Preparation method of microporous layer in gas diffusion layer

A gas diffusion layer and microporous layer technology, which is applied in electrical components, battery electrodes, circuits, etc., can solve the problems that the single-layer microporous layer cannot meet the function of air conduction and drainage, water flooding, etc., to enhance water management capabilities and The effect of gas diffusivity, improving hydrophobicity, reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

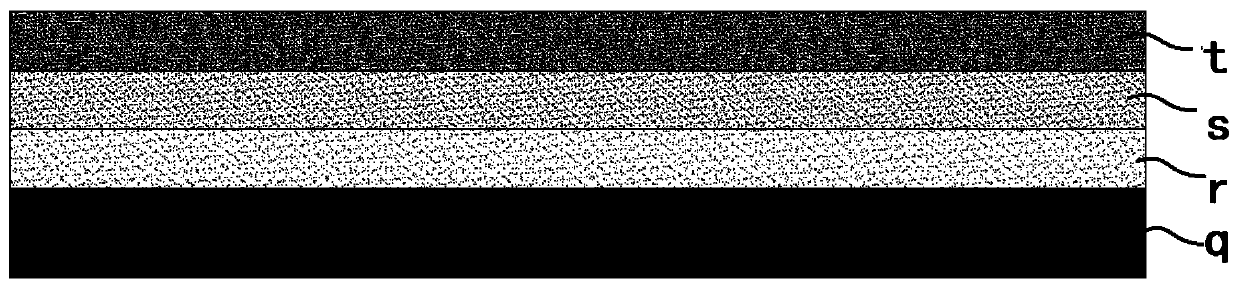

[0014] The invention provides a method for preparing a microporous layer in a gas diffusion layer, such as figure 1 shown, including the following steps,

[0015] (1) Obtain at least two kinds of slurry;

[0016] (2) Select a slurry to be coated on one side of the substrate q;

[0017] (3) drying, hot rolling, and sintering the coated slurry in sequence to form a microporous layer;

[0018] (4) selecting another slurry and coating the other slurry on the side of the microporous layer away from the substrate q;

[0019] (5) Drying, hot rolling, and sintering are performed sequentially on the coated another slurry to form another microporous layer;

[0020] (6) Repeat the above steps (4) to (5) to prepare all the microporous layers after all the slurry is processed.

[0021] The slurry described in step (1) to step (6) is a mixture of hydrophobic material, conductive carbon black and solvent, hydrophobic material includes one or more than two in PTFE, PDDA, PVDF, FEP, ETFE, ...

Embodiment 1

[0032] A method for preparing a microporous layer in a gas diffusion layer, comprising the steps of:

[0033] Step (1), weigh 1.75g conductive carbon black (U.S. Cabot XC-72R), 0.45g TritonX-100, 4.45g ethylene glycol (Shanghai Aladdin Company), 0.51g PTFE emulsion (Shanghai Hesen Electric Co., Ltd. Company), then weighed 13.35g deionized water into a beaker and carried out ultrasonic dispersion for 30min; the mixture obtained after the ultrasonic dispersion treatment was stirred for 60min at 8000rpm to obtain the microporous layer slurry A, and the stirring used was a high-speed disperser (Germany IKA company, T25 digital display type);

[0034] Weigh respectively 2.19g conductive carbon black (U.S. Cabot XC-72R), 0.55g Triton X-100, 4.45g ethylene glycol (Shanghai Aladdin Company), 0.91g PTFE emulsion (Shanghai Hesen Electric Co., Ltd.), and then Weigh 13.35g of deionized water into a beaker and carry out ultrasonic dispersion for 30min; the mixture obtained after the ult...

Embodiment 2

[0043] A method for preparing a microporous layer in a gas diffusion layer, comprising the steps of:

[0044]Step (1), respectively weigh 1.5g conductive carbon black (U.S. Cabot XC-72R), 0.40gTriton X-100, 3.8g ethylene glycol (Shanghai Aladdin Company), 0.4gPTFE emulsion (Shanghai Hesen Electric Co., Ltd.), then weighed 12.15g deionized water into the beaker and carried out ultrasonic dispersion for 30min; the mixture obtained after the ultrasonic dispersion treatment was stirred at 8000rpm for 60min to obtain the microporous layer slurry A, which was stirred using a high-speed disperser ( German IKA company, T25 digital display type);

[0045] Weigh respectively 2.19g conductive carbon black (U.S. Cabot XC-72R), 0.55g Triton X-100, 4.45g ethylene glycol (Shanghai Aladdin Company), 0.91g PTFE emulsion (Shanghai Hesen Electric Co., Ltd.), and then Weigh 13.35g of deionized water into a beaker and carry out ultrasonic dispersion for 30min; the mixture obtained after the ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com