A high temperature adaptable inverter

A frequency converter and adaptive technology, applied in the field of frequency converters, can solve problems such as reducing environmental protection and energy saving properties, failing to achieve heat dissipation effects, increasing energy consumption of frequency converters, etc., to improve heat dissipation effects, reduce the probability of blockage, and improve applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

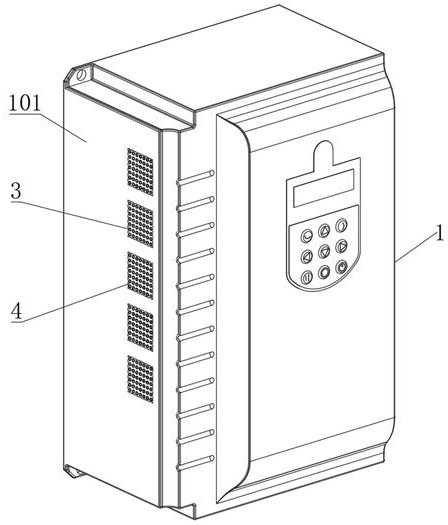

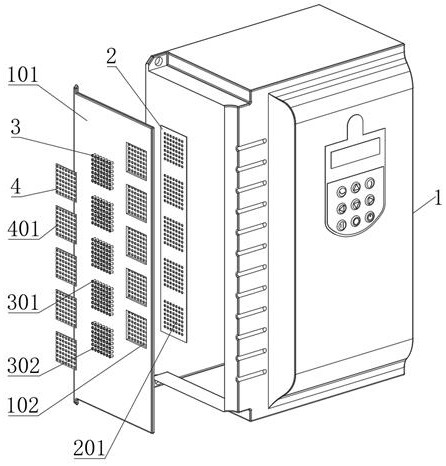

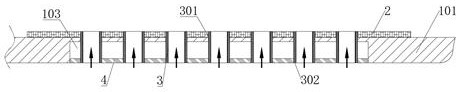

[0043] see Figure 1-12 , an adaptable inverter for high temperature, comprising an adaptable inverter body 1, an air intake baffle 101 is fixedly connected to the left end of the adaptable inverter body 1, and a plurality of air intake temperature sensing grooves 103 are opened on the air intake baffle 101, The right inner wall of the air inlet temperature sensing tank 103 is provided with a plurality of air inlet holes 102 which are connected to the interior of the adaptable frequency converter body 1. The air inlet holes 102 are fixedly connected with a temperature sensing outer sheath 301, and the temperature sensing outer sheath 301 is about Both ends are fixedly connected with a flexible activation ring 302, a flexible diameter-adjusting hollow sleeve 3 is fixedly connected between the two flexible activation rings 302, and the flexible diameter-adjusting hollow sleeve 3 is located inside the temperature-sensing outer sheath 301, and the temperature-sensing outer sheath ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com