Membrane electrode assembly and fuel cell

A membrane-electrode assembly and cathode technology, applied in fuel cells, solid electrolyte fuel cells, fuel cell components, etc., can solve problems such as damage to gas diffusivity, and achieve the effect of improving gas diffusivity and increasing battery voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

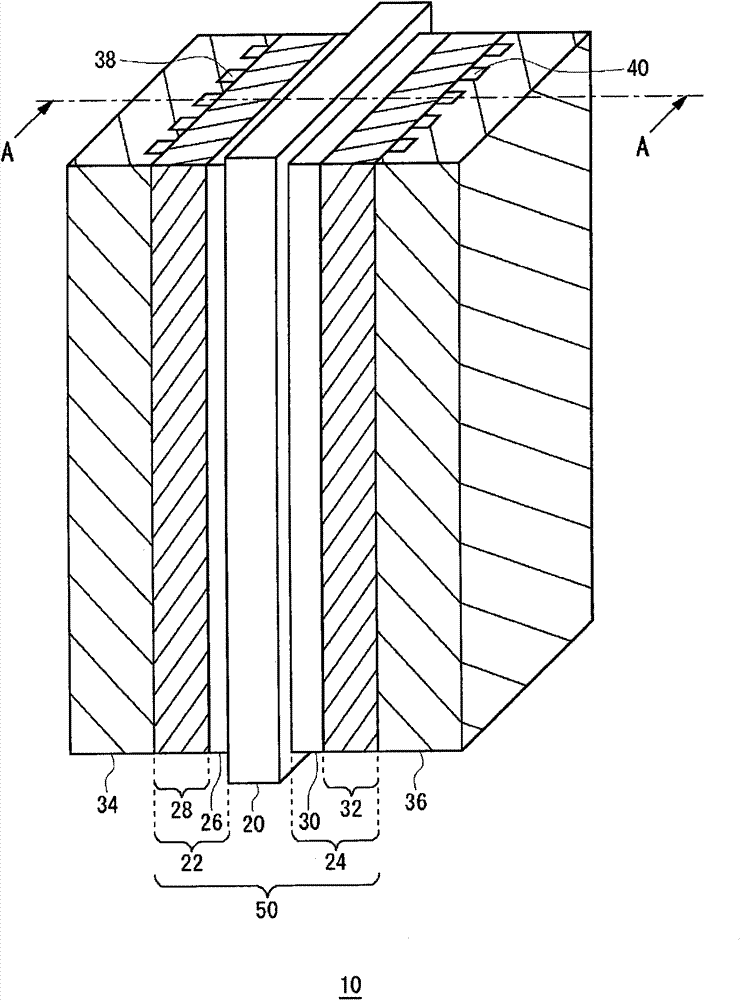

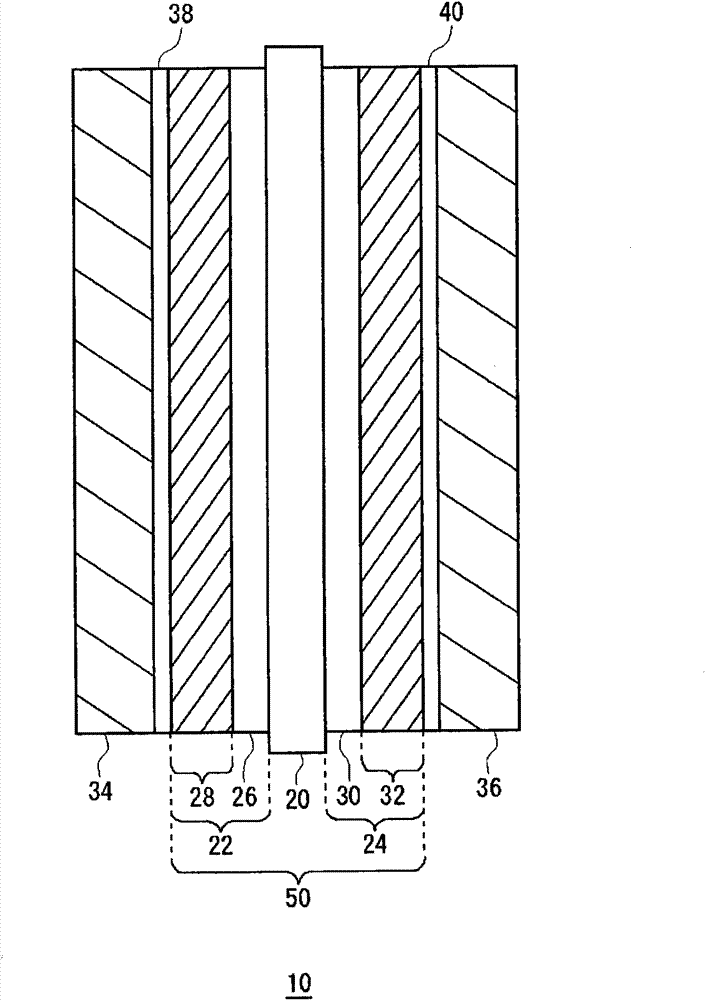

[0030] figure 1 It is a perspective view schematically showing the structure of the fuel cell 10 of the embodiment. figure 2 Yes figure 1 Sectional view on line A-A of . The fuel cell 10 includes a flat membrane electrode assembly 50 , and a separator 34 and a separator 36 are provided on both sides of the membrane electrode assembly 50 . In this example, only one membrane electrode assembly 50 is shown, but a plurality of membrane electrode assemblies 50 may be stacked via spacers 34 and 36 to form a fuel cell stack. Membrane electrode assembly 50 has solid polymer electrolyte membrane 20 , anode 22 and cathode 24 .

[0031] The anode 22 has a laminated body composed of a catalyst layer 26 and a gas diffusion layer 28 . On the other hand, cathode 24 has a laminated body composed of catalyst layer 30 and gas diffusion layer 32 . The catalyst layer 26 of the anode 22 and the catalyst layer 30 of the cathode 24 are provided facing each other with the solid polymer electrol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com