Exhaust gas purifying catalyst

A technology for exhaust gas purification and catalyst, which is applied in the direction of physical/chemical process catalyst, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, etc. , purification performance reduction and other problems, to achieve the effect of sufficient catalyst coating amount, sufficient purification performance, and improved gas diffusivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0091] (Preparation and coating of catalyst slurry)

[0092] In the method for producing S / C in the exhaust gas-purifying catalyst of the present invention, a catalyst slurry comprising: catalytically active noble metal particles having a cumulative 50% diameter of 3 to 10 μm in the volume-based cumulative particle size distribution is used. 0.5-9.0 parts by mass of metal oxide particles within the range, and 0.5 to 9.0 parts by mass of fibrous organic matter with respect to 100 parts by mass of the metal oxide particles.

[0093] The noble metal raw material used to prepare noble metal particles is not particularly limited, for example, salts (such as acetates, carbonates, nitrates, ammonium salts, etc.) of noble metals (such as Pt, Rh, Pd, Ru, etc.) Salt, citrate, dinitrodiammonium salt, etc.) or complexes thereof (for example, tetraammonium complexes) are dissolved in solvents such as water and alcohol. In addition, the amount of the noble metal is not particularly limited...

Embodiment 1

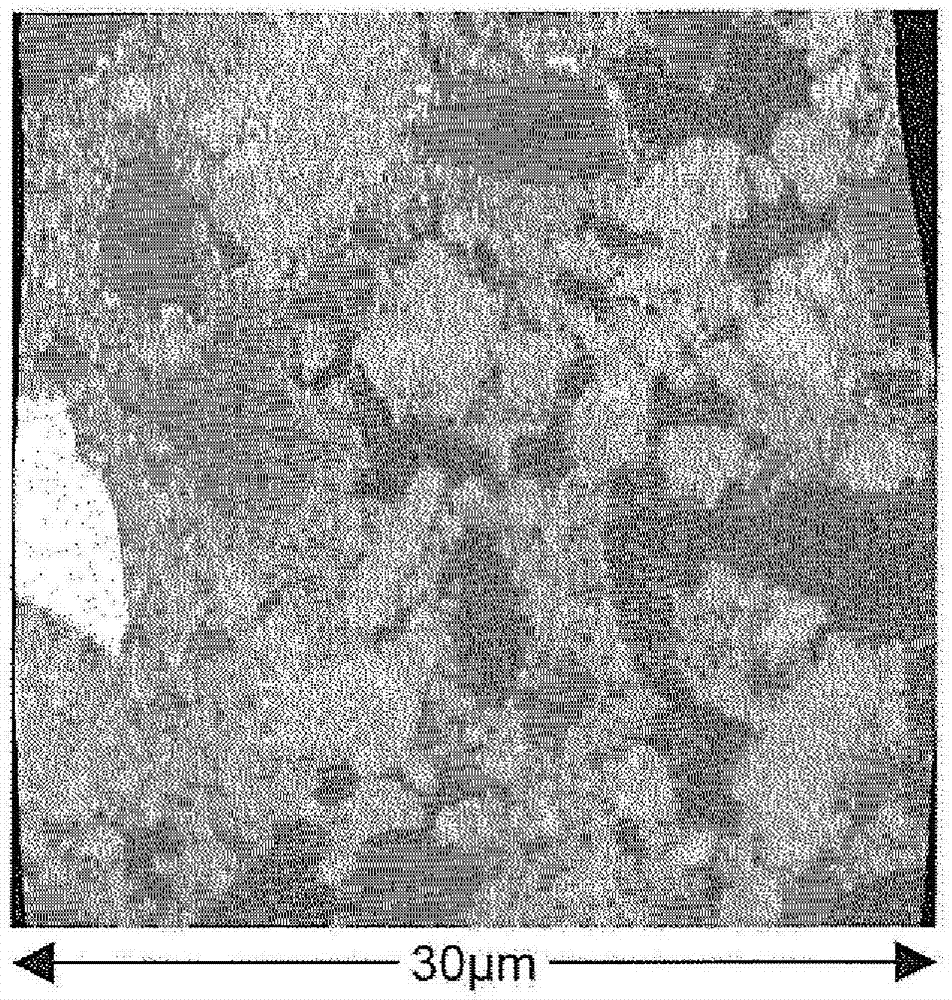

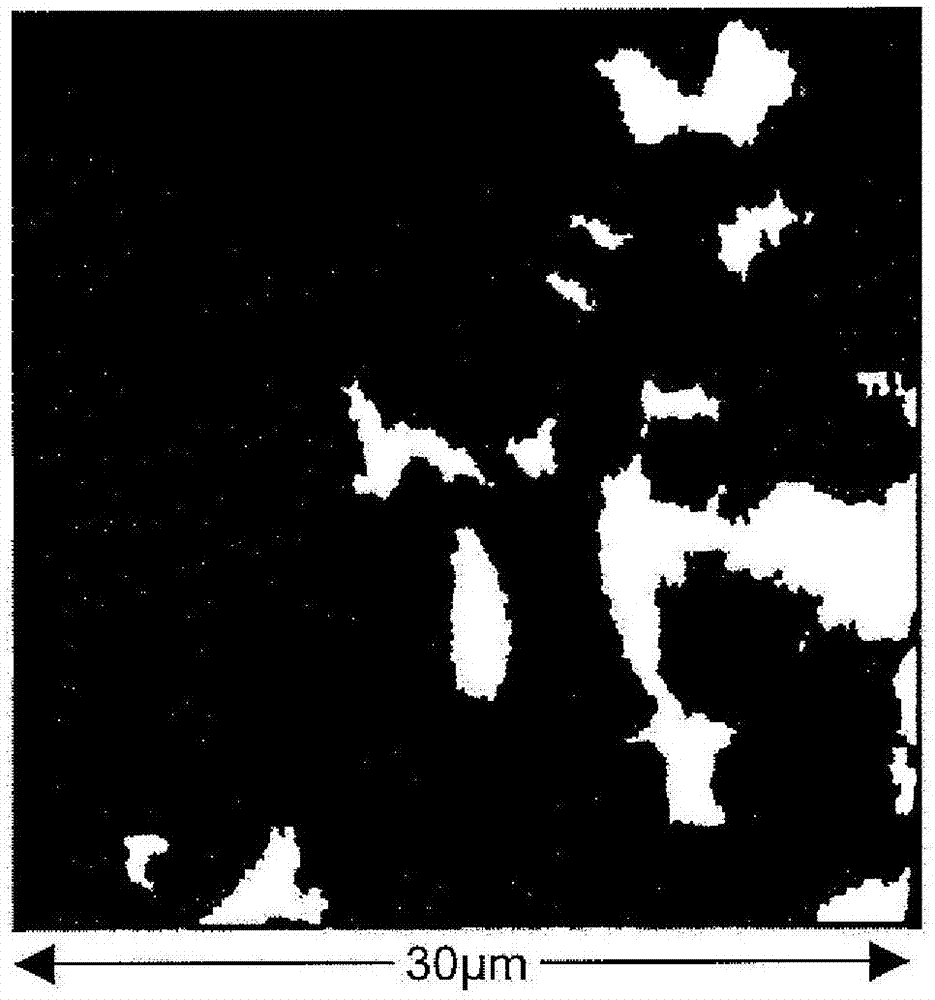

[0123] First, for adding Al to 500 g of ion-exchanged water 2 o 3 Powder (manufactured by Sasol Co., Ltd.: specific surface area 100m 2 / g, average particle size 30μm) 150g and CeO 2 -ZrO 2 Powder of solid solution (manufactured by Daiichi Dien Element Chemical Co., Ltd.: CeO 2 Content 20% by mass, ZrO 2 Content 25% by mass, specific surface area 100m 2 / g, average particle diameter 10nm) 300g and the solution obtained by mixing, using a bead mill (manufactured by Azuwan Co., Ltd., trade name "Almina Ball", beads used: diameter 5000 μm alumina microbeads), in the treatment time: 25 Minutes, under the condition of stirring speed 400rpm, carry out stirring treatment, prepare the 2 -ZrO 2 solid solution and Al 2 o 3 A dispersion liquid of metal oxide particles composed of a powder mixture (composite metal oxide). In addition, using a laser diffraction particle size distribution analyzer (manufactured by Horiba, trade name "LA-920") and measuring the particle diameter of...

Embodiment 2~42

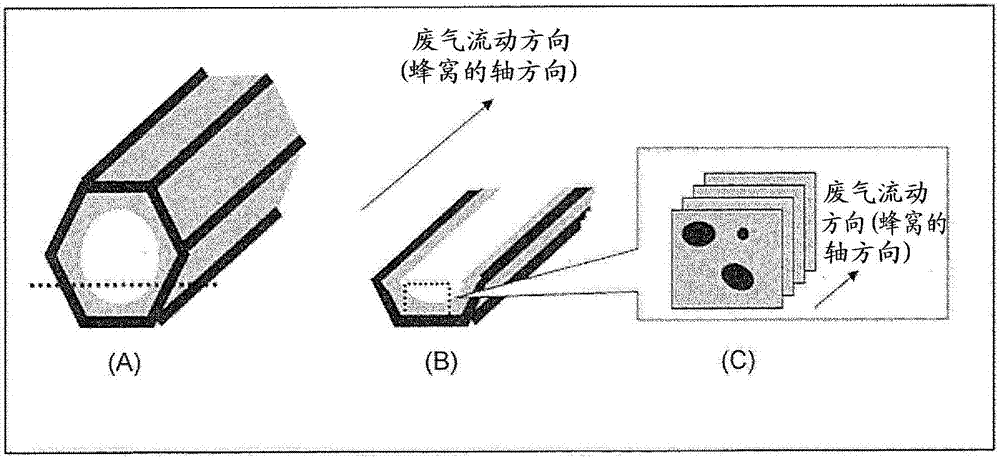

[0133]The processing time using the bead mill is set to the time shown in Tables 1 to 2, and the value of the cumulative 50% diameter in the cumulative particle size distribution of the particle diameter of the metal oxide particles on a volume basis is expressed in Tables 1 to 2. The mode of the value of 2 utilizes bead mill to carry out agitation treatment, uses the kind of raw material, average fiber diameter, average aspect ratio and the fibrous organic matter of mixing amount shown in Table 1~Table 2 as fibrous organic matter, in addition, A catalyst slurry was obtained in the same manner as in Example 1. Next, the obtained catalyst slurry was coated (coated) and fired on the cordierite monolithic honeycomb substrate in the same manner as in Example 1 to obtain a catalyst for exhaust gas purification (catalyst sample).

[0134] It should be noted that the fibrous organic substances used in Examples 31 to 39 were obtained by adding tetraisopropoxytitanium (Ti(OPri) to isop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com