Porous medium auxiliary molten salt electrolysis metal refining device

A technology of molten salt electrolysis and metal refining, which is applied in the direction of electrolysis components, electrolysis process, cells, etc. It can solve the problems that electrolysis refining cannot be carried out smoothly, and the electrolyte cannot be fixed between the crude metal and the refined metal with close density, so as to improve the Stability and practicality, improvement of refining effect, effect of expanding application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

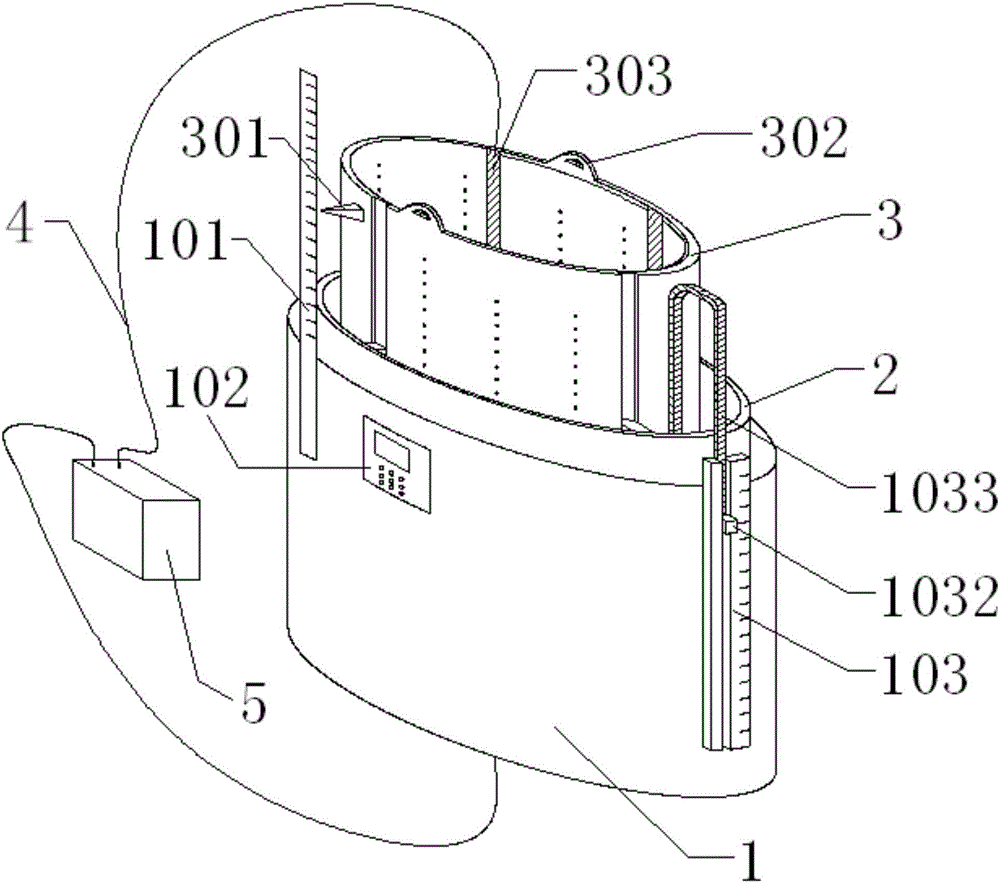

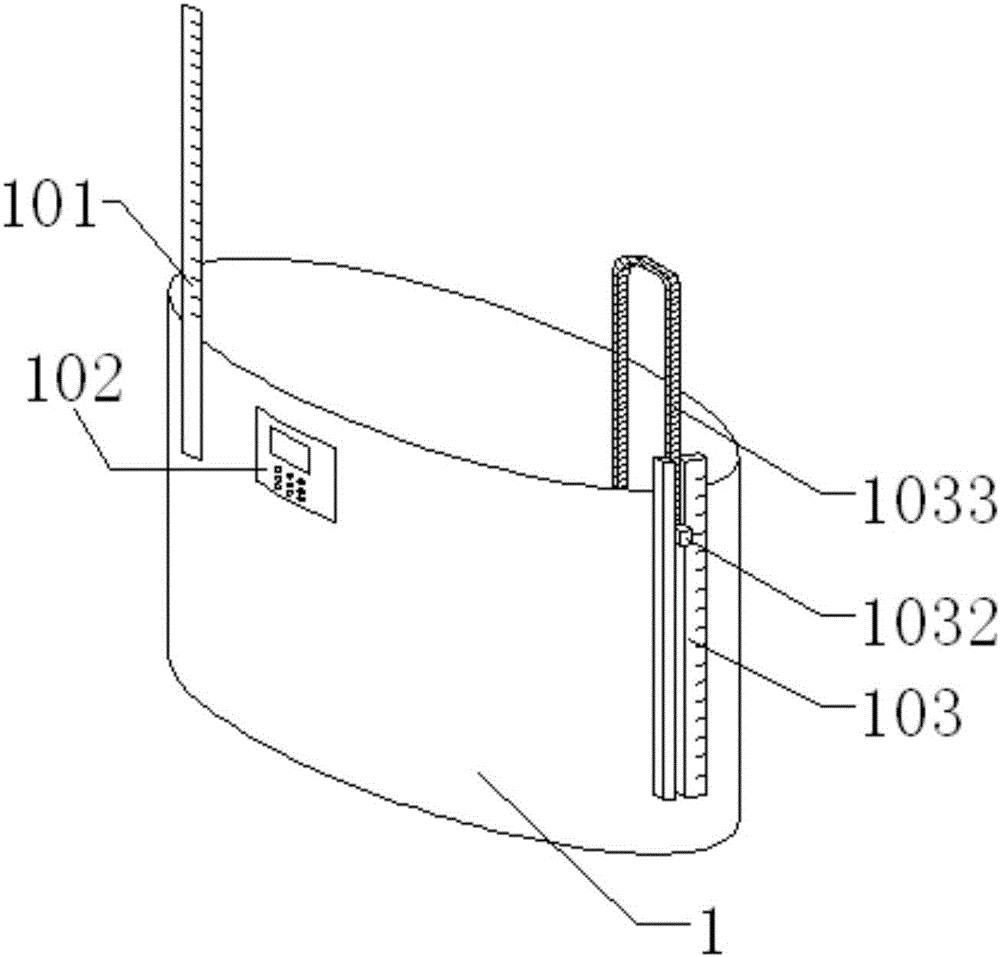

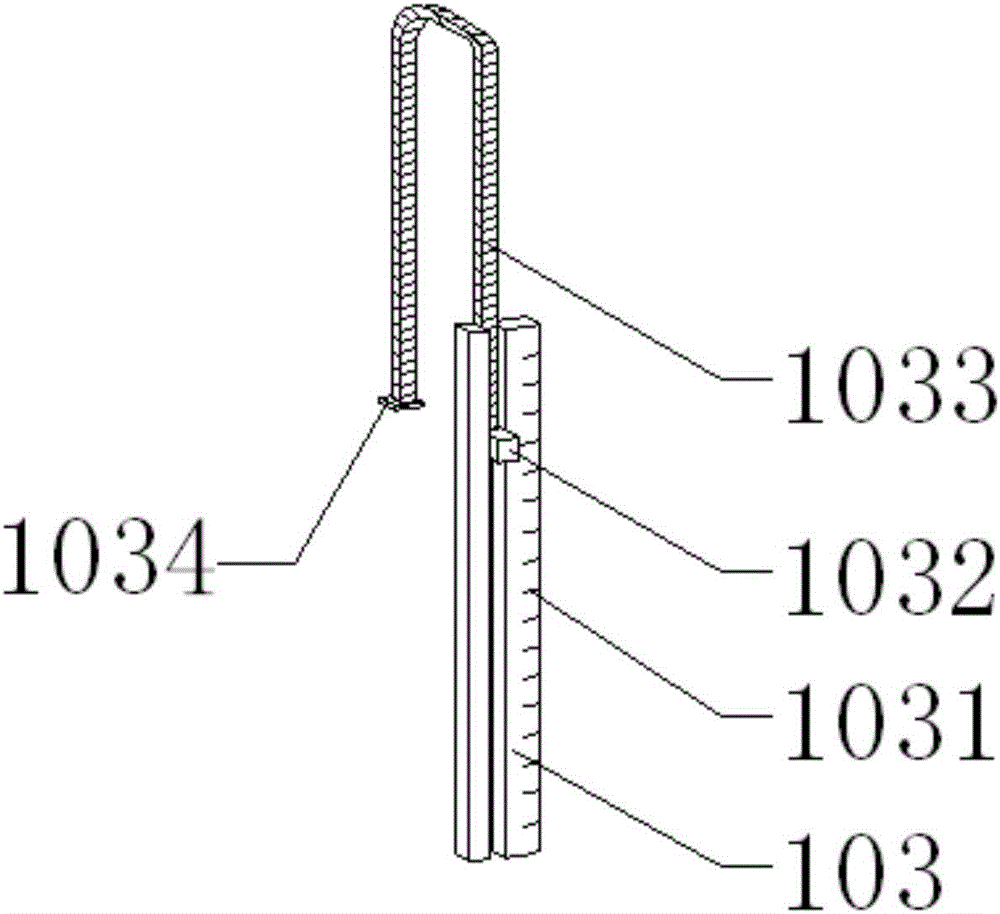

[0052] combine Figure 1-8 , the porous medium-assisted molten salt electrolytic refining metal device of the present embodiment includes a casing 1, an outer barrel 2, an inner barrel 3 and a liquid level measuring device, and the liquid level measuring device includes a chute 103, a U-shaped floating rod 1033, a slider 1032 and floating plate 1034, wherein: the bottom surface and the side surface of the inner barrel 3 are provided with through holes 304, the radius of the two ends of the through hole 304 is 0.6mm, and the inner wall of the through hole 304 is provided with several cylindrical protrusions 3041, The length of the protrusion 3041 is 0.6 mm, and a grid 3042 is arranged on the end faces of the two ends of the through hole 304, and the radius of the end faces of the two ends of the through hole 304 is 0.5 mm smaller than the radius of the cross section of the middle part of the through hole 304; The thickness is 0.9mm, three electrodes 303 are evenly fixed on the ...

Embodiment 2

[0072] The porous medium assisted molten salt electrolytic refining metal device of this embodiment has the same basic structure as that of Embodiment 1, except that: the radius of the end faces at both ends of the through hole 304 is 0.05 mm; the length of the protrusion 3041 is 0.02 mm; The thickness of the barrel body of the inner barrel 3 is 0.1 mm; the radius of the two end faces of the through hole 304 is 0.01 mm smaller than the radius of the cross section in the middle of the through hole 304 .

Embodiment 3

[0074] The basic structure of the porous medium assisted molten salt electrolytic refining metal device of this embodiment is the same as that of Embodiment 1, except that: the radius of the two ends of the through hole 304 is 1.5 mm; the length of the protrusion 3041 is 1.2 mm; The thickness of the barrel body of the inner barrel 3 is 1.8 mm; the radius of the two end faces of the through hole 304 is 1 mm smaller than the radius of the cross section of the middle part of the through hole 304 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com