Electrode catalyst layer and solid polymer fuel cell

An electrode catalyst layer and polymer electrolyte technology, which is applied in the field of solid polymer fuel cells, can solve the problems of hindering gas overflow and reducing the output power of fuel cells, and achieves improved gas diffusivity, improved drainage, and high output power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

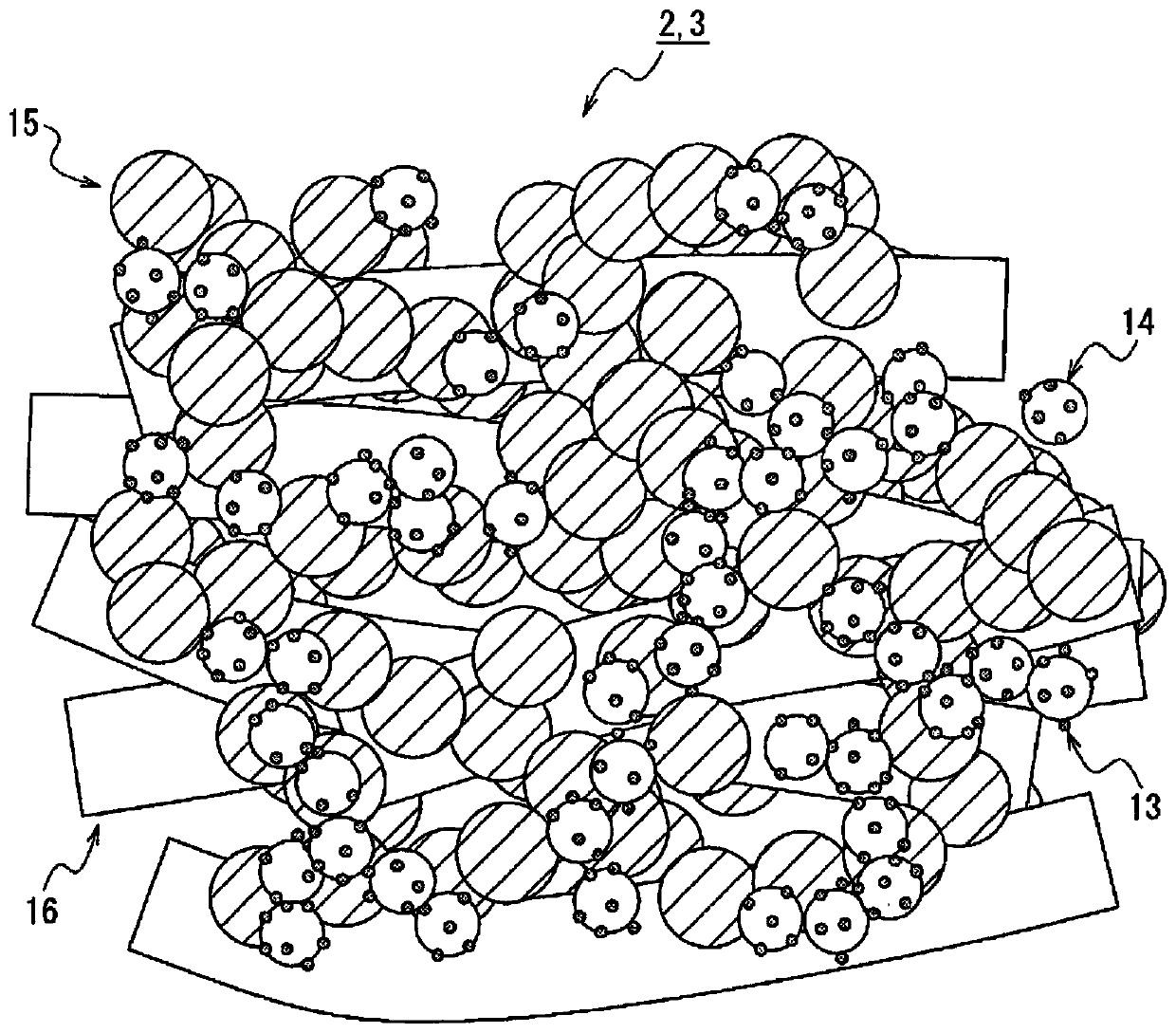

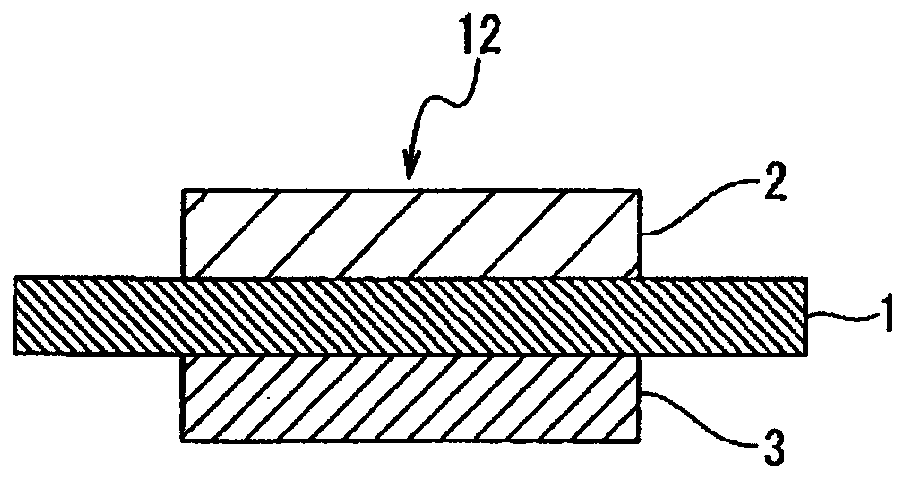

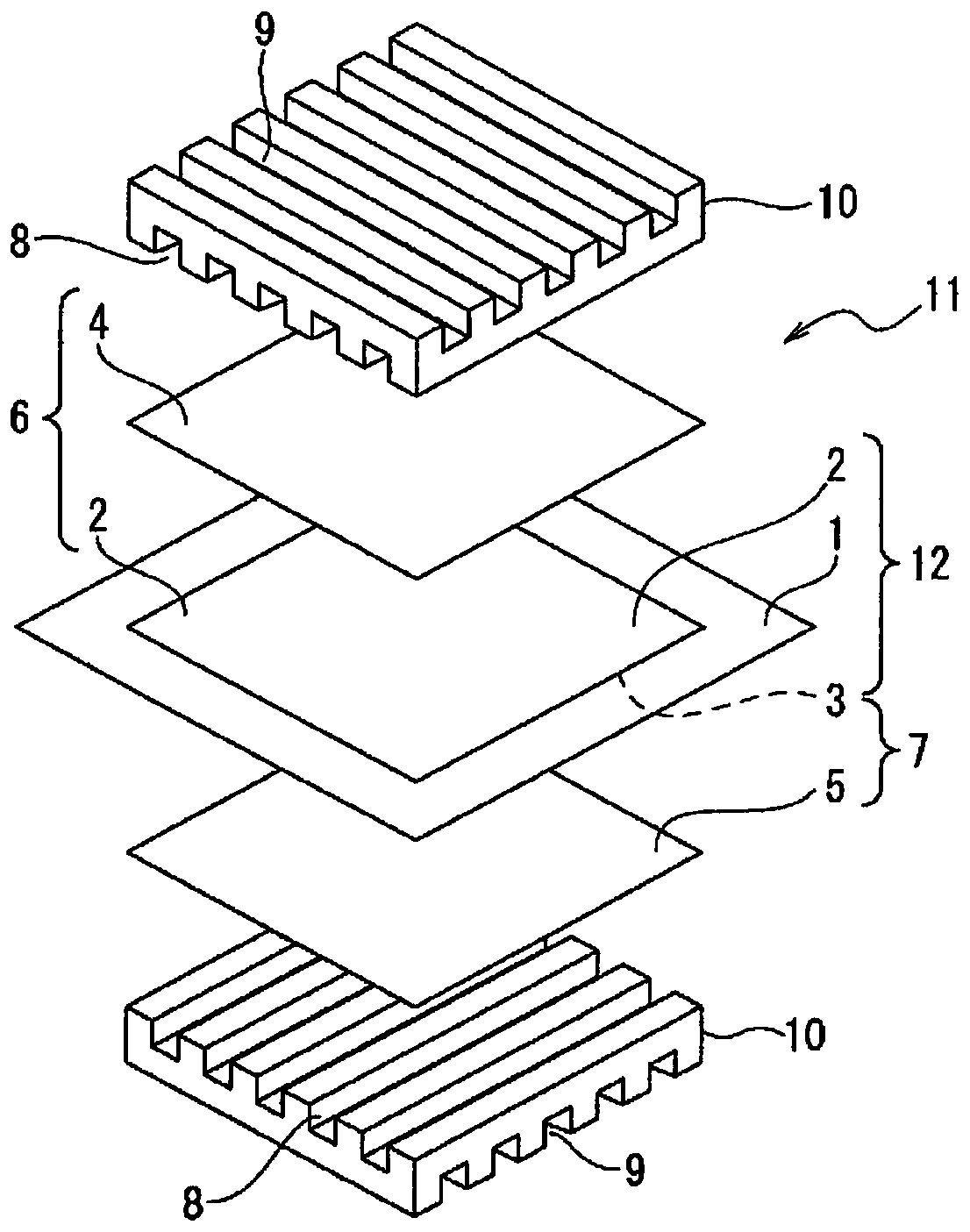

[0071] The electrode catalyst layer was formed such that the thickness and density of the electrode catalyst layer became the values shown in Table 2.

[0072] First, 20 g of platinum-supported carbon (TEC10E50E, manufactured by Tanaka Kikinzoku Co., Ltd.) was put in a container, mixed with water, and 1-propanol, electrolyte (Nafion (registered trademark) dispersion liquid, "Wako Pure Pharmaceutical Co., Ltd." ), 10 g of carbon nanofibers (manufactured by "Showa Denko" Co., Ltd., trade name "VGCF", fiber diameter about 150 nm, fiber length about 10 μm) as a fibrous substance were stirred to obtain a catalyst layer slurry.

[0073] The obtained catalyst layer slurry was coated on a polymer electrolyte membrane (manufactured by DuPont, Nafion 212) by a die coating method, and dried in an oven at 80° C., thereby obtaining the electrode catalyst layer of Example 1-1. membrane electrode assembly.

Embodiment 1-2

[0075] The membrane electrode assembly having an electrode catalyst layer of Example 1-2 was obtained in the same manner as in Example 1-1, except that carbon nanotubes (fiber diameter about 1 nm, fiber length about 1 μm) were used as the fibrous substance.

Embodiment 1-3

[0077] The membrane electrode assembly having the electrode catalyst layer of Example 1-3 was obtained in the same manner as in Example 1-1 except that the drying temperature was increased.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com