Purifying method of aluminum alloy melt

A technology of aluminum alloy melt and aluminum alloy, which is applied in the field of aluminum alloy processing, can solve the problems of higher than 0.10ml/100g, achieve the effect of rapid homogenization temperature, good effect, and accelerate the floating of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

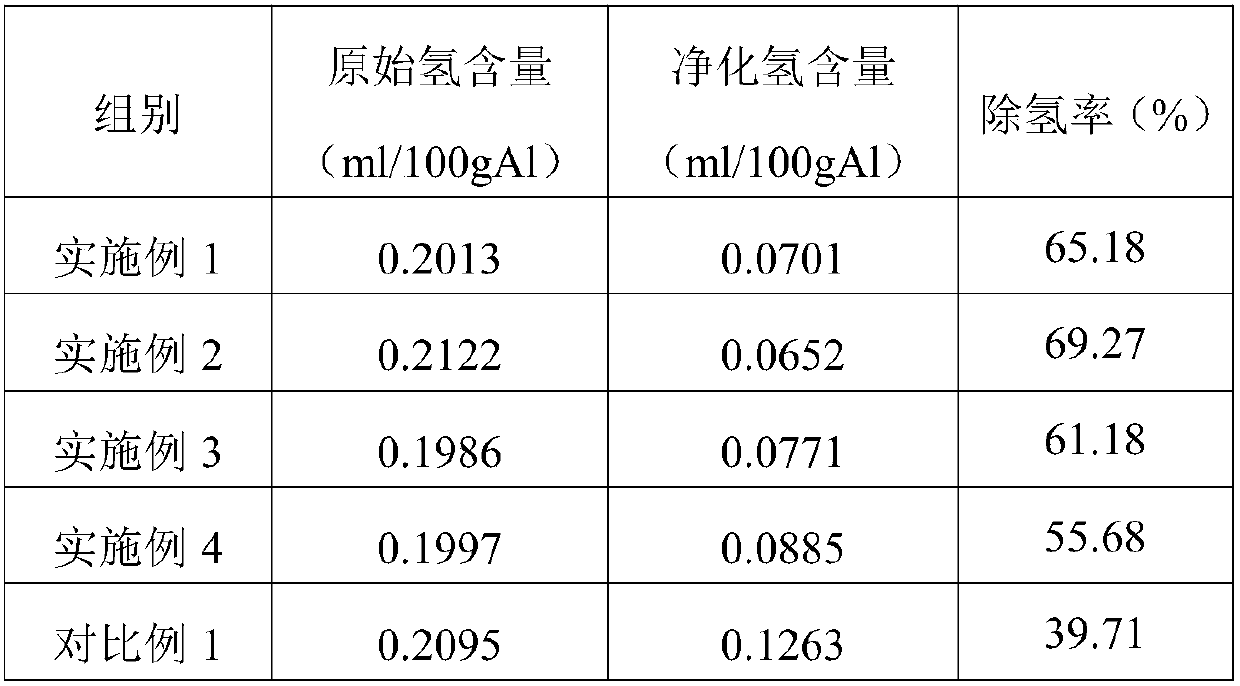

Examples

Embodiment 1

[0031] A method for purifying an aluminum alloy melt, comprising the following steps:

[0032] S1: Heat the aluminum alloy raw material in the crucible furnace to 730°C to make a melt;

[0033] S2: Turn on the switch of the movable rotating arm, make the rotating arm rotate and stir at a uniform speed in the aluminum alloy melt, and at the same time, pass N 2 , Cl 2 The mixed gas and refining agent are uniformly sprayed into the aluminum alloy melt through the jet ball and jet pipe of the rotating arm respectively, and at the same time, the scum on the surface of the aluminum alloy melt is removed; the N 2 , Cl 2 The ratio of mixed gas is N 2 : Cl 2 =1:0.05; the rotating arm rotates around the central axis, the rotation angle is 15 degrees, the rotating speed of the jet pipe is 80r / min, and the rotating speed of the jetting ball is 400r / min;

[0034] S3: After smelting the aluminum alloy melt for 18 minutes, let it stand for 25 minutes, then heat the melt to 730°C, and in...

Embodiment 2

[0038] A method for purifying an aluminum alloy melt, comprising the following steps:

[0039] S1: Heat the aluminum alloy raw material in the crucible furnace to 720°C to make a melt;

[0040] S2: Turn on the switch of the movable rotating arm, make the rotating arm rotate and stir at a uniform speed in the aluminum alloy melt, and at the same time, pass N 2 , Cl 2 The mixed gas and refining agent are uniformly sprayed into the aluminum alloy melt through the spray ball and the spray pipe of the rotating arm respectively, and at the same time, the scum on the surface of the aluminum alloy melt is removed; the N2 , Cl 2 The ratio of mixed gas is N 2 : Cl 2 =2:0.05; the rotating arm rotates around the central axis, the rotation angle is 30 degrees, the speed of the jet pipe is 70r / min, and the speed of the jet ball is 350r / min;

[0041] S3: After smelting the aluminum alloy melt for 15 minutes, let it stand for 20 minutes, then heat the melt to 720°C, and inject N into the ...

Embodiment 3

[0045] A method for purifying an aluminum alloy melt, comprising the following steps:

[0046] S1: Heat the aluminum alloy raw material in the crucible furnace to 740°C to make a melt;

[0047] S2: Turn on the switch of the movable rotating arm, make the rotating arm rotate and stir at a uniform speed in the aluminum alloy melt, and at the same time, pass N 2 , Cl 2 The mixed gas and refining agent are uniformly sprayed into the aluminum alloy melt through the jet ball and jet pipe of the rotating arm respectively, and at the same time, the scum on the surface of the aluminum alloy melt is removed; the N 2 , Cl 2 The ratio of mixed gas is N 2 : Cl 2 =1.5:0.05; the rotating arm rotates around the central axis, the rotation angle is 25 degrees, the speed of the jet pipe is 60r / min, and the speed of the jet ball is 300r / min;

[0048] S3: After smelting the aluminum alloy melt for 20 minutes, let it stand for 15 minutes, then heat the melt to 740°C, and inject N into the melt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com