Double-reaction-electrode water half-electrolysis device

A technology for reacting electrodes and electrolyzing water, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of easy gas mixing, high cost of diaphragm, low electrolysis rate, etc., to avoid gas mixing, improve electrolysis rate, and reduce electrolysis voltage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

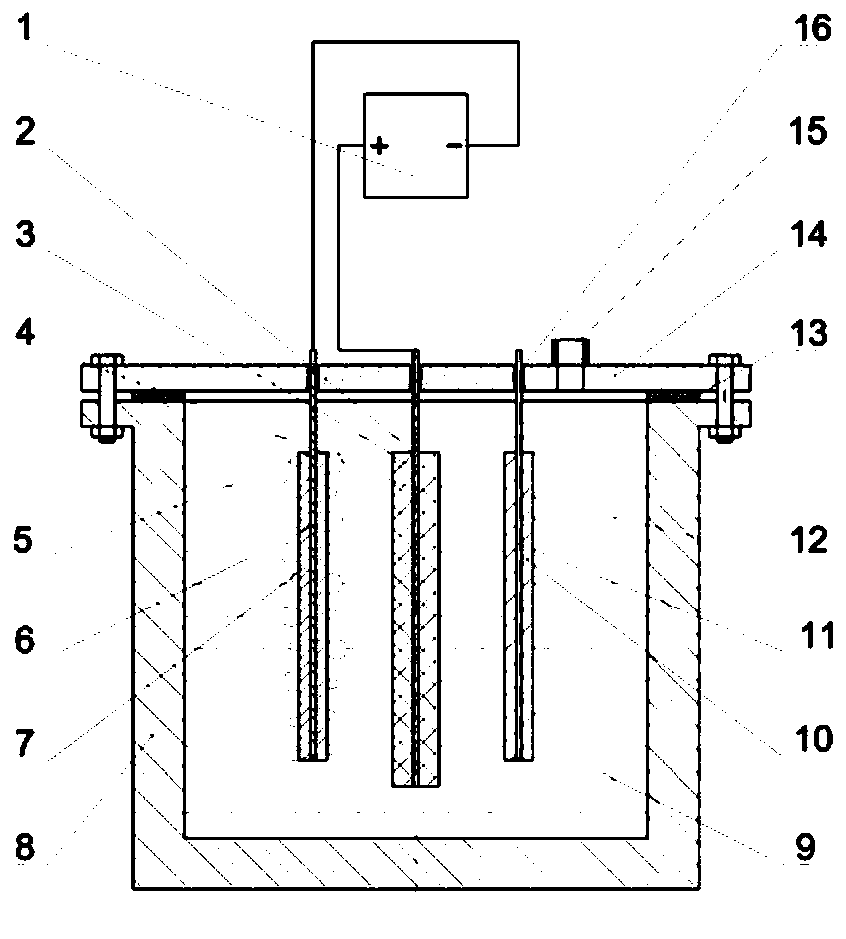

[0040] A double reaction electrode semi-electrolytic water splitting device. The device as figure 1 As shown, the device includes a power source 1, a capacitor electrode 2, a reaction electrode I5, an electrolytic cell 8, an electrolyte solution 9, a reaction electrode II10 and an electrolytic cell cover 14.

[0041] Such as figure 1As shown: there is a sealing ring I13 between the electrolytic cell 8 and the electrolytic cell cover 14, the electrolytic cell 8 and the electrolytic cell cover 14 are fixedly connected by bolts, the electrolytic cell cover 14 is provided with a gas collecting pipe 15, and the gas collecting pipe 15 communicates with the electrolytic cell 8; Electrolyte 9 is installed in electrolytic cell 8 , capacitive electrode 2 , reaction electrode I5 and reaction electrode II10 are arranged in electrolytic solution 9 , and reaction electrode I5 and reaction electrode II10 are located on both sides of capacitive electrode 2 .

[0042] Such as figure 1 As sh...

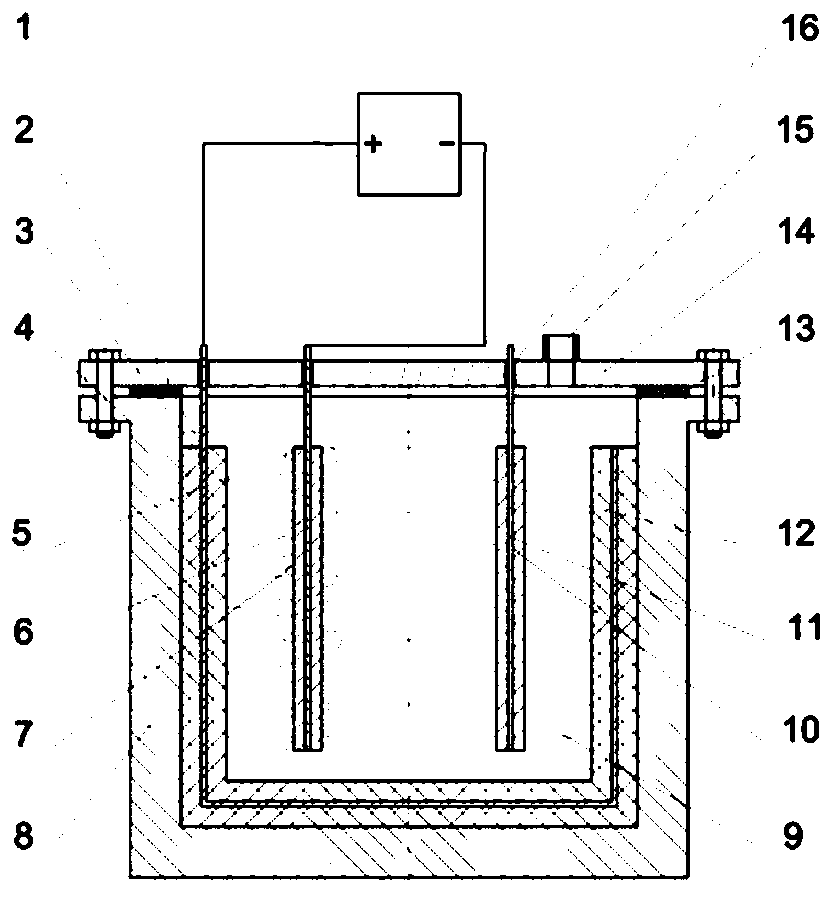

Embodiment 2

[0046] A double reaction electrode semi-electrolytic water splitting device. Except following technical parameter, all the other are with embodiment 1:

[0047] The reaction electrode I5 and the reaction electrode II10 are located on the other side of the capacitance electrode 2;

[0048] One side of the current collector I3 is closely attached to the capacitive electrode body 4;

[0049] The shape of the reaction electrode I5 is one of plate shape and grid shape;

[0050] One side of the current collector II6 is closely attached to the reaction electrode body I7;

[0051] The shape of the reaction electrode II10 is one of plate shape and grid shape;

[0052] One side of the current collector III11 is closely attached to the reaction electrode body II12.

Embodiment 3

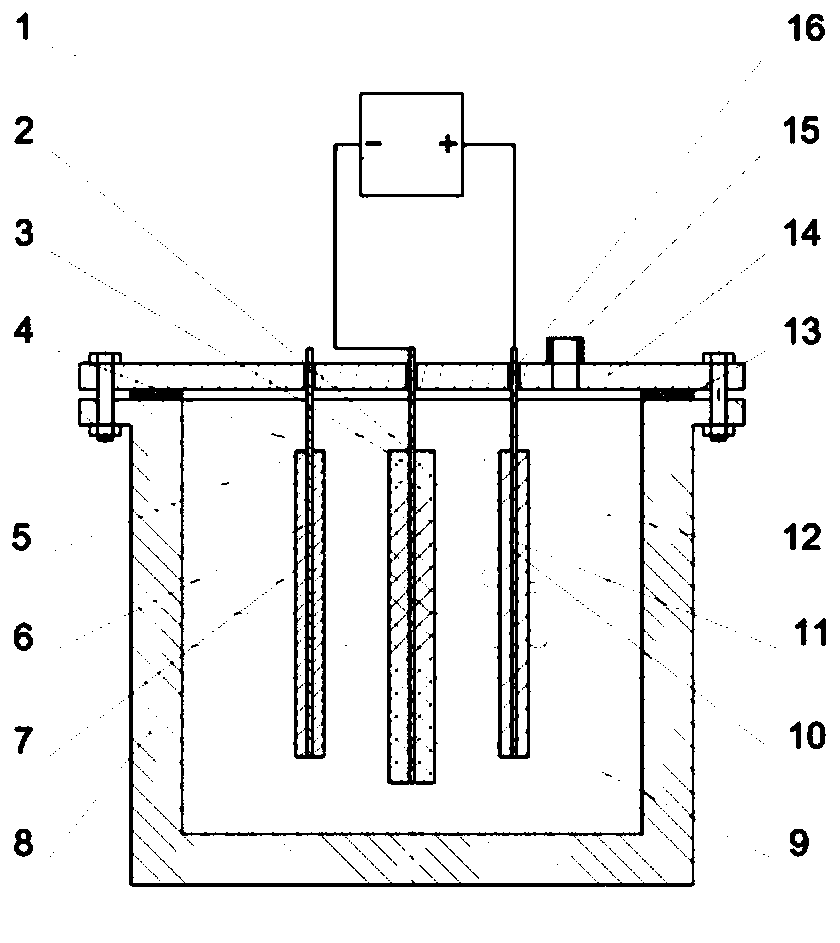

[0054] A double reaction electrode semi-electrolytic water splitting device. The device as figure 2 As shown, the device includes a power source 1, a capacitor electrode 2, a reaction electrode I5, an electrolytic cell 8, an electrolyte solution 9, a reaction electrode II10 and an electrolytic cell cover 14.

[0055] Such as figure 2 As shown: there is a sealing ring I13 between the electrolytic cell 8 and the electrolytic cell cover 14, the electrolytic cell 8 and the electrolytic cell cover 14 are fixedly connected by bolts, the electrolytic cell cover 14 is provided with a gas collecting pipe 15, and the gas collecting pipe 15 communicates with the electrolytic cell 8; Electrolyte 9 is installed in electrolytic cell 8 , capacitive electrode 2 , reaction electrode I5 and reaction electrode II10 are arranged in electrolytic solution 9 , and reaction electrode I5 and reaction electrode II10 are located on both sides of capacitive electrode 2 .

[0056] Such as figure 2 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com