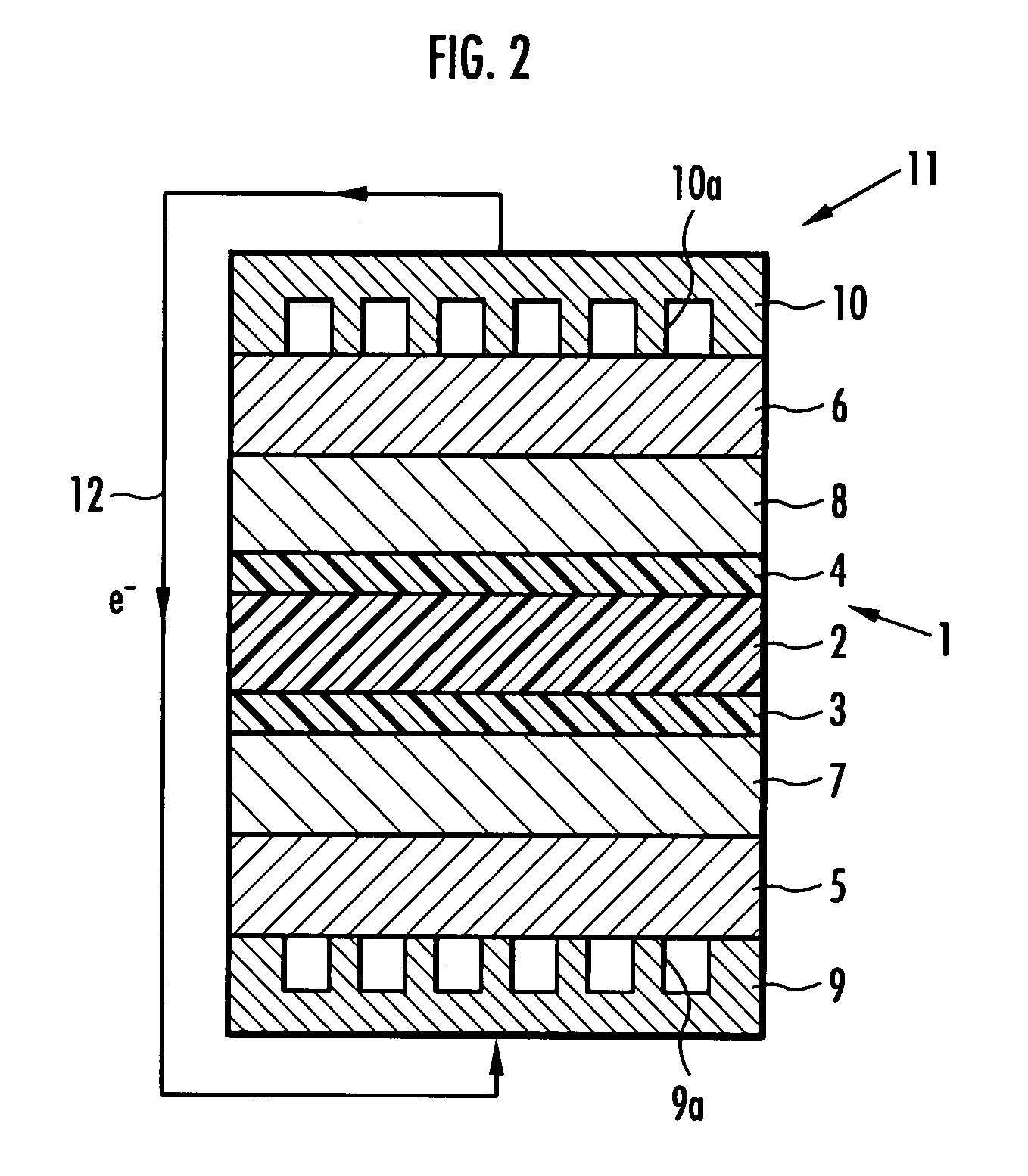

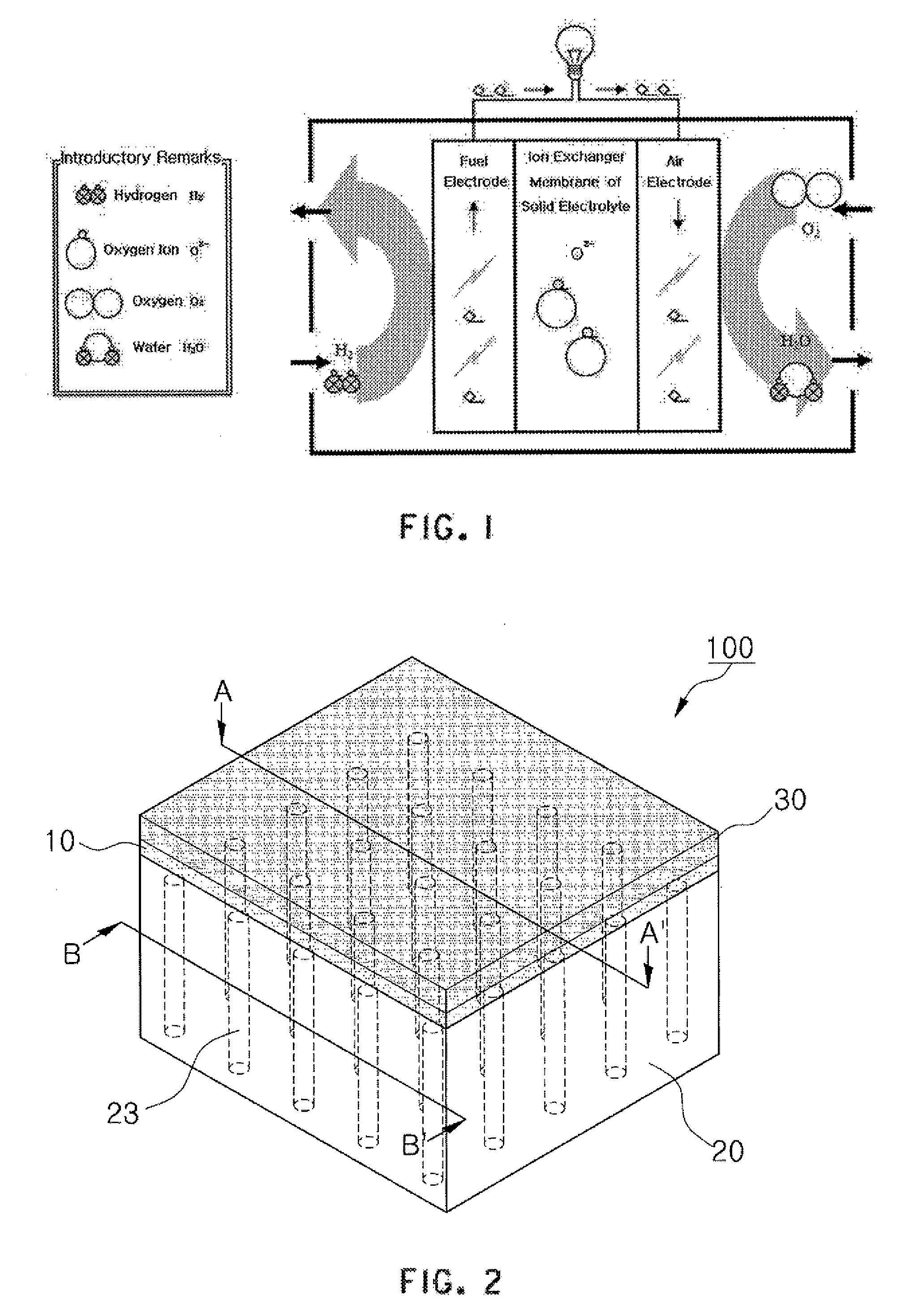

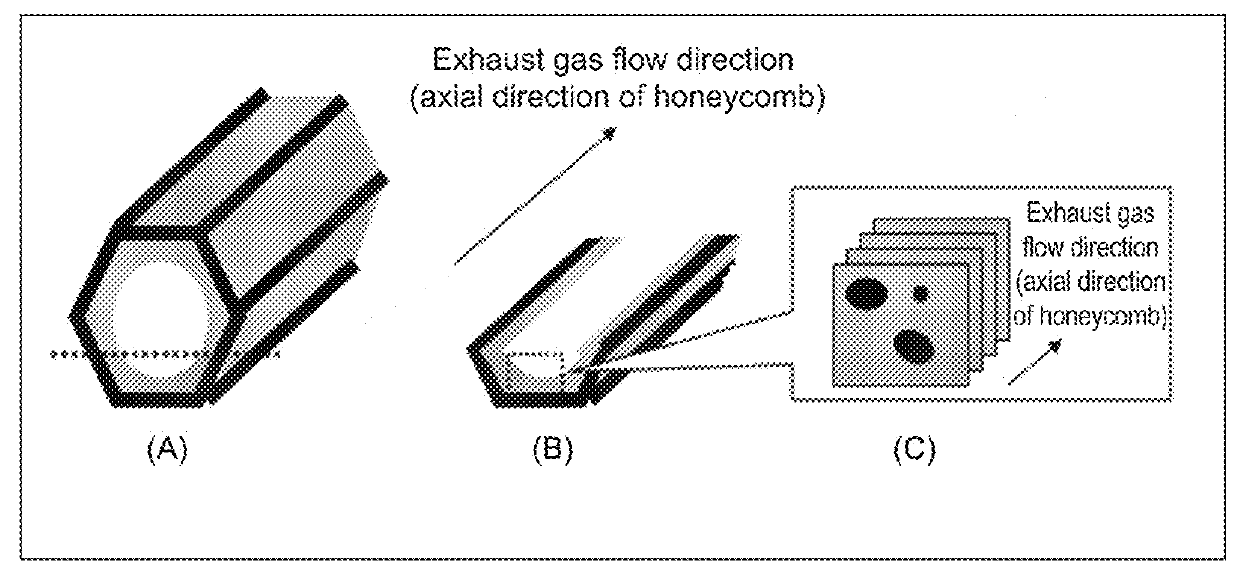

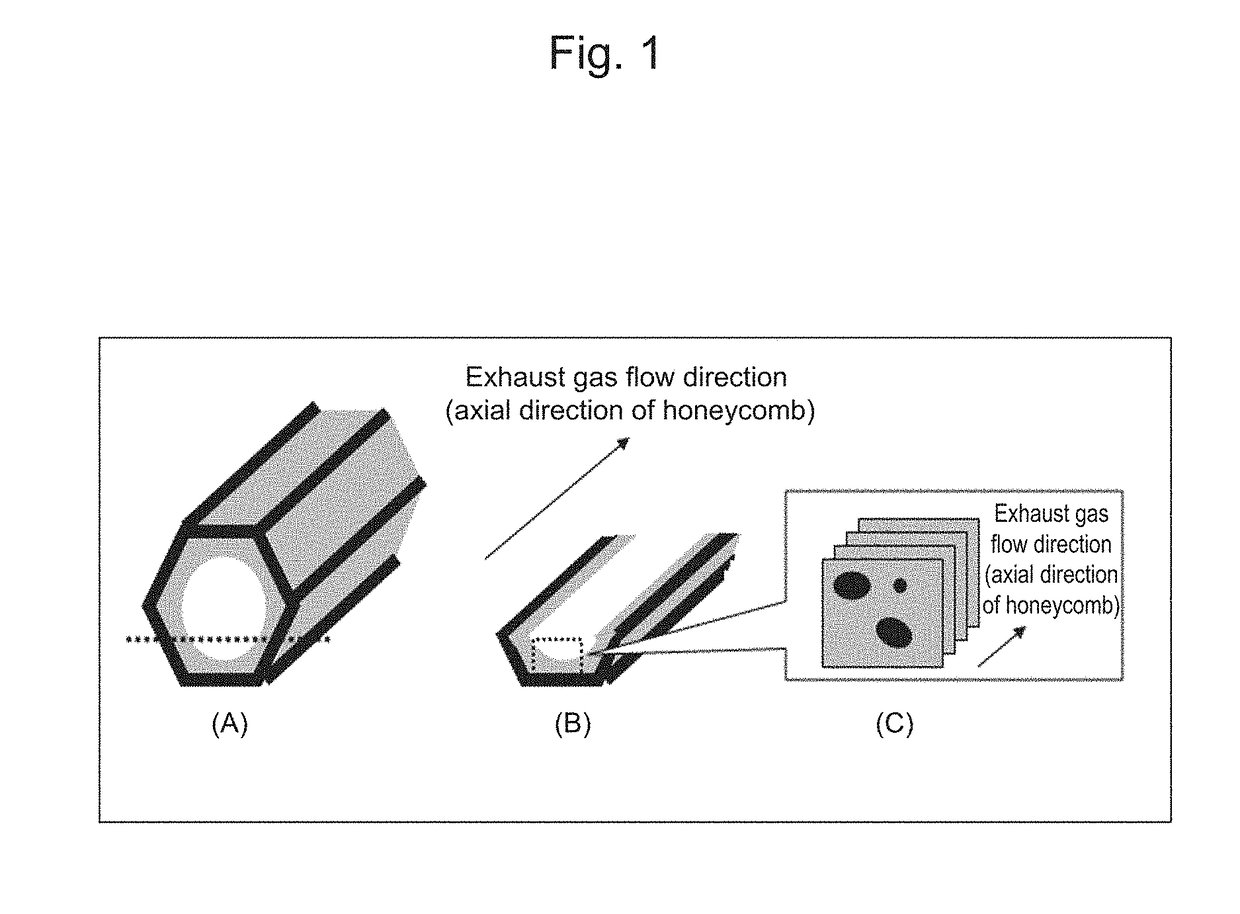

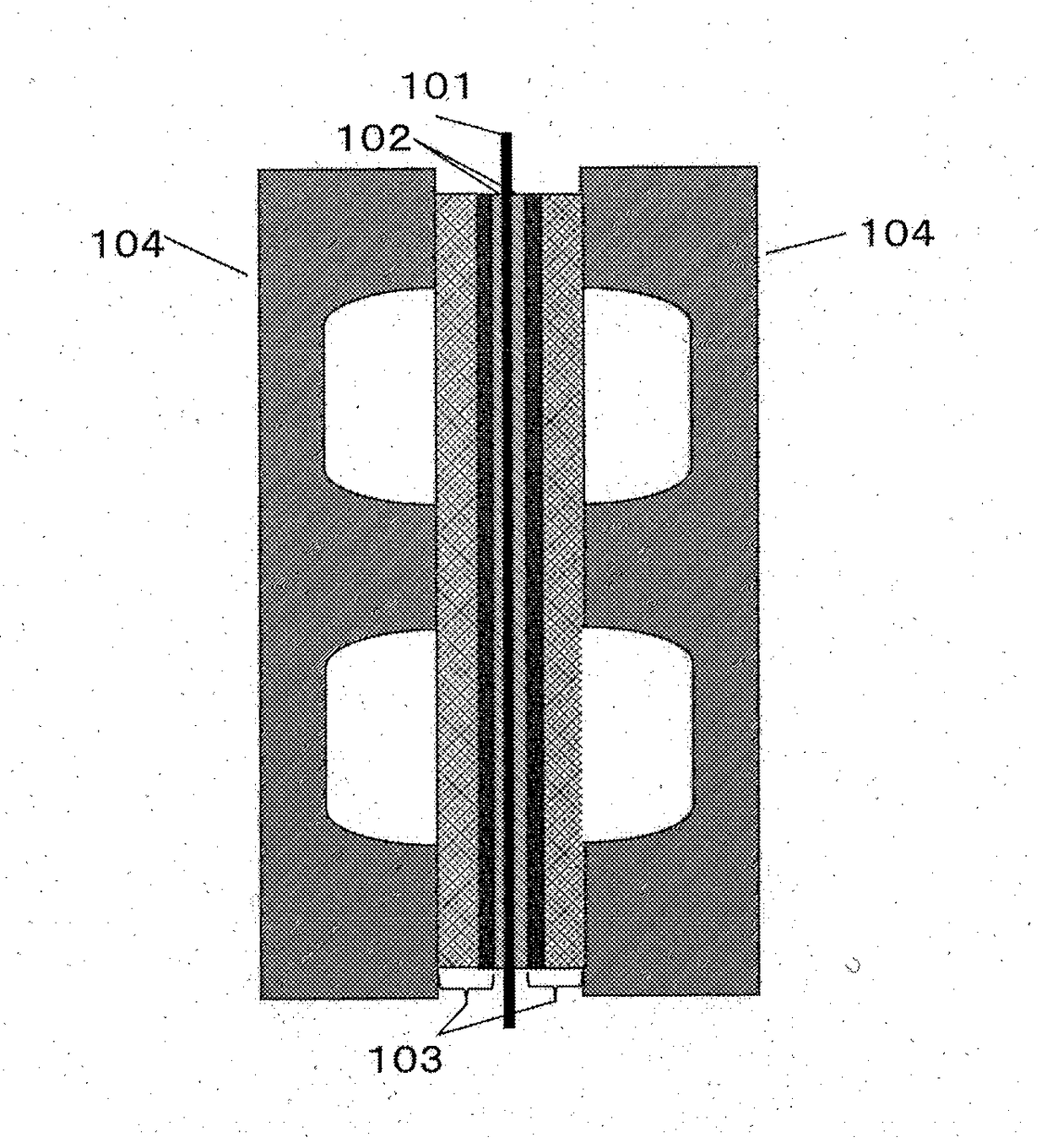

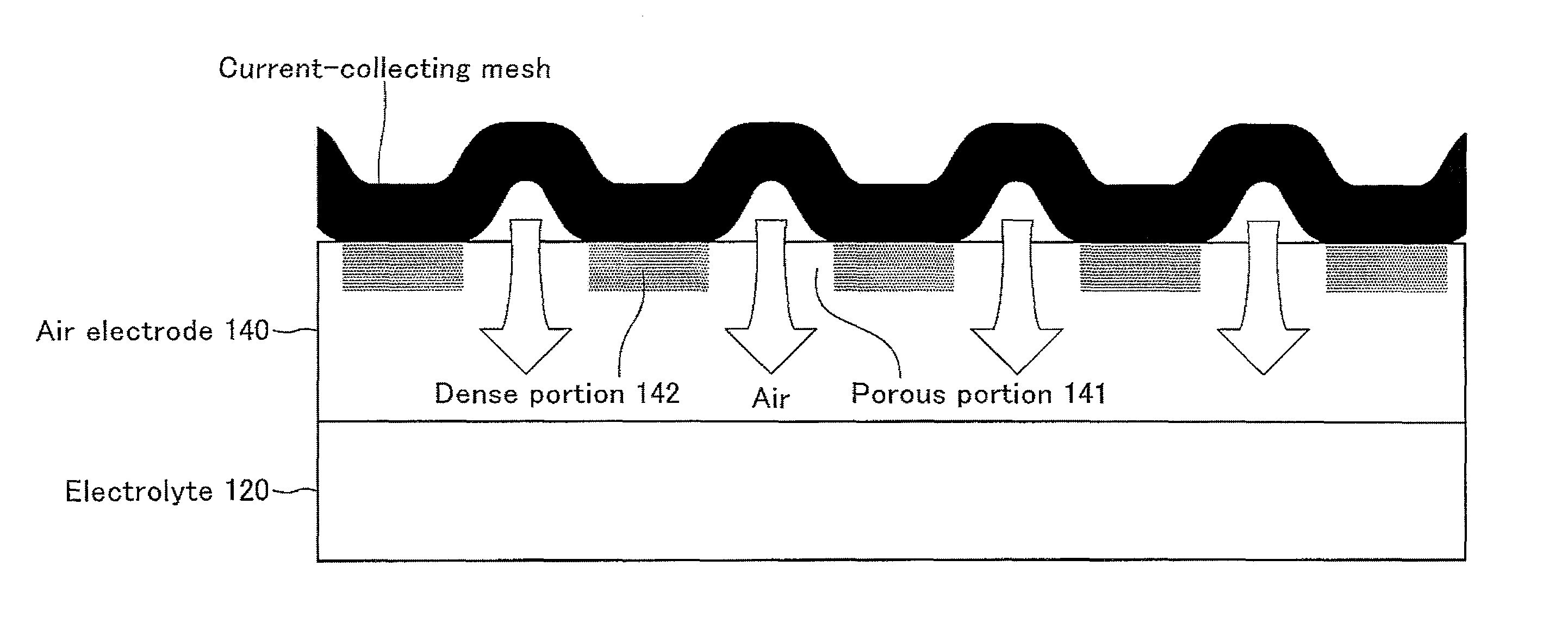

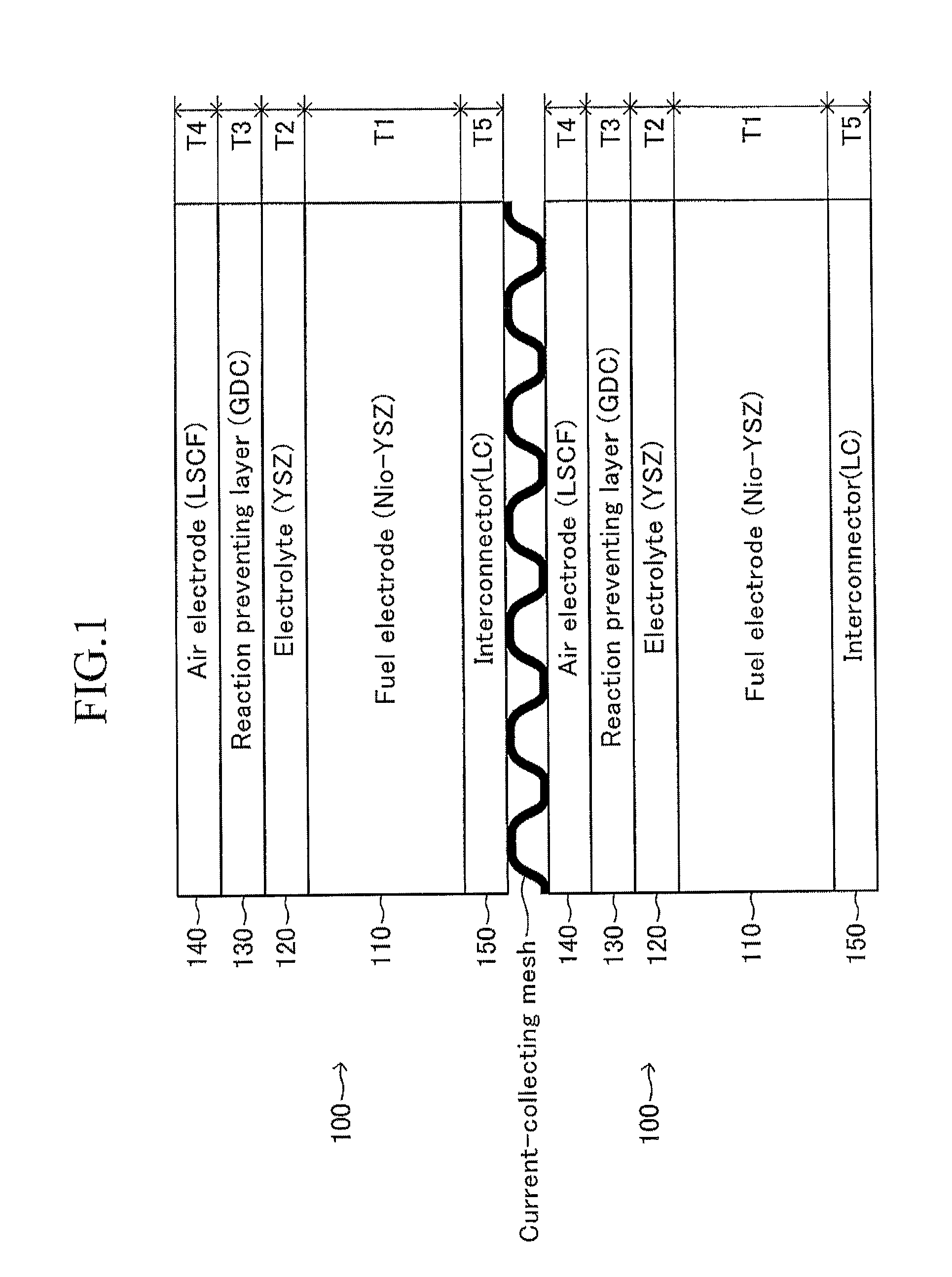

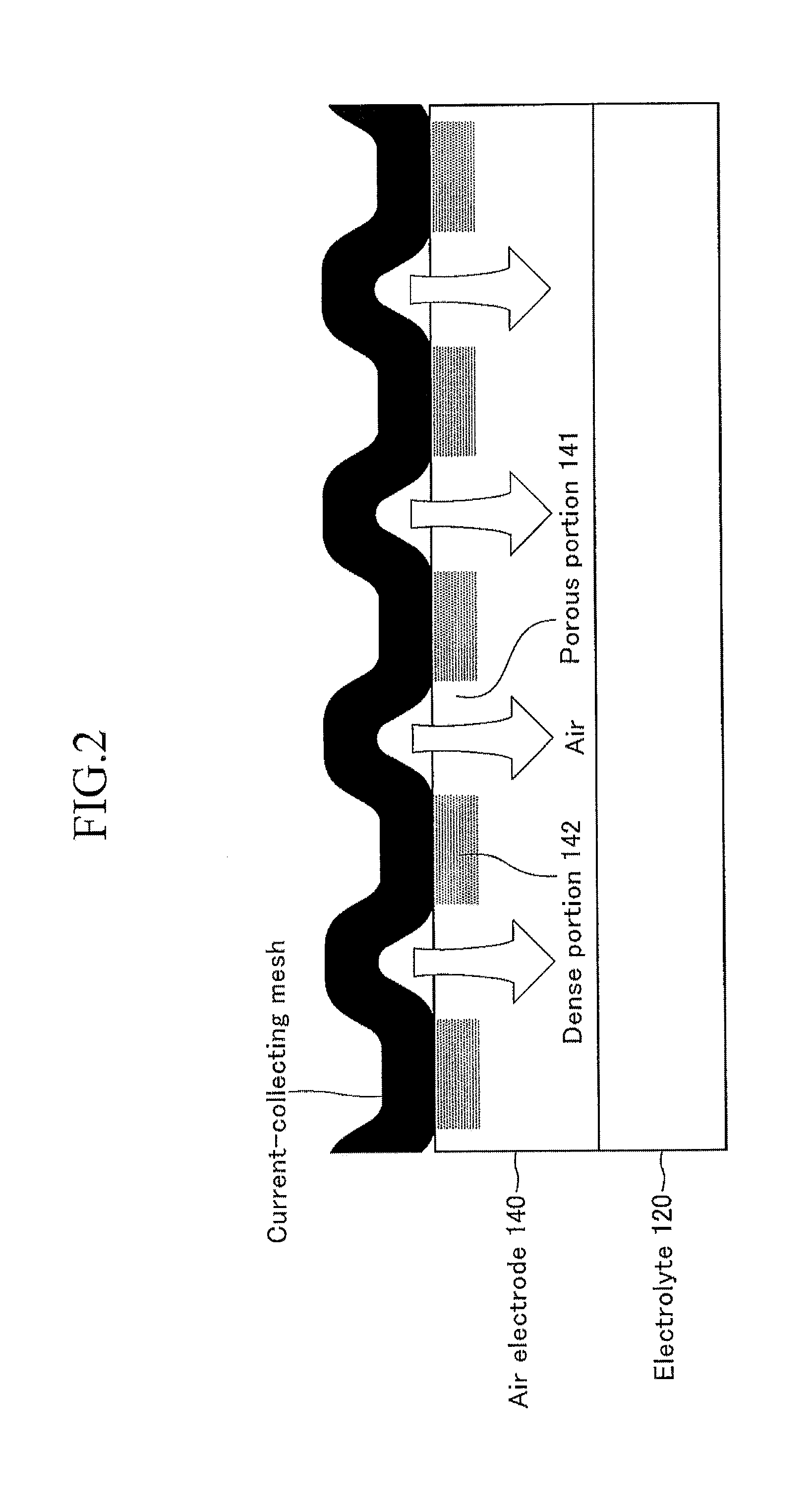

Solid oxide fuel cell

ActiveUS20120164552A1Reduced responseIncrease productionFinal product manufactureElectrode carriers/collectorsPorosityFuel cells

A solid oxide fuel cell having a fuel electrode, a solid electrolyte film, an air electrode, and a conductive current-collecting mesh bonded to an upper surface, opposite to a lower bonding surface with the solid electrolyte film, of the air electrode. Plural bonding portions that are bonded to the current-collecting mesh and plural non-bonding portions that are not bonded to the current-collecting mesh are present on the upper surface of the air electrode. In the air electrode, regions having a porosity smaller than a porosity of the other region are respectively formed on the position in the middle of the thickness of the air electrode from each bonding portion. The average of the porosity of the dense portion is 20% or more and less than 35%, while the average of the porosity of the porous portion is 35% or more and less than 55%.

Owner:NGK INSULATORS LTD

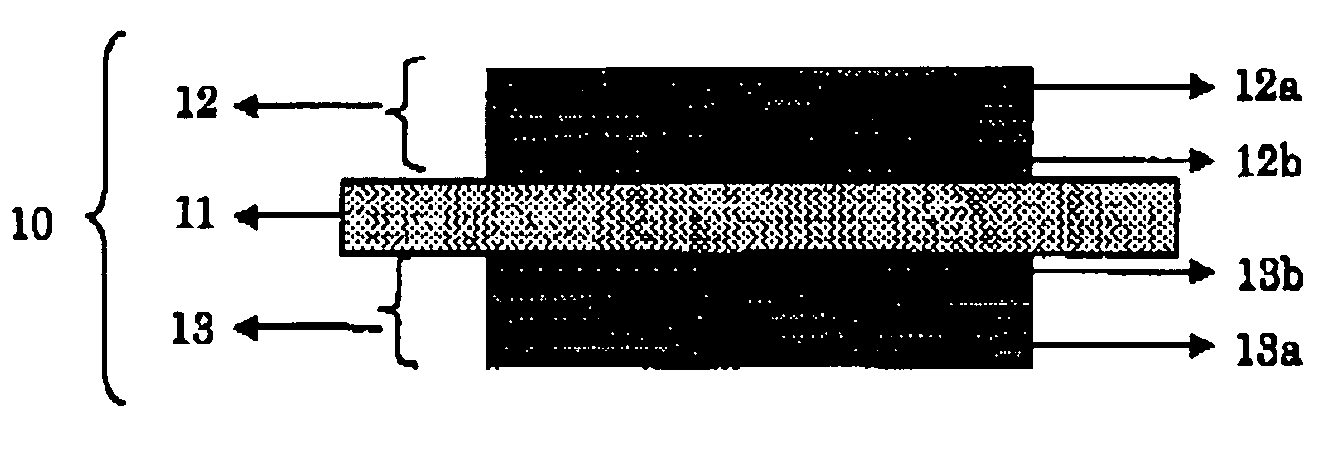

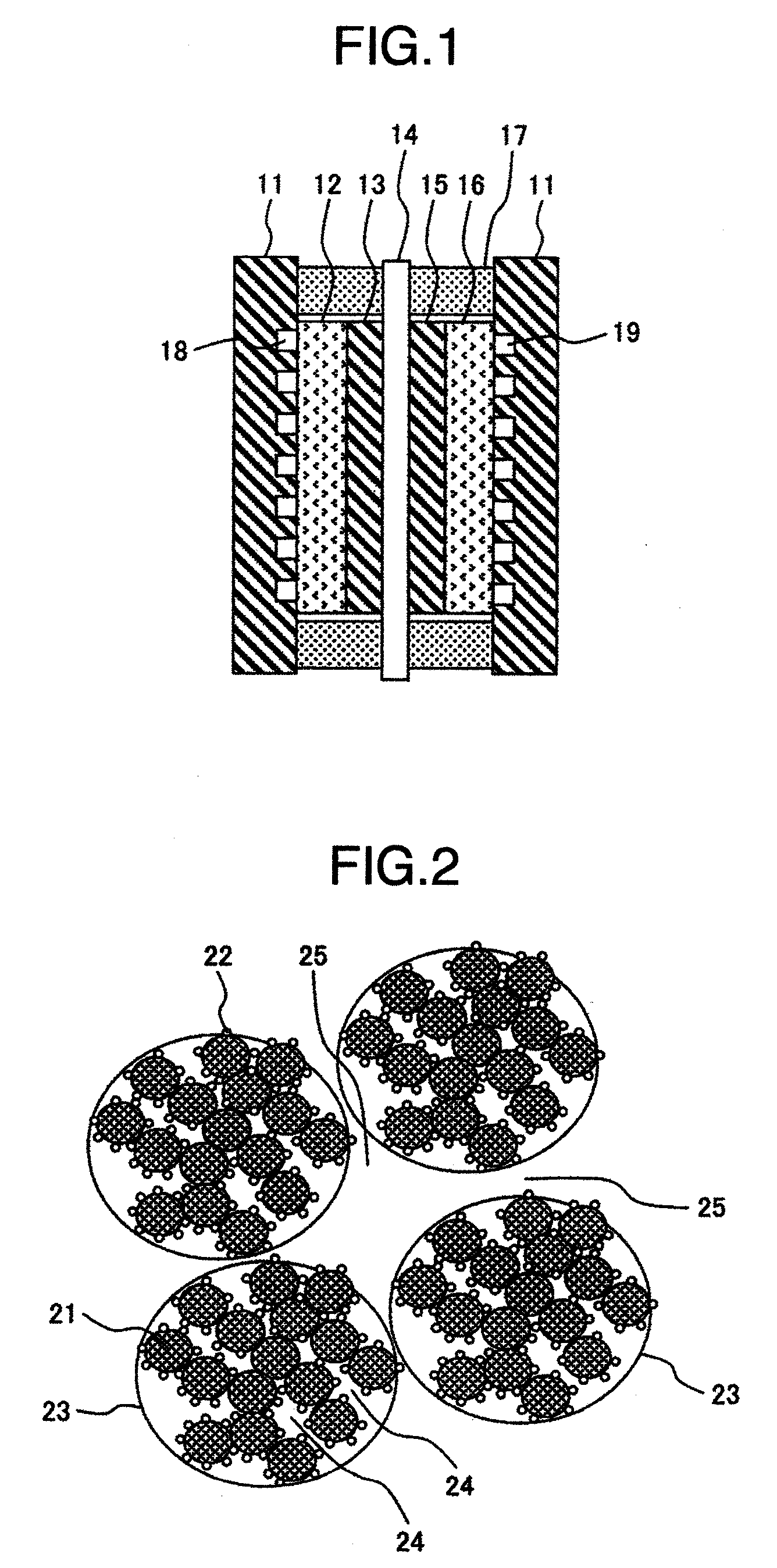

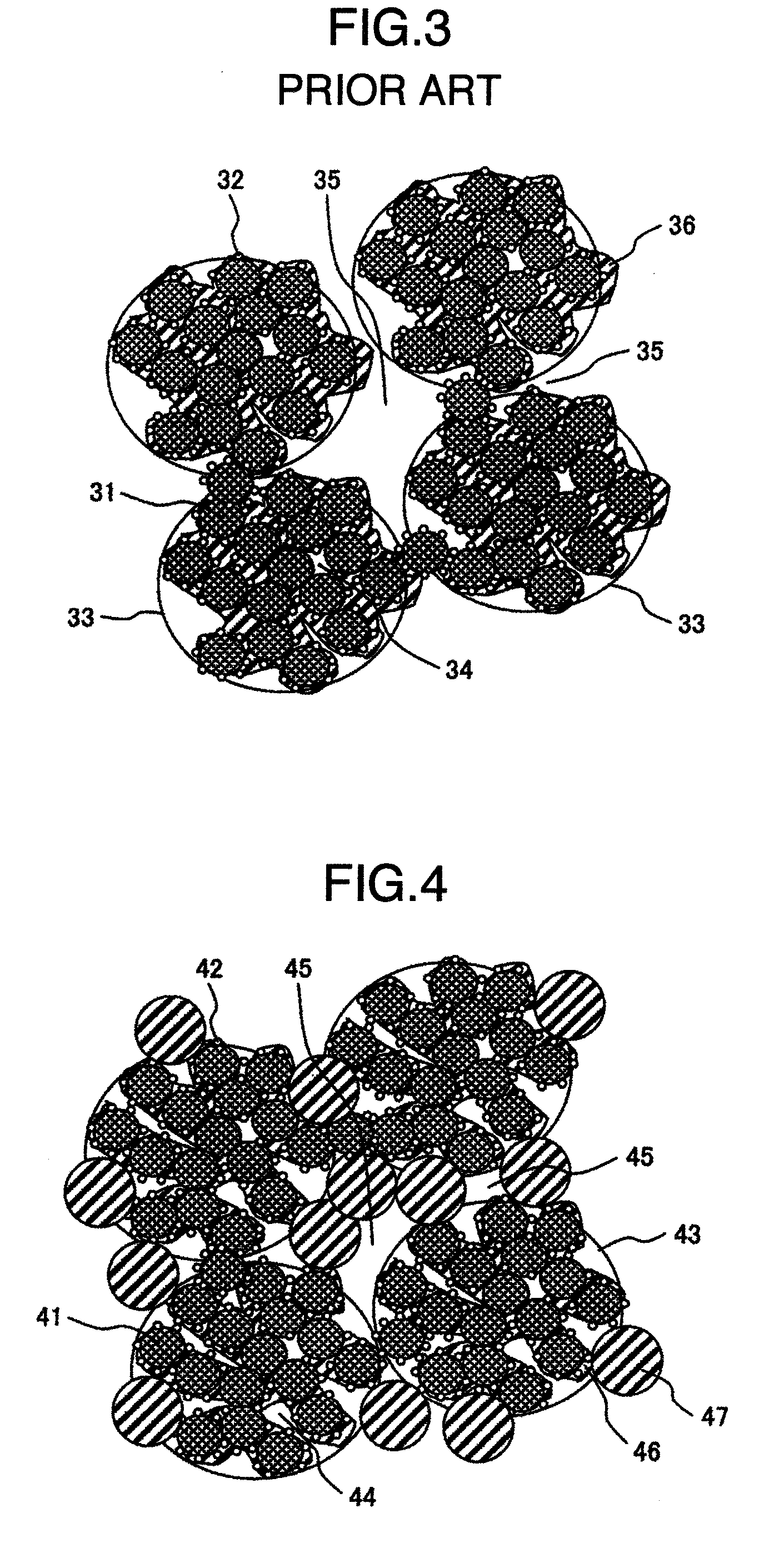

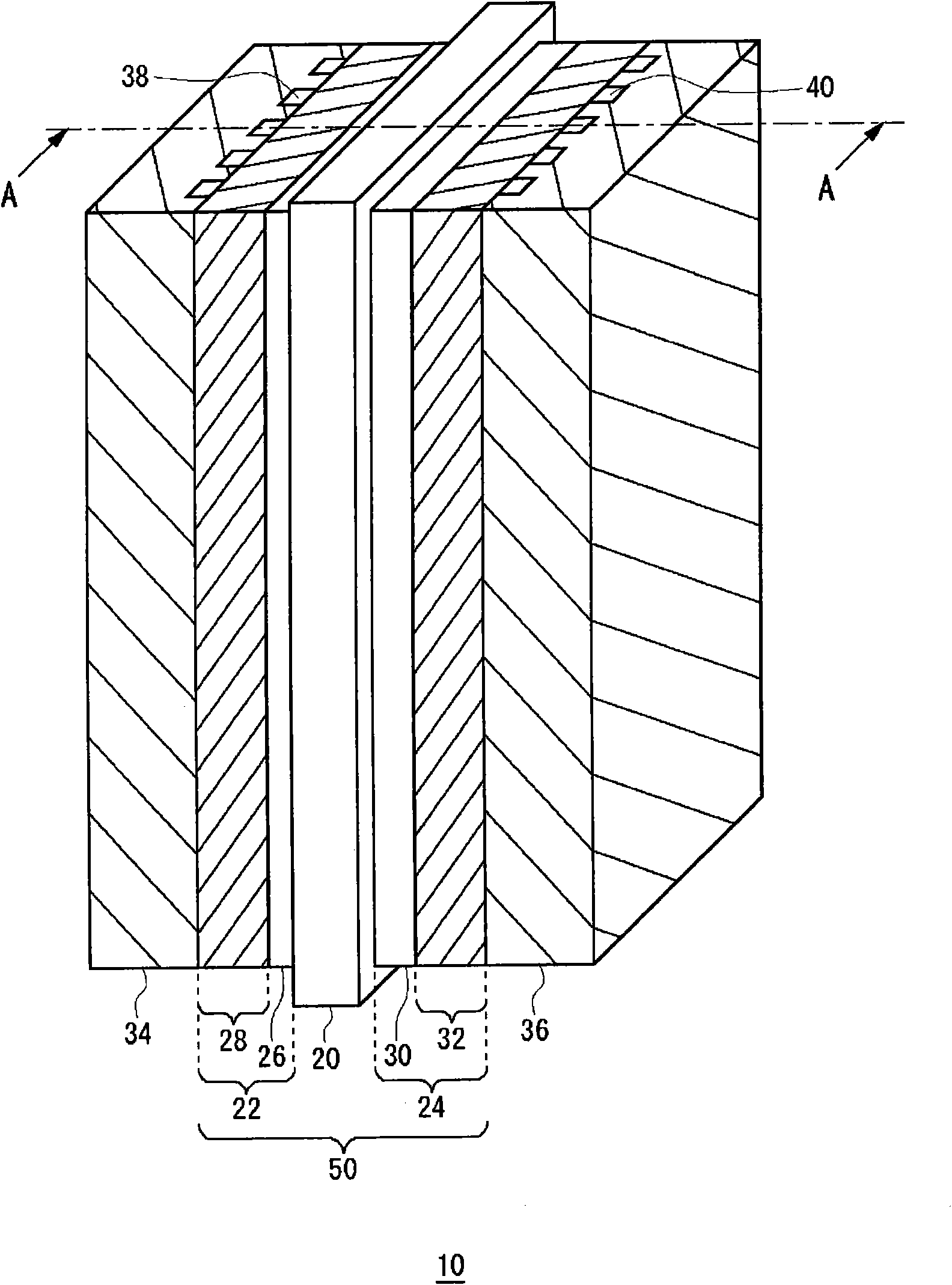

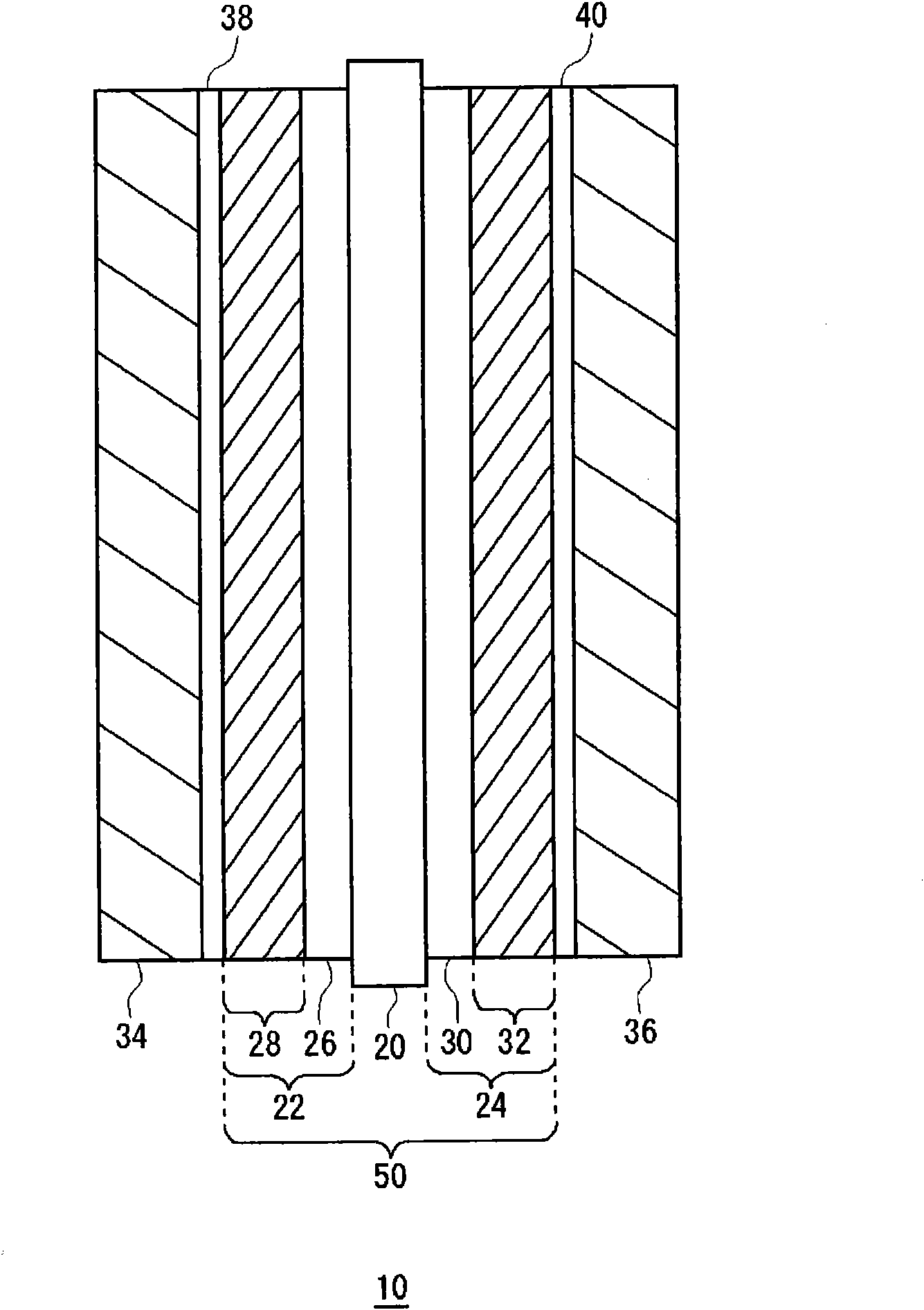

Membrane-electrode assembly and fuel cell using the same

InactiveUS20110123897A1High catalyst utilizationIncrease output powerFinal product manufactureCell electrodesPolymer electrolytesFuel cells

In a membrane-electrode assembly comprising an anode, a cathode and a polymer electrolyte membrane and having a constitution in which the polymer electrolyte membrane is interleaved between the anode and the cathode, an agglomerate structure of carbon support formed with a plurality of carbon primary particles supporting catalyst particles is contained in the anode and the cathode, and particulate media having polymer electrolyte on the surface thereof are contained between adjacent agglomerate structures of carbon supports.

Owner:HITACHI LTD

Fuel cell electrode catalyst

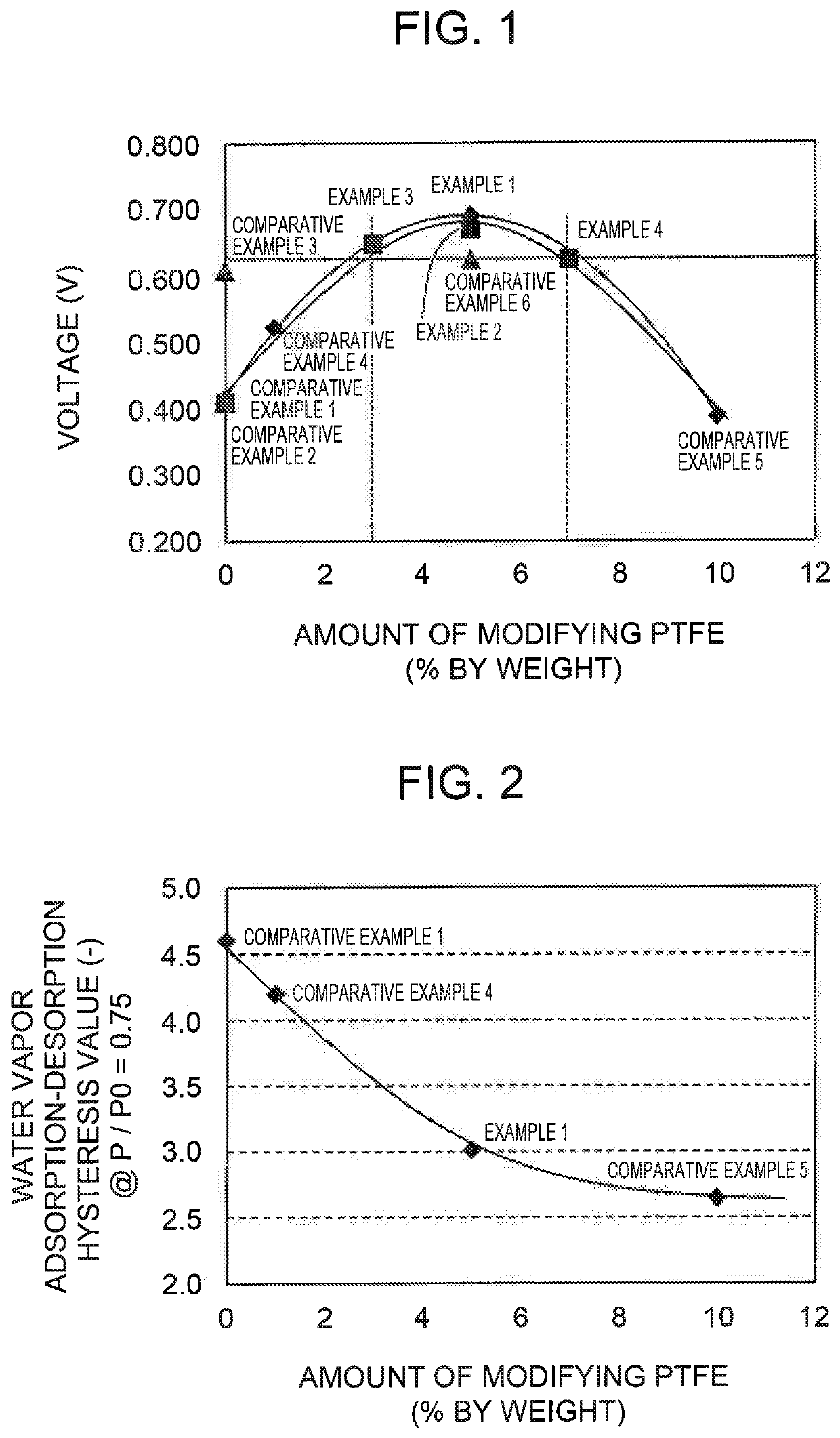

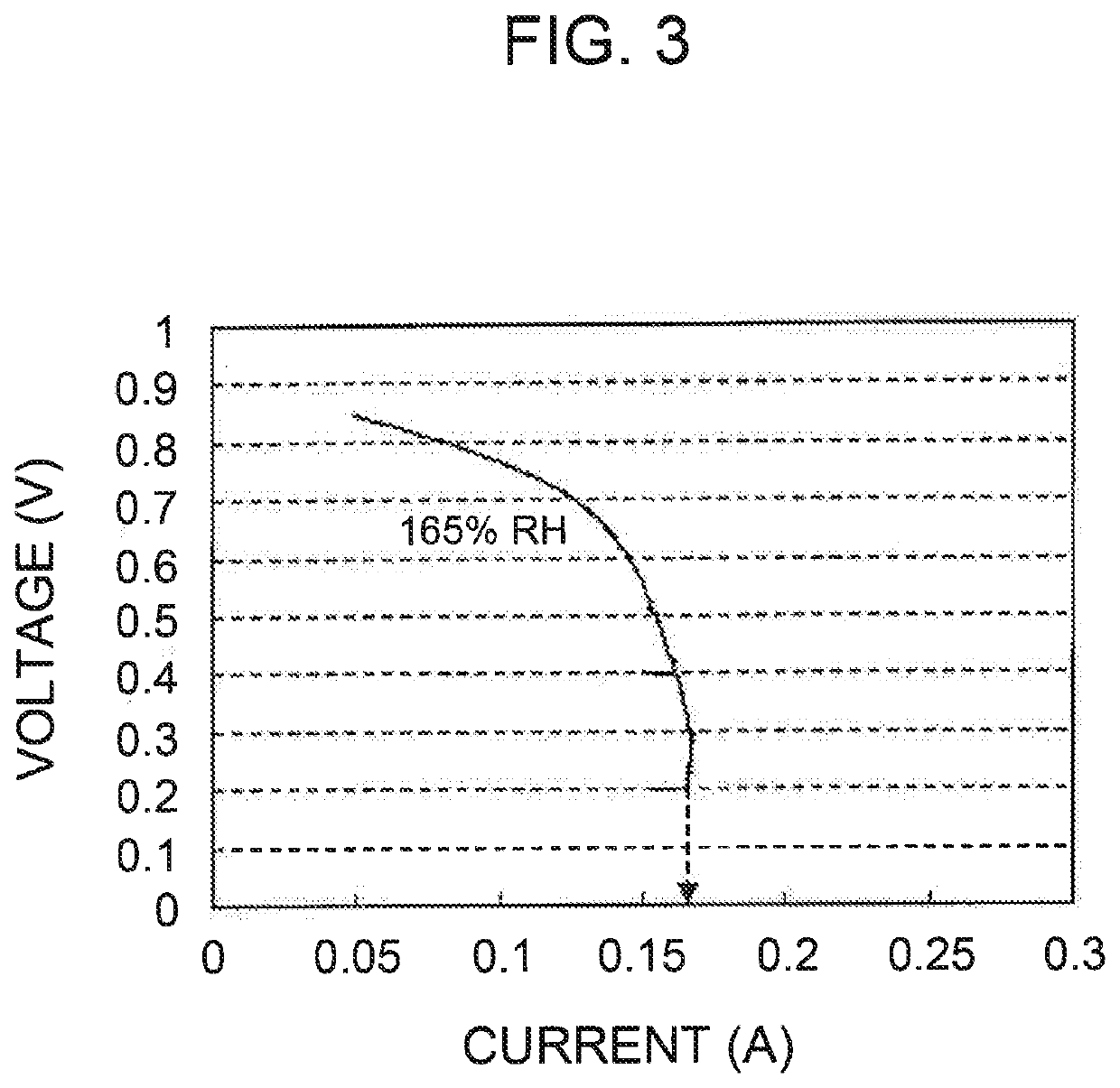

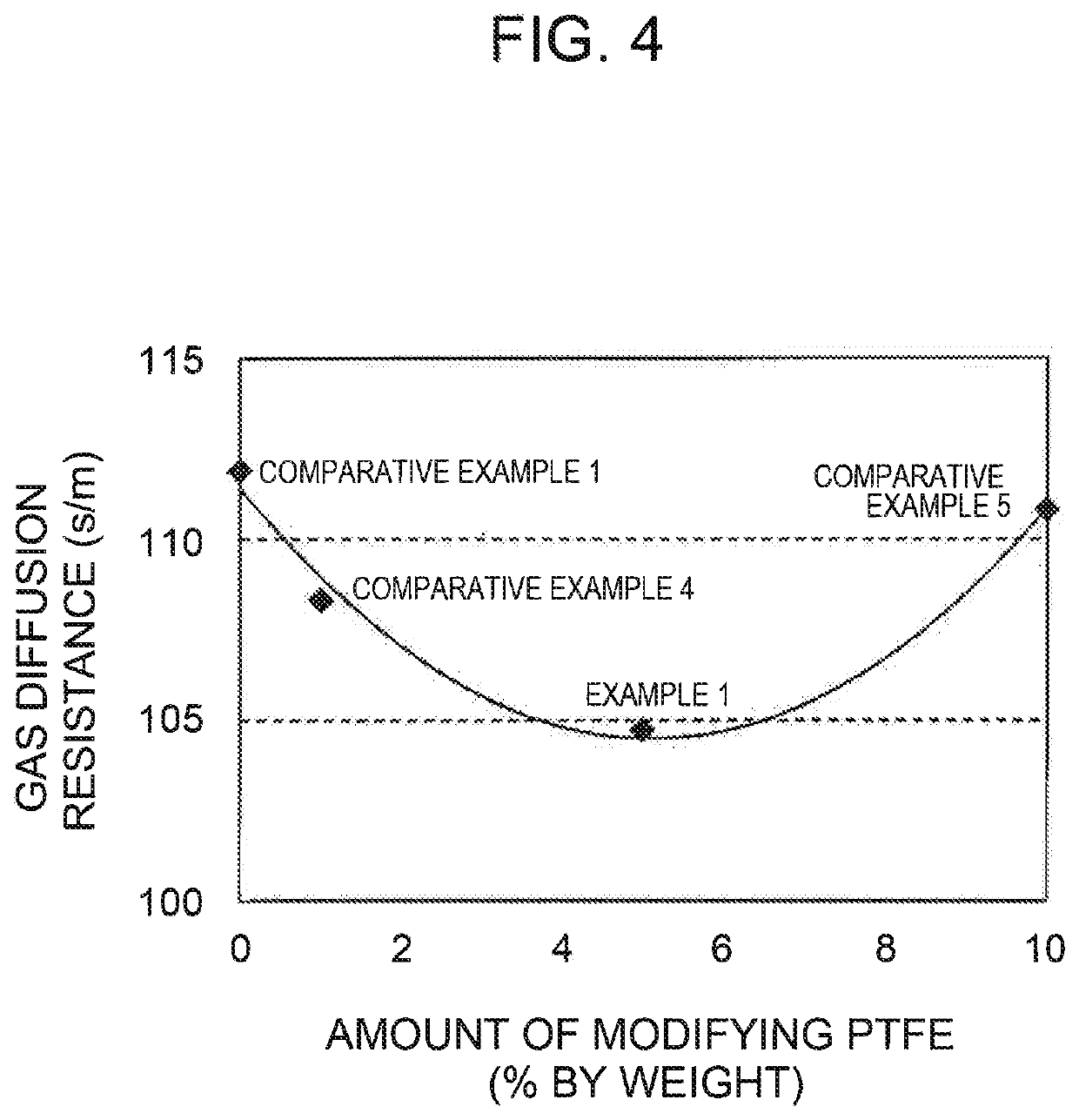

ActiveUS20180166697A1Good gas diffusionImprove waterproof performanceGraphiteCell electrodesFuel cellsOrganic chemistry

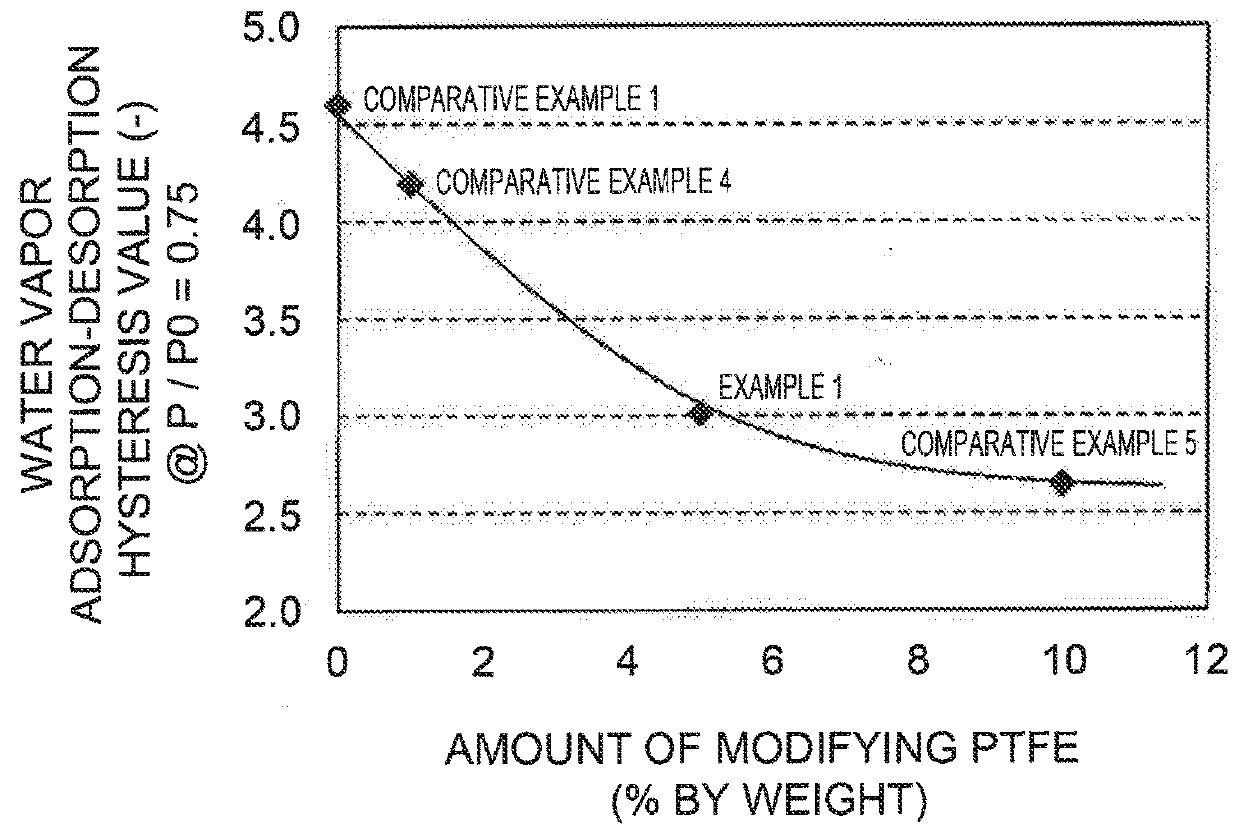

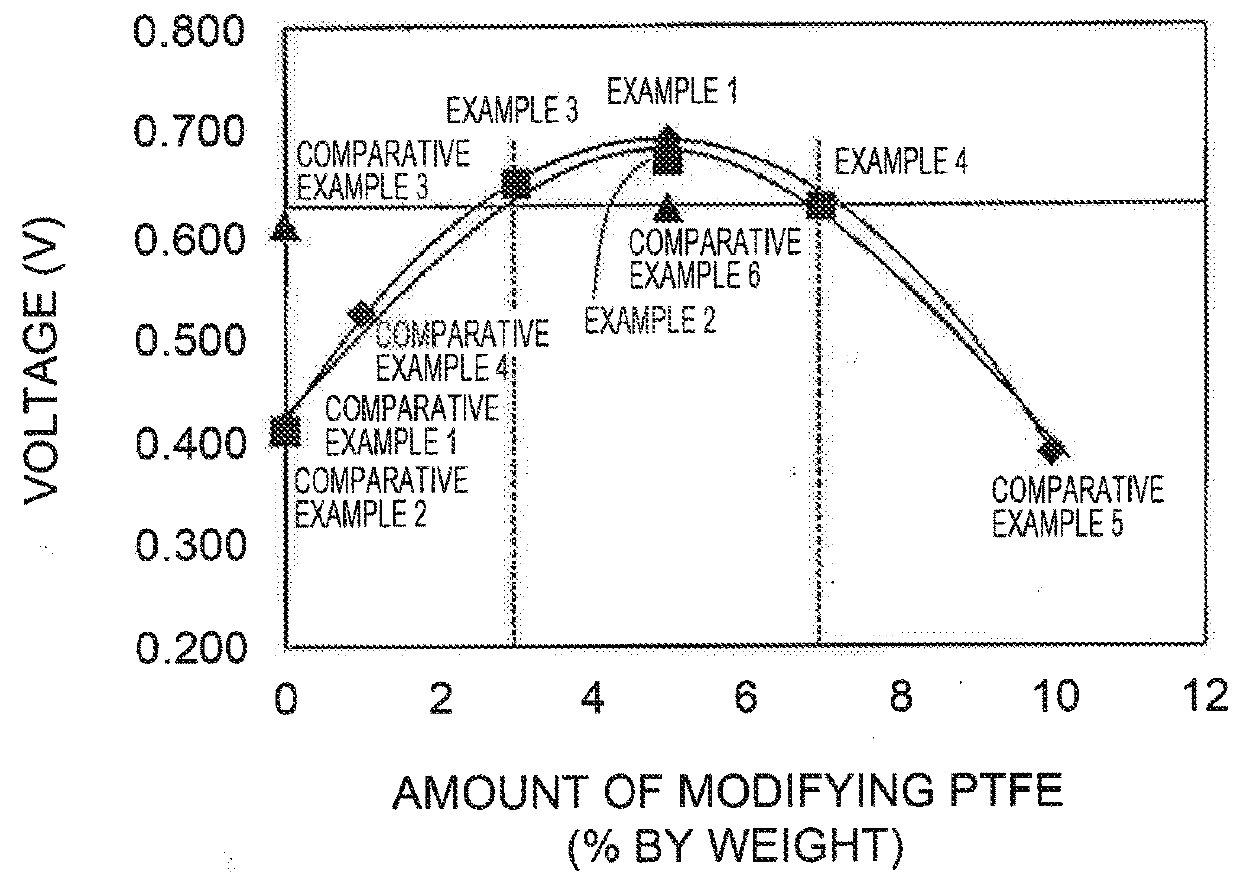

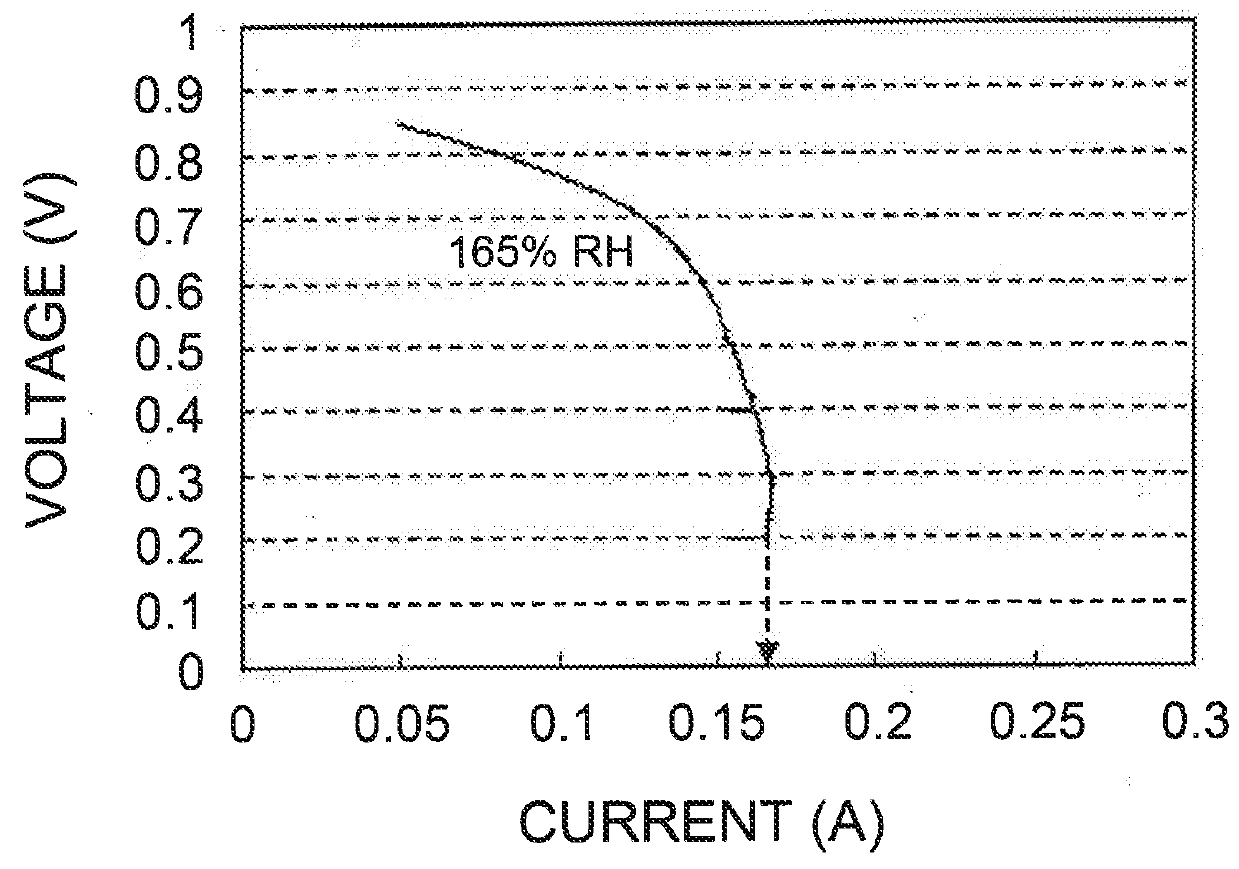

A fuel cell electrode catalyst includes: a noble-metal-supported catalyst including a carbon support and a noble metal supported on the carbon support; and a water-repellent material with which the noble-metal-supported catalyst is modified. The carbon support is mesoporous carbon in which a pore volume of pores having a pore size of 2 nm to 5 nm is 2.1 ml / g to 2.4 ml / g. An amount of the water-repellent material is 3% by weight to 7% by weight with respect to a total weight of the mesoporous carbon and the water-repellent material.

Owner:TOYOTA JIDOSHA KK

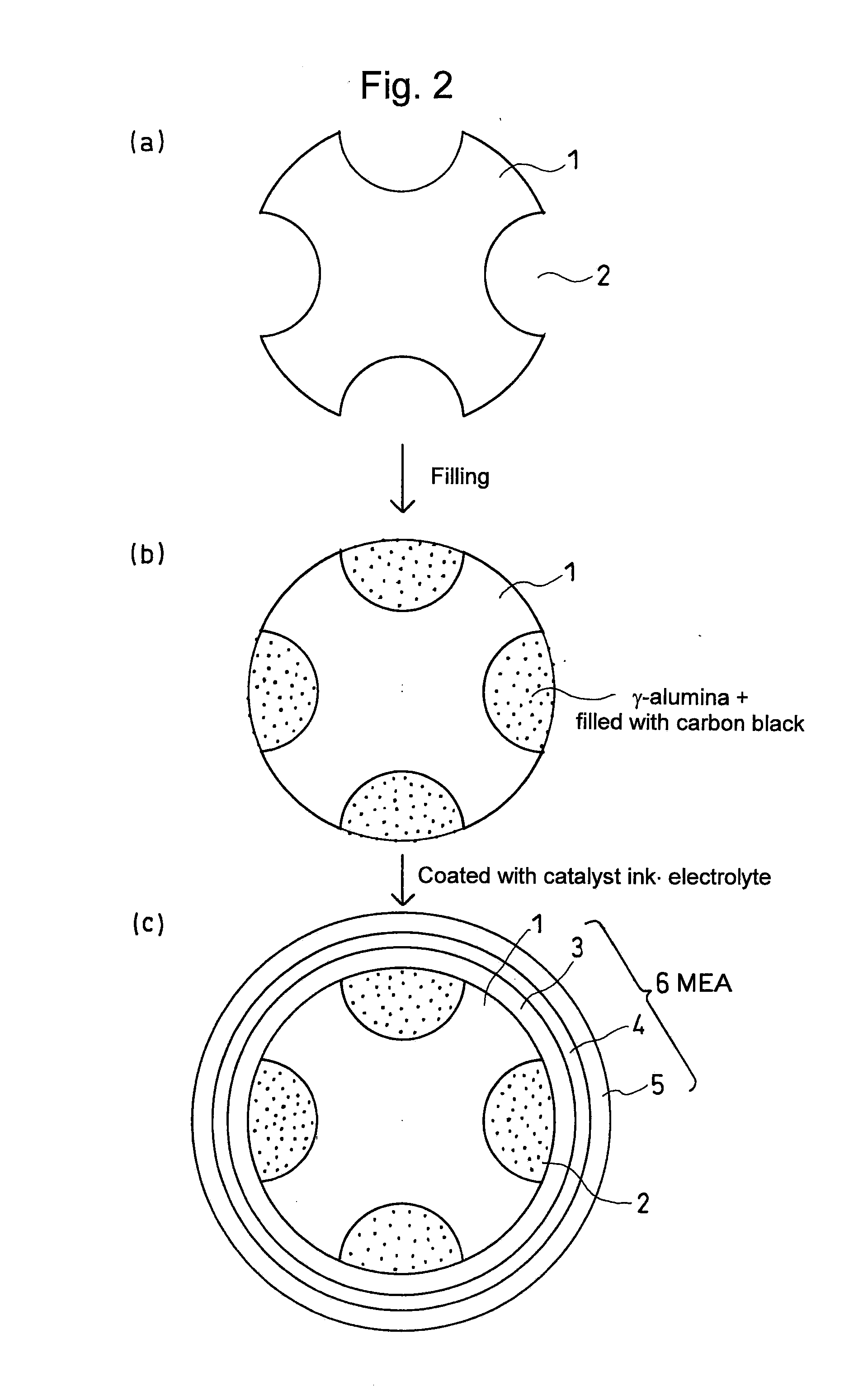

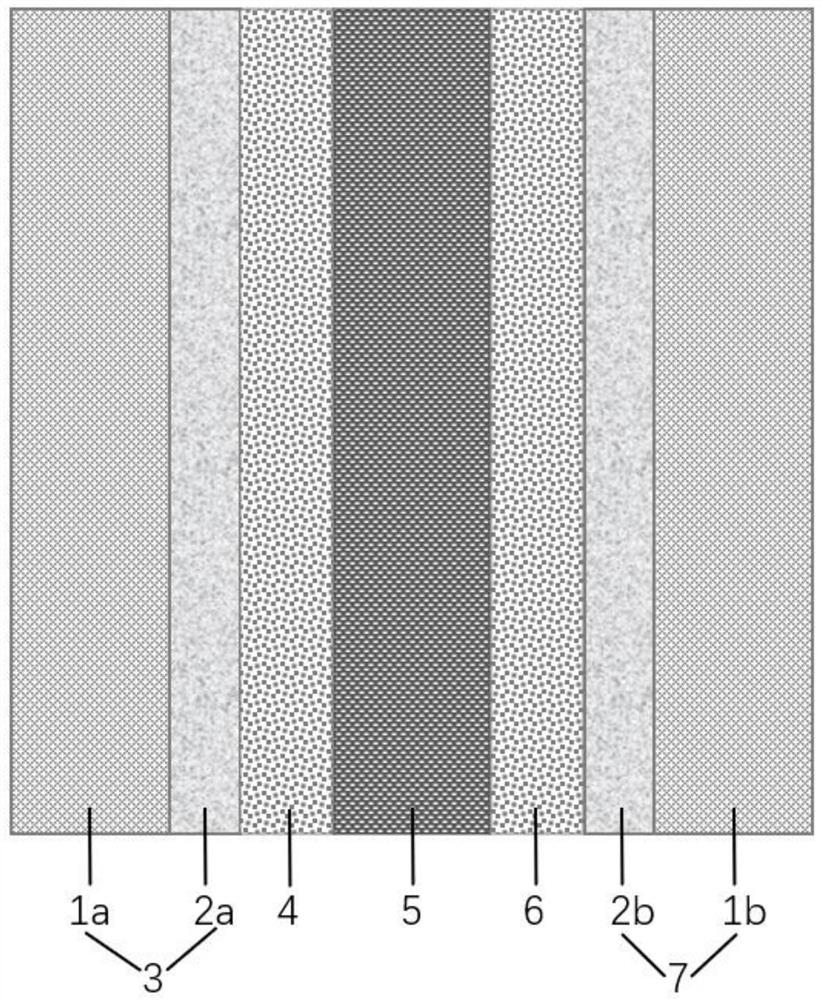

Membrane electrode assembly for use in solid polymer electrolyte fuel cell

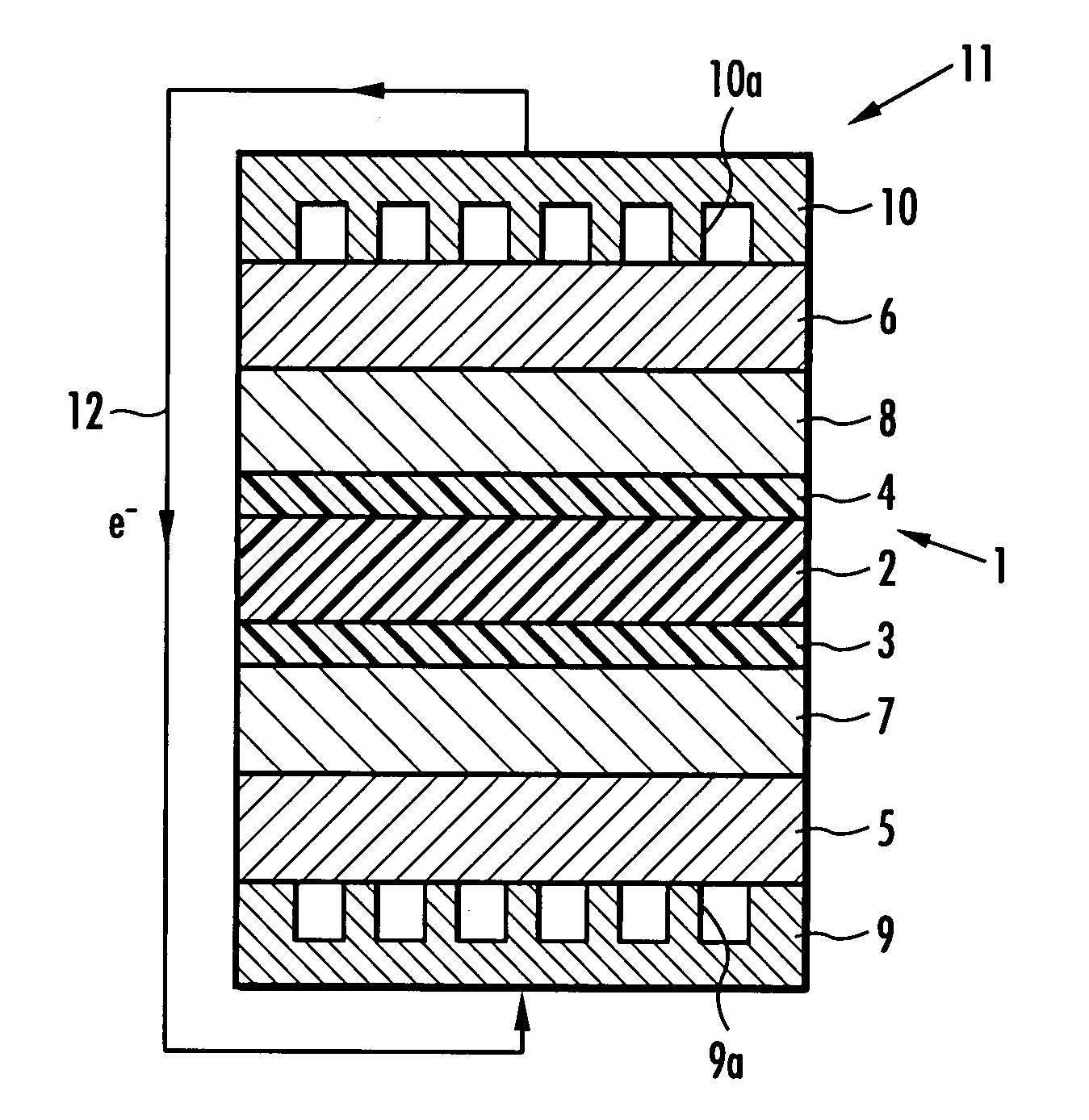

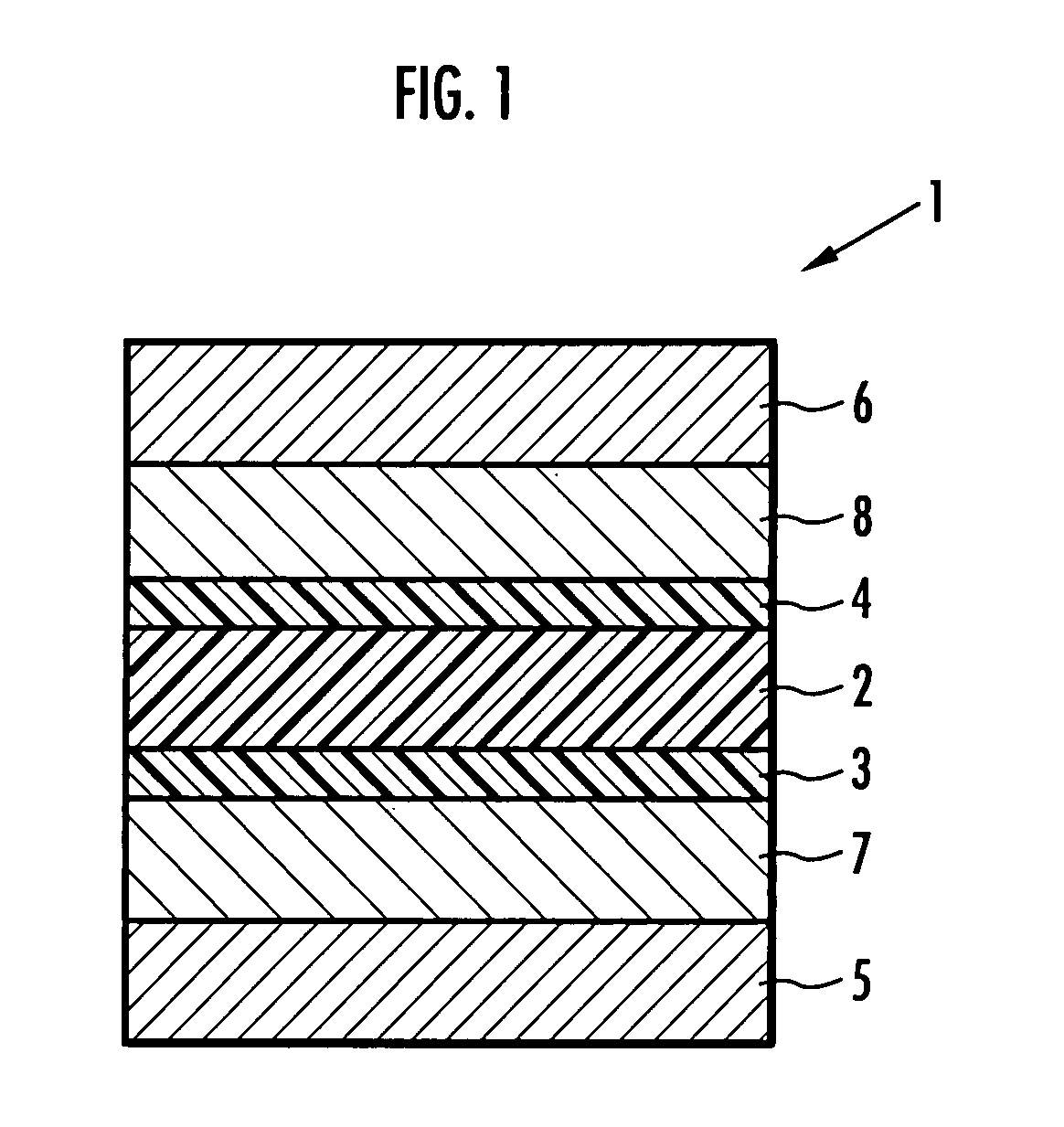

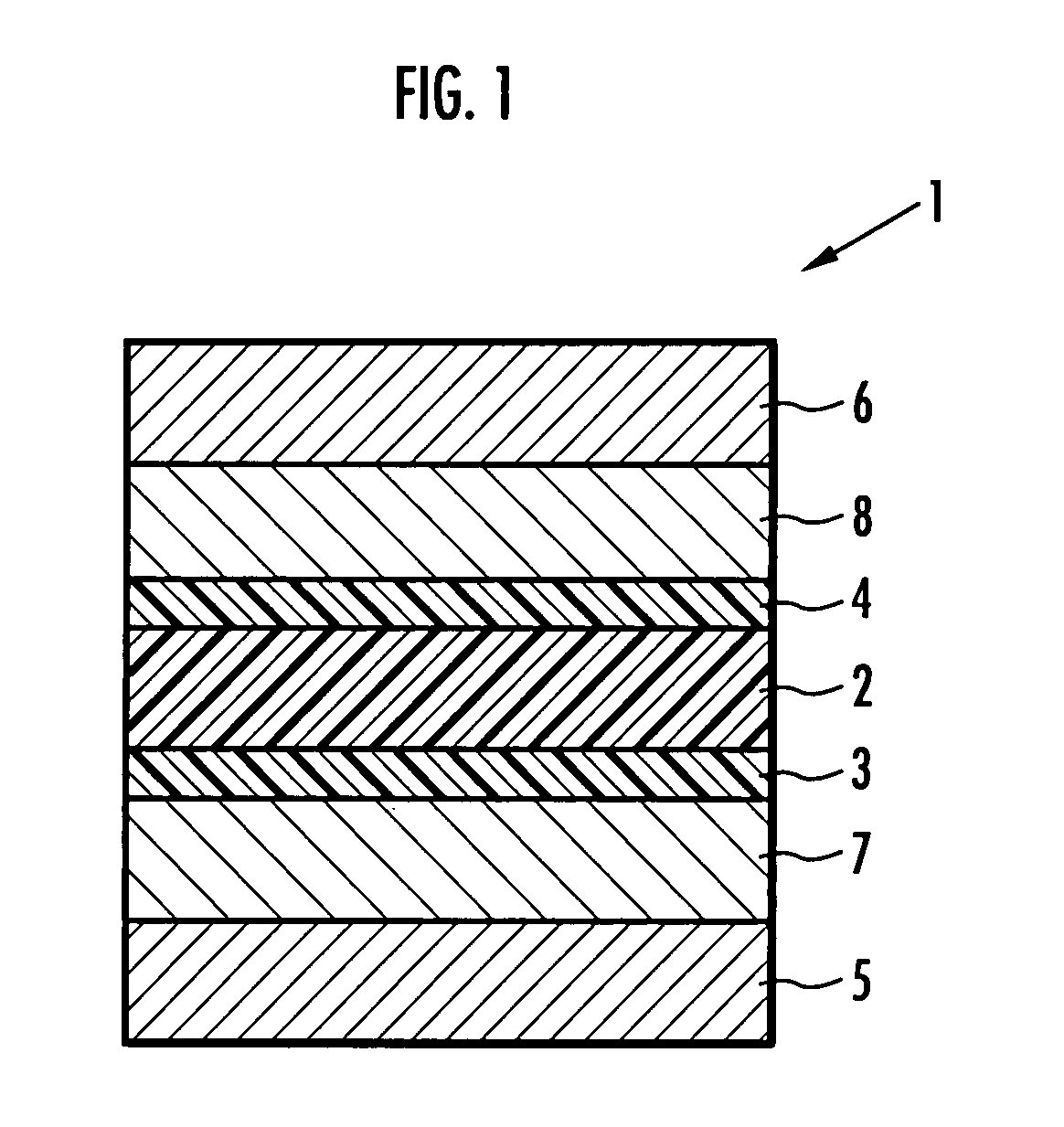

ActiveUS20070218348A1Improve power generation effectImprove gas diffusivityFuel cell auxillariesActive material electrodesPolymer electrolytesEngineering

The present invention provides a membrane electrode assembly for use in a solid polymer electrolyte fuel cell which assembly can ensure the gas diffusivity, the capability of discharging the generated water and the moisture retentivity, and can attain an excellent electric power generation performance in the gas atmosphere under a wide variety of humidity conditions. The membrane electrode assembly comprises: a cathode electrode catalyst layer 3 and an anode electrode catalyst layer 4 respectively disposed on one side and the other side of a solid polymer electrolyte membrane 2; gas diffusion layers 5 and 6 disposed respectively on the sides of the electrode catalyst layers 3 and 4; and intermediate layers 7 and 8 comprising pores and disposed respectively between the electrode catalyst layer 3 and the gas diffusion layer 5 and between the electrode catalyst layer 4 and the gas diffusion layer 6. The volume per unit area and per unit mass (pore volume) of the pores having pore size of 0.1 to 10 μm in the intermediate layer 7 in the cathode side is larger than that in the intermediate layer 8 in the anode side. The pore volume of the intermediate layer 7 in the cathode side is 1.7 to 4.3 μl / cm2 / mg and that of the intermediate layer 8 in the anode side is 0.5 to 1.4 μl / cm2 / mg. The intermediate layers 7 and 8 are each formed of a water-repellent resin comprising an electrically conducting particle.

Owner:HONDA MOTOR CO LTD

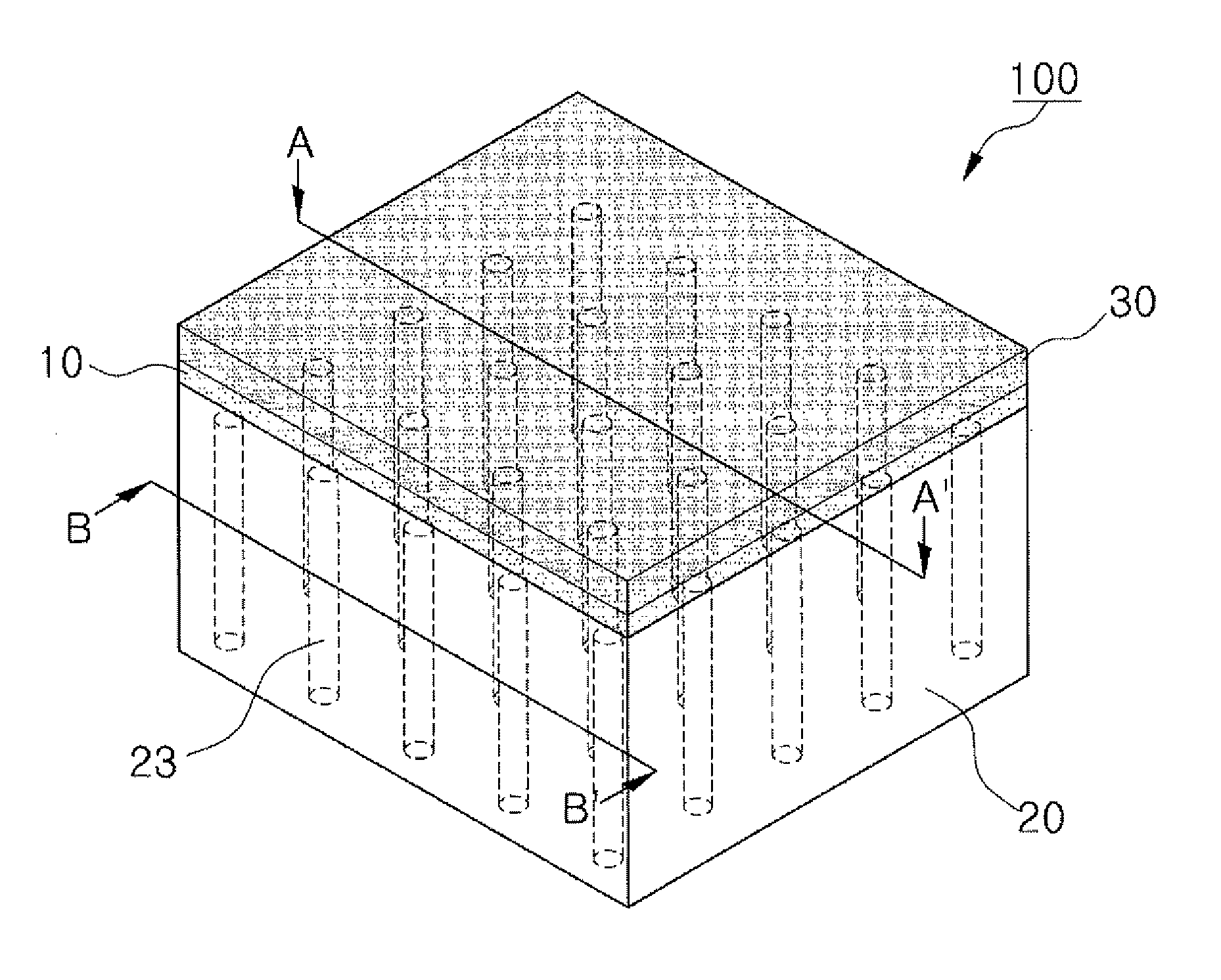

Solid oxide fuel cell

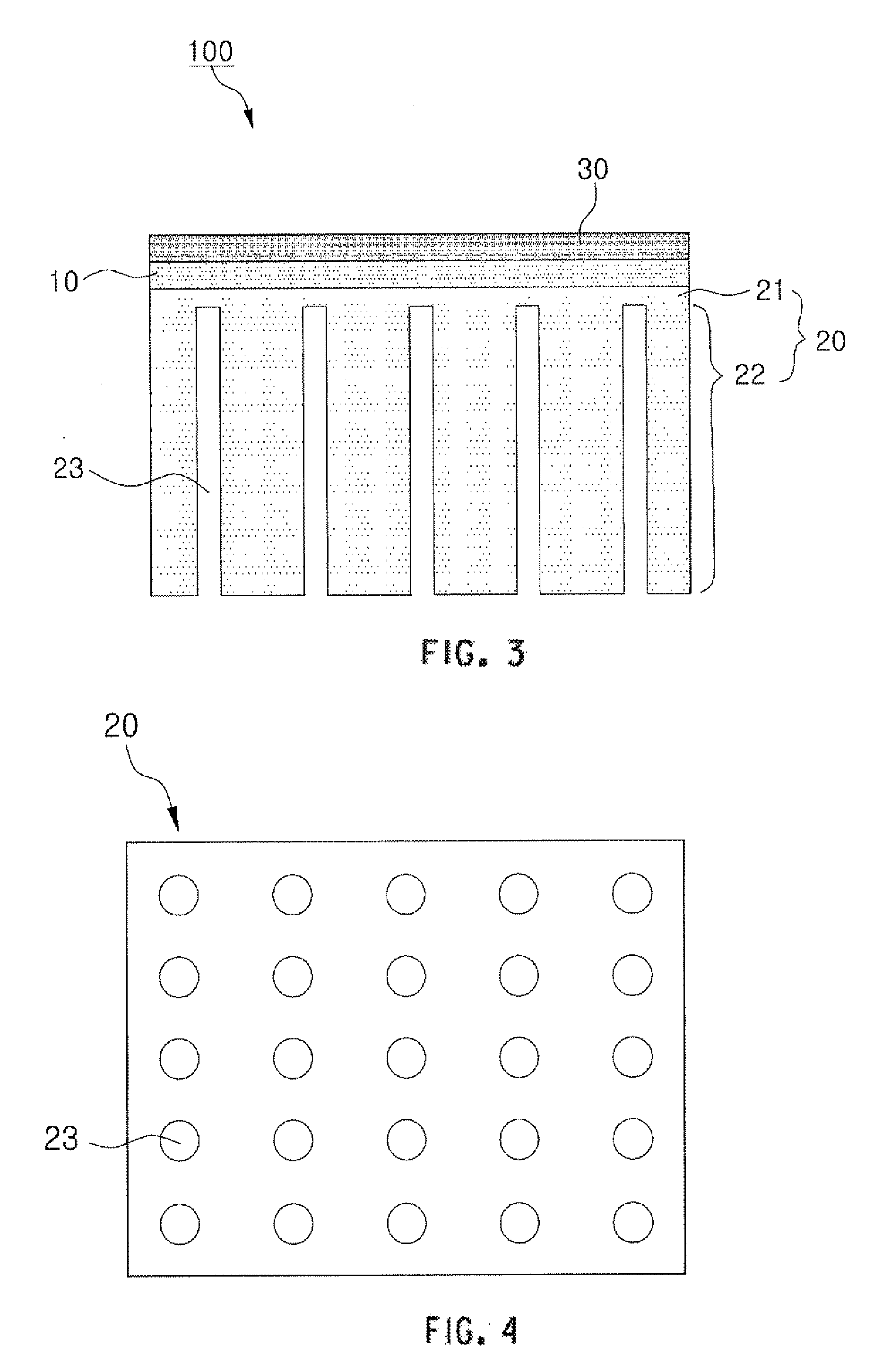

ActiveUS20090035636A1Increase fuel gas diffusion performanceReduce resistanceActive material electrodesSolid electrolyte fuel cellsFuel cellsEngineering

The present invention relates to a solid oxide fuel cell in which an anode is formed with a hollow portion, and the hollow portion may be used as a gas diffusion path, thereby improving gas diffusion performance, and the hollow portion may be also used as a reinforcement hole for reinforcing a strength or a current collecting hole for increasing a current collecting efficiency, thereby improving a cell strength and also increasing an efficiency of producing electric energy. The solid oxide fuel cell has an electrolyte layer; an anode; a cathode; and a hollow portion formed in the anode.

Owner:KOREA ADVANCED INST OF SCI & TECH

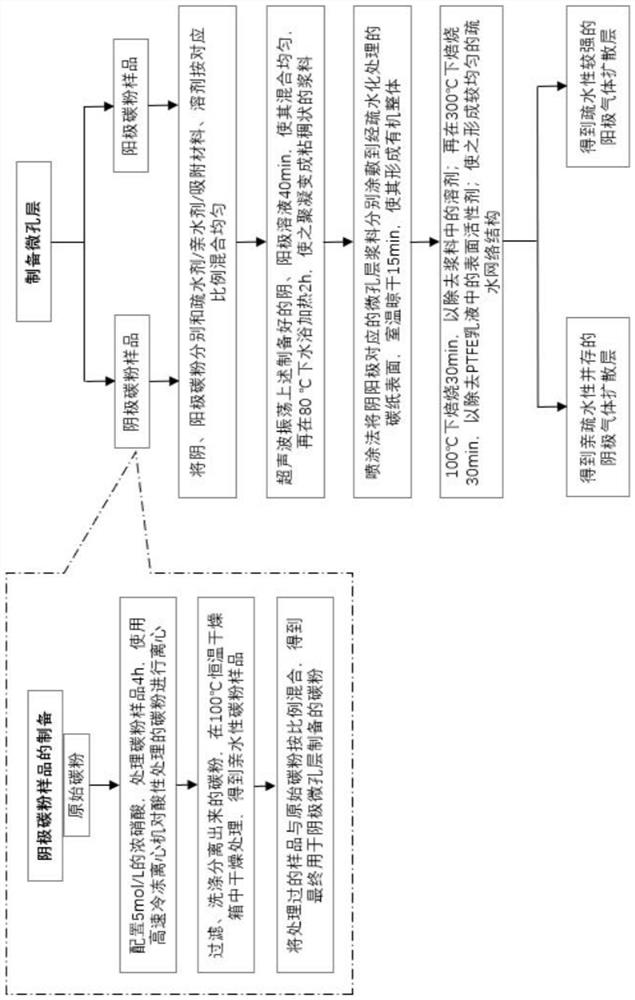

Preparation method of microporous layer in gas diffusion layer

InactiveCN110993965AImprove hydrophobicityReduce porosityCell electrodesPolymer chemistryHot pressing

The invention relates to the technical field of preparation of microporous layers of fuel cells, and discloses a preparation method of a microporous layer in a gas diffusion layer, which comprises thefollowing steps: (1) obtaining at least two slurries; (2) selecting a slurry to coat one side of the substrate; (3) sequentially carrying out drying, hot pressing and sintering treatment on the coated slurry to form a microporous layer; (4) selecting another slurry and coating the other slurry on one side, far away from the substrate, of the microporous layer; (5) sequentially carrying out drying, hot pressing and sintering treatment on the other coated slurry to form another microporous layer; and (6) repeating the steps (4) to (5), preparing all microporous layers after the slurry is completely treated, and continuously reducing the porosity of the microporous layers along the direction far away from the substrate. The fuel cell provided by the invention cannot be flooded by water.

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

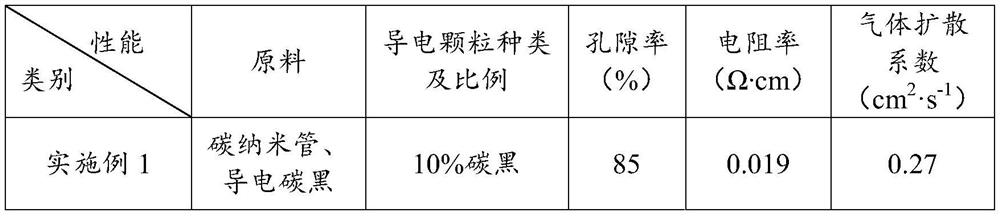

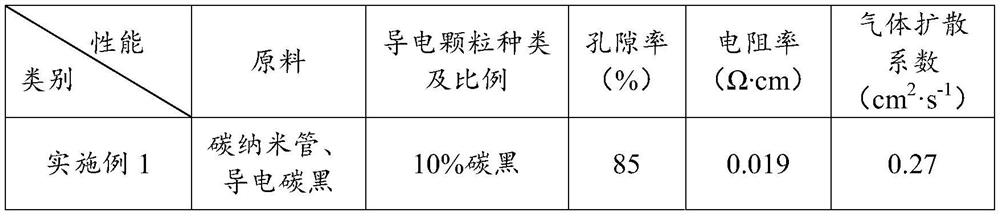

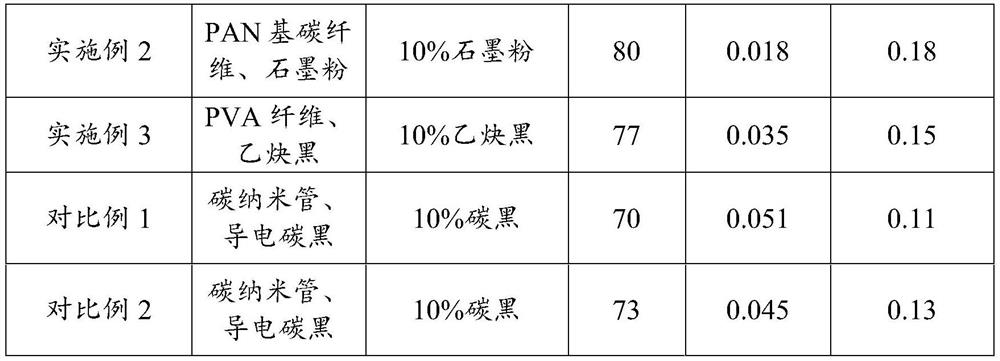

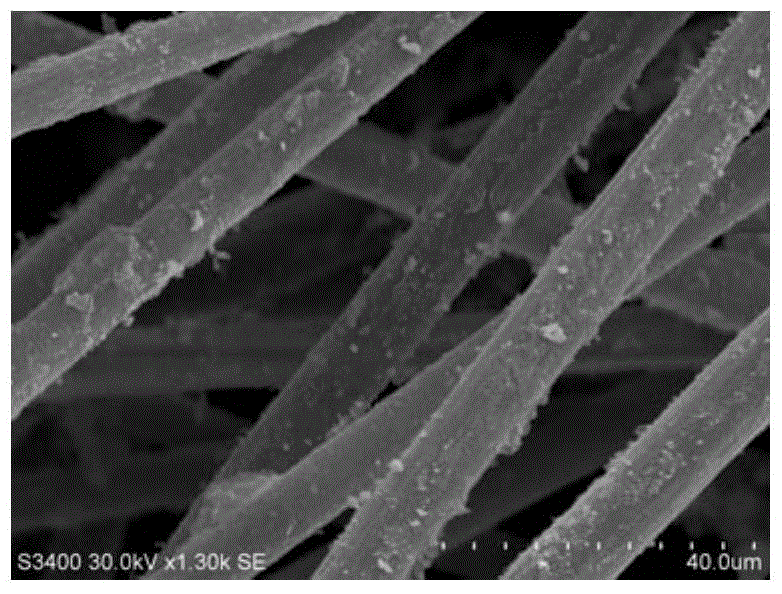

Preparation method of carbon paper for gas diffusion layer of high-carbon-content fuel cell

ActiveCN111900417ASuppress or eliminate the effectHigh carbon contentFinal product manufactureCell electrodesFiberCarbon fibers

The invention discloses a preparation method of carbon paper for a gas diffusion layer of a high-carbon-content fuel cell. The method comprises the following steps: immersing carbon fiber paper into first conductive ink, carrying out ultrasonic treatment, carrying out negative pressure impregnation, and drying to compound solute in the first conductive ink with the carbon fiber paper to obtain a carbon paper precursor A; carbonizing the carbon paper precursor A to obtain a carbon paper precursor B; the carbon paper precursor B and the second conductive ink being subjected to dipping-curing-carbonization treatment to obtain a carbon paper precursor C, and the carbon paper precursor C and the third conductive ink being repeatedly subjected to dipping-curing-carbonization treatment once to obtain a carbon paper precursor D; and graphitizing the carbon paper precursor D to obtain the carbon paper. The prepared carbon paper has the mechanical strength and gas diffusion performance of a gasdiffusion layer, is high in porosity, and has the characteristics of stable chemical performance, low resistivity and high conductivity.

Owner:QILU UNIV OF TECH

Fuel cell

InactiveUS7641996B2Improve heat transfer efficiencyEnsure diffusivityActive material electrodesSolid electrolyte fuel cellsFuel cellsEngineering

Owner:TOYOTA JIDOSHA KK

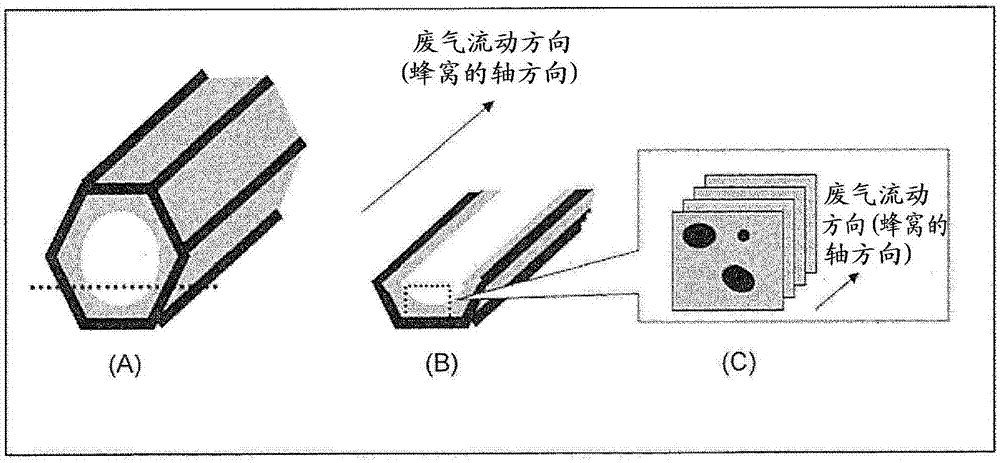

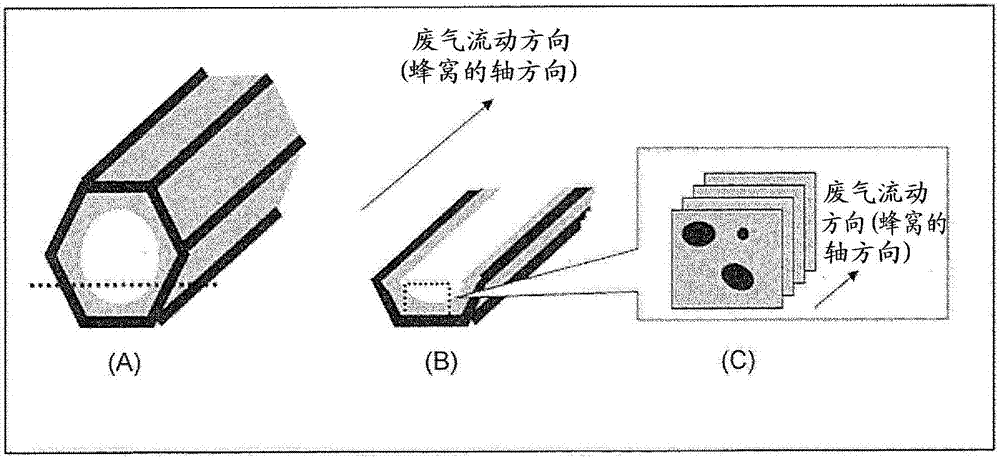

Exhaust purification catalyst

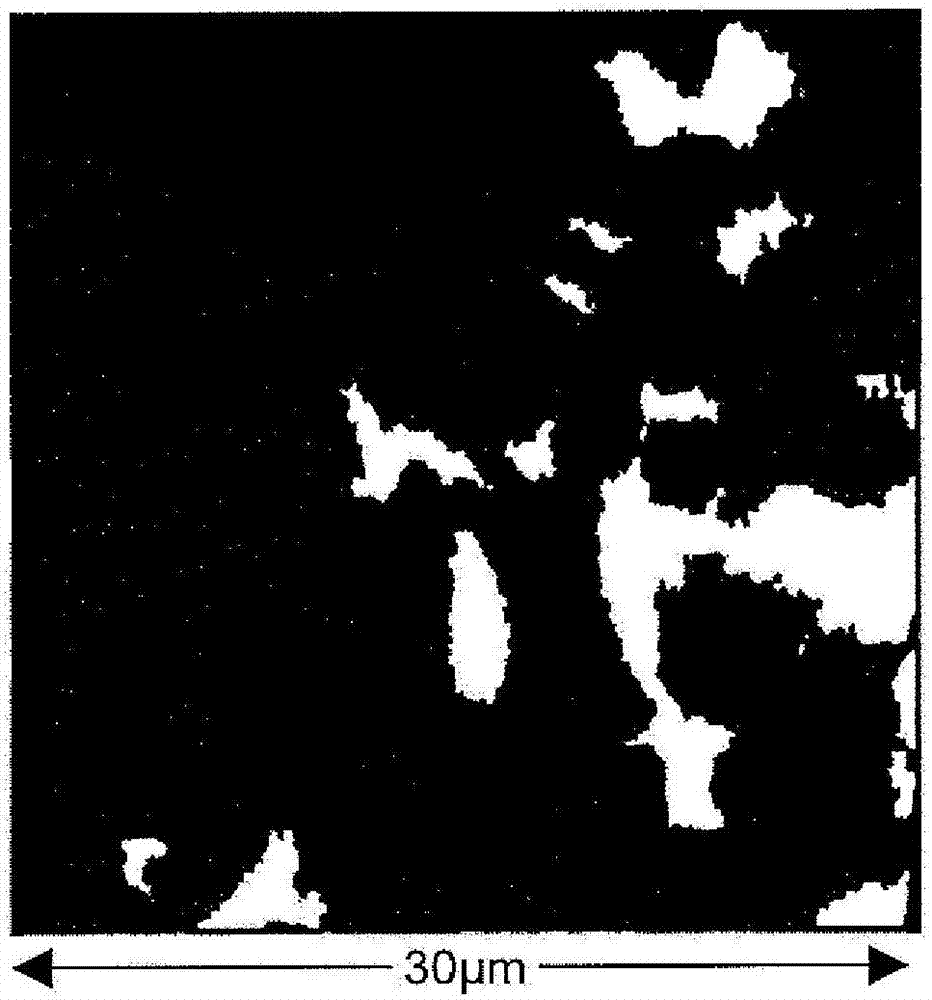

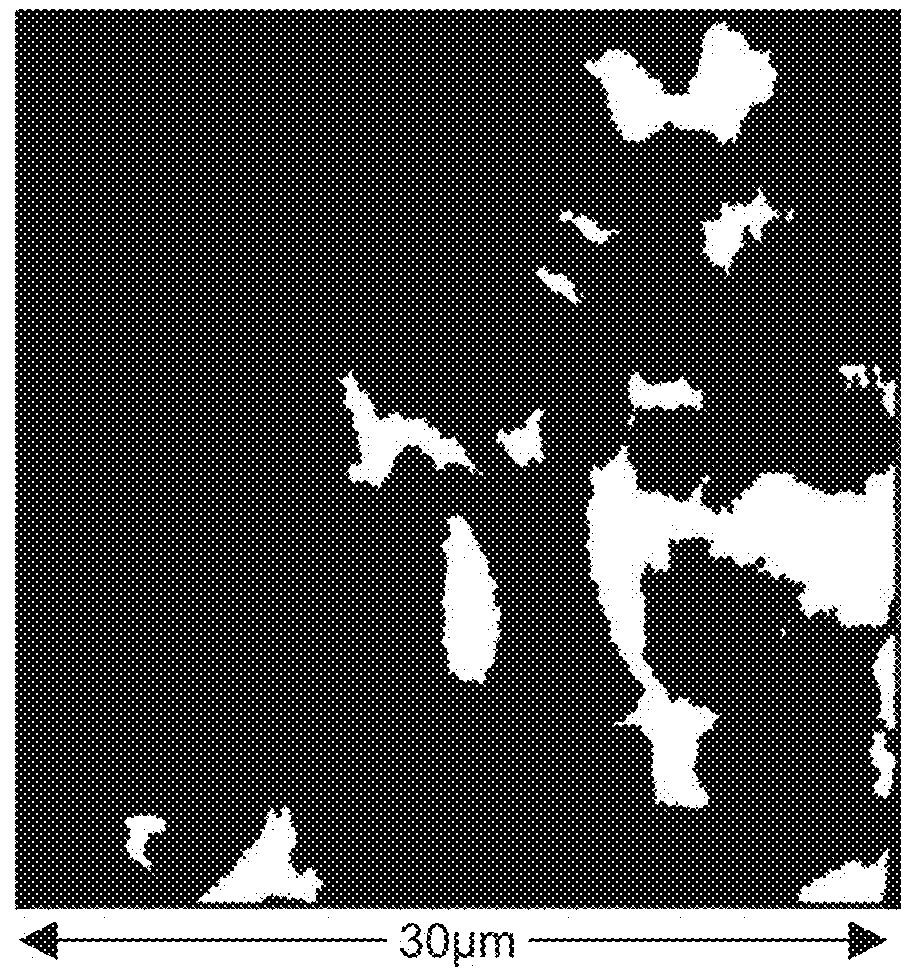

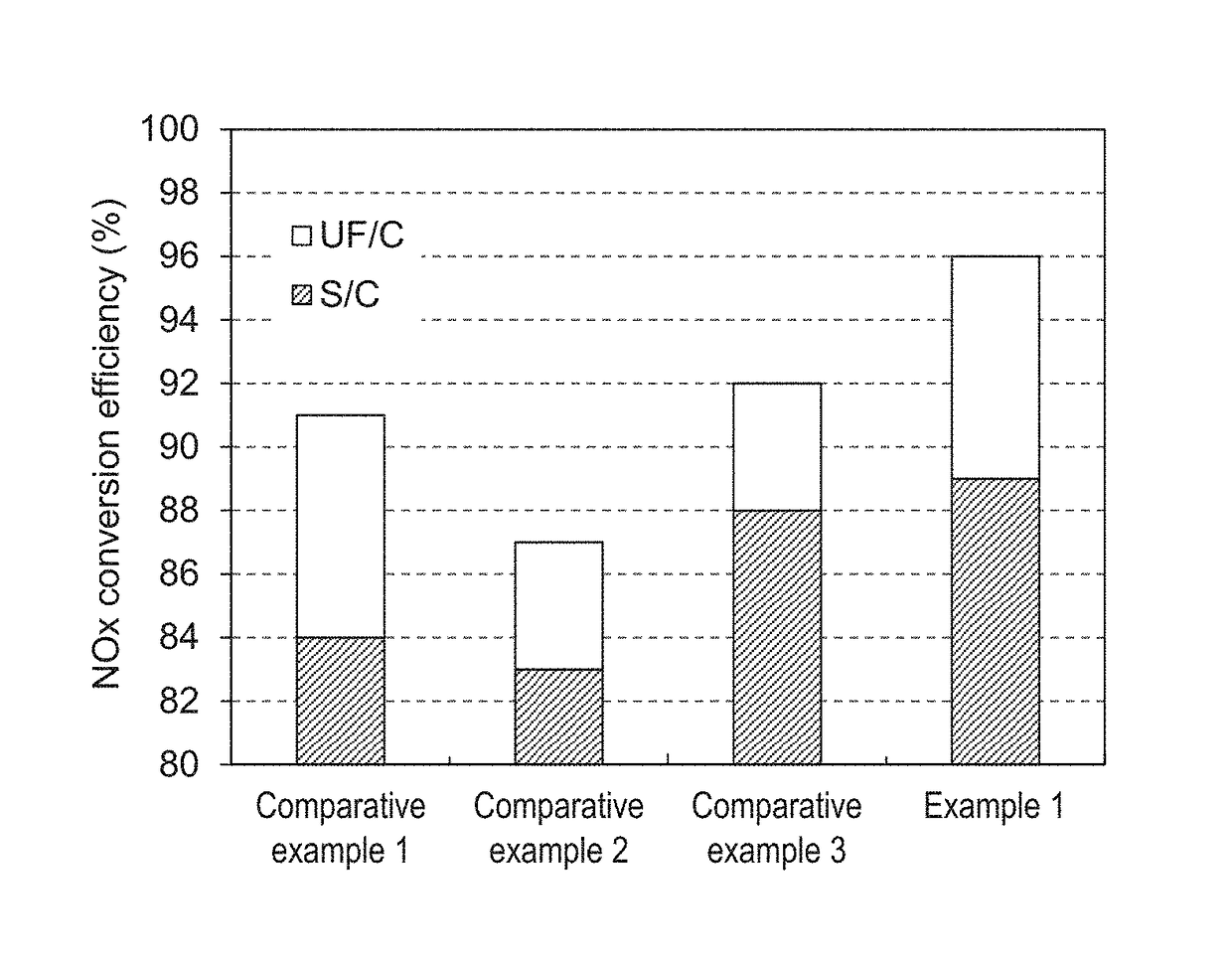

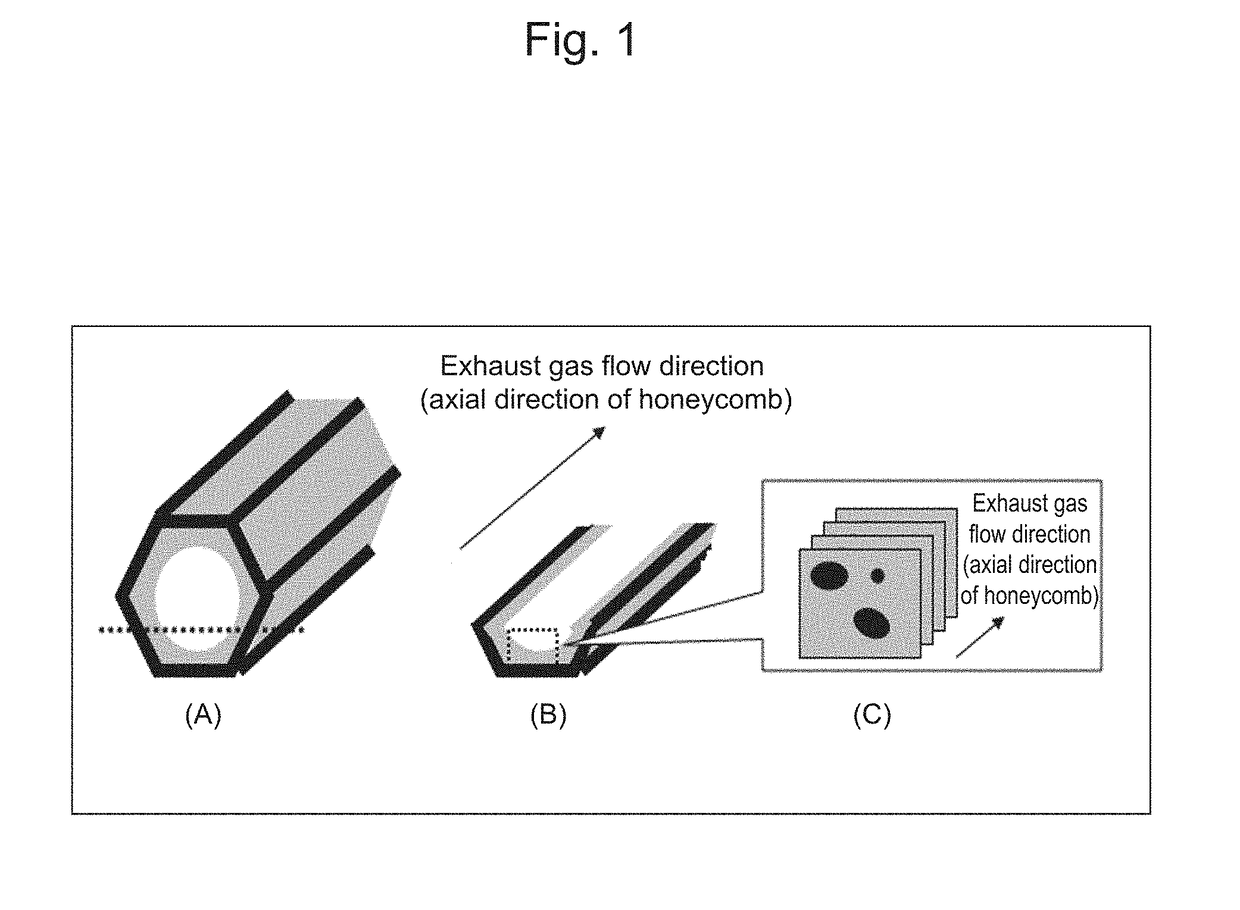

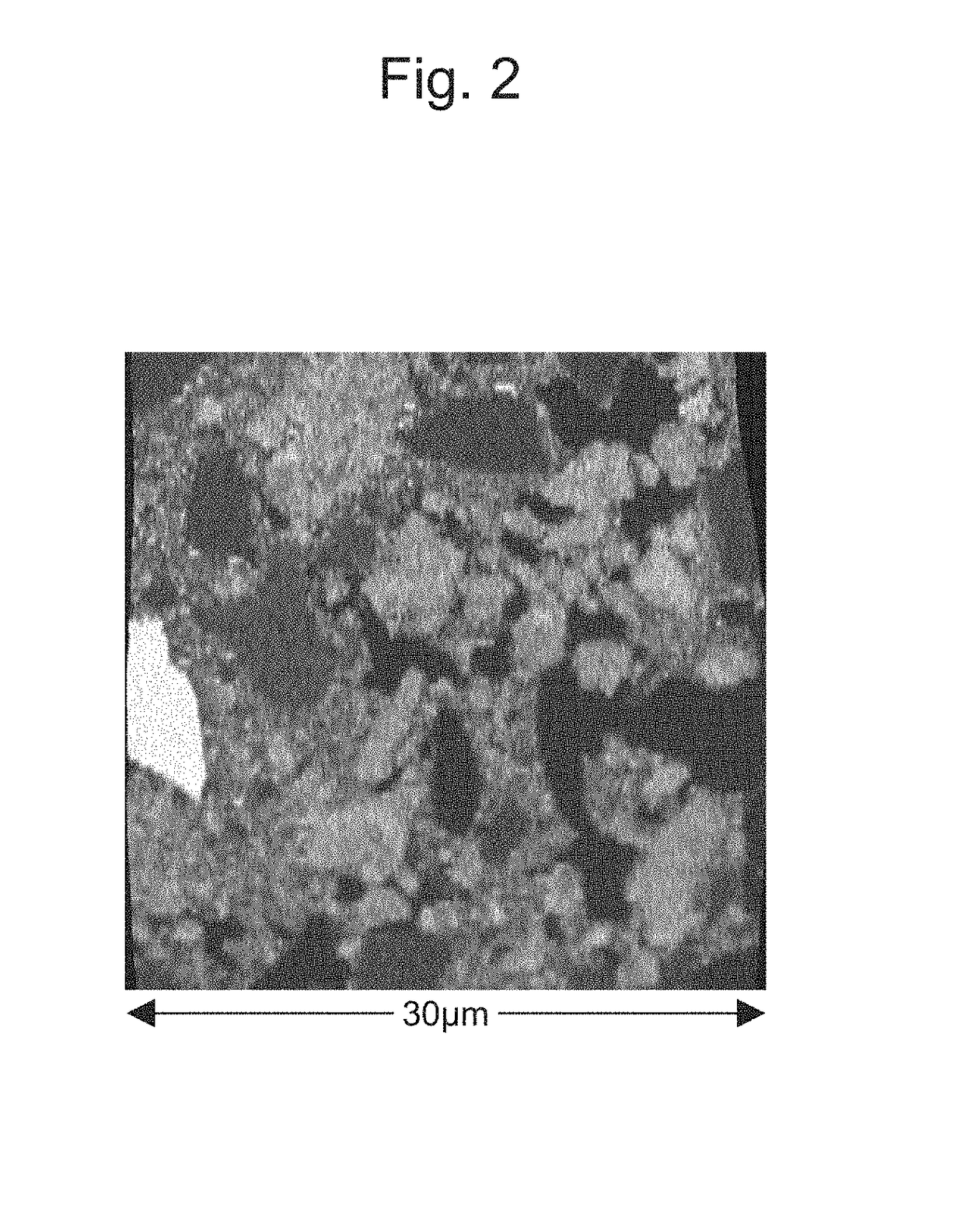

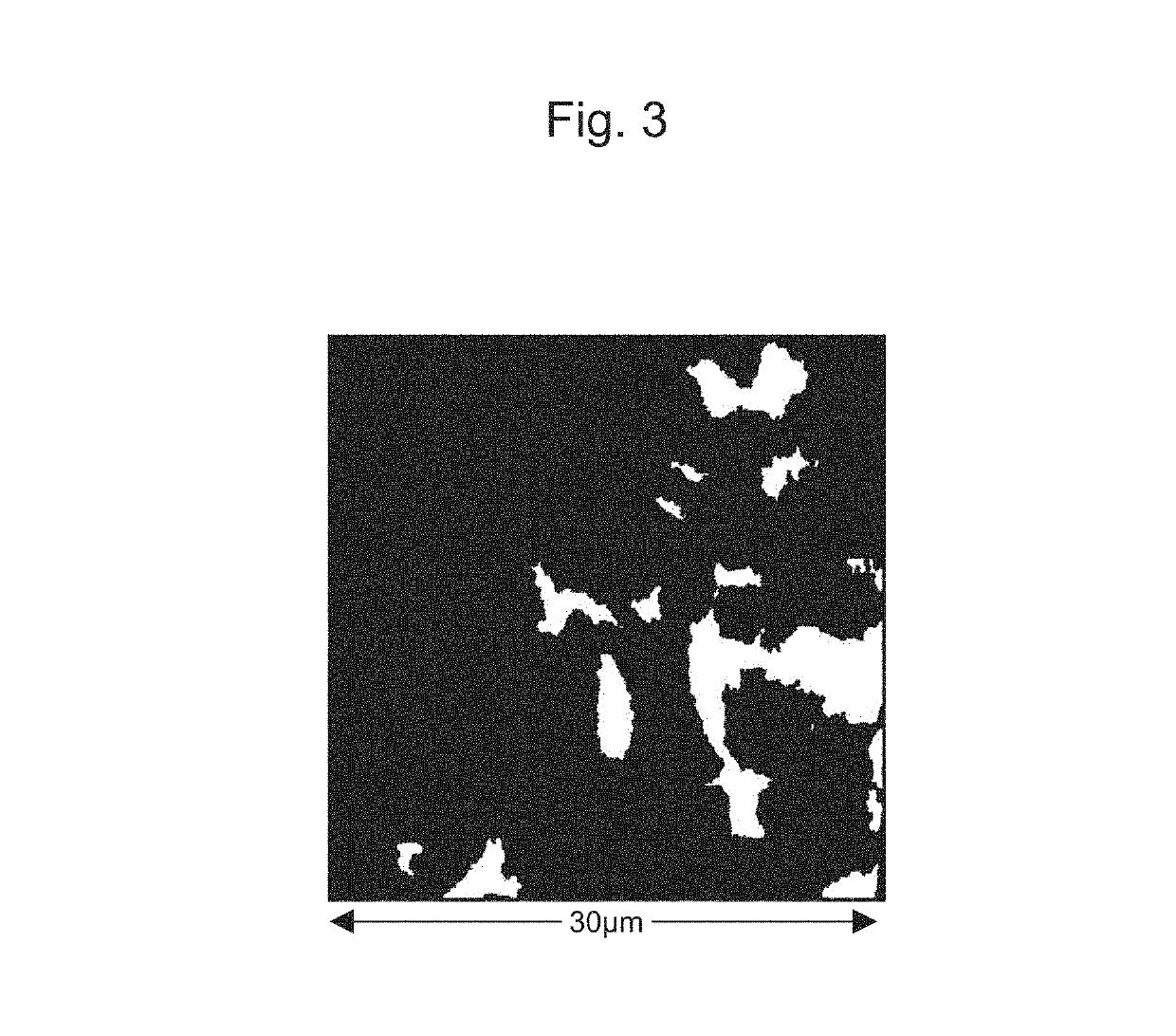

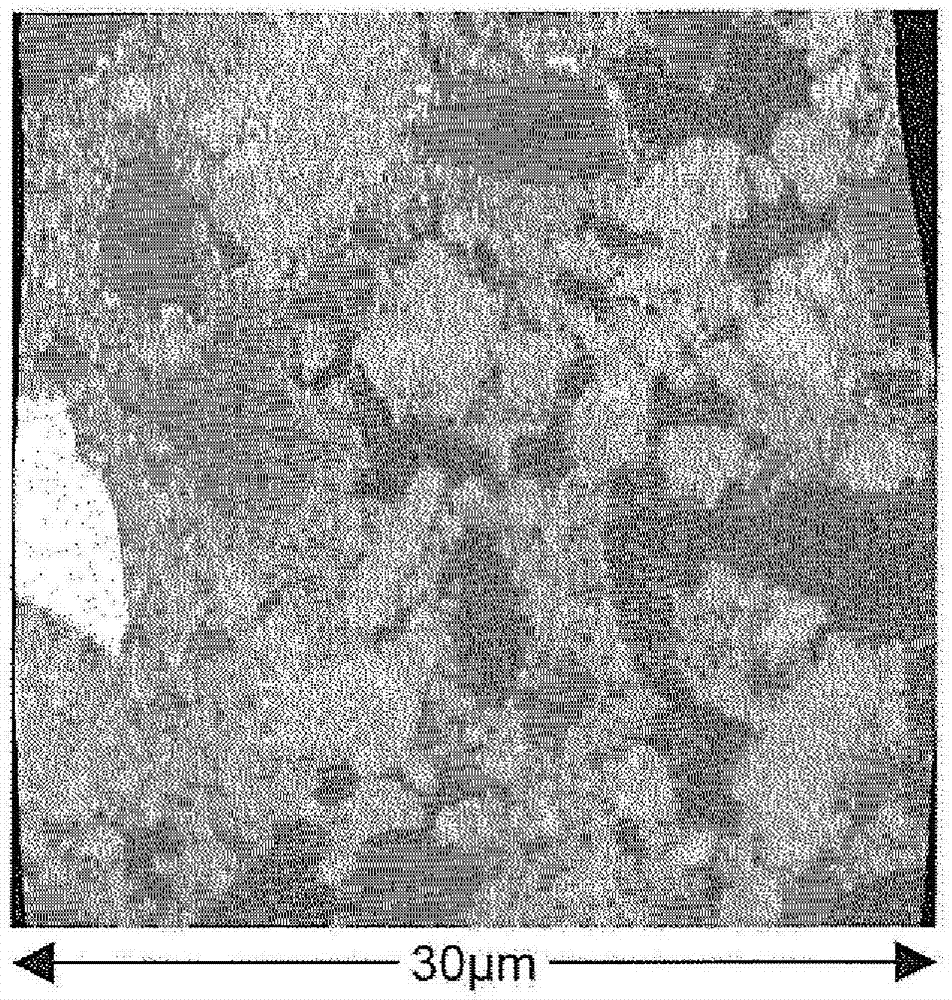

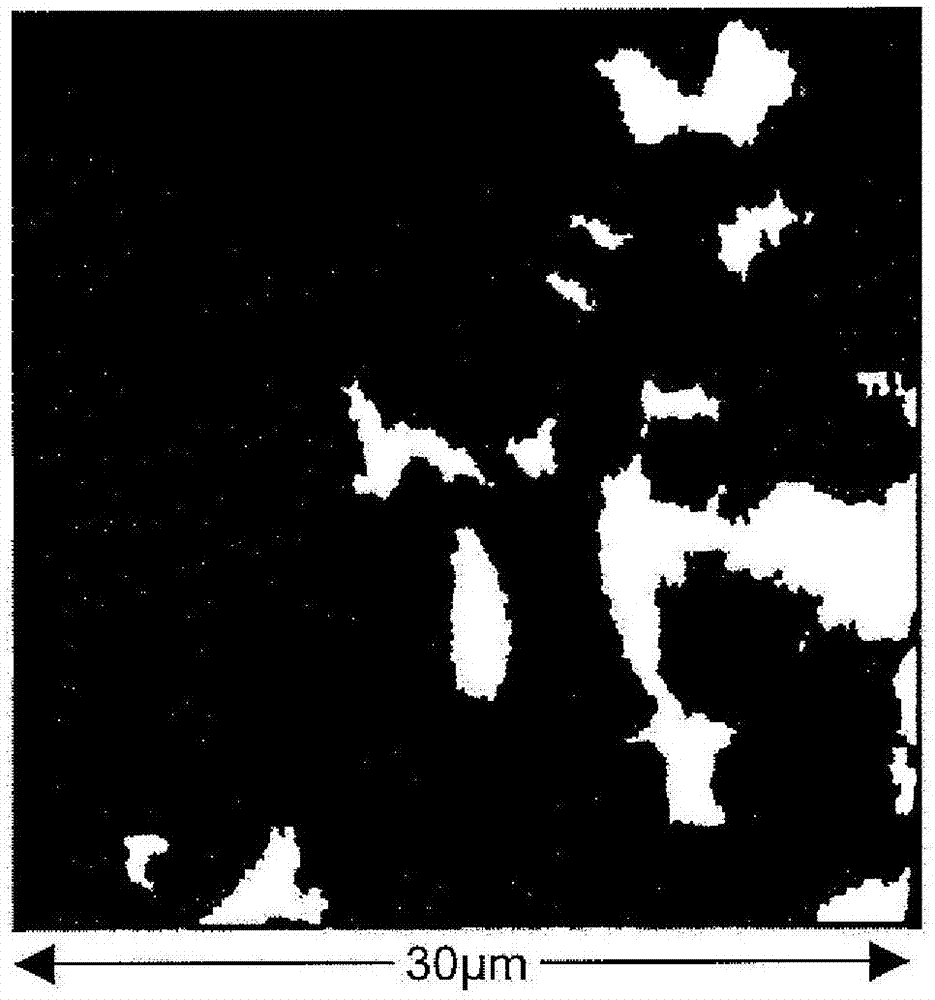

ActiveCN107427825ADurableImprove gas diffusivityInternal combustion piston enginesExhaust apparatusPtru catalystStress factor

The present invention addresses the problem of providing an exhaust purification catalyst that has durability against stress factors such as high temperature and against poisonous substances, and is capable of exhibiting sufficient purification performance even under a high Ga condition. The present invention relates to an exhaust purification catalyst having two or more catalyst coating layers on a base material. The present invention has improved gas diffusibility of an underlying catalyst coating, which is present under the uppermost catalyst coating layer, due to the underlying catalyst coating having a structure with many voids, with a certain portion or more of all the voids comprising pores having a high aspect ratio of 5 or more.

Owner:TOYOTA JIDOSHA KK +1

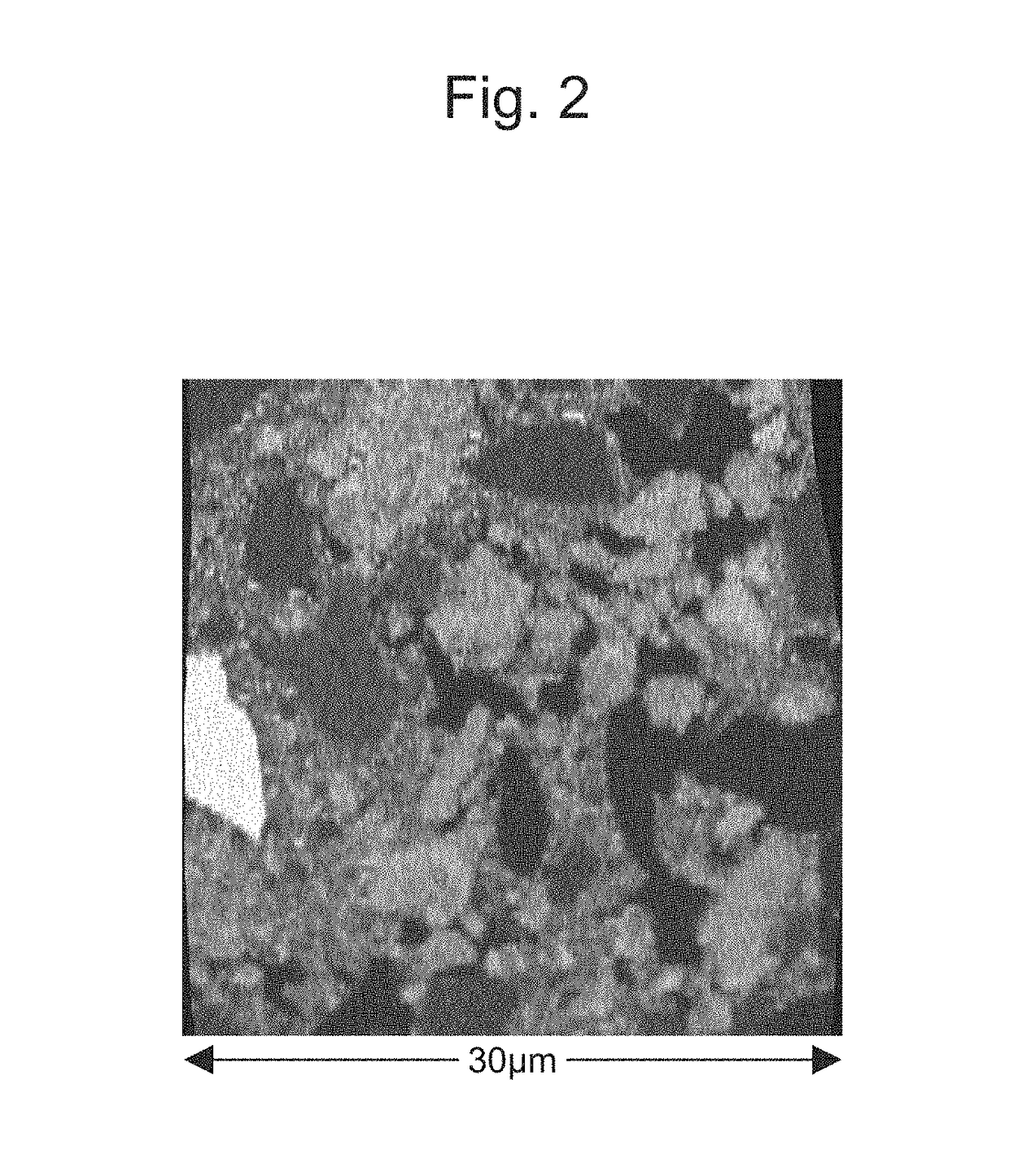

Exhaust gas purification catalyst

ActiveUS20180104679A1Sufficient purification performanceImprove gas diffusivityInternal combustion piston enginesDispersed particle separationFiberActive site

When the amount of coating is increased in a two-layer catalyst or the like containing two noble metals in respective different layers, gas diffusivity in the catalyst and use efficiency of a catalytic active site are reduced to thereby reduce purification performance. In view of this, an organic fiber having a predetermined shape is used as a pore-forming material in formation of an uppermost catalyst coating layer of a multi-layer catalyst, to thereby form an uppermost catalyst coating layer having a high-aspect-ratio pore excellent in connectivity and therefore excellent gas diffusivity.

Owner:TOYOTA JIDOSHA KK +1

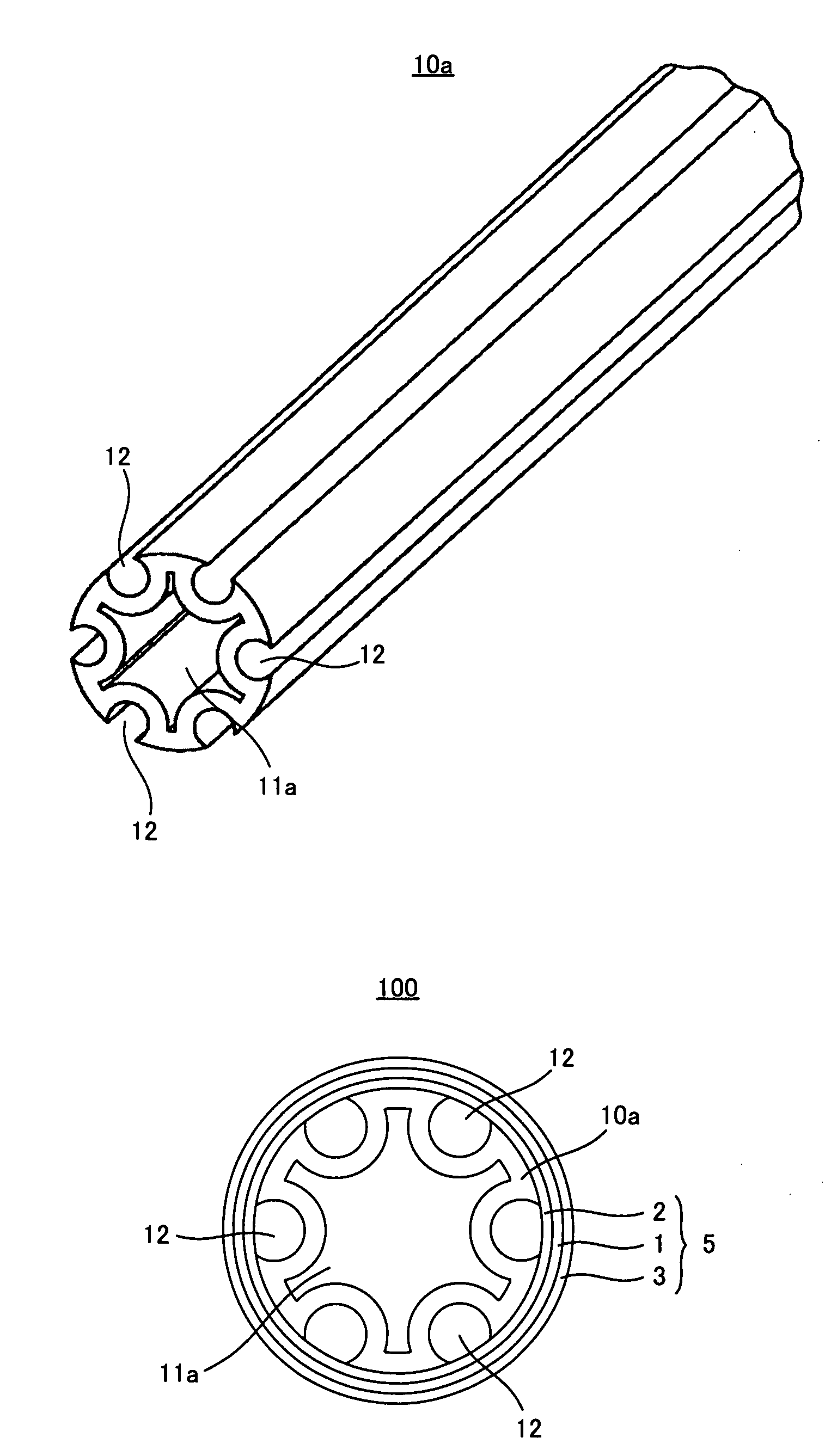

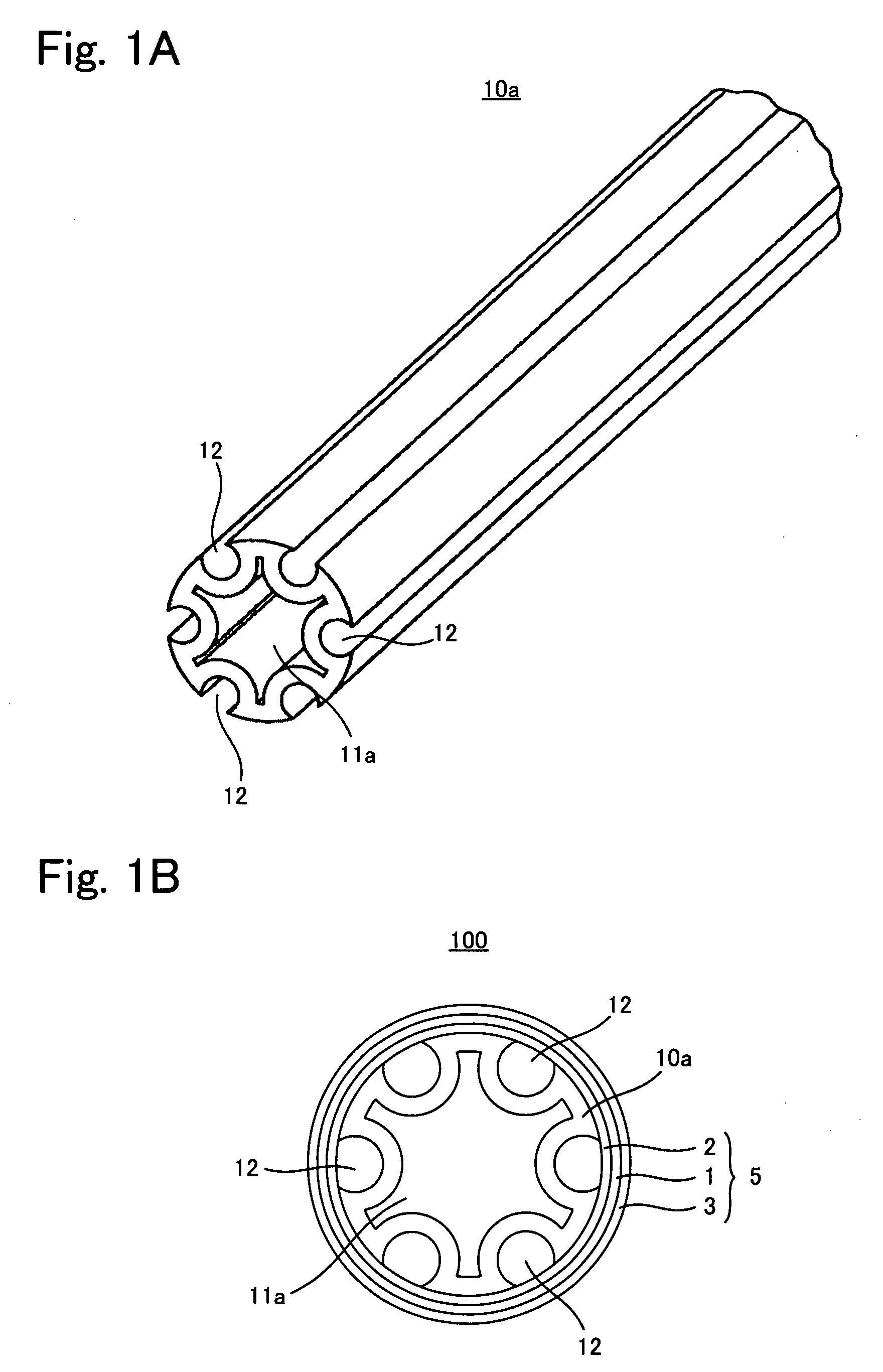

Fuel Cell

InactiveUS20090148741A1Improve heat transfer efficiencyIncrease power generation capacityActive material electrodesSolid electrolyte fuel cellsFuel cellsEngineering

a fuel cell capable of improving heat exchange efficiency with respect to tubular fuel cells is provided. A fuel cell includes a hollow electrolyte membrane, hollow electrodes arranged on an inside and an outside of the electrolyte membrane, respectively, and an internal charge collector arranged inside of the electrolyte membrane and the electrodes, wherein the internal charge collector is hollow and made of a nonporous member.

Owner:TOYOTA JIDOSHA KK

Exhaust gas purification catalyst

InactiveUS20180071680A1Improve gas diffusivitySufficient purification performanceInternal combustion piston enginesDispersed particle separationActive siteExhaust gas

The present invention is directed to address the following problem: in an exhaust gas purification catalyst comprising a dual catalyst of a combination of a startup catalyst and an underfloor catalyst, reduction in the gas diffusivity of the startup catalyst results in reduction in the use efficiency of a catalytic active site, resulting in reduction in purification performance. The present invention relates to an exhaust gas purification catalyst comprising a dual catalyst of a combination of a startup catalyst having a catalyst coating where a large number of voids are included and an underfloor catalyst, wherein high-aspect-ratio pores having an aspect ratio of 5 or more account for a certain rate or more of the whole volume of the voids, to thereby enhance the purification performance of the catalyst.

Owner:TOYOTA JIDOSHA KK +1

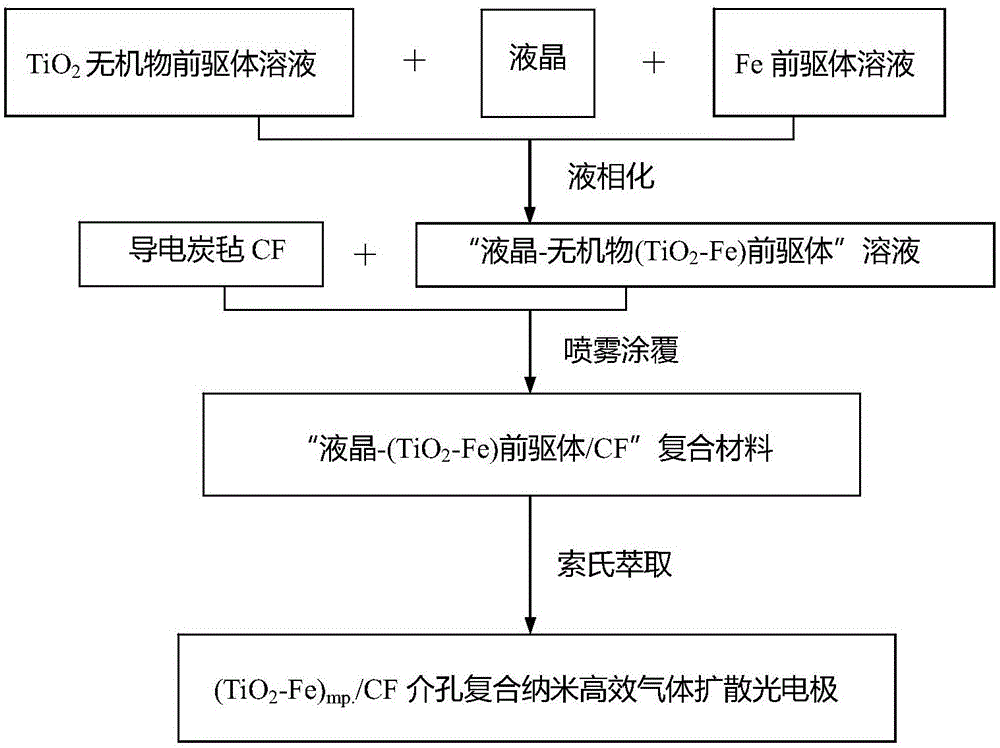

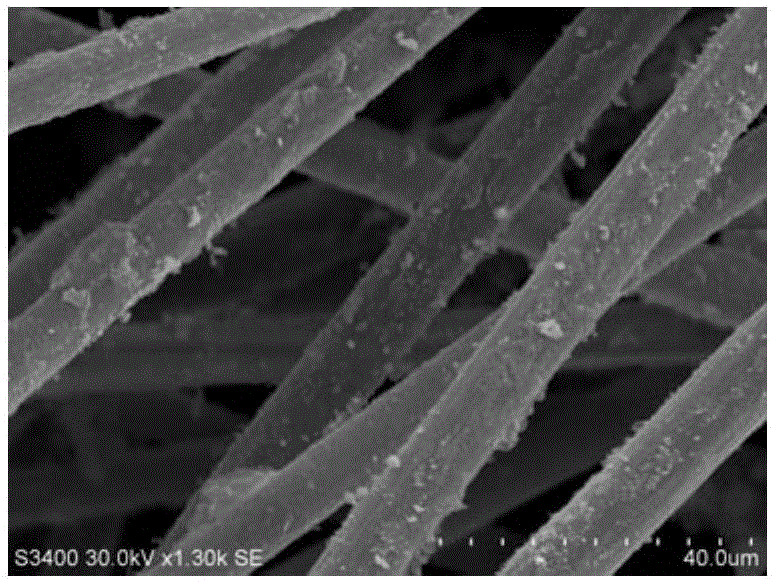

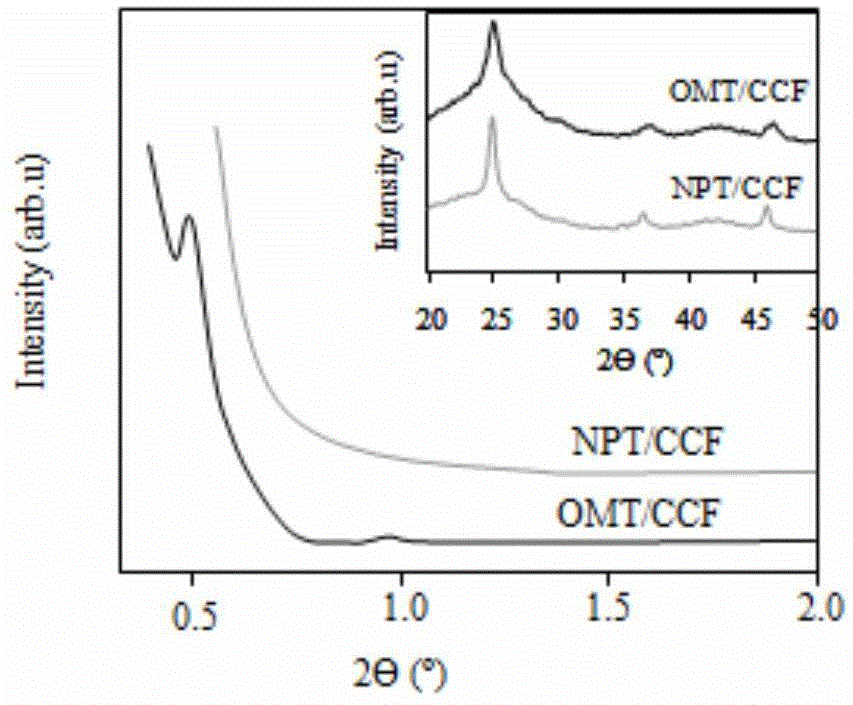

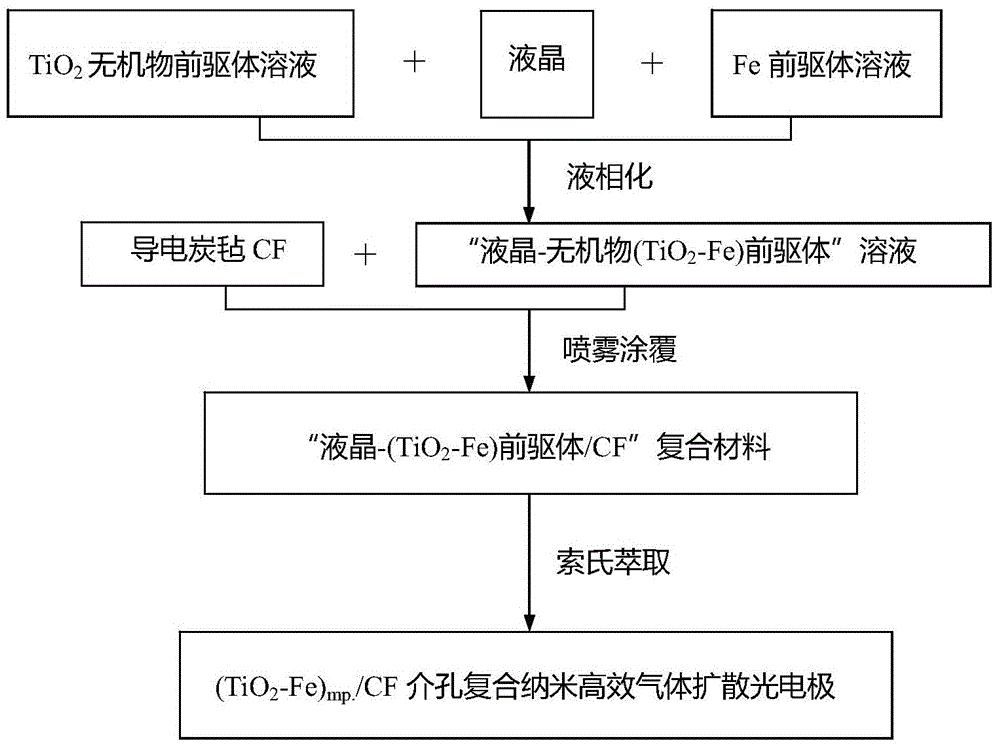

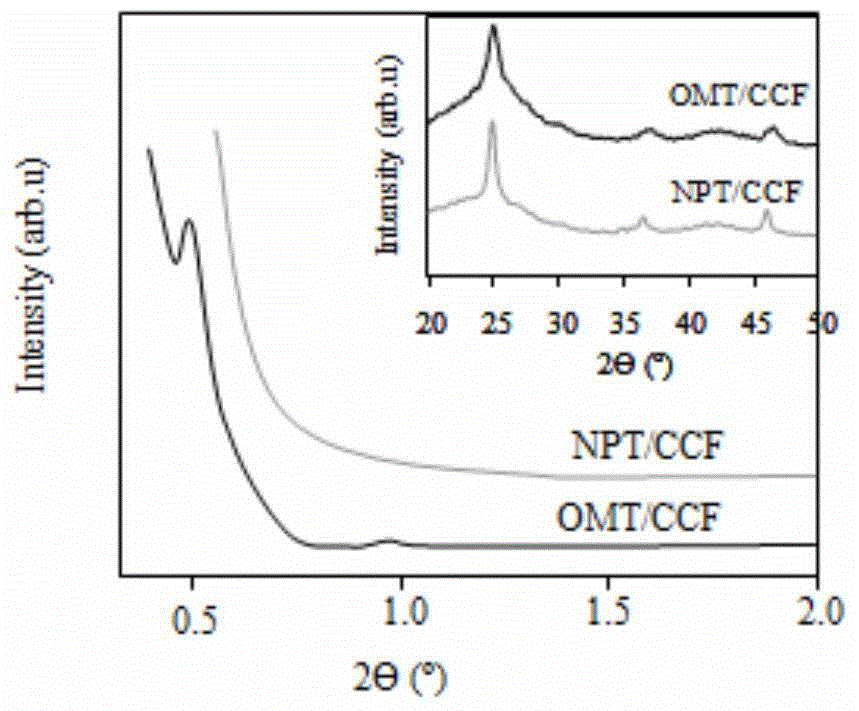

Conductive carbon felt loaded ferric ferric-doped mesoporous titanium oxide gas diffuse photoelectrode and preparation method therefor

ActiveCN105080546AReduce degradation costReduce stickingOther chemical processesDispersed particle separationPore distributionSpray coating

The invention relates to a conductive carbon felt loaded ferric ferric-doped mesoporous titanium oxide gas diffuse photoelectrode and a preparation method therefore. An efficient gas diffusion photoelectrode (TiO2-Fe)mp. / CF mesoporous loaded composite nano material is prepared by adopting a liquid crystal template method and a spray coating technology. The method has the remarkable characteristics that the conductive carbon felt loaded mesoporous (TiO2-Fe) composite nano material with a special structure and the efficient gas diffusion photoelectrode is prepared by applying the spray coating technology and the liquid crystal template method, thereby providing a novel path for application and research of a porous material loaded mesoporous doped TiO2 photocatalytic material. The conductive carbon felt loaded ferric ferric-doped mesoporous titanium oxide gas diffuse photoelectrode is simple in process and easy for industrial production. The prepared efficient gas diffusion photoelectrode mesoporous loaded composite material is good in conductivity, large in specific surface area and uniform in pore distribution.

Owner:JISHOU UNIVERSITY

Gas diffusion electrode and method for producing same

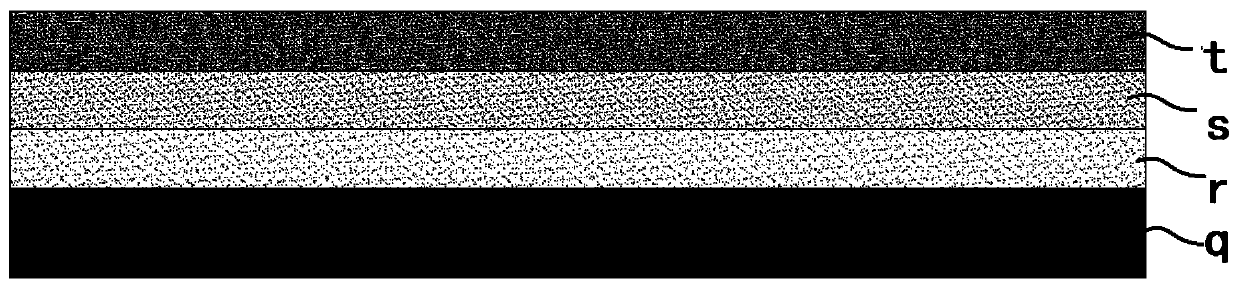

InactiveUS20180248197A1Improve adhesionImprove gas diffusivityCell electrodesFinal product manufactureFuel cellsGas diffusion electrode

The present invention provides a gas diffusion layer for a fuel cell that is balanced between performance and durability. The present invention provides a gas diffusion electrode having a microporous layer, wherein the microporous layer has at least a first microporous layer and a second microporous layer, the first microporous layer has a cross-sectional F / C ratio of 0.06 or more and 0.33 or less, the second microporous layer has a cross-sectional F / C ratio less than 0.06, and wherein the first microporous layer is equally divided into a part not in contact with the second microporous layer and a part in contact with the second microporous layer, in the equally divided first microporous layer. The part not in contact with the second microporous layer is referred to as a microporous layer 1-1, the part in contact with the second microporous layer is referred to as a microporous layer 1-2, and the microporous layer 1-1 has a cross-sectional F / C ratio smaller than that of the microporous layer 1-2, wherein “F” is the mass of fluorine atoms, “C” is the mass of carbon atoms, and the “cross-sectional F / C ratio” is the value of “mass of fluorine atoms” / “mass of carbon atoms” as measured in the cross-sectional direction.

Owner:TORAY IND INC

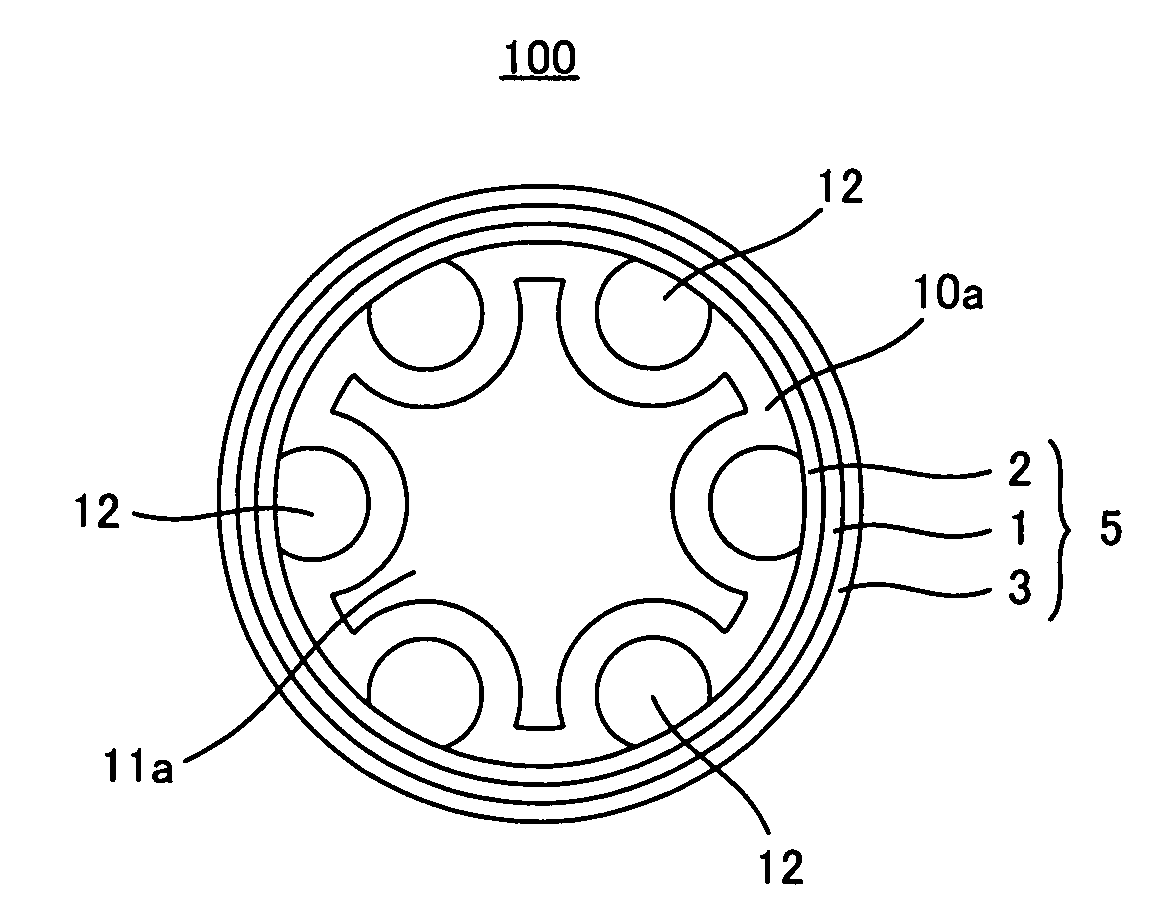

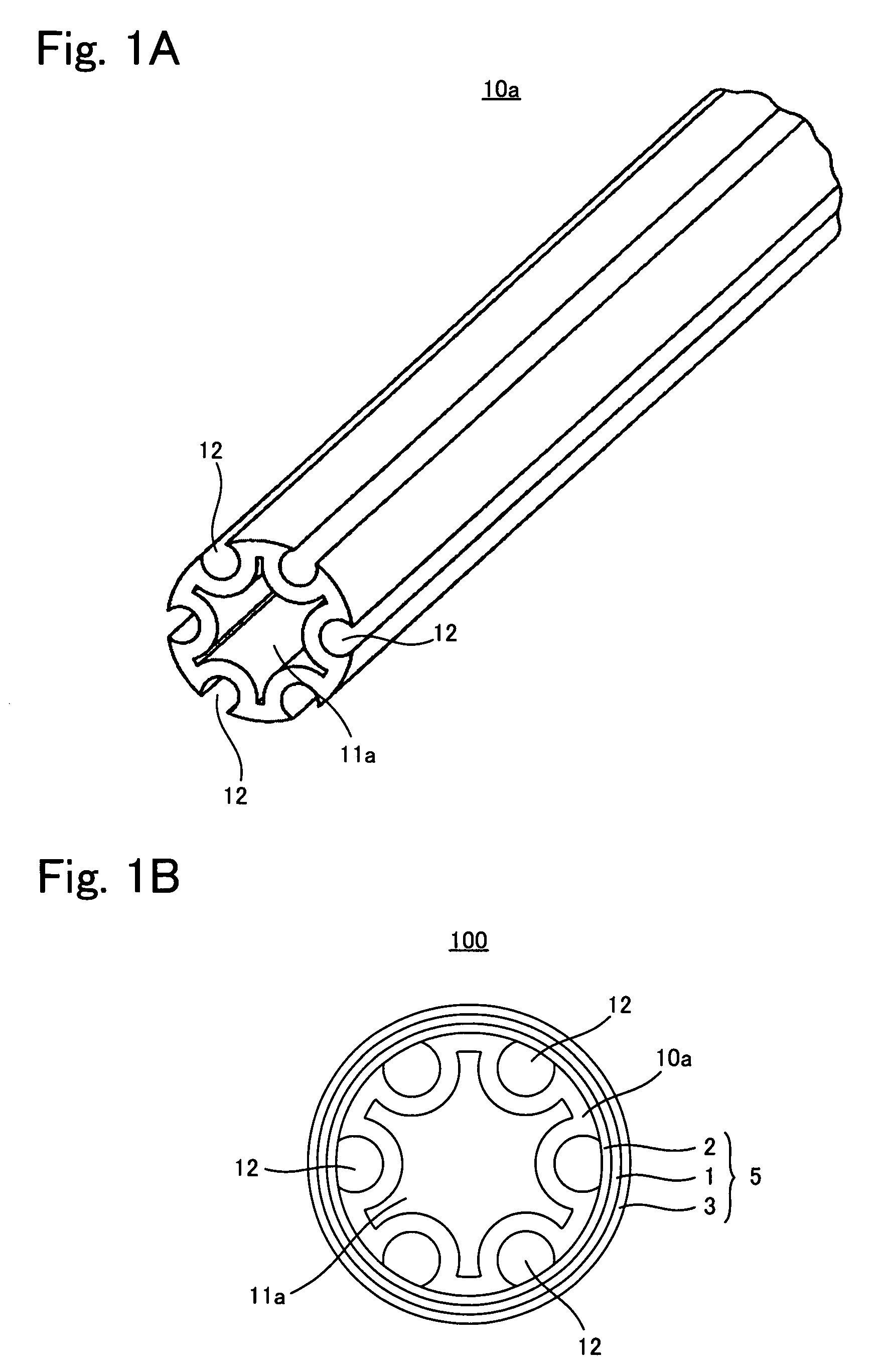

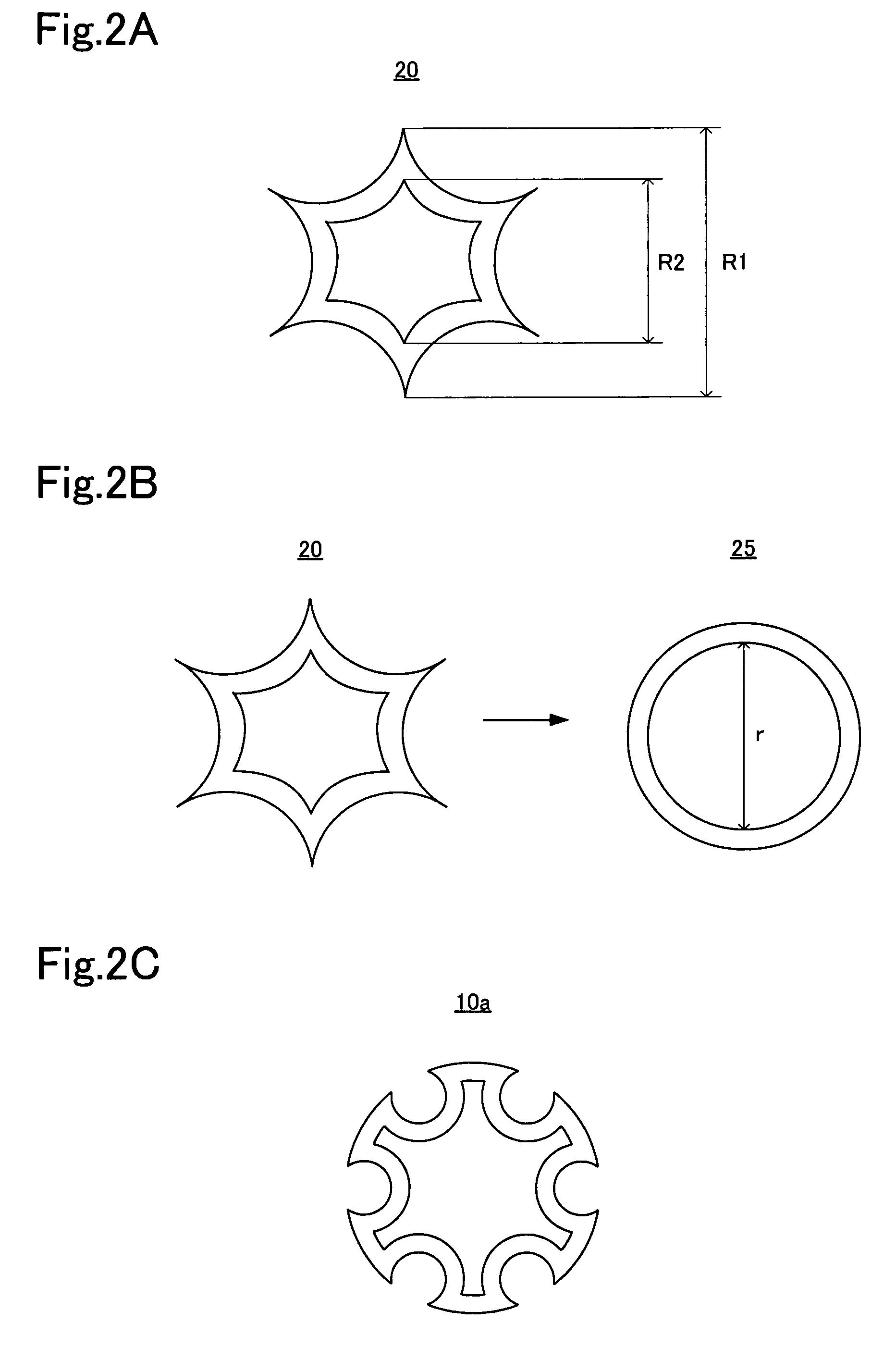

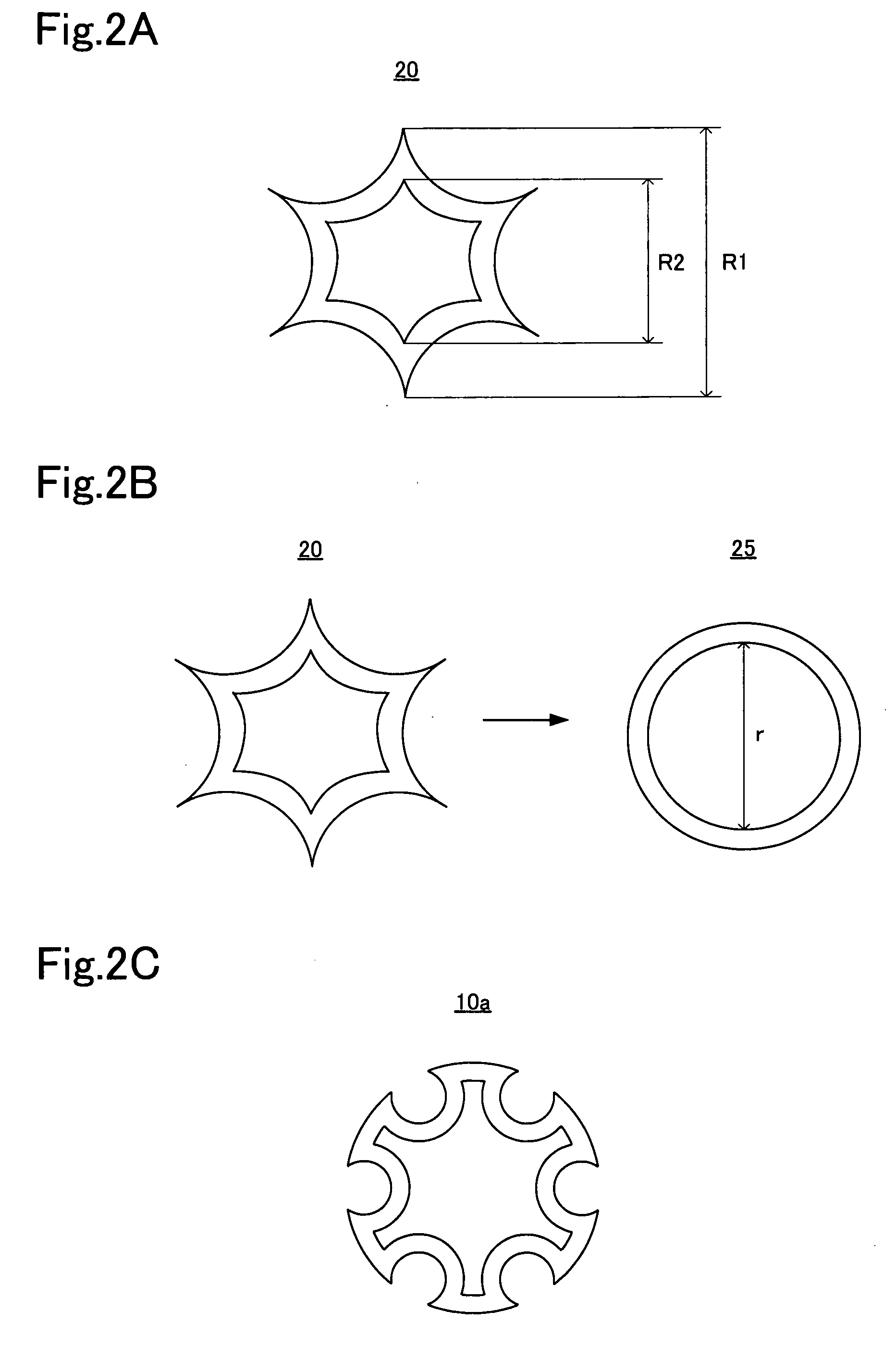

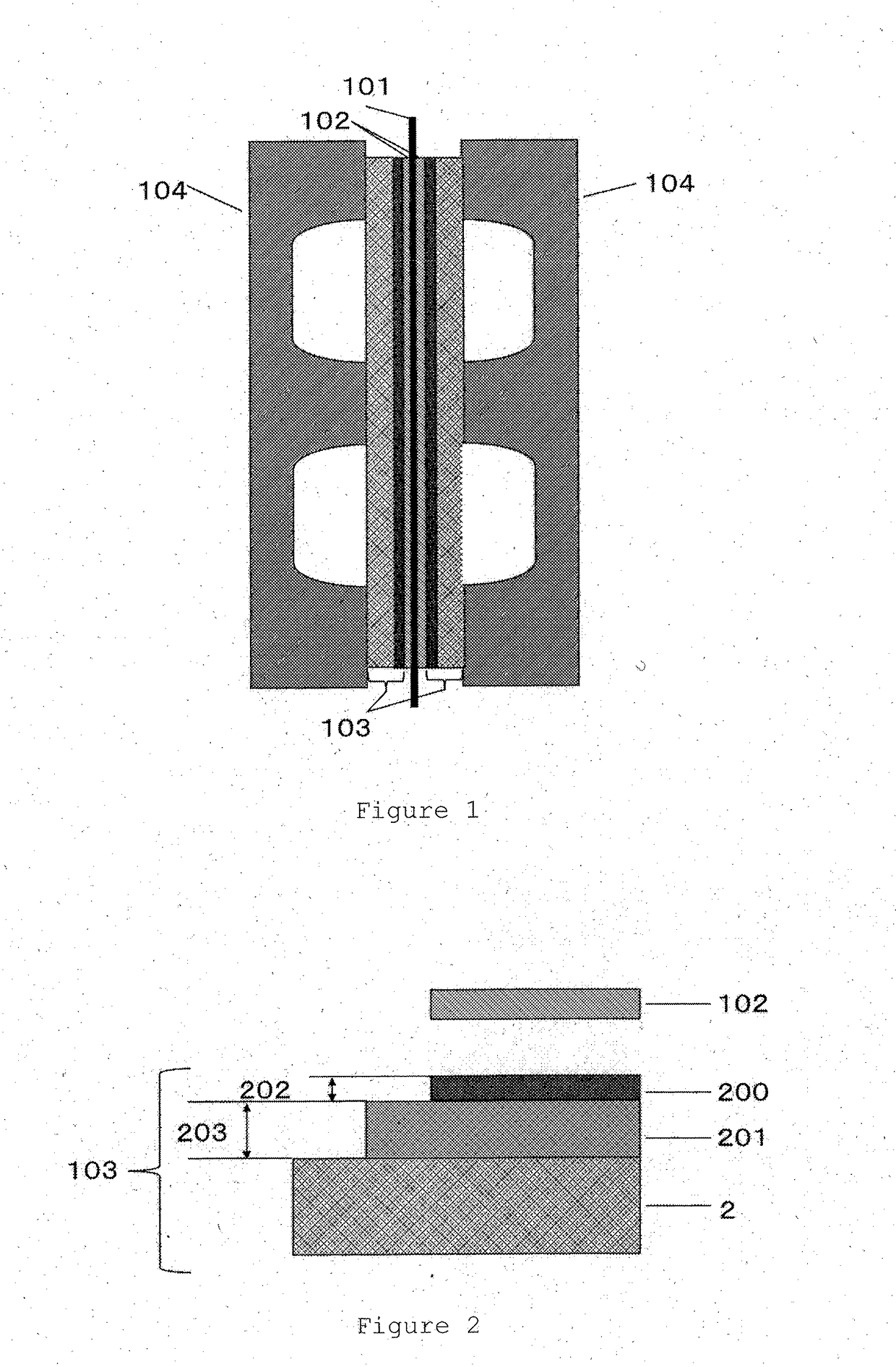

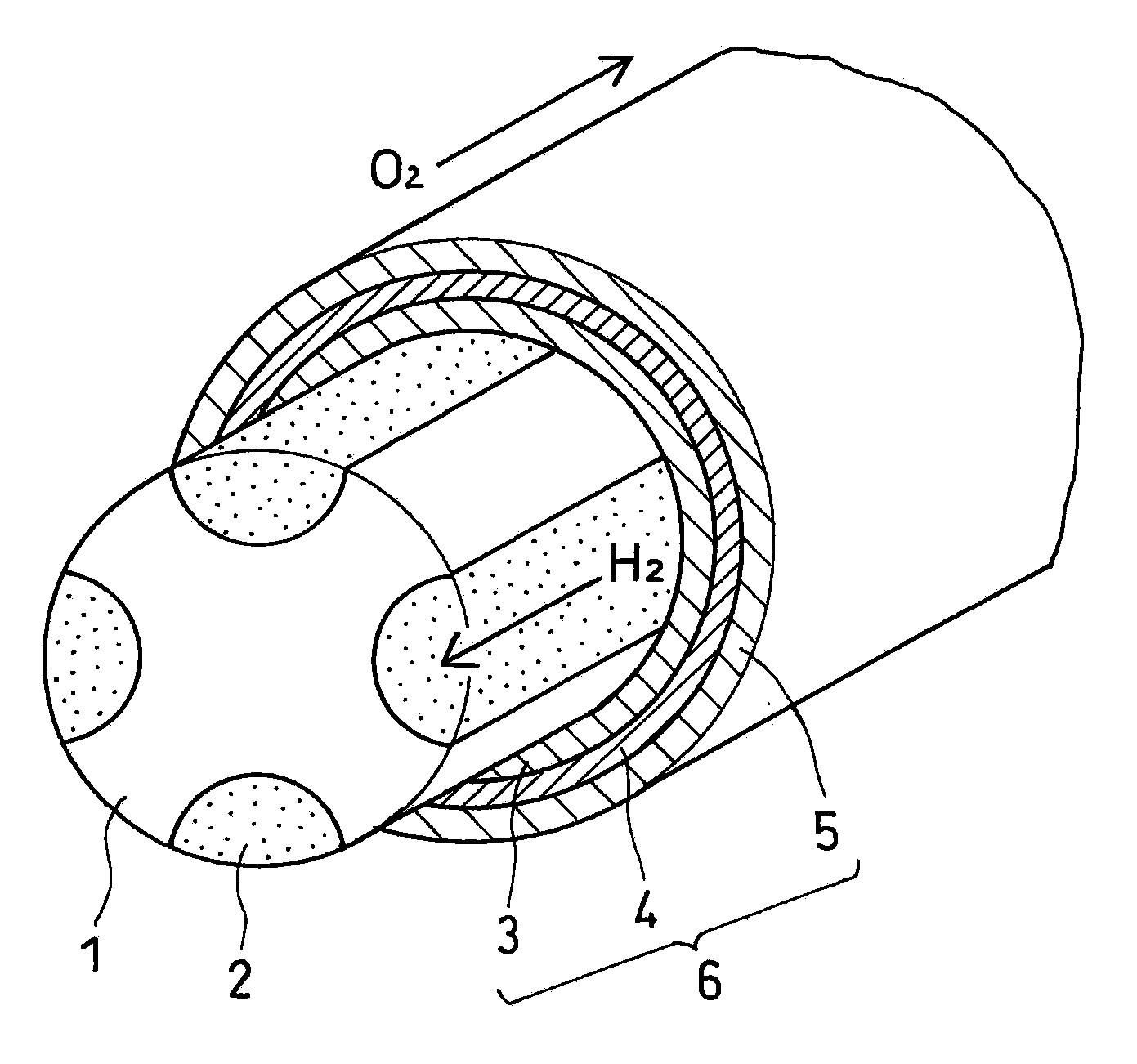

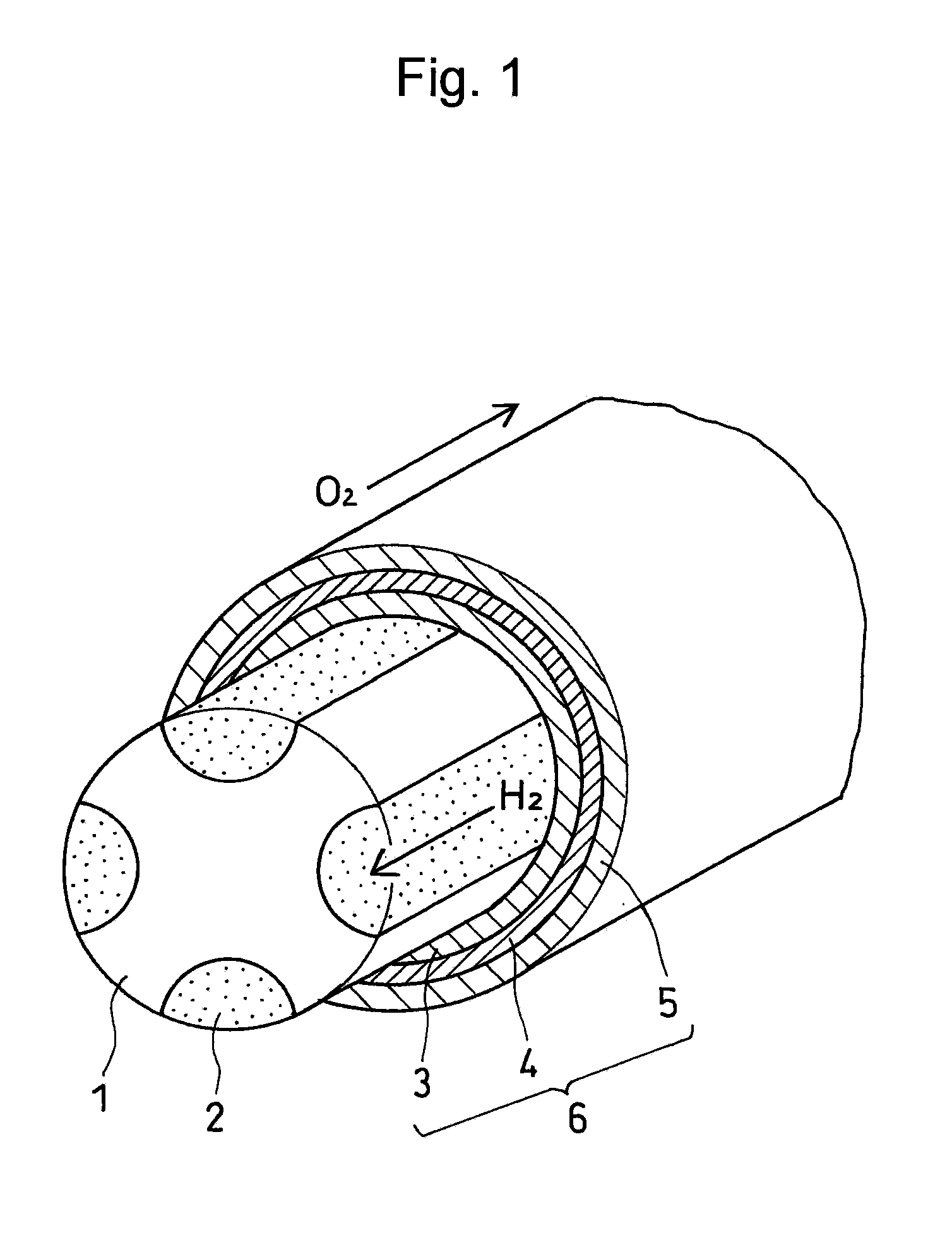

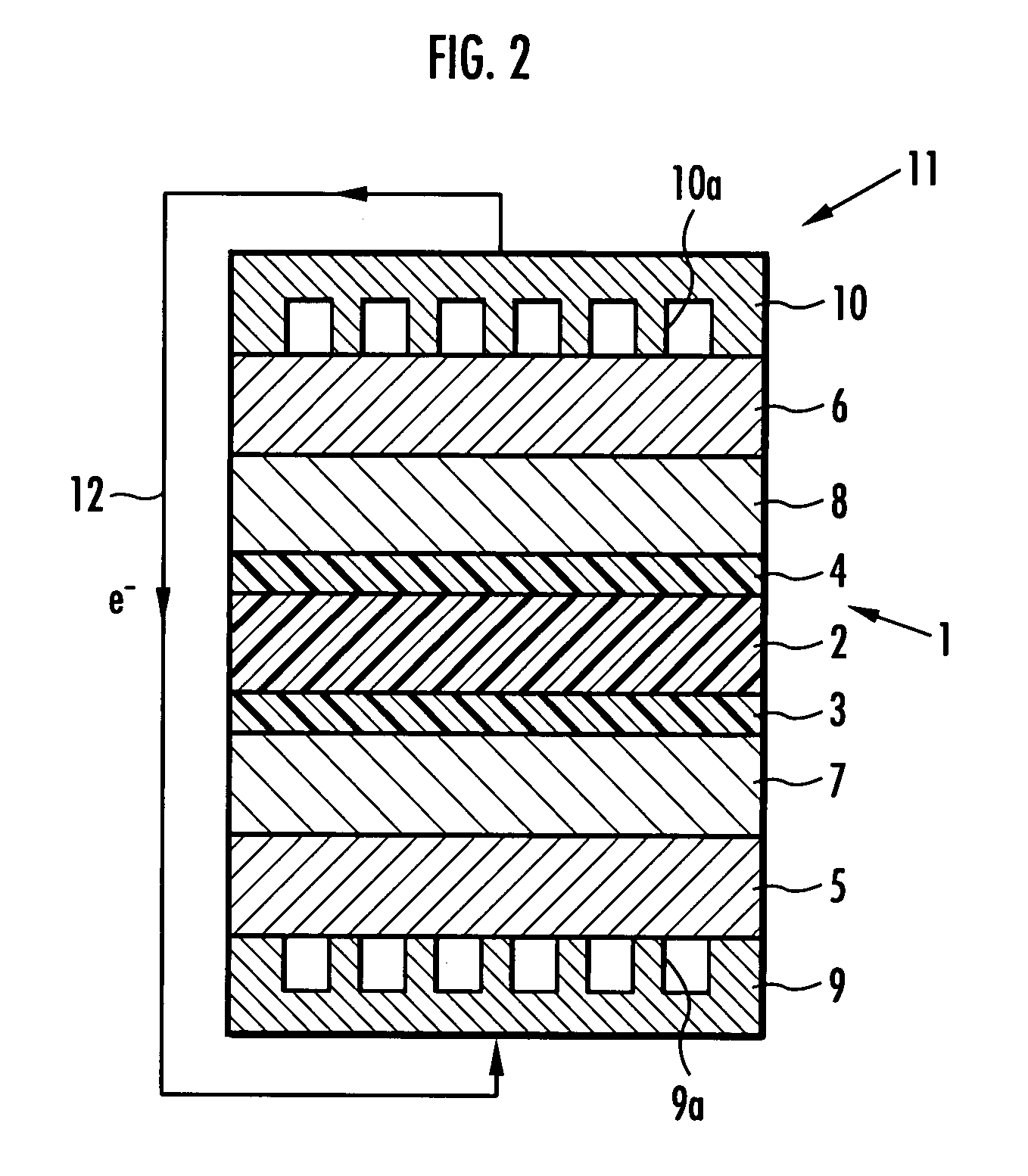

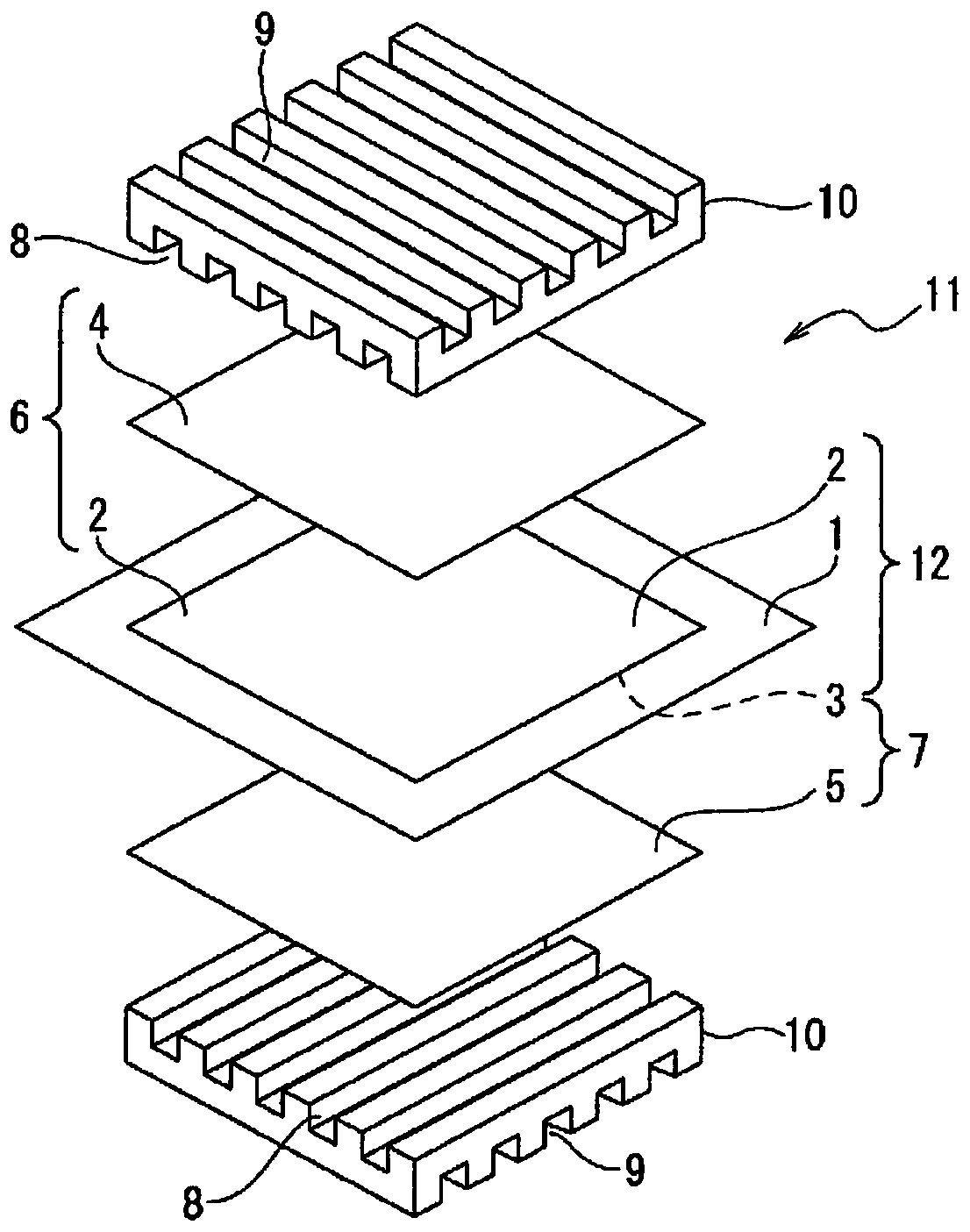

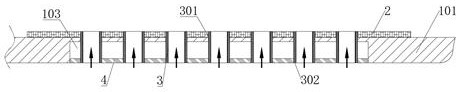

Tube-shaped solid polymer fuel cell and method for producing tube-shaped solid polymer fuel cell

InactiveUS20090286126A1Limitation in power generation performanceIncrease resistanceFinal product manufactureFuel cell shape/formParticulatesCell resistance

A tube-shaped solid polymer fuel cell is provided with communicating fuel gas channels 2 on the periphery of a bar-shaped current collector 1 and along the axis of the bar-shaped current collector 1 and the membrane-electrode assembly (MEA) 6 on the outside of the bar-shaped current collector 1 and the fuel gas channels 2 and has a structure in which a fuel gas flows through the fuel gas channels 2 and an oxide gas flows outside the membrane-electrode assembly (MEA) 6, whereinsome or all of the fuel gas channels 2 are filled with a porous material having communication pores along the axis thereof and a conductive particulate having resistance to corrosion is mixed in with the porous material.The tube-shaped solid polymer fuel cell of the present invention makes it possible to improve gas flowability at the time of production of catalyst layers while avoiding infiltration of the gas channels by a catalyst ink so as to block the channels and thus lower cell resistance at the time of fuel cell operation. Thus, power generation performance is improved by the present invention.

Owner:TOYOTA JIDOSHA KK

Membrane electrode assembly for use in solid polymer electrolyte fuel cell

ActiveUS7807314B2Improve power generation effectImprove gas diffusivityFuel cell auxillariesActive material electrodesPolymer electrolytesCathode electrode

A membrane electrode assembly that includes a cathode electrode catalyst layer and an anode electrode catalyst layer respectively disposed on one side and the other side of a solid polymer electrolyte membrane, gas diffusion layers disposed respectively on the sides of the electrode catalyst layers; and intermediate layers having pores and disposed respectively between the electrode catalyst layer and the gas diffusion layer and between the electrode catalyst layer and the gas diffusion layer. The volume per unit area and per unit mass of the pores having pore size of 0.1 to 10 μm in the intermediate layer in the cathode side is larger than that in the intermediate layer in the anode side. The pore volume of the intermediate layer in the cathode side is 1.7 to 4.3 μl / cm2 / mg and that of the intermediate layer in the anode side is 0.5 to 1.4 μl / cm2 / mg.

Owner:HONDA MOTOR CO LTD

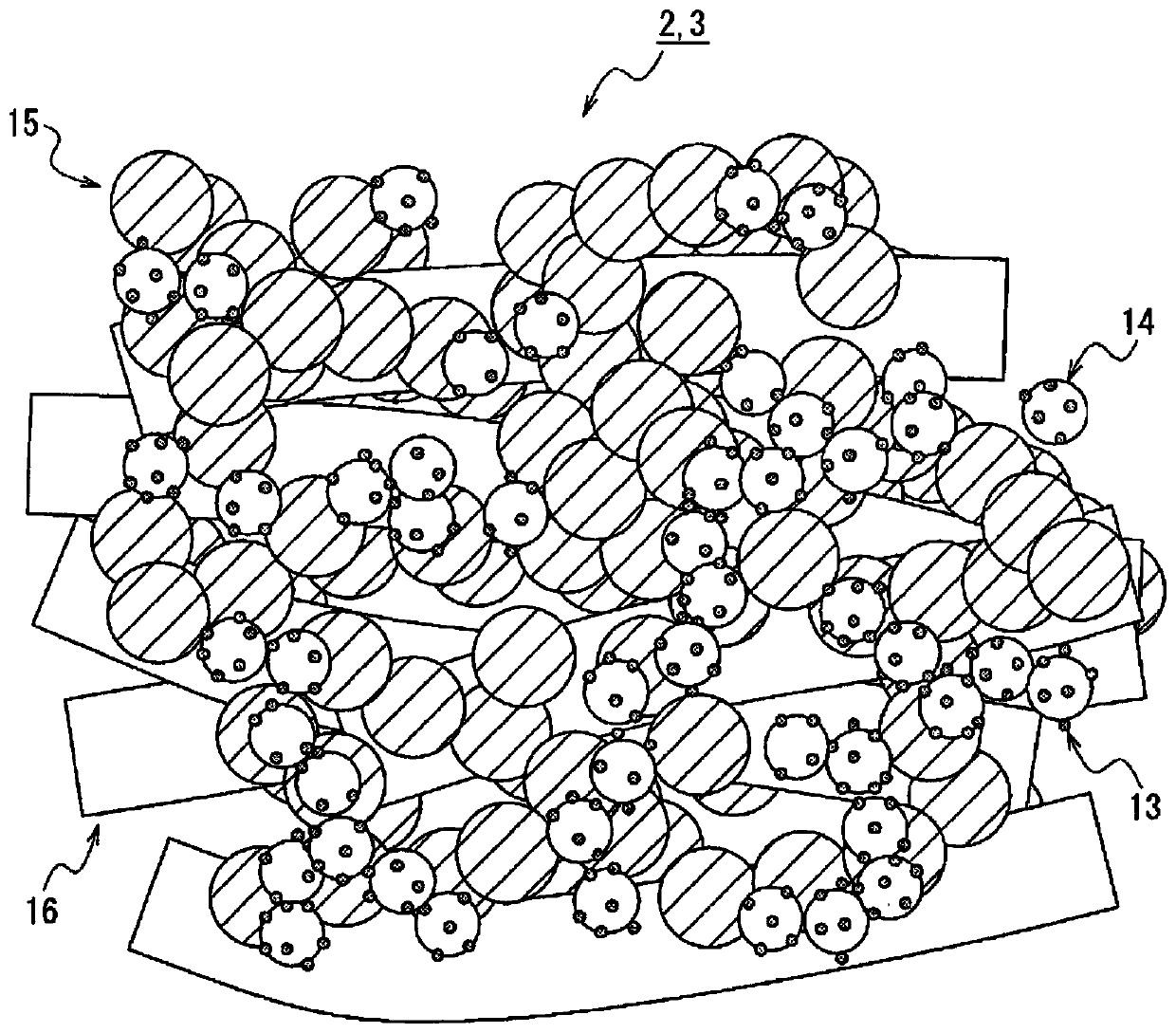

Electrode catalyst layer and solid polymer fuel cell

ActiveCN111247677AIncrease output powerImprove drainage capacityCell electrodesSolid electrolyte fuel cellsPolymer electrolytesPtru catalyst

Provided are: an electrode catalyst layer for solid polymer fuel cells, which is capable of having high output, while being able to have improved water discharge performance and improved gas diffusibility; and a solid polymer fuel cell which is provided with this electrode catalyst layer for solid polymer fuel cells. Electrode catalyst layers (2, 3) according to one embodiment of the present invention are bonded to a polymer electrolyte membrane (1), and comprise a catalyst (13), carbon particles (14), a polymer electrolyte (15) and a fibrous material (16). The electrode catalyst layers (2, 3)have a density of from 500 mg / cm3 to 900 mg / cm3 (inclusive); or alternatively, the electrode catalyst layers (2, 3) have a density of from 400 mg / cm3 to 1,000 mg / cm3 (inclusive), and the mass of thepolymer electrolyte (15) is within the range of from 10% by mass to 200% by mass (inclusive) relative to the total mass of the carbon particles (14) and the fibrous material (16).

Owner:TOPPAN PRINTING CO LTD

Gas diffusion layer structure of electrochemical oxygen generator membrane electrode and preparation method

PendingCN114164444AIncrease the rate of electrolysisImprove gas diffusivityElectrodesPorous substrateElectrolysis

The invention discloses a gas diffusion layer structure of an electrochemical oxygenerator membrane electrode and a preparation method, the gas diffusion layer structure comprises a cathode gas diffusion layer and an anode gas diffusion layer, the cathode gas diffusion layer comprises a cathode conductive porous substrate layer and a cathode microporous layer arranged at the inner side of the cathode conductive porous substrate layer; the anode gas diffusion layer comprises an anode conductive porous substrate layer and an anode microporous layer arranged on the inner side of the anode conductive porous substrate layer, the anode microporous layer comprises carbon particles and a binder, and the cathode microporous layer comprises carbon particles, a binder, a water absorbent and an adsorption material. Compared with the prior art, the electrochemical oxygen generator has the advantages that the conductivity is good, the hydrophilic and hydrophobic properties of the cathode gas diffusion layer and the anode gas diffusion layer are different, the gas diffusion performance and the water management performance of the electrochemical oxygen generator are improved, the water-gas distribution performance of the cathode gas diffusion layer and the anode gas diffusion layer is optimized, the electrolysis rate of the anode side water is further improved, and the electrochemical oxygen generator is more stable. And oxygen can be stably produced under the condition of low humidity.

Owner:江西德合医疗器械有限公司

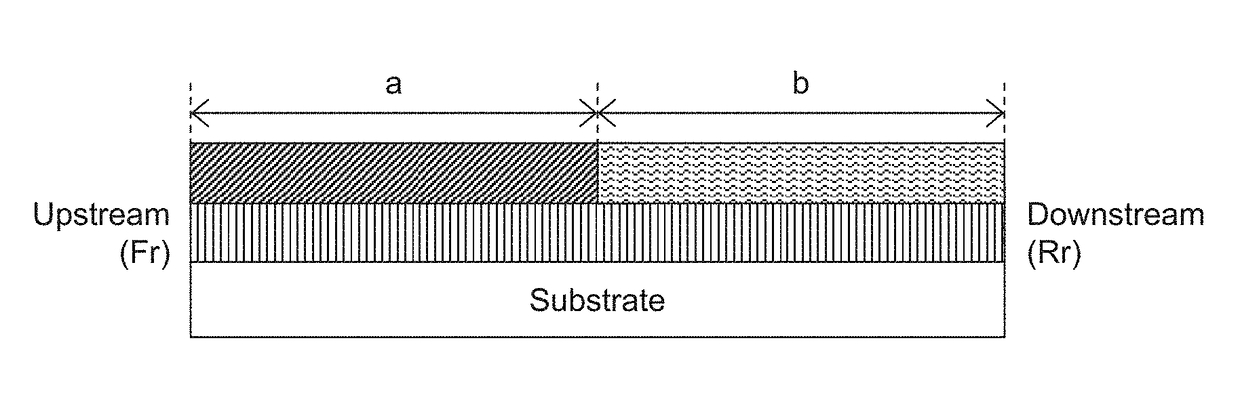

Exhaust gas purification catalyst

ActiveUS20180243690A1Improve gas diffusivitySufficient purification performanceInternal combustion piston enginesDispersed particle separationExhaust gasCoating

An object of the present invention is to provide an exhaust gas purification catalyst which can exhibit sufficient purification performance even under a high Ga condition. The present invention relates to an exhaust gas purification catalyst comprising a substrate and a catalyst coating layer formed on the substrate, wherein the catalyst coating layer comprises catalyst particles, the catalyst coating layer having an upstream region extending by 40 to 60% of the entire length of the substrate from an upstream end of the catalyst in the direction of an exhaust gas flow and a downstream region corresponding to the remainder portion of the catalyst coating layer, the composition of the catalyst particle of the upstream region being different from that of the downstream region. The downstream region in the direction of an exhaust gas flow has a structure where a void is included in a large number, and furthermore high-aspect-ratio pores having an aspect ratio of 5 or more account for a certain percentage or more of the whole volume of voids. Thus, the exhaust gas purification catalyst exhibits enhanced purification performance.

Owner:TOYOTA JIDOSHA KK +1

Exhaust gas purification catalyst

ActiveUS10323554B2Improve gas diffusivitySufficient purification performanceInternal combustion piston enginesDispersed particle separationActive siteExhaust gas

The present invention is directed to address the following problem: in an exhaust gas purification catalyst comprising a dual catalyst of a combination of a startup catalyst and an underfloor catalyst, reduction in the gas diffusivity of the underfloor catalyst results in reduction in the use efficiency of a catalytic active site, resulting in reduction in purification performance. The present invention relates to an exhaust gas purification catalyst comprising a dual catalyst of a combination of a startup catalyst and an underfloor catalyst having a catalyst coating where a large number of voids are included, wherein high-aspect-ratio pores having an aspect ratio of 5 or more account for a certain rate or more of the whole volume of the voids, to thereby enhance the purification performance of the catalyst.

Owner:TOYOTA JIDOSHA KK +1

Exhaust gas purifying catalyst

ActiveCN107530698AFull coating amountImprove gas diffusivityInternal combustion piston enginesDispersed particle separationReactive siteProduct gas

The present invention addresses the problem in exhaust gas purifying catalysts comprising two catalysts in which a startup catalyst and an underfloor catalyst are combined, whereby a decrease in the gas diffusibility of the underfloor catalyst causes the efficiency of using a catalytic active site to be lowered and thus the purification performance to be degraded. The present invention relates toan exhaust gas purifying catalyst comprising two catalyst in which a startup catalyst having a catalyst coat including many voids and an underfloor catalyst are combined, wherein a certain portion ormore of all the voids are composed of pores having a high aspect ratio of 5 or greater, thereby improving the purification performance of the catalyst.

Owner:TOYOTA JIDOSHA KK +1

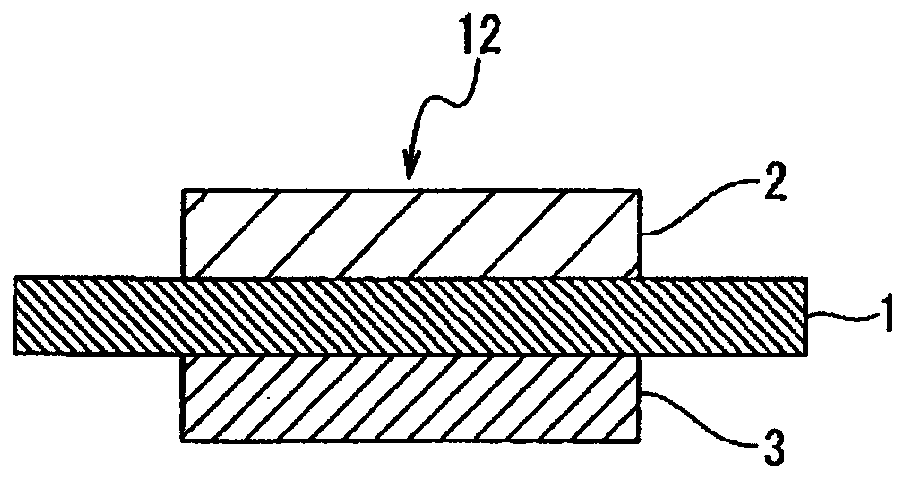

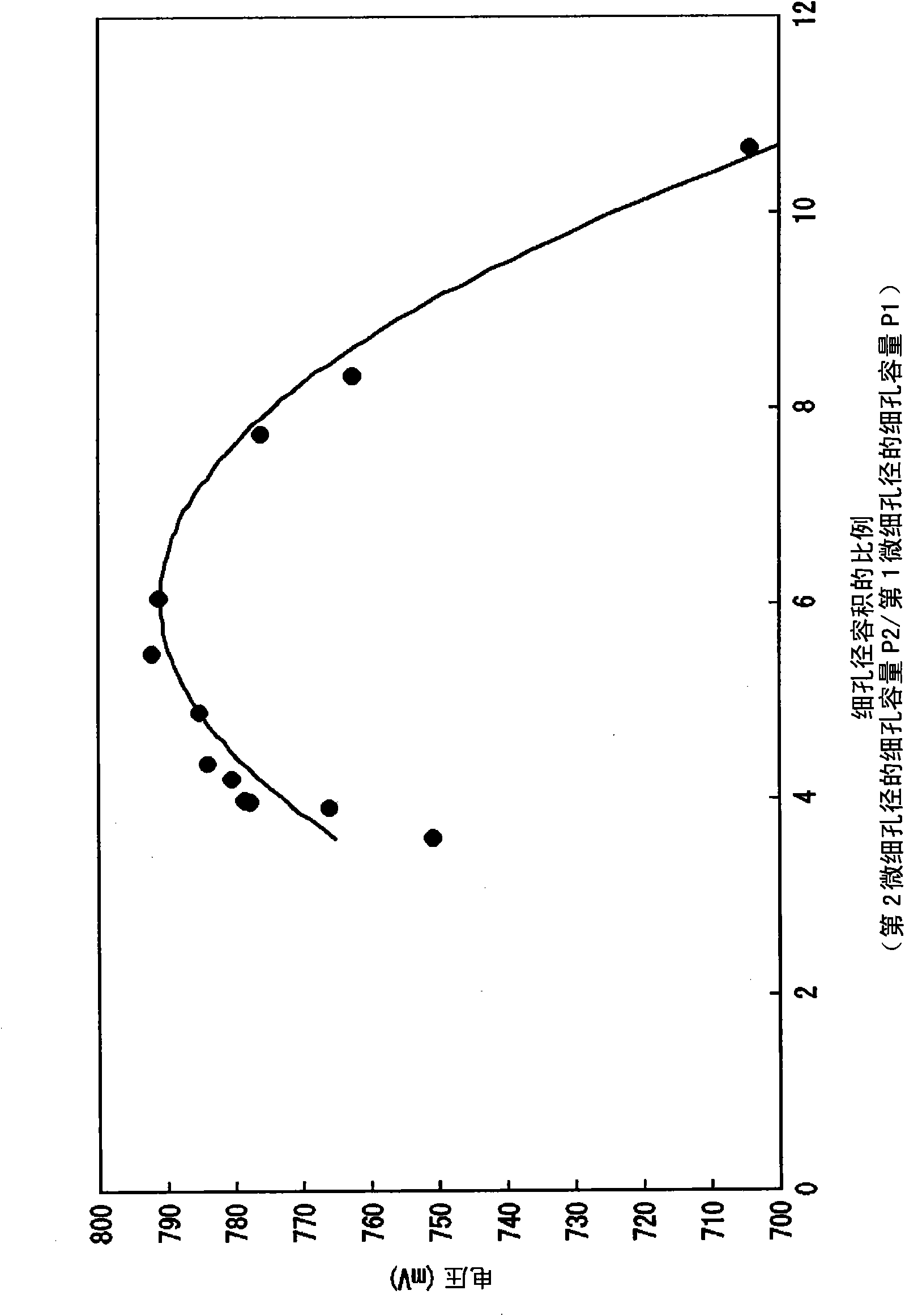

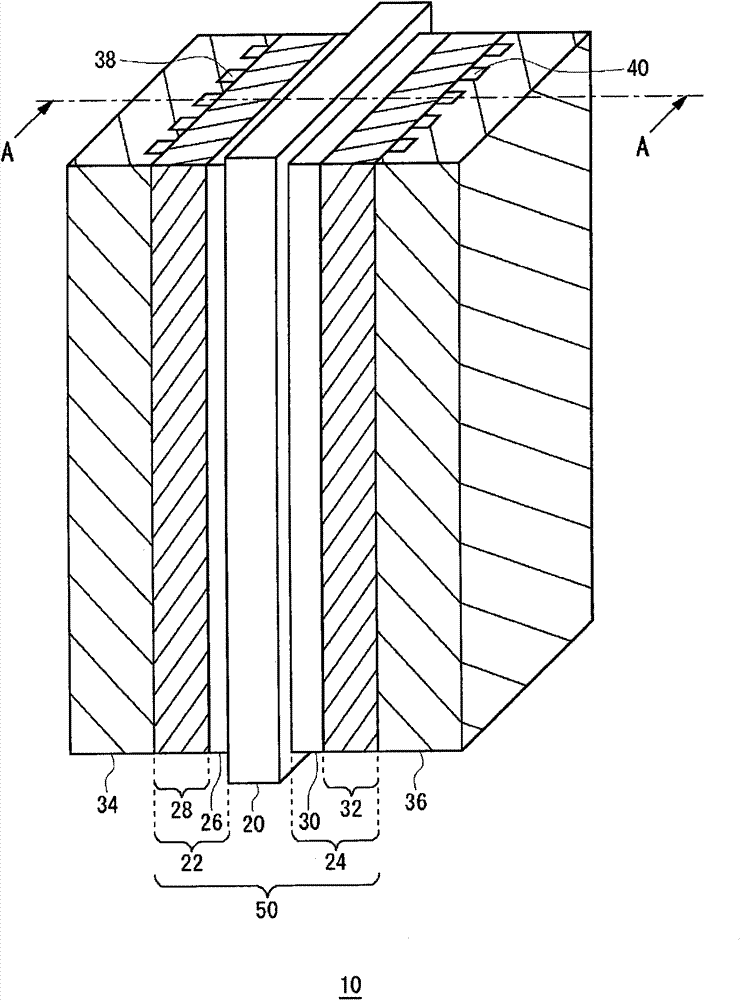

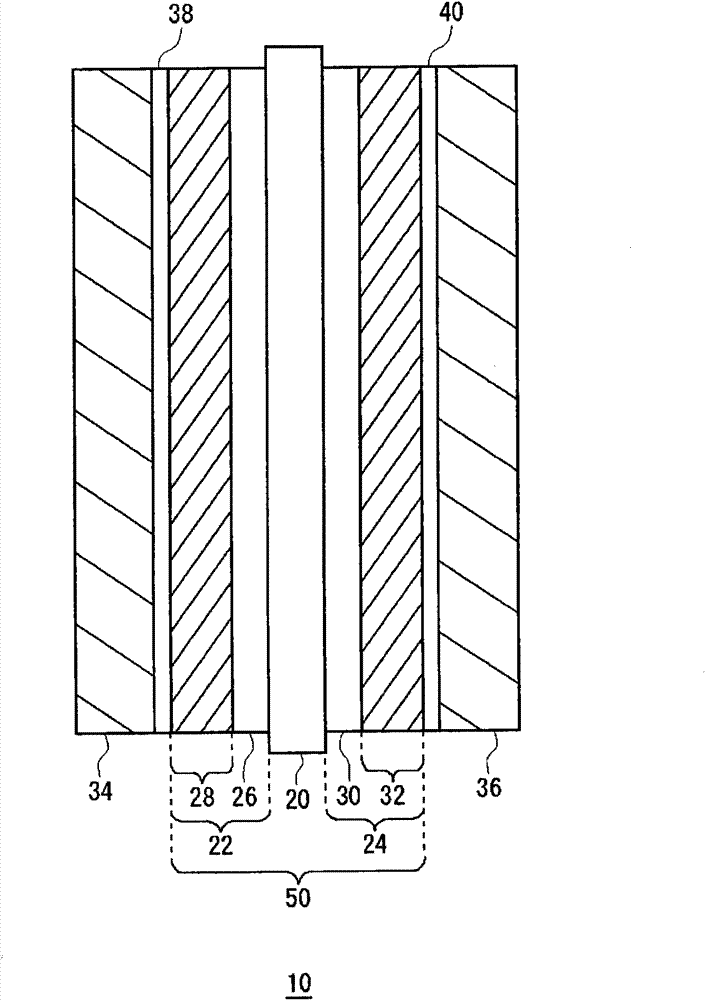

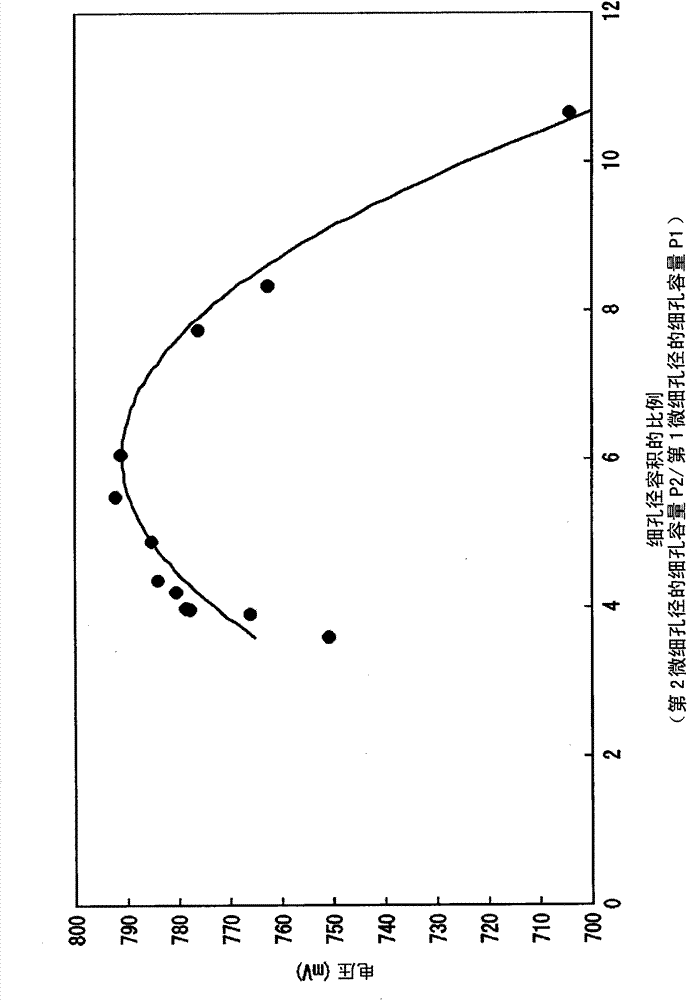

Membrane electrode assembly and fuel cell

ActiveCN101978536AImprove gas diffusivityHigh voltageCell electrodesSolid electrolyte fuel cellsPlatinumPolymer electrolytes

Disclosed is a membrane electrode assembly (50) comprising a solid polymer electrolyte membrane (20), an anode (22) and a cathode (24). The catalyst layer (30) comprises carbon particles each having platinum and cobalt carried thereon and an ionic conductor. In the catalyst layer (30), the ratio (P2 / P1) of the pore volume P2 (ml / g) per gram of catalyst layer in a second micro-pore diameter, ranging from 0.1 [mu]m to less than 1 [mu]m, over the pore volume P1 per gram of catalyst layer in a first micro-pore diameter, ranging from 0.01 [mu]m to less than 0.1 [mu]m, is in a range of 3.8 to 8.3.

Owner:SANYO ELECTRIC CO LTD

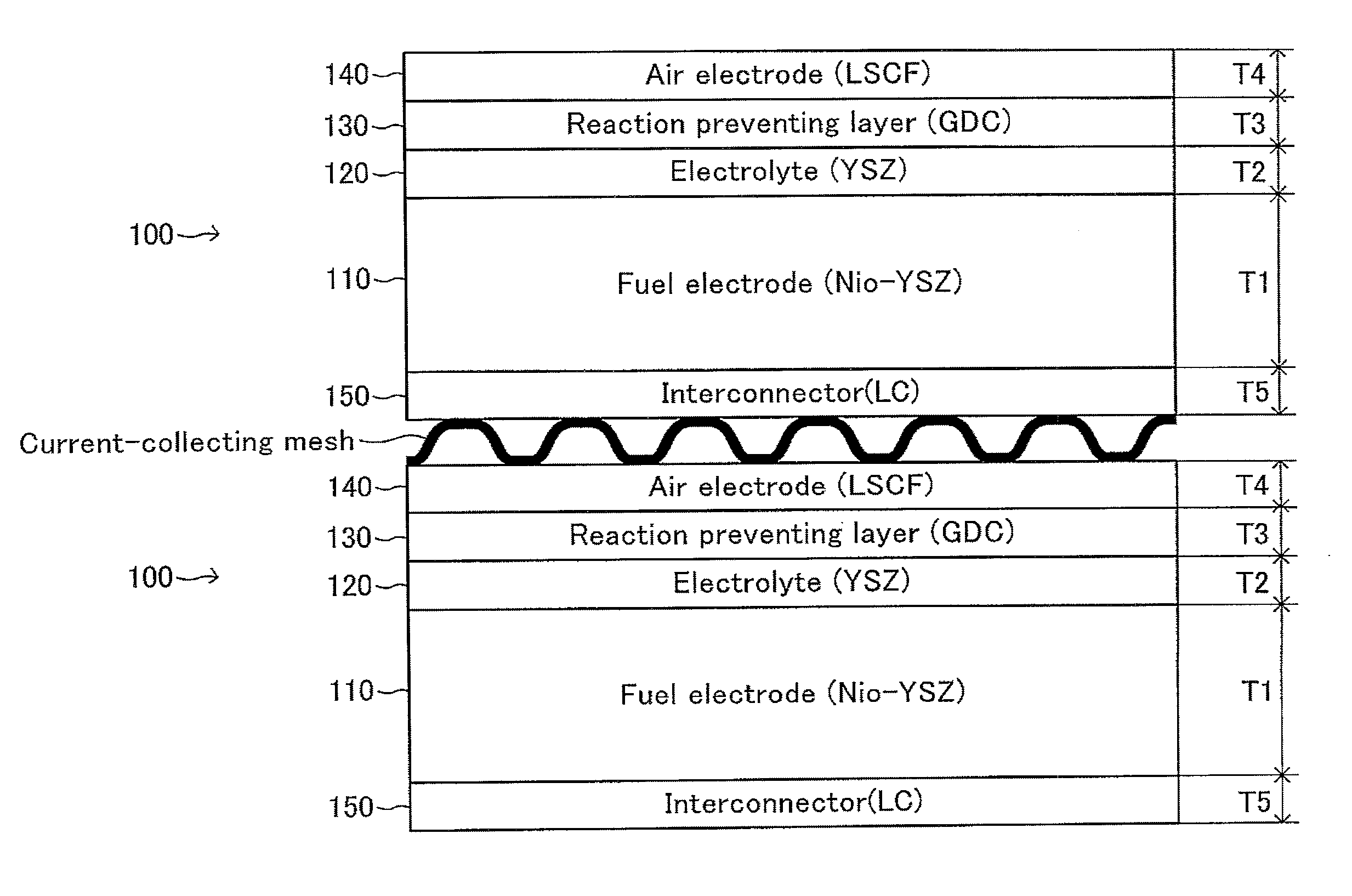

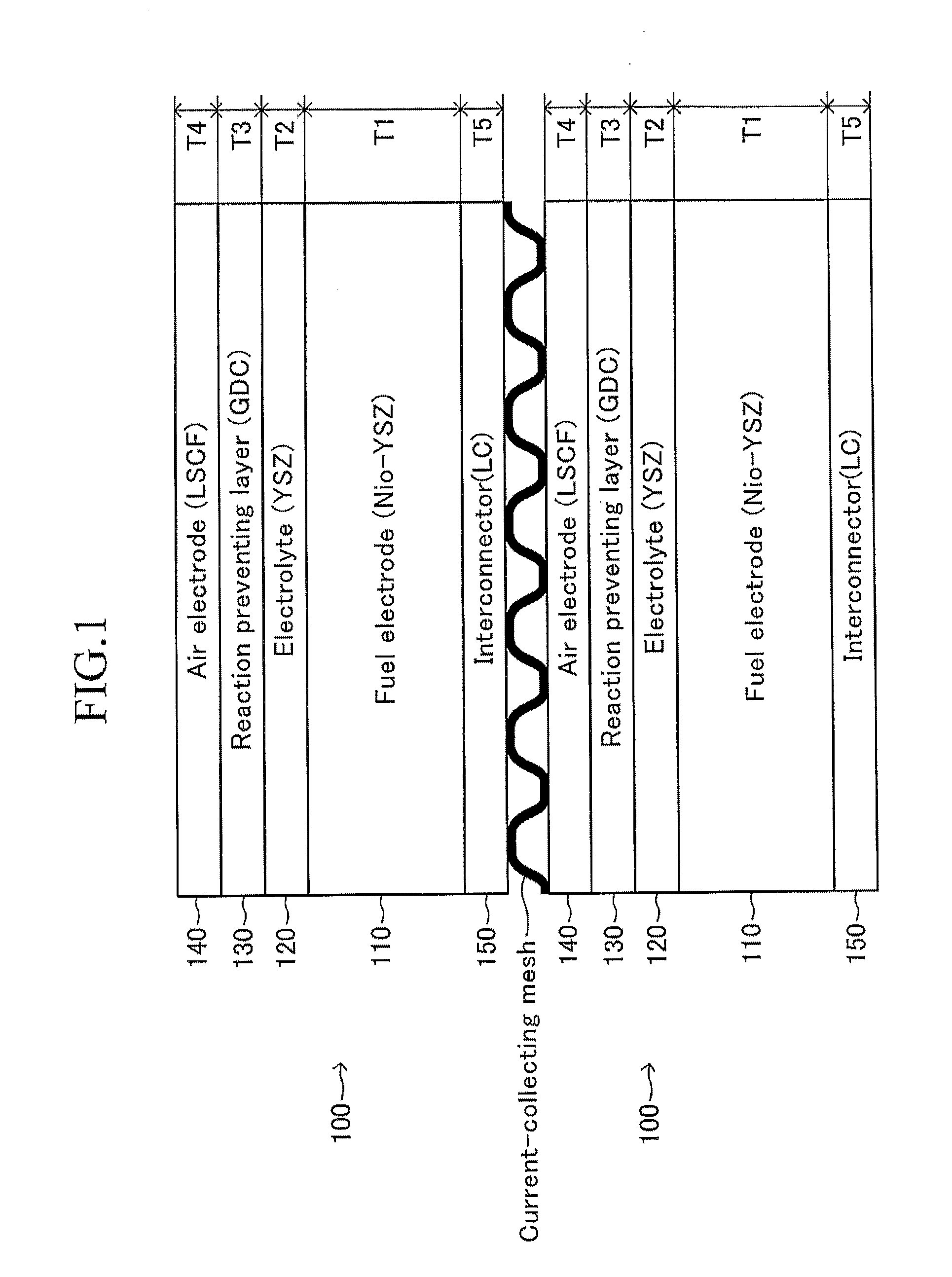

Solid oxide fuel cell including electrode containing dense bonding portions and porous non-bonding portions

ActiveUS8574784B2High strengthPorosity of the materialFinal product manufactureElectrode carriers/collectorsPorosityFuel cells

A solid oxide fuel cell having a fuel electrode, a solid electrolyte film, an air electrode, and a conductive current-collecting mesh bonded to an upper surface, opposite to a lower bonding surface with the solid electrolyte film, of the air electrode. Plural bonding portions that are bonded to the current-collecting mesh and plural non-bonding portions that are not bonded to the current-collecting mesh are present on the upper surface of the air electrode. In the air electrode, regions having a porosity smaller than a porosity of the other region are respectively formed on the position in the middle of the thickness of the air electrode from each bonding portion. The average of the porosity of the dense portion is 20% or more and less than 35%, while the average of the porosity of the porous portion is 35% or more and less than 55%.

Owner:NGK INSULATORS LTD

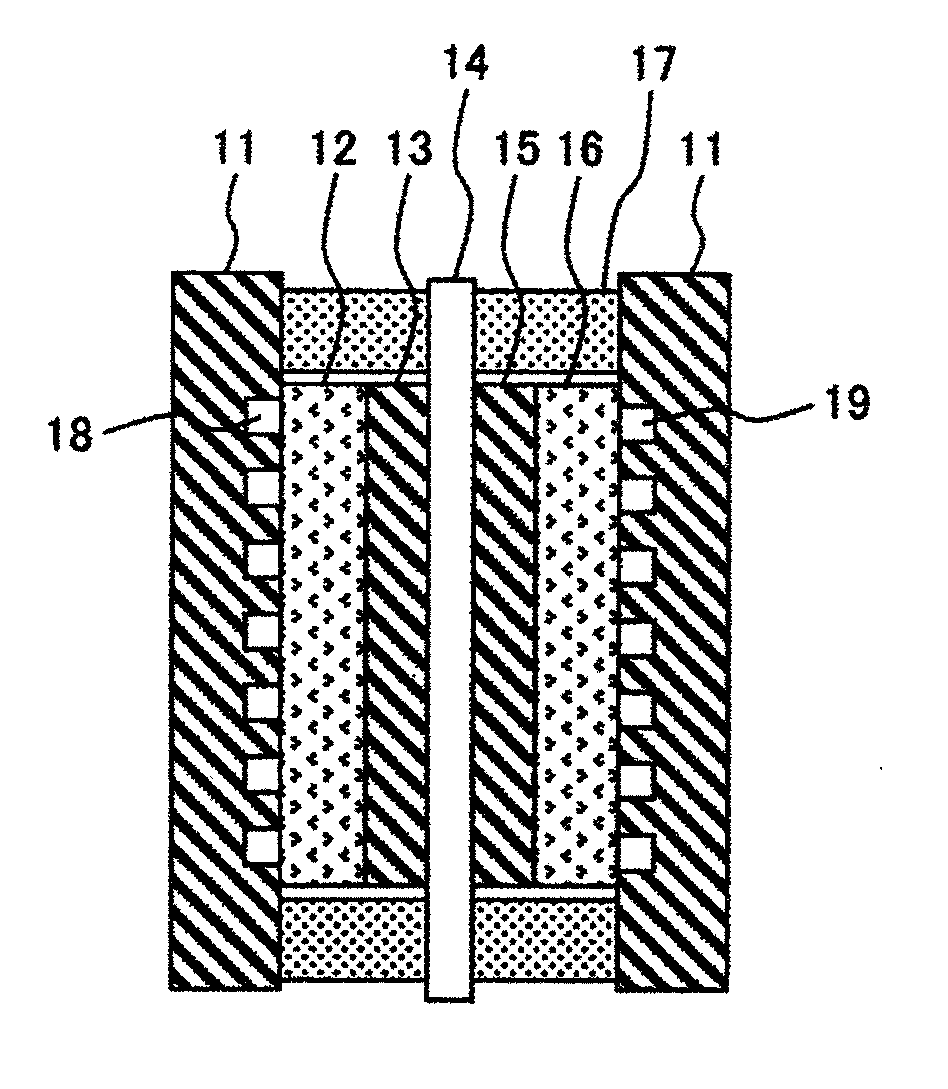

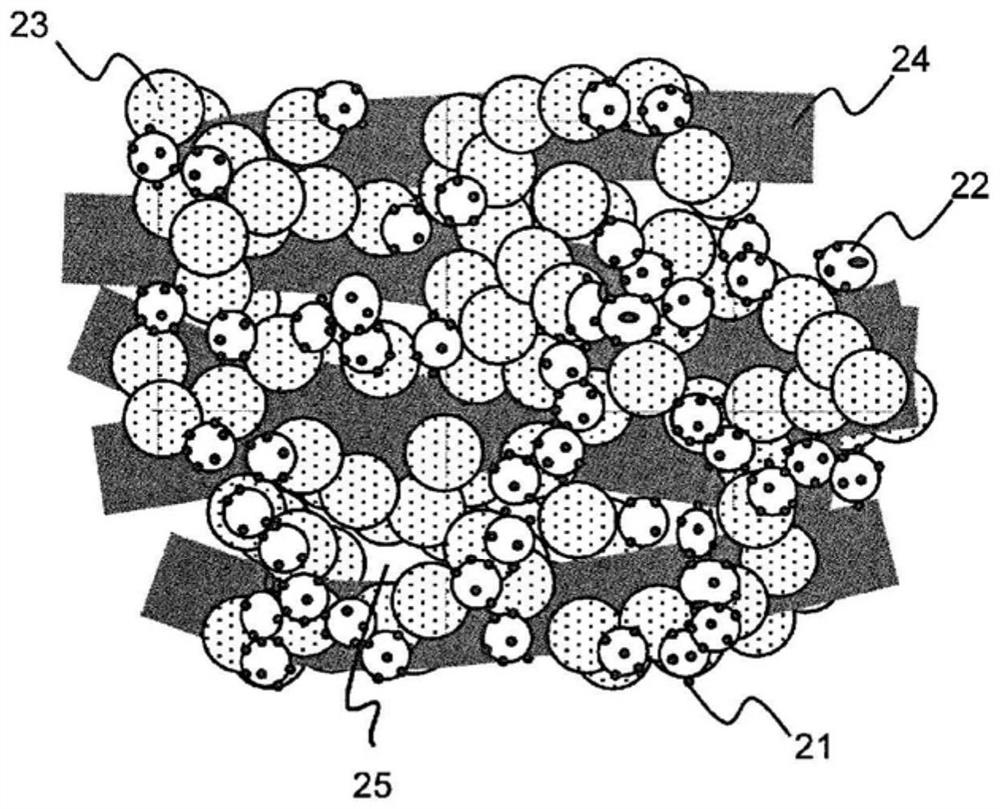

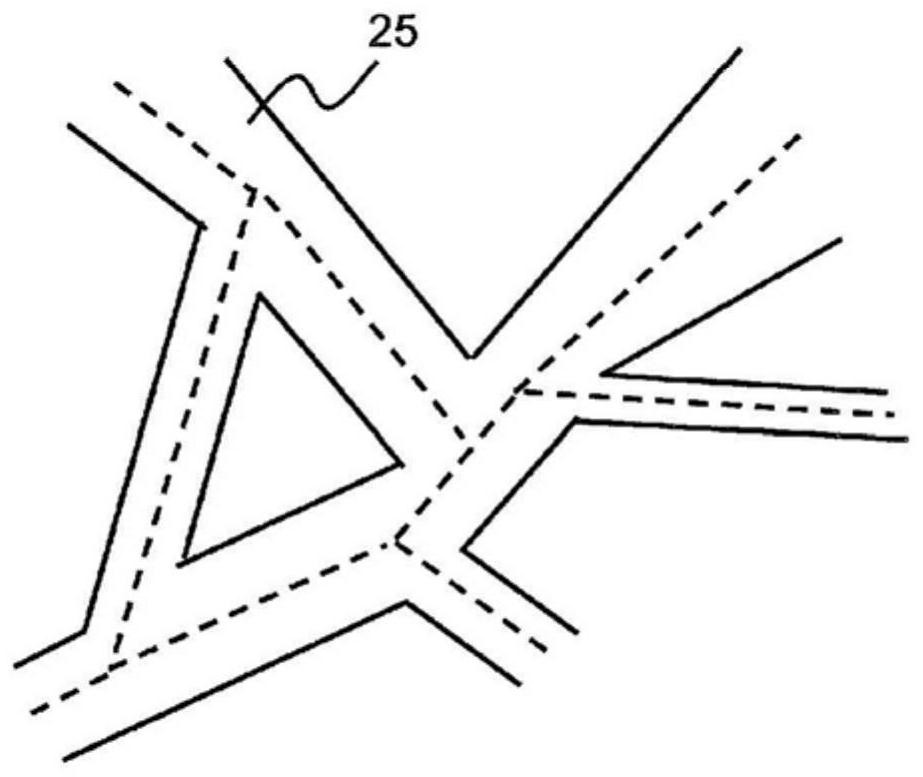

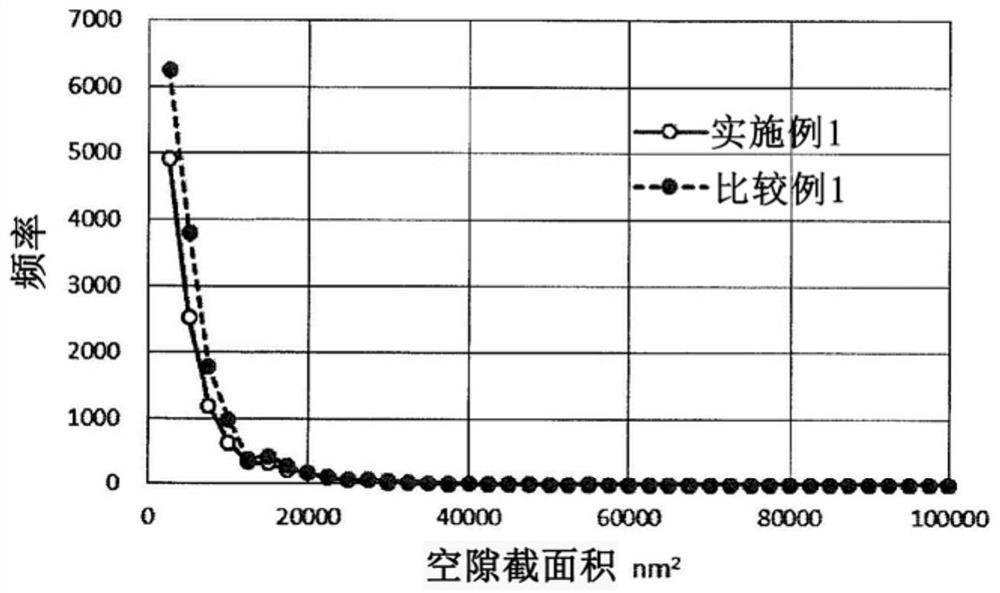

Catalyst layer for solid polymer fuel cells, membrane electrode assembly, and solid polymer fuel cell

PendingCN113557618AImprove utilization efficiencyCrack suppressionSolid electrolytesCell electrodesPolymer electrolytesPolymer science

The present invention provides a catalyst layer for solid polymer fuel cells, a membrane electrode assembly, and a solid polymer fuel cell that improve drainage properties and gas diffusion properties, suppress cracks in the catalyst layer, improve catalyst utilization efficiency, increases energy conversion efficiency at high output, and provide good durability. This catalyst layer for solid polymer fuel cells includes a catalyst 21, carbon particles 22, a polymer electrolyte 23, and a fibrous substance 24. The carbon particles 22 support the catalyst 21. The catalyst layer for solid polymer fuel cells has gaps 25 and the frequency of gaps 25 that have a cross-sectional area of at least 10,000 nm2 among gaps 25 observed in a cross-section in the thickness direction intersecting the surface of the catalyst layer for solid polymer fuel cells is 13%-20%.

Owner:TOPPAN PRINTING CO LTD

A kind of preparation method of carbon paper for fuel cell gas diffusion layer with high carbon content

ActiveCN111900417BSuppress or eliminate the effectHigh carbon contentCell electrodesFinal product manufactureFiberCarbon fibers

Owner:QILU UNIV OF TECH

Conductive carbon felt-supported iron-doped mesoporous titanium oxide gas diffusion photoelectrode and preparation method thereof

ActiveCN105080546BReduce degradation costReduce stickingOther chemical processesDispersed particle separationFiberPore distribution

The invention relates to a conductive carbon felt loaded ferric ferric-doped mesoporous titanium oxide gas diffuse photoelectrode and a preparation method therefore. An efficient gas diffusion photoelectrode (TiO2-Fe)mp. / CF mesoporous loaded composite nano material is prepared by adopting a liquid crystal template method and a spray coating technology. The method has the remarkable characteristics that the conductive carbon felt loaded mesoporous (TiO2-Fe) composite nano material with a special structure and the efficient gas diffusion photoelectrode is prepared by applying the spray coating technology and the liquid crystal template method, thereby providing a novel path for application and research of a porous material loaded mesoporous doped TiO2 photocatalytic material. The conductive carbon felt loaded ferric ferric-doped mesoporous titanium oxide gas diffuse photoelectrode is simple in process and easy for industrial production. The prepared efficient gas diffusion photoelectrode mesoporous loaded composite material is good in conductivity, large in specific surface area and uniform in pore distribution.

Owner:JISHOU UNIVERSITY

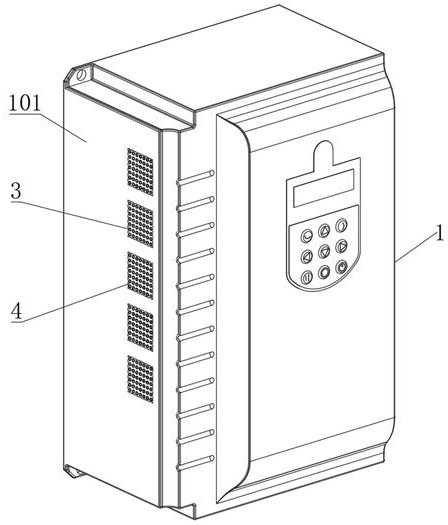

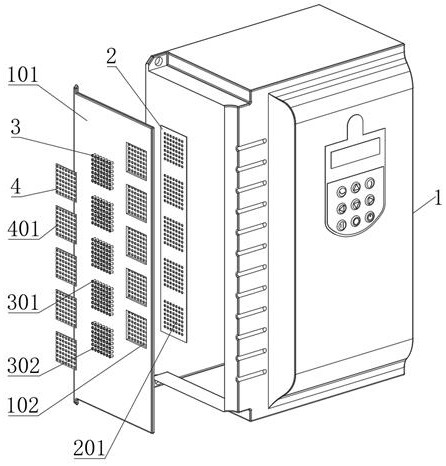

A high temperature adaptable inverter

ActiveCN114552947BImprove air flowImprove cooling effectCasings/cabinets/drawers detailsEnergy industryConvertersThermodynamics

Owner:南通华研自动化科技有限公司

Membrane electrode assembly and fuel cell

ActiveCN101978536BImprove gas diffusivityHigh voltageCell electrodesSolid electrolyte fuel cellsElectrical conductorCobalt

A membrane electrode assembly includes an solid polymer electrolyte membrane, an anode, and a cathode. The cathode has a stacked body of a catalyst layer and a gas diffusion layer. The catalyst layer has platinum-cobalt-supporting carbon particles and an ion conductor. The ratio (P2 / P1) of the pore volume P2 (ml / g) per gram of catalyst layer in a second micro-pore diameter, ranging from 0.1 µm to less than 1 µm, over the pore volume P1 per gram of catalyst layer in a first micro-pore diameter, ranging from 0.01 µm to less than 0.1 µm, is in a range of 3.8 to 8.3.

Owner:SANYO ELECTRIC CO LTD

Fuel cell electrode catalyst

ActiveUS11258075B2Cause an electrode reaction more efficientlyImprove gas diffusivityGraphiteCell electrodesFuel cellsPtru catalyst

A fuel cell electrode catalyst includes: a noble-metal-supported catalyst including a carbon support and a noble metal supported on the carbon support; and a water-repellent material with which the noble-metal-supported catalyst is modified. The carbon support is mesoporous carbon in which a pore volume of pores having a pore size of 2 nm to 5 nm is 2.1 ml / g to 2.4 ml / g. An amount of the water-repellent material is 3% by weight to 7% by weight with respect to a total weight of the mesoporous carbon and the water-repellent material.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com