Preparation method of carbon paper for gas diffusion layer of high-carbon-content fuel cell

A gas diffusion layer and fuel cell technology, applied in fuel cells, electrical components, battery electrodes, etc., can solve the problems of poor structural compactness of carbon fiber paper and difficult industrial production, and achieve stable chemical properties, increased carbon content, and high gas diffusion. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

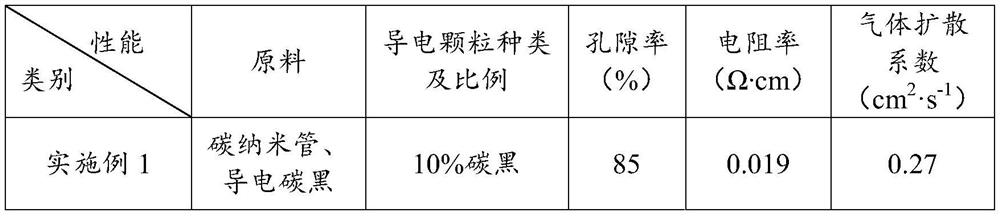

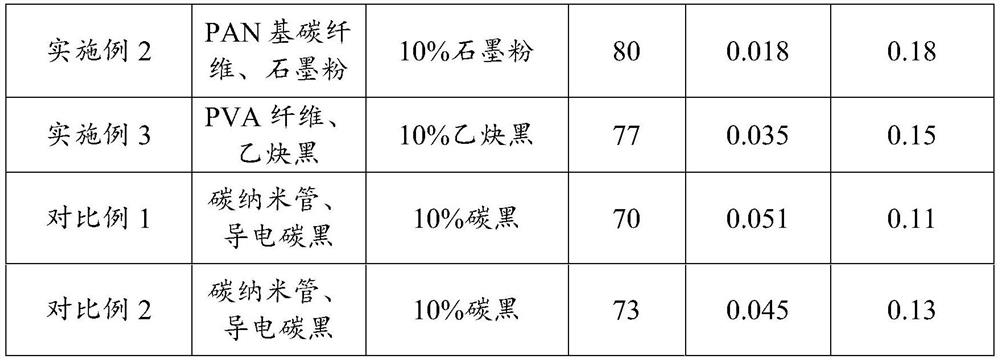

Examples

Embodiment approach

[0025] A typical embodiment of the present invention provides a method for preparing carbon paper for a gas diffusion layer of a high-carbon fuel cell, the steps of which include:

[0026] Immerse the carbon fiber paper in the first conductive ink, first ultrasonically treat it, then impregnate it under negative pressure, and then dry it, so that the solute in the first conductive ink is combined with the carbon fiber paper to obtain a carbon paper precursor A; carbonize the carbon paper precursor A to obtain Carbon paper precursor B;

[0027] The carbon paper precursor B and the second conductive ink are impregnated-cured-carbonized to obtain the carbon paper precursor C, and the carbon paper precursor C and the third conductive ink are repeatedly impregnated-cured-carbonized to obtain the carbon paper precursor D;

[0028] Graphitizing the carbon paper precursor D to obtain carbon paper;

[0029] Wherein, the preparation process of the first conductive ink, the second cond...

Embodiment 1

[0054] A preparation method of carbon paper for a fuel cell gas diffusion layer with high carbon content, comprising the following steps:

[0055] (1) Mix fibrils and conductive particles: pretreat carbon nanotubes with a length of 10-20 μm and a diameter of 1-100 nm in 0.1 wt % hydrochloric acid solution, stir at a speed of 600 r / min for 5 min, and pretreat After completion, wash with deionized water and dry, according to 1wt% of the absolute dry mass of phenolic resin ethanol solution, add in 50wt% phenolic resin ethanol solution, stir 5min after adding; Add 10 wt% of ethanol solution into ethanol solution of phenolic resin and stir for 1 hour. Under the condition of ultrasonic frequency of 400-500KHz, perform ultrasonic treatment for 5 minutes to prepare uniform conductive ink A.

[0056] (2) Slowly immerse the carbon fiber paper in conductive ink A, and put the beaker into an ultrasonic disperser. After ultrasonic treatment for 10 minutes, it is immersed in negative pressu...

Embodiment 2

[0063] A preparation method of carbon paper for a fuel cell gas diffusion layer with high carbon content, comprising the following steps:

[0064] (1) Mixing fibrils and conductive particles: Pretreat PAN-based carbon fibers with a length of 3-7 mm and a diameter of 10-20 μm in 0.1 wt % hydrochloric acid solution, stir at a speed of 600 r / min for 5 min, and pretreat Clean and dry with deionized water after completion, then add in the absolute ethanol solution of 50wt% PTFE according to 1wt% of absolute dry mass in the absolute ethanol solution of PTFE, stir 5min after adding; 200-mesh graphite powder is added to the absolute ethanol solution of PTFE according to 10wt% of the absolute dry mass in the absolute ethanol solution of PTFE, stirred for 1 hour, and ultrasonically treated for 5 minutes at an ultrasonic frequency of 400-500KHz to obtain a uniform Conductive ink A.

[0065] (2) Slowly immerse the carbon fiber paper in conductive ink A, and put the beaker into an ultraso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com