Patents

Literature

50results about How to "Long reaction life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

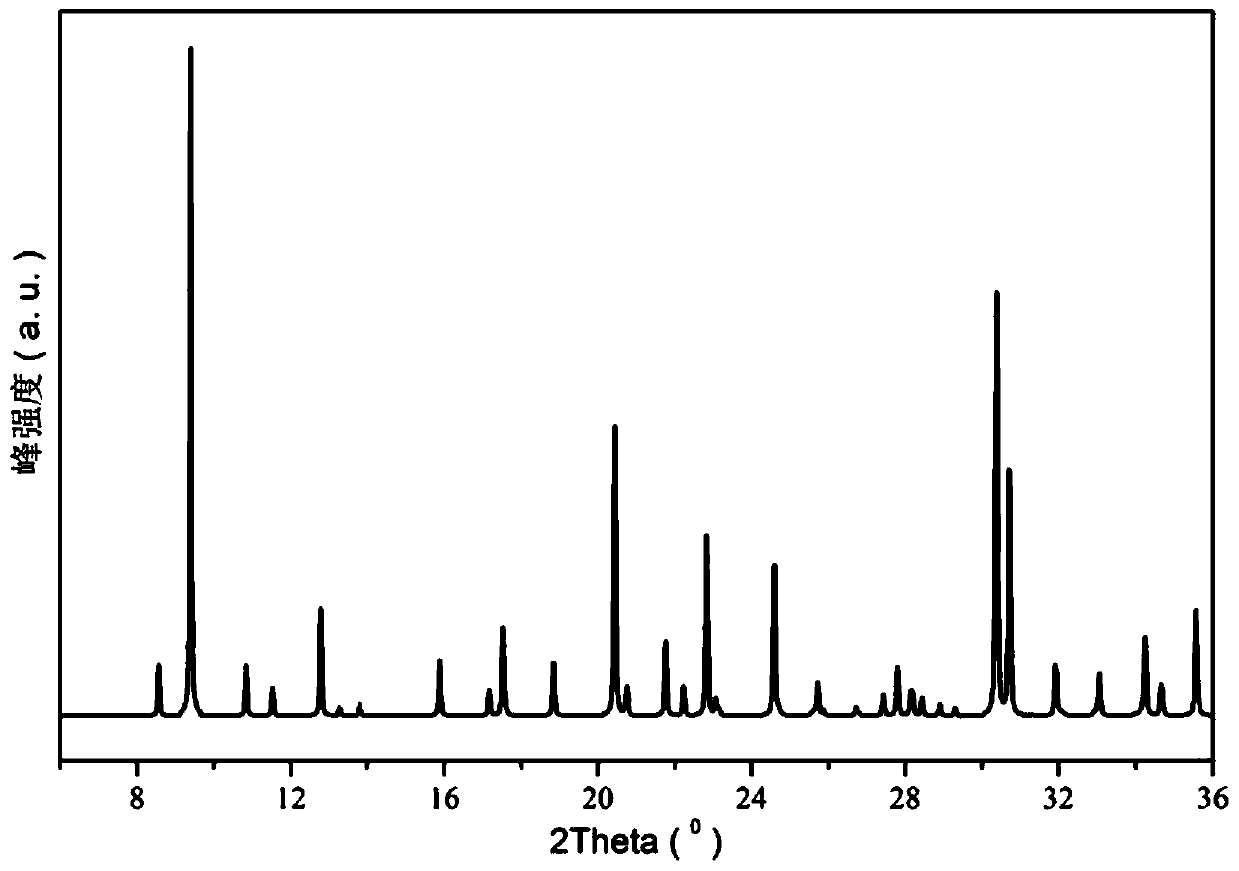

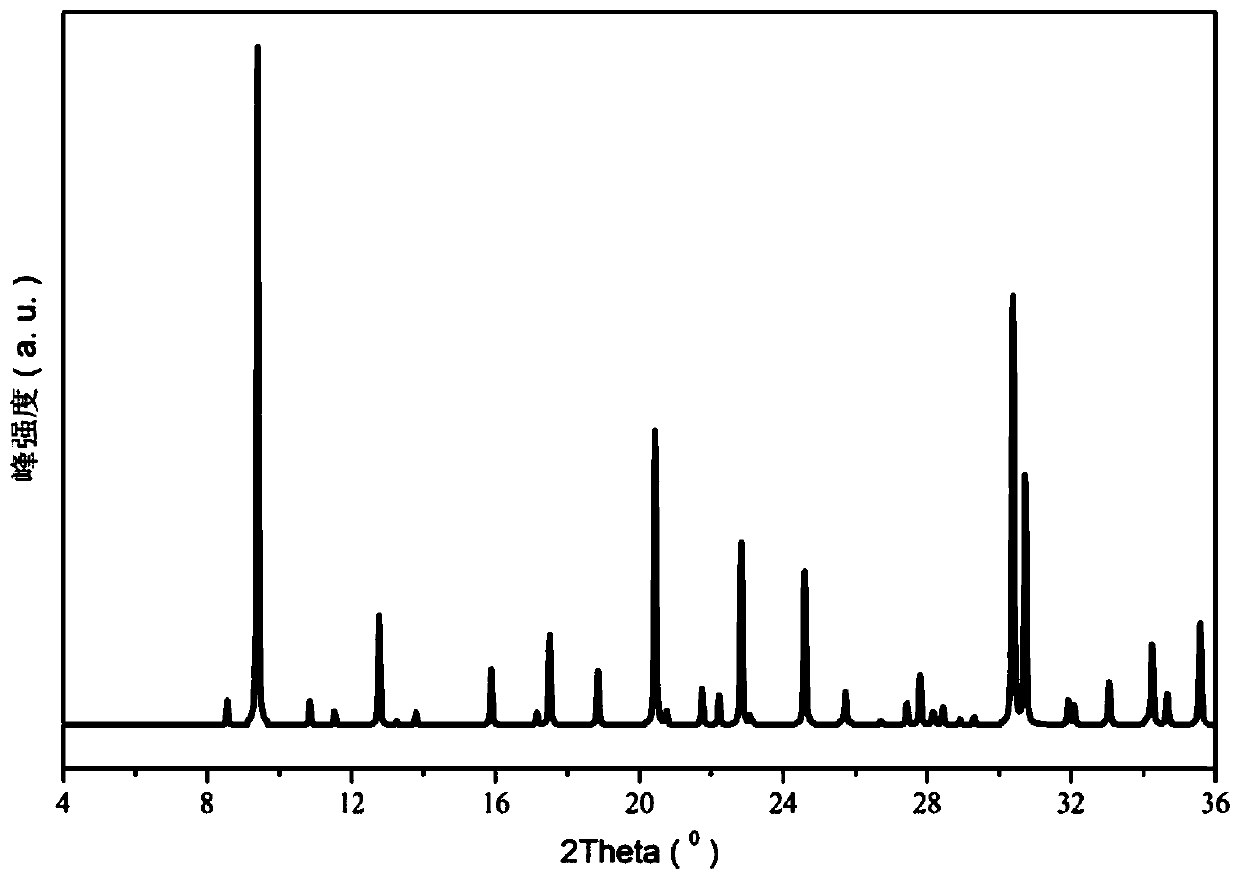

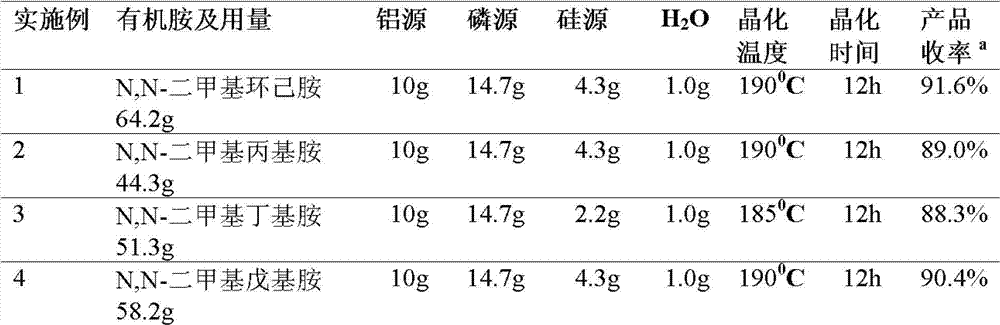

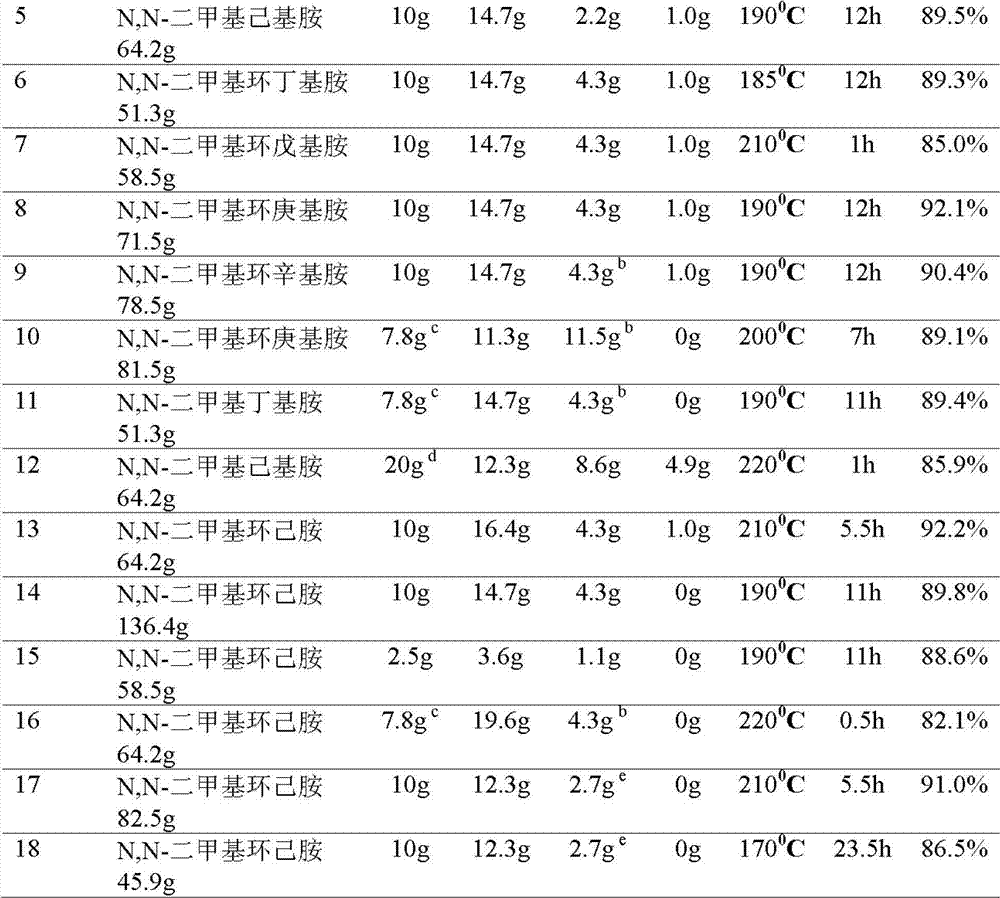

Solvent thermal synthesis method of SAPO (silicoaluminophosphate) molecular sieve and catalyst prepared by SAPO molecular sieve

InactiveCN102530987AHigh synthetic yieldEasy to separateMolecular sieve catalystsMolecular sieve catalystMolecular sieveSynthesis methods

The invention relates to a solvent thermal synthesis method of an SAPO (silicoaluminophosphate) molecular sieve and a catalyst prepared by the SAPO molecular sieve. The solvent thermal synthesis method provided by the invention is characterized in that organic amine is directly used as a solvent and a template agent of a synthesis system, and the SAPO molecular sieve is prepared through solvent thermal synthesis.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

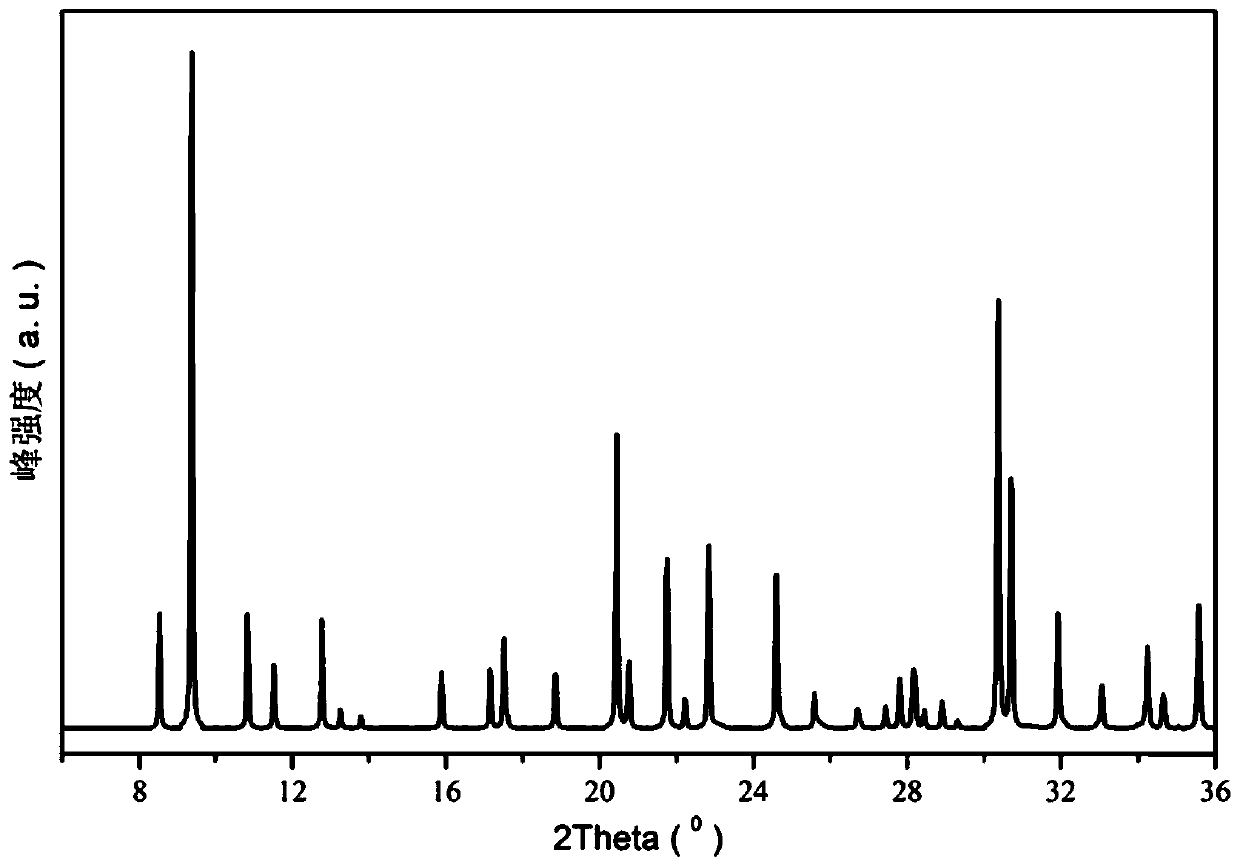

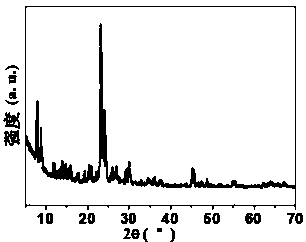

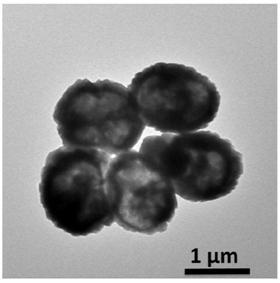

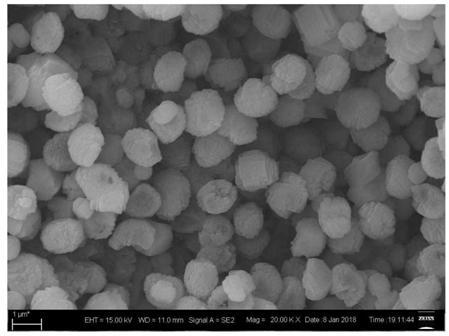

Synthesis method of low-silicon nano SAPO-34 molecular sieve

ActiveCN103130241AShorten the timeLower crystallization temperatureMaterial nanotechnologyMolecular-sieve and base-exchange phosphatesSynthesis methodsHigh pressure

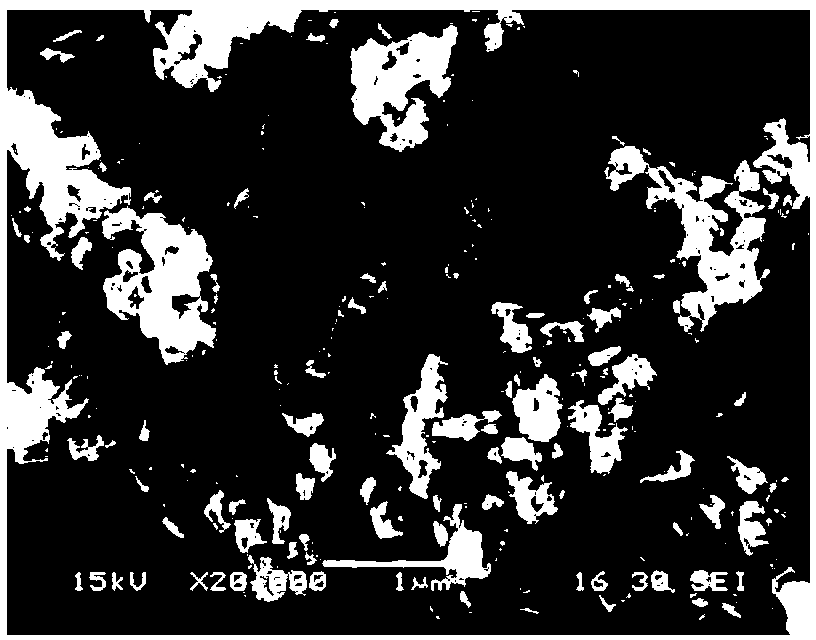

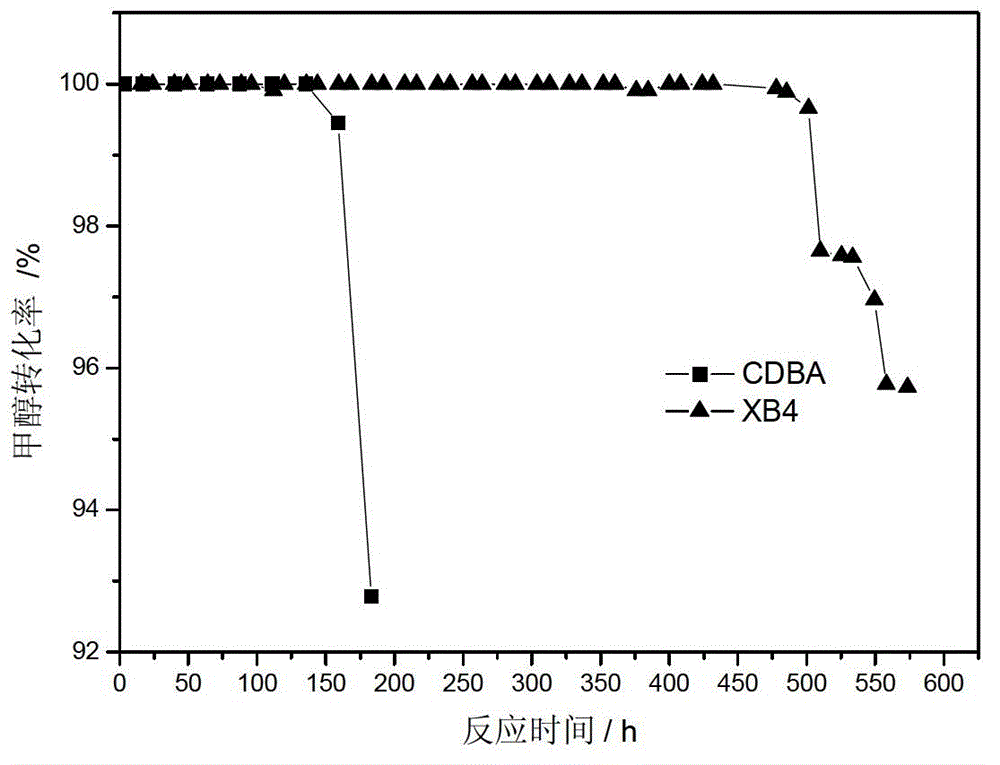

The invention relates to a synthesis method of a low-silicon nano SAPO-34 molecular sieve, which comprises the following steps: sequentially mixing a silicon source, an aluminum source, a template agent R, deionized water and a phosphorus source to obtain a gel mixture; placing the gel mixture in a stainless steel high-pressure reaction kettle of which the liner is made of polytetrafluoroethylene, sealing, putting into a drying oven, and performing primary traditional hydrothermal crystallization; adding a dispersant agent S into the primary traditional hydrothermal crystallization solution, stirring for 0.5-4 hours, transferring into the reaction kettle of which the liner is made of polytetrafluoroethylene, sealing, putting into a microwave reactor, and performing secondary microwave hydrothermal crystallization; and washing, drying, and roasting to obtain the nano SAPO-34 molecular sieve. Compared with the prior art, the invention greatly lowers the crystallization temperature and shortens the time of the whole synthesis process. The nano molecular sieve can be widely used for conversion, separation and absorption of hydrocarbons, and especially has the advantages of high conversion rate, high low-carbon alkene selectivity, low carbon deposition rate, long reaction life and the like in the process of preparing alkene from methanol.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

Nano grade transition metal oxidation catalyst and its preparing method and use

InactiveCN1714936AHigh activityEnhanced anti-toxicityCatalyst carriersCatalyst activation/preparationMischmetalGranularity

The present invention is efficient oxidizing catalyst for organic waste water treating and its preparation process and application. The carrier prepared with composite powder of Ti, Si, Al and RE oxide and in the average granularity smaller than 100 nm is loaded with at least two kinds of transition metal to prepare the catalyst. The catalyst contains TiO2-SiO2-Al2O3 65-85 wt%, RE oxide 5-15 wt%, and transition oxide 5-30 wt%. The preparation process of the catalyst includes preparing carrier powder with the carrier components and through precipitation, homogenization, ageing, filtering, washing, pulping, dispersing, fluidizing at supercritical condition to eliminate water and activating; forming the carrier, soaking, fluidizing and drying, and activating to obtain the catalyst. The catalyst is used in acid organic waste water treatment and has COD degrading rate higher than 95 %, ammonia nitrogen oxidizing conversion rate higher than 99 % and chroma eliminating rate higher than 95 %.

Owner:CNPC JILIN CHEM GROUP CORP

Metal modification ZSM-5 molecular sieve based catalyst and preparation method and application

ActiveCN106140266ASimple and efficient operationReduce energy consumptionMolecular sieve catalystsHydrocarbon by hydrocarbon crackingAlkaneMass content

The invention provides a metal modification ZSM-5 molecular sieve based catalyst. The catalyst is characterized in that the catalyst is prepared by modifying and preparing a ZSM-5 molecular sieve through a hydrothermal method by means of modification elements, wherein the modification elements are La and / or Ce; the total mass of ZSM-5 in ZSM-5 molecular sieve based catalyst is 100%, and the mass content of modified elements is 0.01-15%; preferentially, the metal modification ZSM-5 molecular sieve is used for light dydrocarbon catalytic cracking to prepare low carbon olefin, and light hydrocarbon is alkane or olefin simple substance or a mixture with the carbon number being 4-8. The metal modification ZSM-5 molecular sieve based catalyst is easy and convenient to operate and free of high-temperature operation, lowers energy consumption and improves modified element utilization rate, the modification effect is better than a traditional mode, the addition amount of modification elements is reduced, the selectivity of catalyst for low-carbon olefin is improved, the reaction service life is enhanced greatly in the long-period reaction, and the better application value is achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Hydrocatalyst for preparing fuel by hydrodealkylation of coal-tar pitch and preparation thereof

InactiveCN101302439AImprove qualityVersatilityRefining to eliminate hetero atomsHydrodealkylationBiological activation

The invention relates to hydrosenation catalyst for producing oil by converting heavy coal tar pitch into light coal tar pitch, which is characterized in that: 100 portions of macroporous alumina is immersed into 100 portions of solution which consists of 3.5 to 20.5 weight percent of nickel nitrate and 3.0 to 25.0 weight percent of molybdenum nitrate for 2 hours at a temperature of between 50 and 60 DEG C; the mixture stands and supernatant is poured out, and then the mixture is dried for 4 hours at a temperature of 120 DEG C, activated for 5 hours at a temperature of 480 DEG C, and then immersed into cupric nitrate solution, cobalt nitrate solution, silver nitrate solution, ferric nitrate solution or bismuth nitrate solution with a concentration between 1.1 and 12.0 weight percent; and the catalyst is prepared through immersion, drying and activation which are the same as the above. The content of the nickel oxide and the molybdenum oxide in the catalyst is respectively 1.2 to 11.2 weight percent and 1.1 to 15.4 weight percent of the weight of carrier, and the content of cupric oxide, cobalt oxide, silver oxide, ferric oxide or bismuth oxide is 1.1 to 7.8 weight percent of the weight of the carrier. The hydrogenation catalyst has good adaptability to various coal tar pitch raw materials, high hydrogenation degree, strong controllability, low operating cost, and high yield of the oil produced by converting the heavy coal tar pitch into the light coal tar pitch; and the overall oil yield of fuel can reach over 75 percent.

Owner:TONGJI UNIV

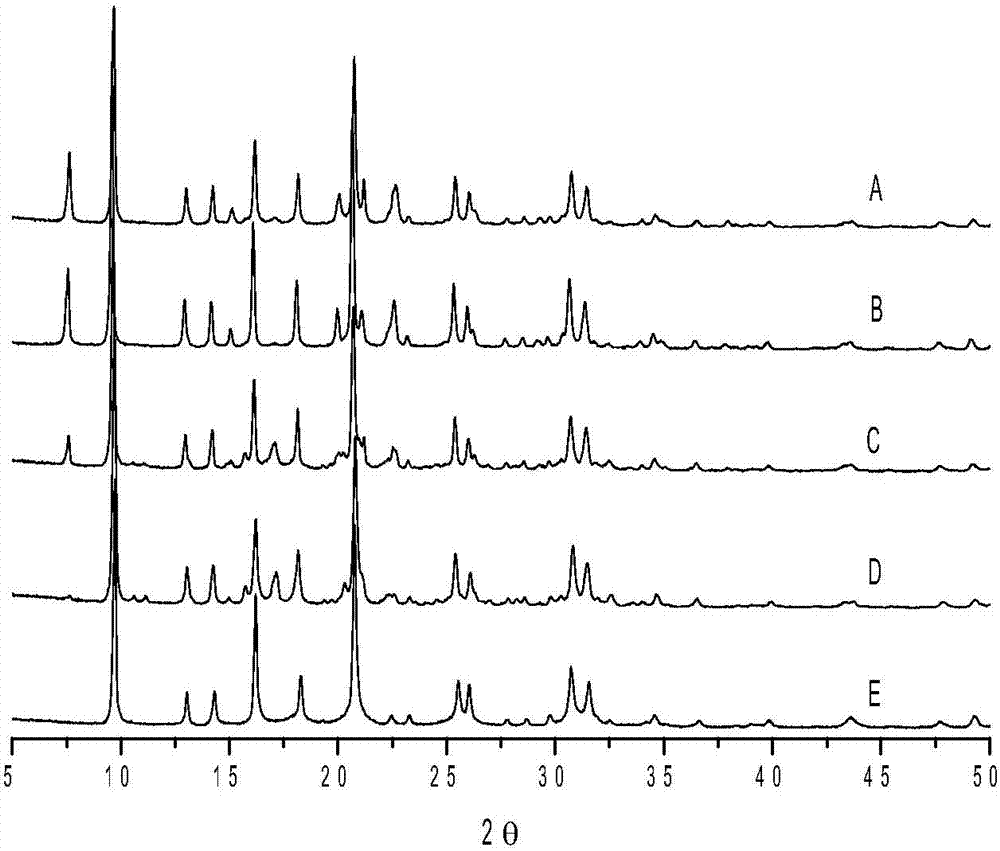

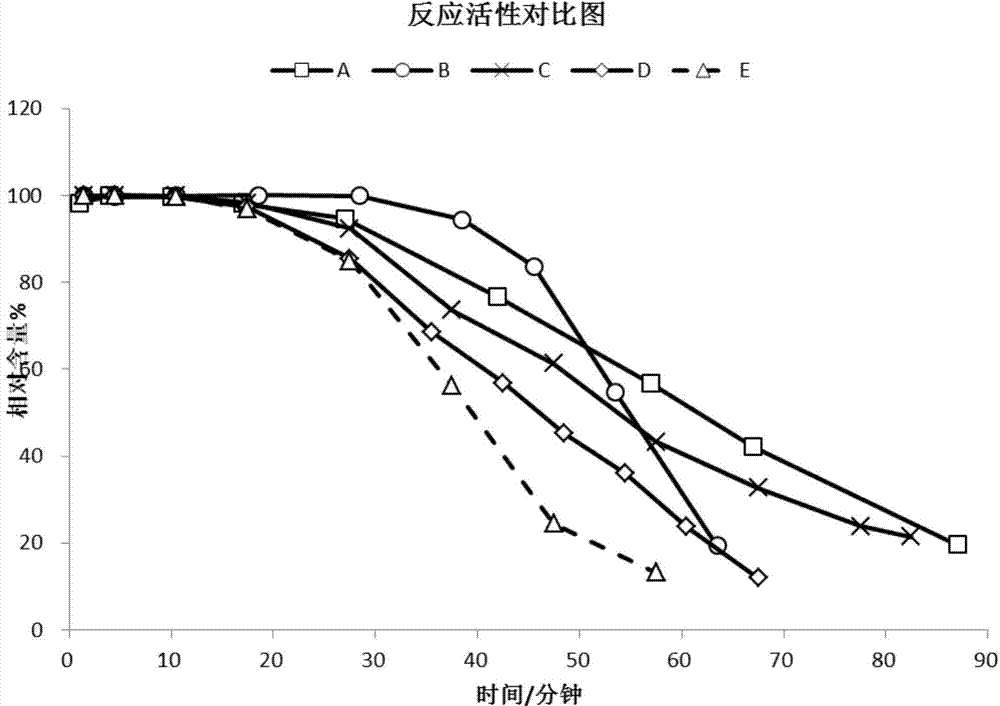

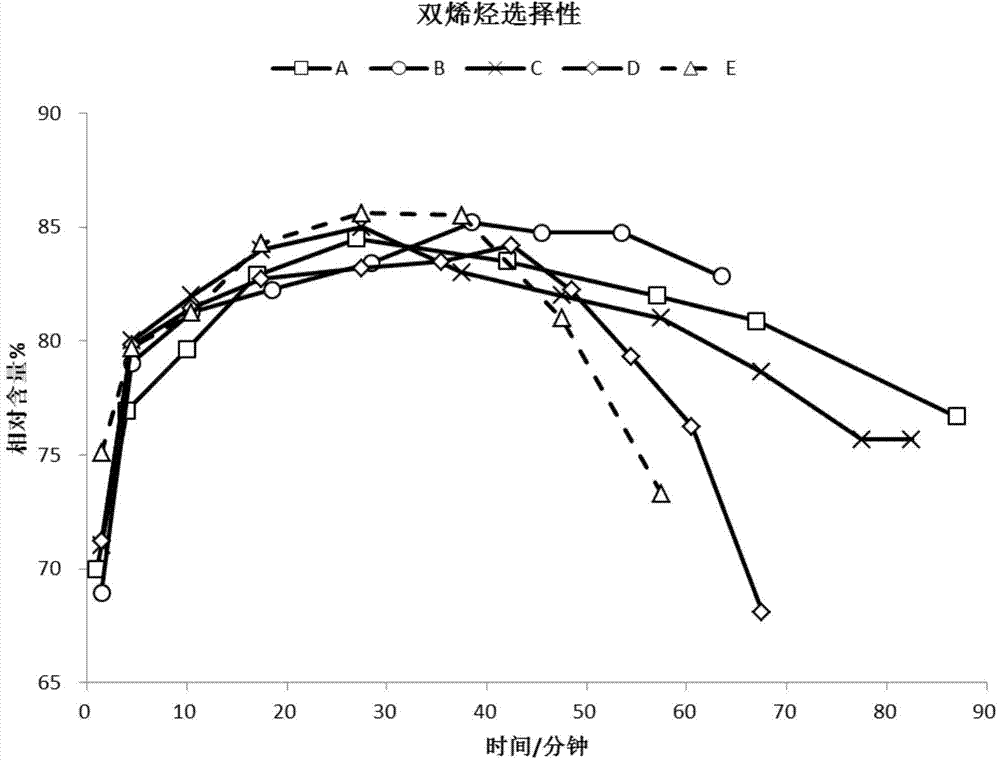

Low-silicon composite molecular sieve, and synthetic method and application thereof

ActiveCN104326483AIncrease profitReduce the feed ratioMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveComputational chemistry

A low-silicon composite molecular sieve comprises, by mass, 2-25% of an SAPO-5 molecular sieve and 75-98% of an SAPO-34 molecular sieve, and a molar ratio of SiO2 / Al2O3 is 0.07-0.15. The low-silicon composite molecular sieve has the advantages of low silicon, low cost, simple synthesis technology, high average diolefin selectivity in a methanol-to-olefin reaction, and long life.

Owner:天津众智科技有限公司

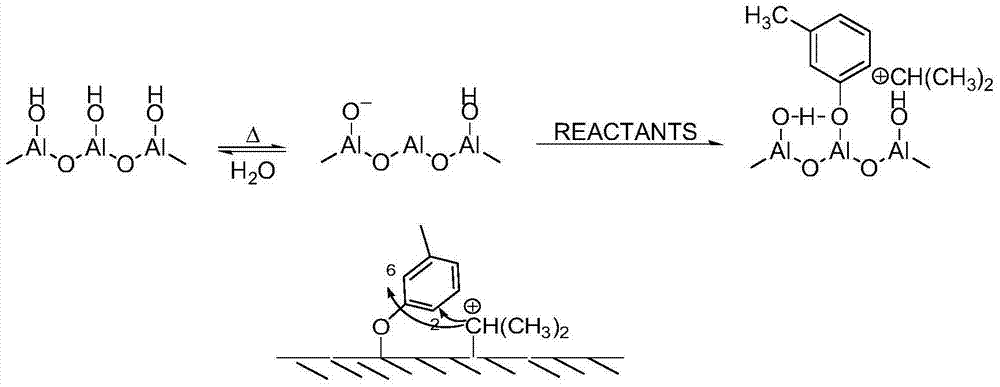

Catalyst and application of catalyst to method for preparing thymol

ActiveCN104190391AIncrease the areaHigh pore volumePhysical/chemical process catalystsOrganic chemistryPtru catalystM-Cresol

The invention discloses a catalyst. The catalyst is prepared from Al2O3 and gamma-Al2O3 according to a mass ratio of 1 to (0.1-9). The invention also provides a preparation method of the catalyst. The preparation method of the catalyst comprises the following steps: preparing Al2O3 by an ammonia precipitation method, then mixing Al2O3 with commercially purchased gamma-Al2O3, adding a nitrite acid solution into a mixed material, pulping the mixed material, injecting the pulp into a specific die, drying and forming at the temperature of 140-170 DEG C and roasting formed particles at the temperature of 300-1,000 DEG C for 1-10 hours. The invention also discloses a method for preparing thymol by using the catalyst. Compared with a pure commercial formed aluminum oxide catalyst, the catalyst has high specific surface area and pore volume and a variety of acid sites, can be applied to reaction for synthesizing thymol by virtue of alkylation of m-cresol and has high catalytic activity and selectivity; meanwhile, the catalyst is high in stability, long in service life and easy to regenerate.

Owner:上海泾维化工科技有限公司

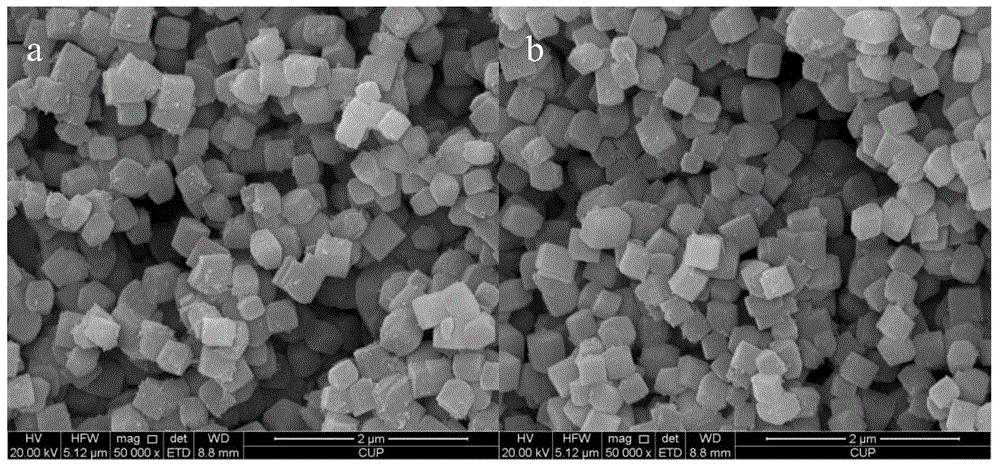

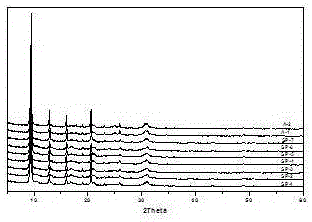

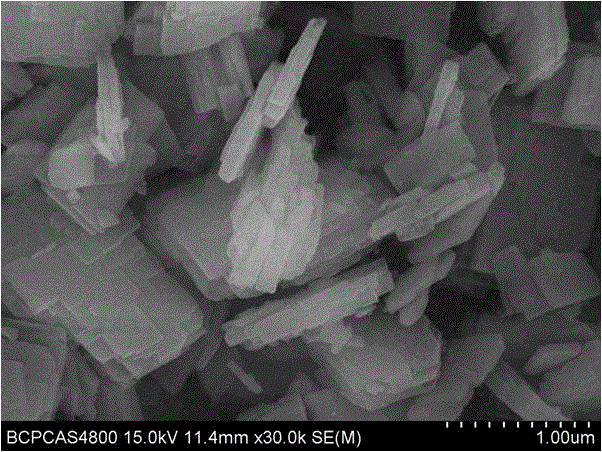

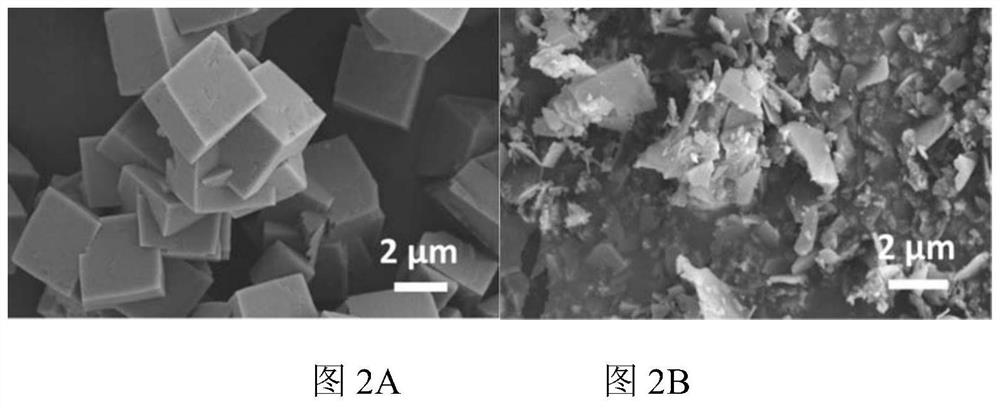

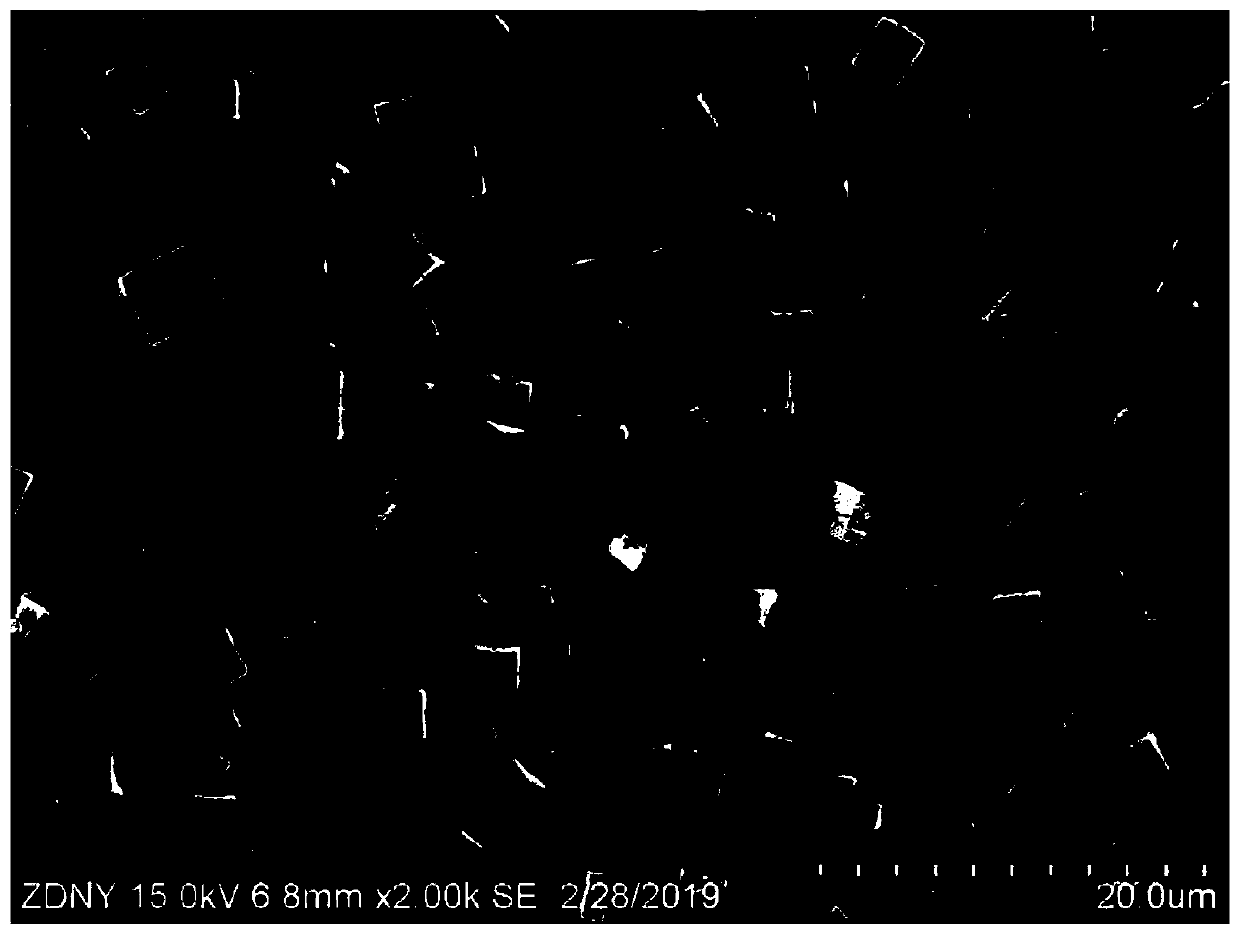

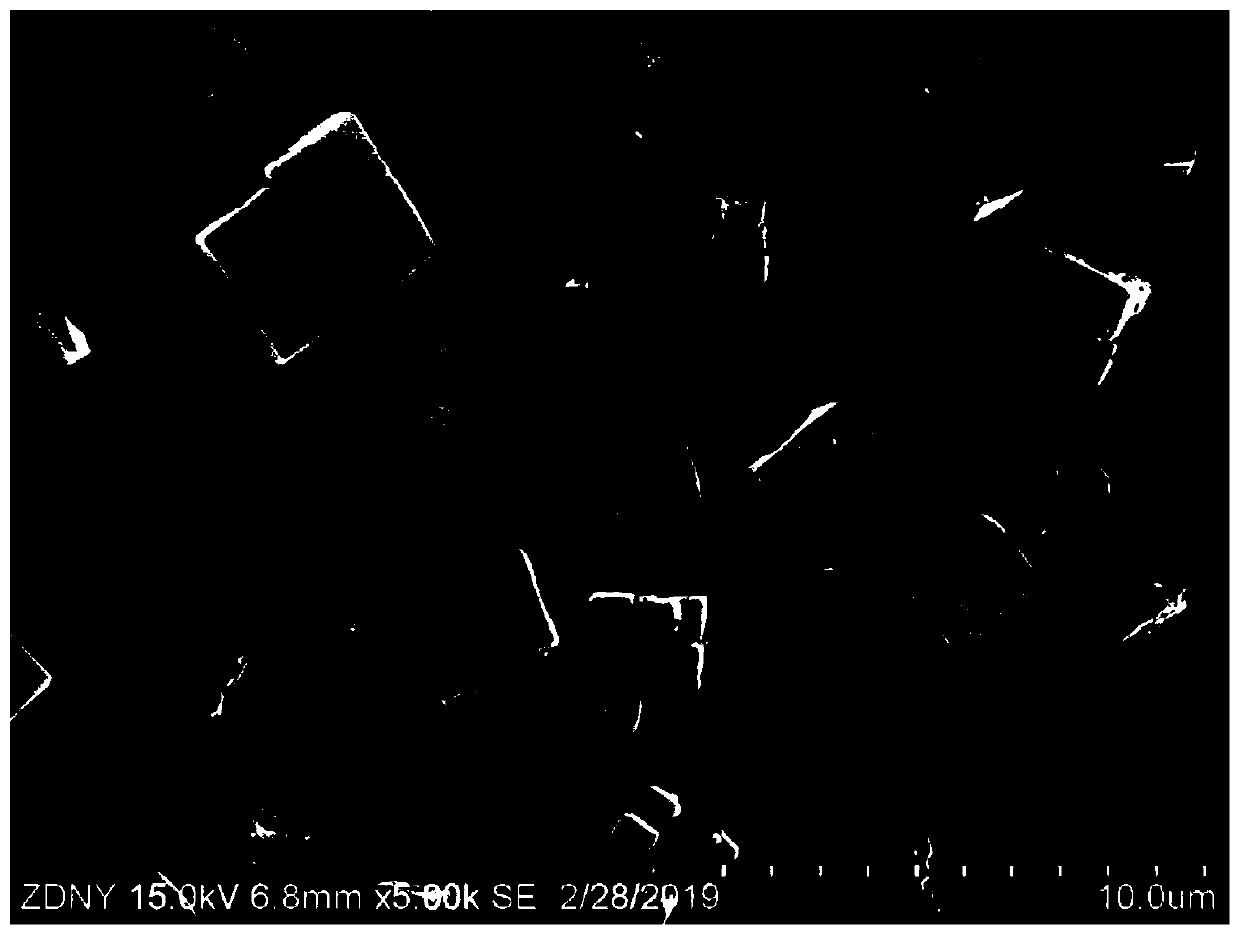

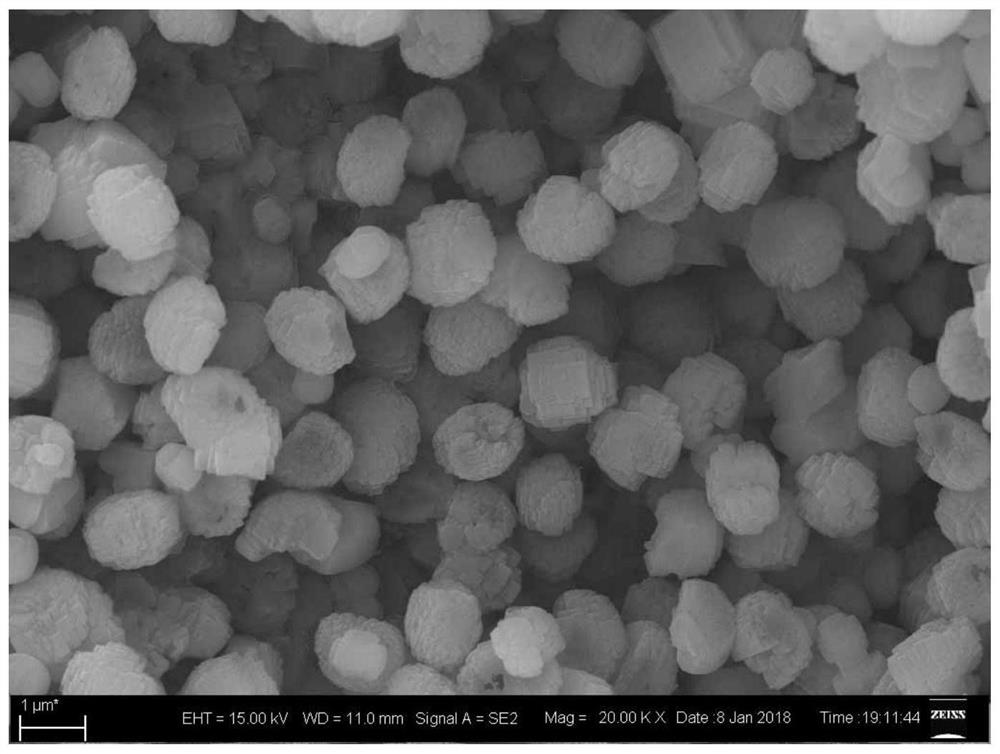

Preparation method and application of SAPO-34 molecular sieves with flaky morphology

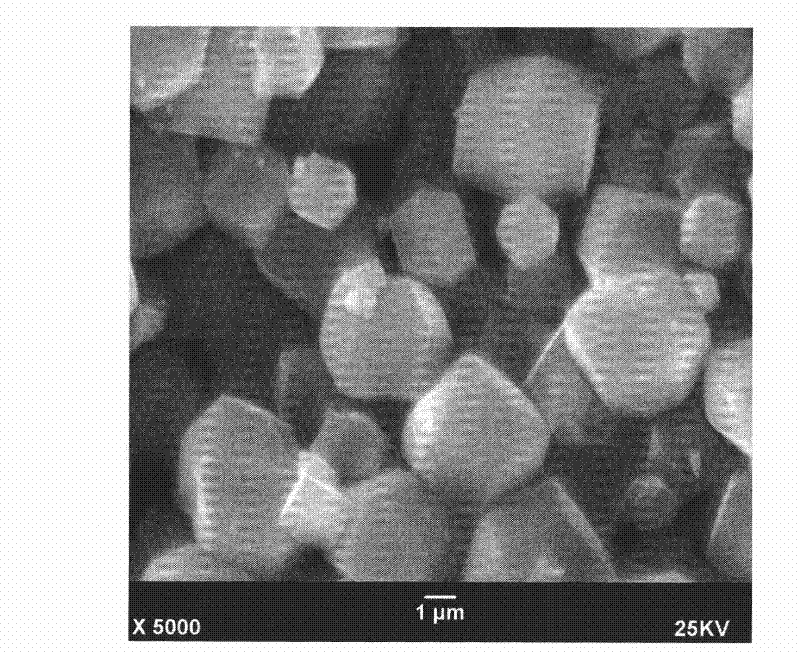

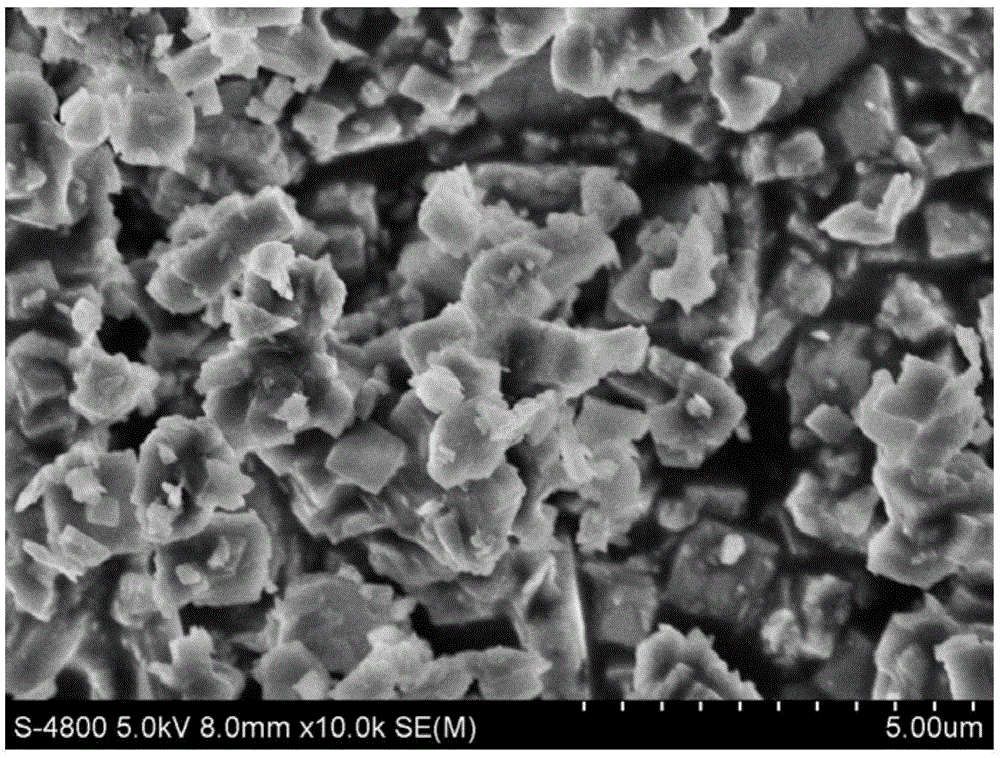

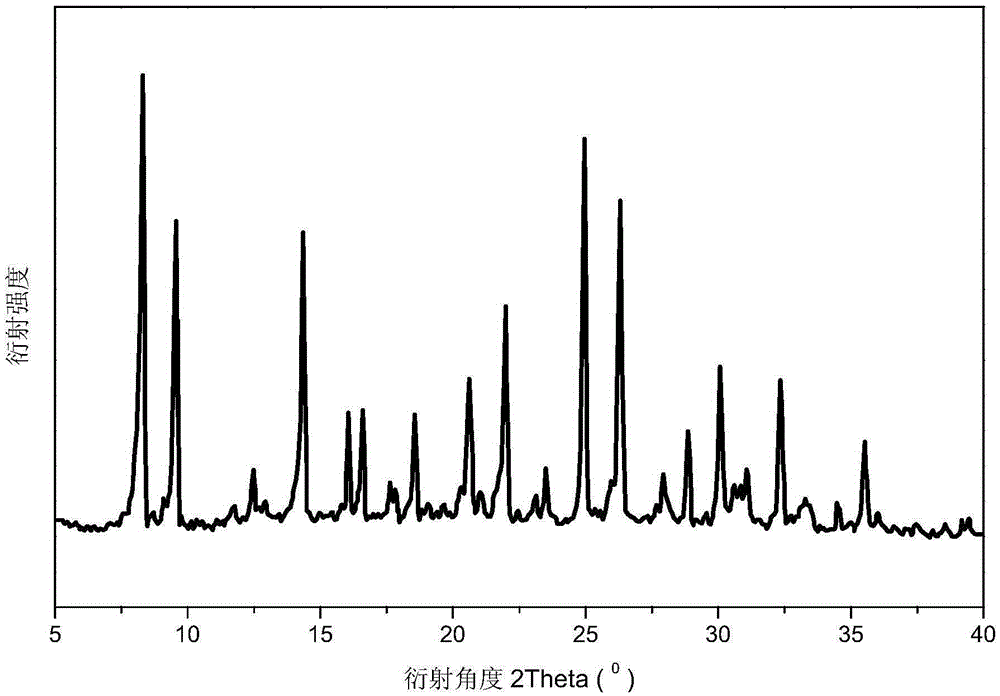

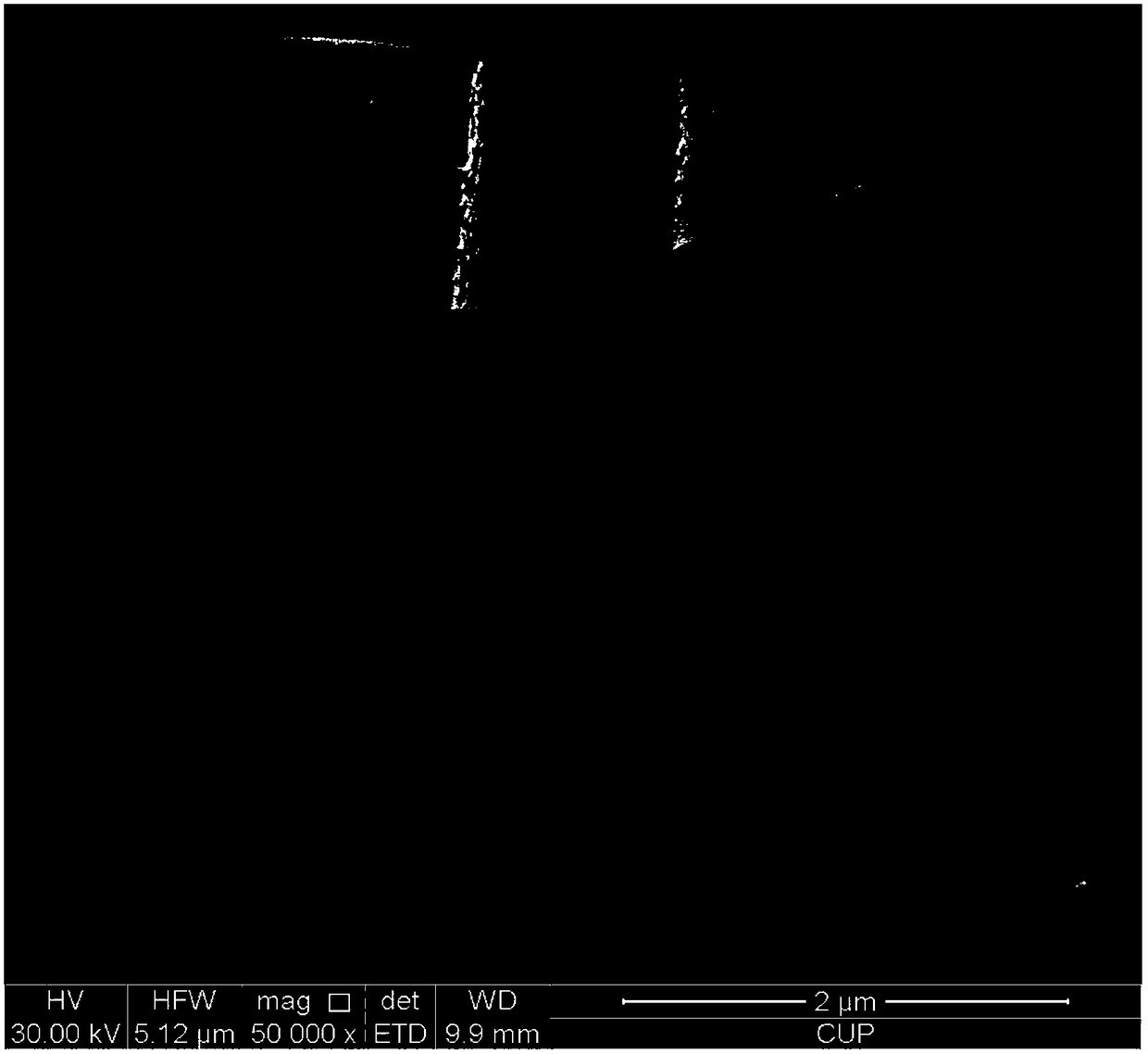

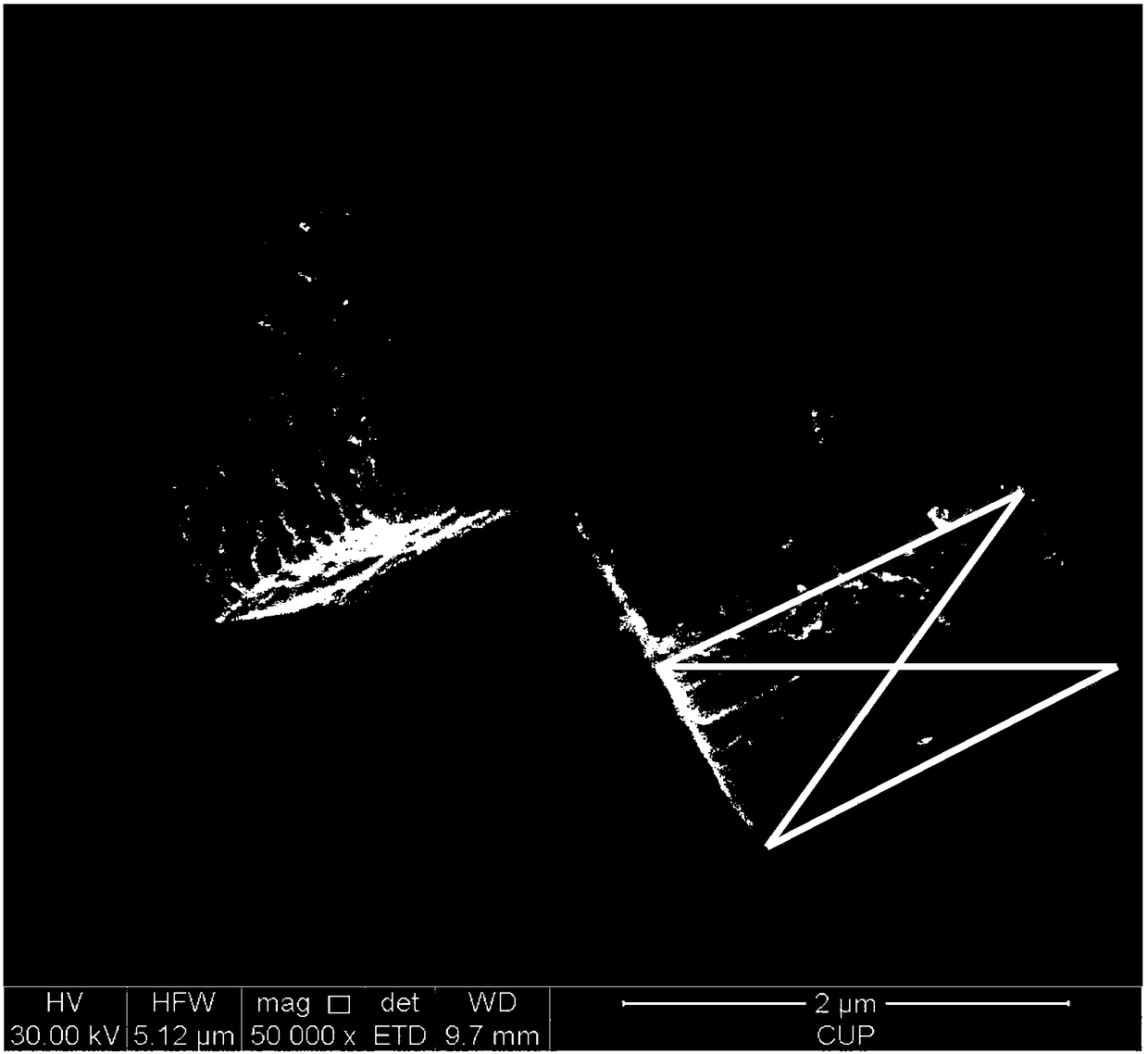

ActiveCN106477595AHigh selectivityIncreased diffusion rateMaterial nanotechnologyEthylene productionSynthesis methodsSolvent

The invention belongs to the technical field of preparation of molecular sieves and particularly relates to synthesis of SAPO-34 molecular sieves with flaky morphology and an application of the SAPO-34 molecular sieves in preparation of methanol to olefin. The molecular sieves are subjected to one-step hydrothermal synthesis, a double-template agent is mixed with an aluminum source, a silicon source and a phosphorus source, hydrothermal crystallization is performed, and the SAPO-34 molecular sieves are prepared. The synthesized SAPO-34 product adopts the flaky morphology, the crystal size ranges from 0.5 mu m to 2 mu m, and the thickness ranges from 50 nm to 200 nm. The synthesis method is simple, other solvents, surfactants and the like do not need to be added. The prepared product has high low-carbon olefin selectivity, especially high ethylene selectivity in a methanol-to-olefin reaction.

Owner:陕西煤化工技术工程中心有限公司

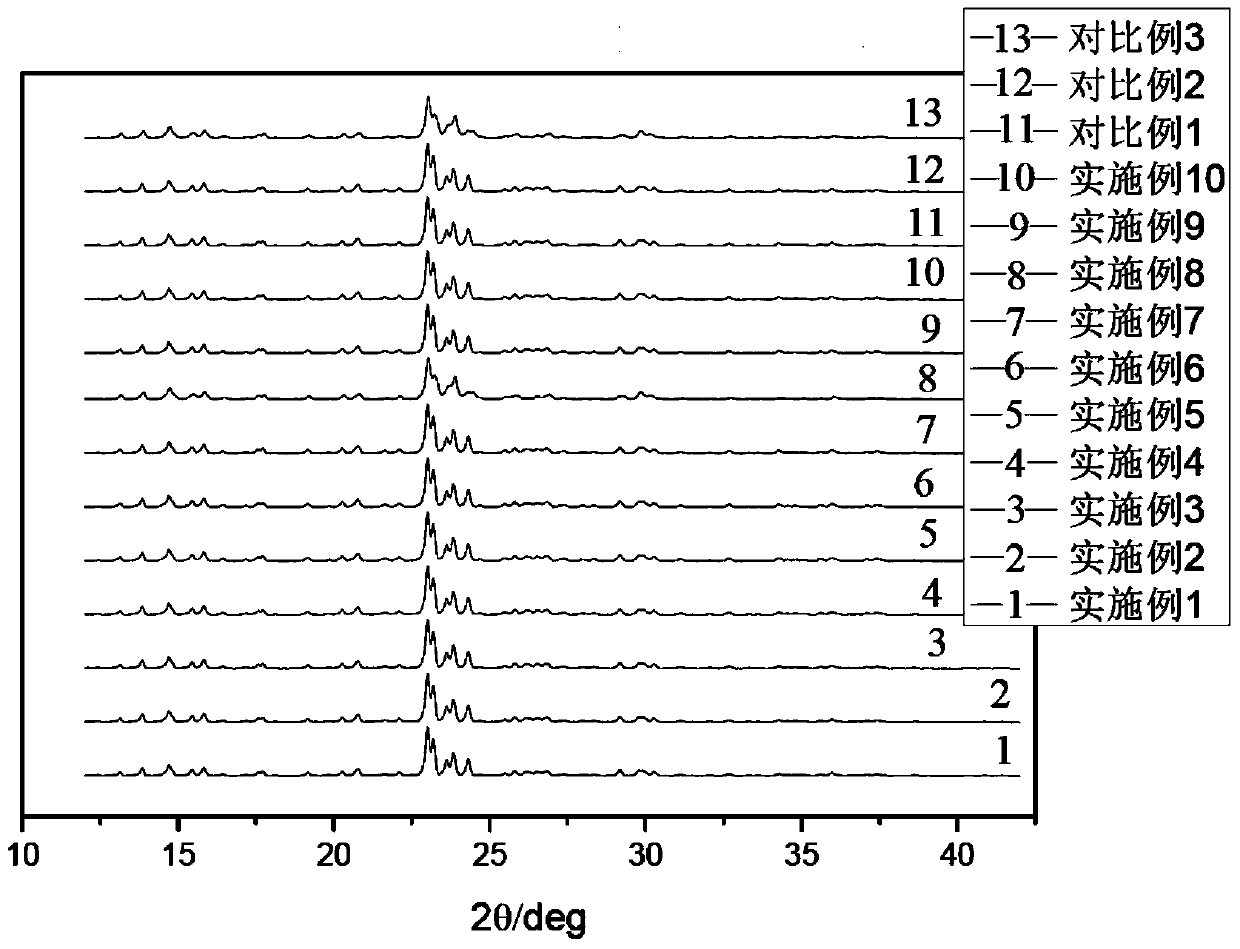

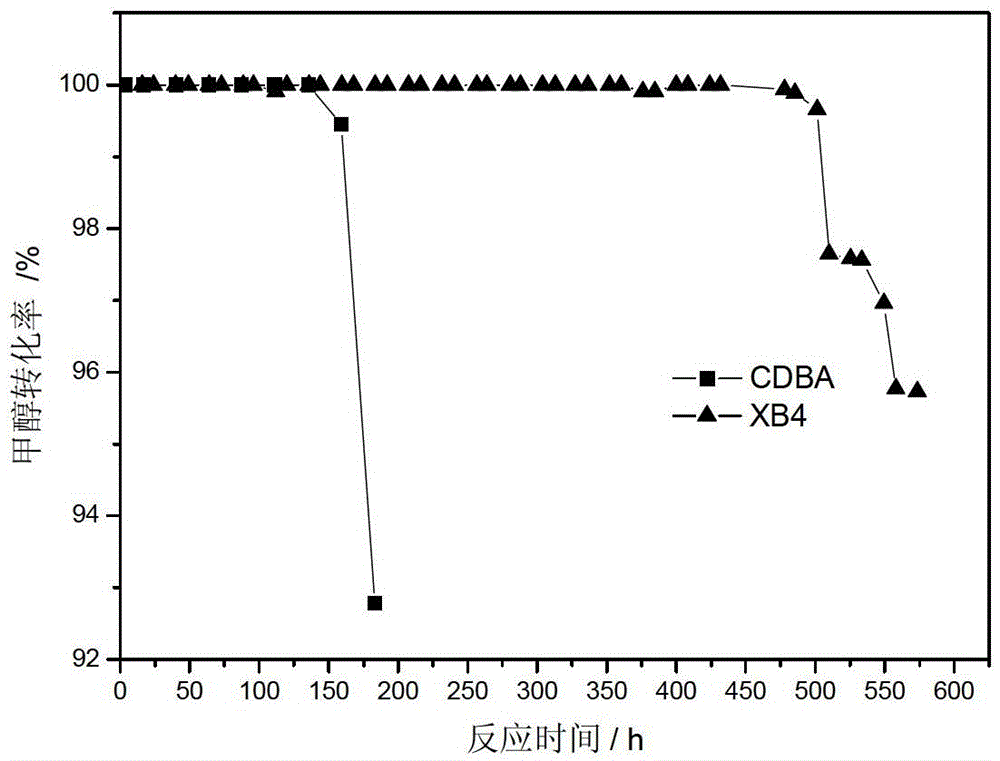

CHA-RHO type composite molecular sieve as well as preparation method and application thereof

ActiveCN106694032AHigh selectivityLong reaction lifeMolecular sieve catalystsOther chemical processesIonMolecular sieve

The invention discloses a CHA-RHO type composite molecular sieve as well as a preparation method and application thereof. The preparation method comprises the following steps: uniformly mixing a phosphorus source, an aluminum source and deionized water according to the mole ratio being (0.5 to 3):1:(50 to 100), drying, roasting and crushing to obtain granular phosphorous and aluminum dry glue; uniformly mixing the granular phosphorous and aluminum dry glue, a template agent R, a silicon source and the deionized water according to the mole ratio being 1:(0.5 to 3): (0.05 to 0.25):(25 to 50), crystallizing, cooling, carrying out suction filtering, washing and drying to obtain molecular sieve raw powder; roasting the molecular sieve raw powder to obtain CHA-RHO type SAPO (Silicoaluminophosphate) composite molecular sieve. The composite molecular sieve disclosed by the invention is prepared from 90 to 99 weight percent of CHA type molecular sieve and 1 to 10 weight percent of RHO type molecular sieve; in a composite molecular sieve framework, the mole ratio of SiO2 to Al2O3 is (0.05 to 0.35):1. The composite molecular sieve has the advantages of small crystalline grains, low silicon content, long service life and high catalytic activity; the composite molecular sieve is used for a catalyst for a reaction of preparing lower olefins by catalytic dehydration of methanol and high higher olefin selectivity; by means of the composite molecular sieve, the oligomerization of the lower olefins can be greatly reduced, so that the yield of the olefins is increased; the composite molecular sieve can be used as an adsorbent for adsorbing and separating small-molecule gases.

Owner:CHINA CATALYST HLDG CO LTD

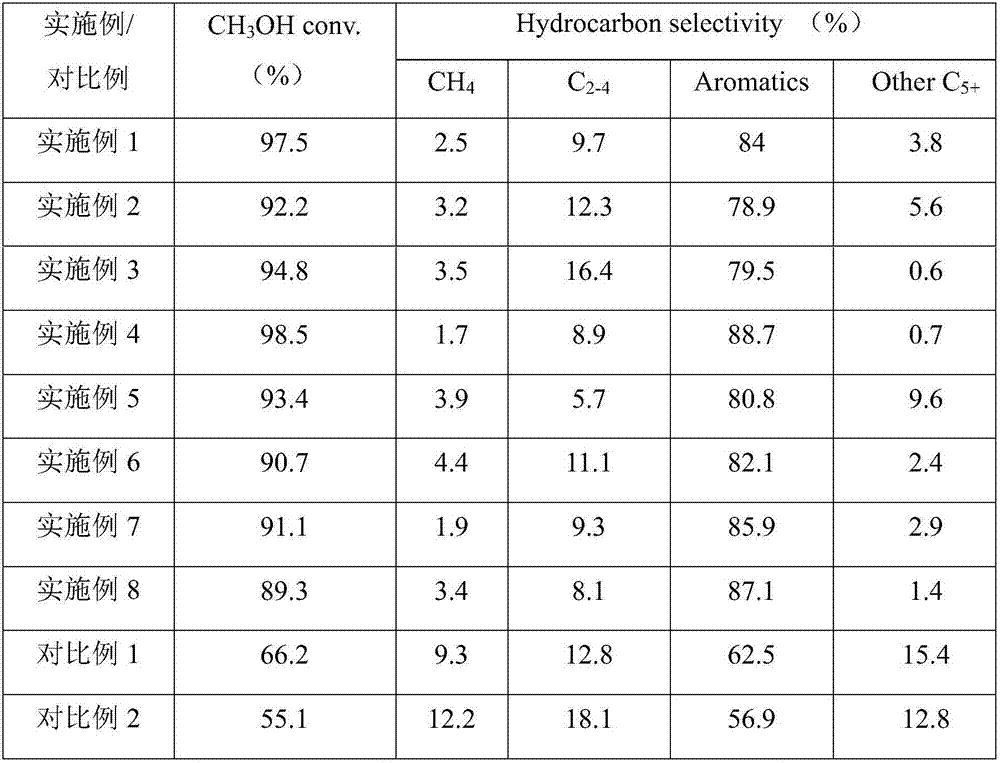

Method for preparing aromatic hydrocarbon by methyl alcohol at high selectivity

ActiveCN106866328AImprove catalytic performanceHigh selectivityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsSolventHigh selectivity

The invention relates to a method for preparing aromatic hydrocarbon by methyl alcohol at high selectivity, and relates to aromatic hydrocarbon. The method comprises the following steps of pretreating a catalyst; catalyzing: after the catalyst is pretreated, adding reaction raw materials, forming the methyl alcohol and a hydrogen trapping-removing agent, and reacting by a solid catalyst bed layer at the air speed of 500 to 10000h<-1>, so as to obtain the aromatic hydrocarbon; adding a salt compound of metal element into a solvent, dispersing by ultrasonic waves, adding a modified acid zeolite molecular sieve, and continuing to disperse by ultrasonic waves, so as to obtain a mixture; sucking, filtering and washing the mixture, and drying a filter cake; calcining the dried sample, and reducing, so as to obtain the catalyst. The method has the characteristics that when the aromatic hydrocarbon is prepared by the methyl alcohol, the aromatic hydrocarbon selectivity is excellent, the methane and C5+ hydrocarbon selectivity is low, and the catalyst selectivity is high; the aromatic hydrocarbon selectivity is 85% or above, and the methane selectivity is lower than 2%.

Owner:XIAMEN UNIV

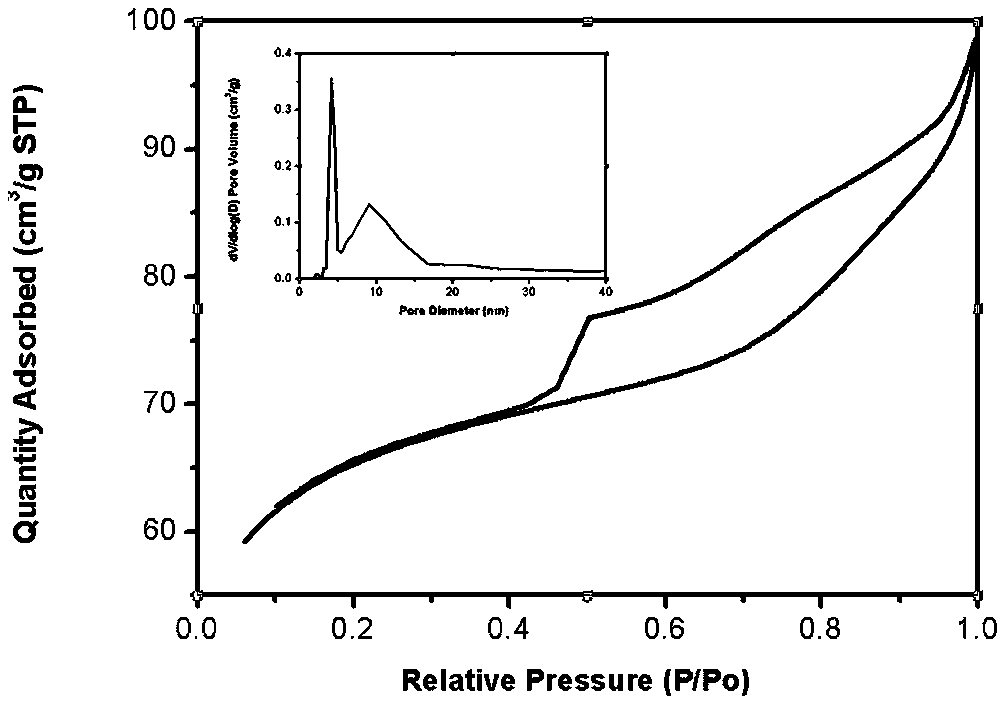

Preparation method and application of hierarchical pore SSZ-13 molecular sieve and method for preparing olefin from methanol

ActiveCN112978749AReduce over etchGood alkali resistanceMolecular sieve catalystsMolecular sieve catalystMolecular sieveIon exchange

The invention provides a preparation method of a hierarchical porous SSZ-13 molecular sieve. The method comprises the following steps: mixing a microporous SSZ-13 molecular sieve, a molecular sieve skeleton protective agent and water to obtain a skeleton-protected SSZ-13 molecular sieve; sequentially carrying out alkali treatment, acid treatment, ammonium ion exchange and roasting treatment on the skeleton-protected SSZ-13 molecular sieve, so as to obtain the hydrogen type hierarchical pore SSZ-13 molecular sieve. Compared with the conventional preparation method of the hierarchical porous SSZ-13 molecular sieve, the preparation method has the advantages of simplicity in operation, low cost and no need of an organic template agent. The obtained hierarchical pore SSZ-13 molecular sieve shows more excellent performance in the methanol-to-olefin process, the selectivity of ethylene and propylene is high, and the reaction life is long.

Owner:PETROCHINA CO LTD

Method for preparing and using cracking catalyst for oil production by lightening coal-tar pitch

InactiveCN101301621AHigh hydrocracking efficiencyRaise the ratioMolecular sieve catalystsCatalyst activation/preparationFixed bedOil production

Preparation and application of a coaltar pitch oil preparation cracking catalyst, relate to a cracking catalyst for coaltar pitch oil preparation, which is characterized by the following: immerging 100 portion zeolite into 100 portion metal nitrate aqueous solution with the concentration of 2.8 wt%-24.2 wt% for 2 hours at the temperature of 80 DEG C; standing after dipping, and then obtaining supernatant fluid; drying the supernatant fluid for 4 hours at 120 DEG C, and then activating for 5 hours at 500 DEG C. to get the cracking catalyst which metal oxide content is 1.2 wt%-20.0 wt% of the weight of the zeolite. While in use, the catalyst is filled into a third stage fixed-bed reactor for coaltar pitch oil preparation to ensure the pitch which has already been hydrogenation modified and refined in a second stage fixed-bed reactor to perform catalytic cracking reaction, under the conditions of 400-450 DEG C, 1.0-5.0 bar, hydrogen-oil ratio of 900 / 1-1500 / 1 and catalytic reaction space-velocity WHSV of 0.5-2.0 h<-1>, wherein, the total oil yield of fuel can reach 75%. The invention with flexible operation condition and low operating cost is applicable for preparing oil by catalytic cracking various coaltar pitch.

Owner:TONGJI UNIV

Preparation method of ZnO-ZrO2@Al2O3@SAPO-34 dual-core-shell catalyst

InactiveCN108246356AExtend your lifePromote growthHydrocarbon from carbon oxidesMolecular sieve catalystsMorpholineDual core

The invention discloses a preparation method of a ZnO-ZrO2@Al2O3@SAPO-34 dual-core-shell catalyst. The preparation method comprises the following steps: preparing ZnO-ZrO2@Al2O3 powder; taking Al2O3,P2O5, SiO2, MOR and H2O in a molar ratio of 1.0:0.8:0.6:2.5:80; adding pseudo-boehmite, ethyl orthosilicate and a template agent morpholine to an orthophosphoric acid solution sequentially while stirring, performing uniform stirring continuously, and performing stirring and aging for 24h at room temperature to form a sol system; adding 200-400-mesh ZnO-ZrO2@Al2O3 powder to the system according tothe core-shell mass ratio of ZnO-ZrO2@Al2O3: SAPO-34 of (1:4)-(4:1), performing uniform stirring continuously, and then, transferring the product into a reactor; and performing hydrothermal crystallization for 24-48h at 190-210 DEG C, performing cooling and filtration, performing washing to neutrality with deionized water, performing drying for 6h at 105 DEG C, and performing roasting for 3h at 500-600 DEG C to obtain the catalyst. The catalyst prepared by the preparation method disclosed by the invention can simultaneously improve the conversion rate of carbon dioxide and the selectivity of low-carbon olefin in a two-step process for preparing low-carbon olefin by CO2 hydrogenation through methanol.

Owner:GUIZHOU UNIV

Preparation method of gamma-Al2O3@CuO-ZnO@ZSM-5 double-core-shell catalyst

InactiveCN108295892AHigh selectivityExtend your lifeHydrocarbon from carbon oxidesMolecular sieve catalystsPtru catalystPhysical chemistry

The invention discloses a preparation method of a gamma-Al2O3@CuO-ZnO@ZSM-5 double-core-shell catalyst. The preparation method comprises the following steps: preparing gamma-Al2O3@CuO-ZnO powder; according to a molar ratio of raw materials, namely n(TEOS), n(NaAlO2), n(TPAOH) and n(H2O), of (40-360):1:19:4015, sequentially adding NaAlO2, TPAOH and TEOS into deionized water while stirring, continuously stirring uniformly, stirring and aging at room temperature for 3h to form a sol system, adding the gamma-Al2O3@CuO-ZnO powder into the system according to a core-shell mass ratio of gamma-Al2O3@CuO-ZnO to ZSM-5 of 1:2 to 2:1, continuing stirring uniformly, performing a hydrothermal reaction in a homogeneous reactor at 170-190 DEG C for 24-48h (at a rotating speed of 4r / min), cooling to room temperature, centrifuging, washing by using deionized water, washing by using anhydrous ethanol, drying at 120 DEG C for 12 h, and roasting at 500-600 DEG C for 3h to obtain the gamma-Al2O3@CuO-ZnO@ZSM-5 double-core-shell catalyst. The catalyst prepared by the preparation method provided by the invention can simultaneously increase the carbon dioxide conversion rate and the low-carbon olefin selectivity in a two-step technology in which the low-carbon olefin is prepared from methanol through CO2 hydrogenation.

Owner:GUIZHOU UNIV

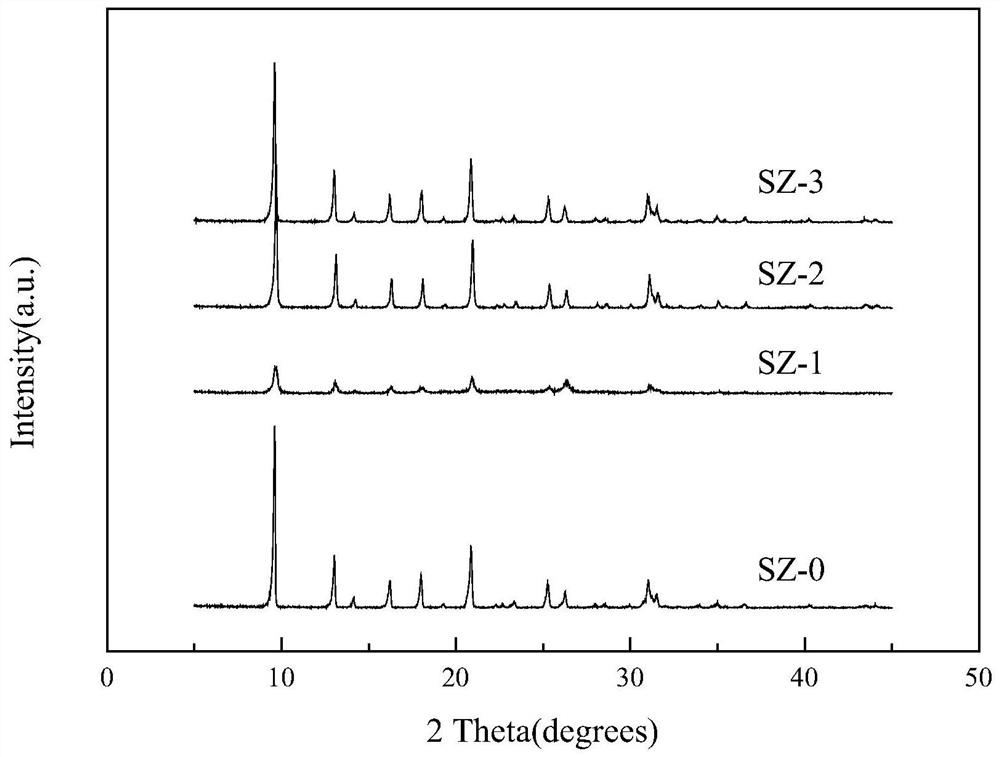

A kind of hierarchical porous ZSM-5 molecular sieve and its preparation method and the method for preparing MTA catalyst

ActiveCN107010639BHigh selectivityLong reaction lifeMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sievePtru catalyst

The invention belongs to the field of catalyst synthesis and in particular relates to a preparation method of a hierarchical porous ZSM-5 molecular sieve. The preparation method comprises the following steps: 1) mixing an alkali source, an aluminum source and water to obtain mixed liquor A; 2) stirring and mixing an anionic surfactant, a dispersing agent and water to obtain mixed liquor B; 3) mixing the mixed liquor A and the mixed liquor B to obtain mixed liquor C; 4) mixing the mixed liquor C, a silicon source and ZSM-5 crystal seeds to obtain mixed liquor D; 5) crystallizing the mixed liquor D at the temperature of 140-180 DEG C, drying, and then washing; and 6) roasting a product obtained after washing in the step 5) at the temperature of 500-600 DEG C, so that the hierarchical porous ZSM-5 molecular sieve is obtained. The preparation method provided by the invention has the advantages that the hierarchical porous ZSM-5 molecular sieve with a hierarchical porous structure and high dispersibility can be simply and successfully synthesized, and life of the hierarchical porous ZSM-5 molecular sieve in MTA reaction is prolonged.

Owner:REZEL CATALYSTS CORP

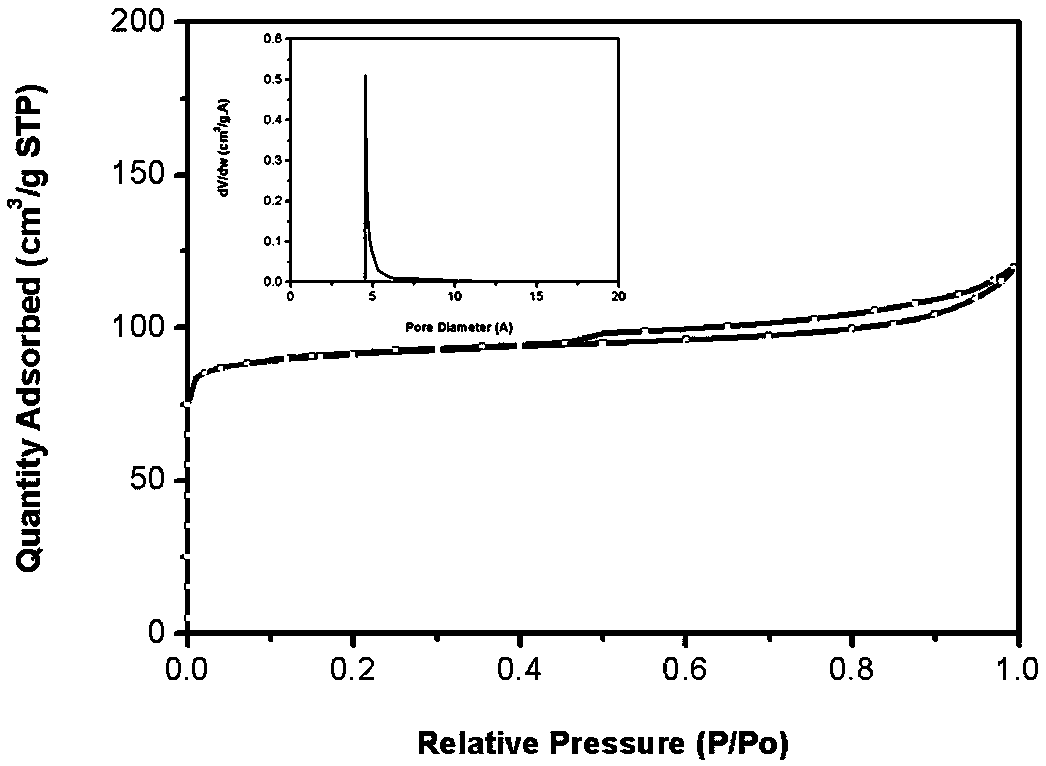

Composite mesoporous-microporous structure SAPO-34 molecular sieve and synthesis method thereof

PendingCN111302353ASimple structureHigh selectivityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sievePtru catalyst

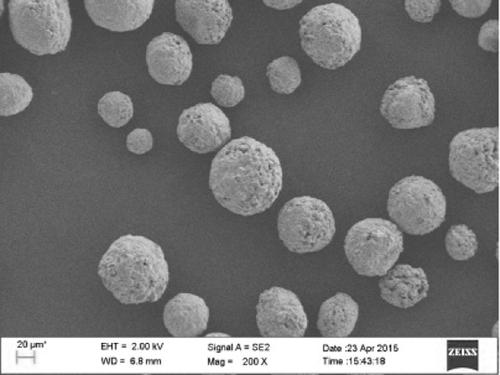

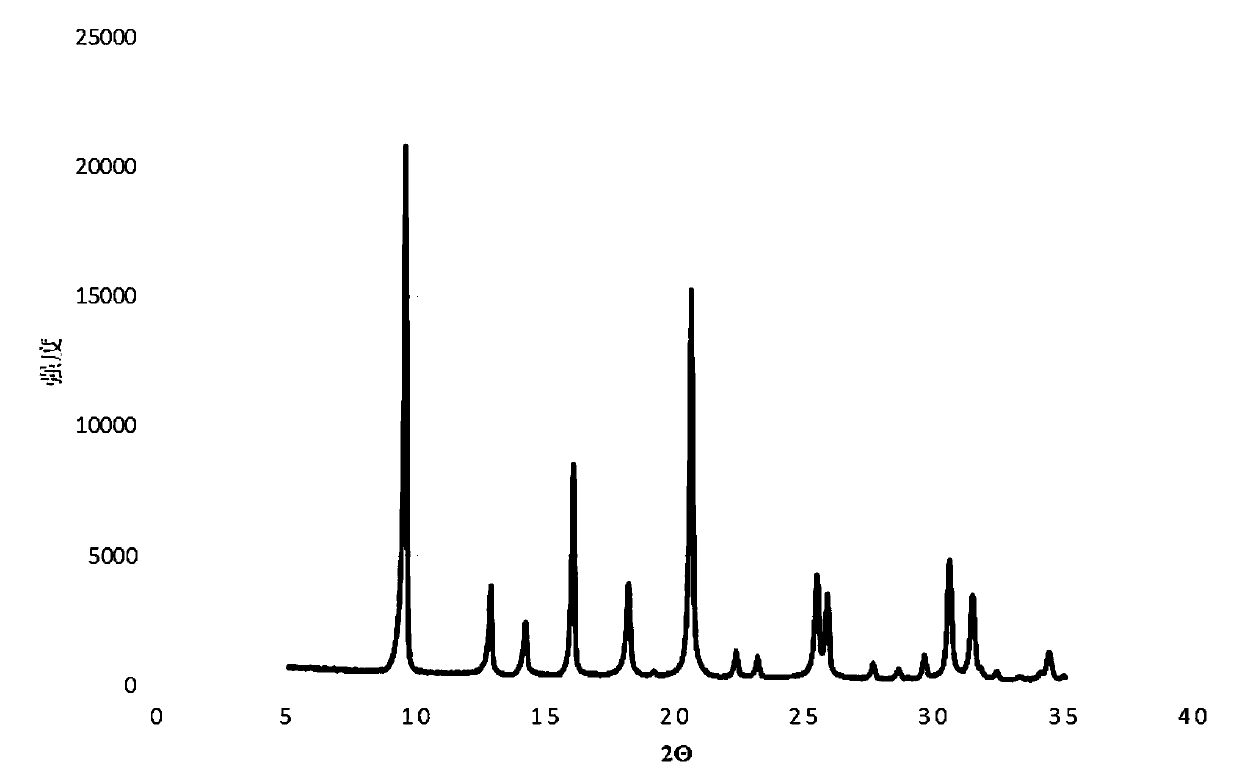

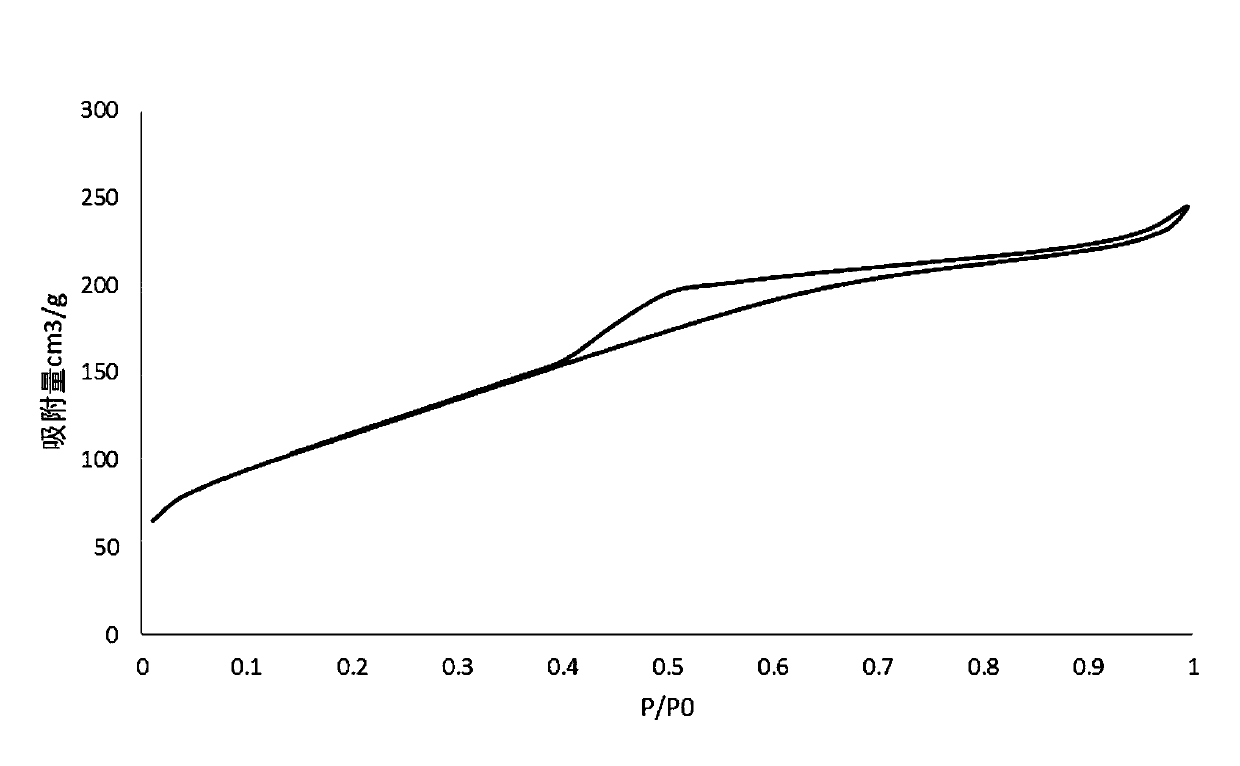

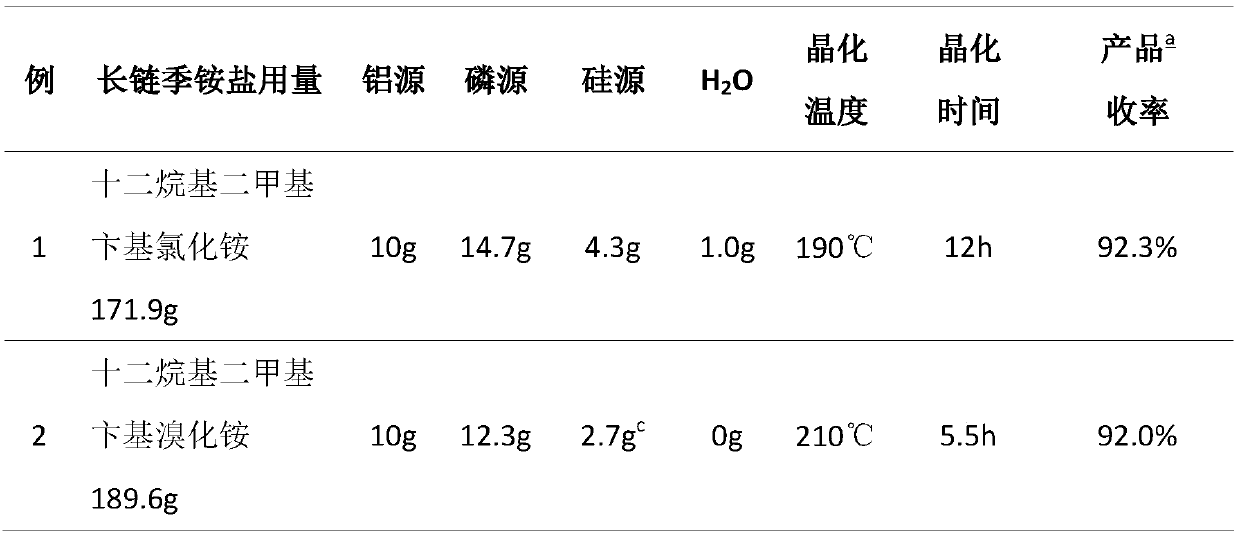

The invention provides a composite mesoporous-microporous structure SAPO-34 molecular sieve and a synthesis method thereof. A long-chain quaternary ammonium salt is adopted as a novel organic structure directing agent to synthesize an SAPO-34 molecular sieve catalyst with mesopores and micropores at the same time. The novel organic structure directing agent is an organic long-chain quaternary ammonium salt with an R1-(CH3)2N-R2 structure, wherein R1 is a straight-chain or branched-chain alkyl group containing 2-4 carbon atoms or a cycloalkane group containing 4-8 carbon atoms, R2 is a straight-chain or branched-chain alkyl group containing 10-30 carbon atoms, and anions can be one or more of hydroxide ions, chloride ions, bromide ions and the like. Compared with an SAPO-34 catalyst prepared from other template agents, the SAPO-34 molecular sieve catalyst synthesized by the method has a unique composite mesoporous-microporous structure, and the service life of the catalyst can be prolonged to a certain extent while the selectivity of ethylene and propylene in MTO reaction is effectively improved.

Owner:中科催化新技术(大连)股份有限公司

Catalyst for directly preparing low carbon olefin through hydrogenation of carbon dioxide and preparation method thereof

ActiveCN108837834AGood effectEasy to prepareHydrocarbon from carbon oxidesHeterogenous catalyst chemical elementsButeneNitrate

The invention relates to a layer structure catalyst for directly preparing ethylene, propylene and butene through hydrogenation of carbon dioxide. The layer structure catalyst for directly preparing the ethylene, the propylene and the butene through hydrogenation of the carbon dioxide is prepared in the steps of mixing iron nitrate nonahydrate, potassium carbonate and titanium dioxide under a certain condition and then calcining an obtained mixture at a certain temperature for two times by using a high temperature solid state method so as to prepare the layer structure catalyst. The layer structure catalyst for directly preparing the ethylene, the propylene and the butene through hydrogenation of the carbon dioxide has the advantages that a stable layer structure is obtained, the layer structure can be stably kept before and after the reaction of directly preparing the ethylene, the propylene and the butene through hydrogenation of the carbon dioxide, olefin secondary reaction caused by readsorption of primary olefin is inhibited to a certain degree, and high olefin selectivity is realized in the reaction of preparing low carbon olefin through hydrogenation of the carbon dioxide. Apreparation method is simple and environmentally friendly and has potential application values.

Owner:NINGXIA UNIVERSITY

Core-shell microsphere catalyst

ActiveCN104056655AHigh activityLong reaction lifeMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMicrosphereCore component

A core-shell microsphere catalyst is characterized by comprising a core component and a shell component. The core component comprises 30-95 wt% of a ZSM-5 molecular sieve composition and 5-70 wt% of an inorganic oxide; the diameter of the core component accounts for at least 50% of the diameter of the microsphere; the shell component comprises 30-95 wt% of a ZSM-11 molecular sieve composition and 5-70 wt% of an inorganic oxide; the ZSM-5 molecular sieve composition comprises 0.1-10 wt% of phosphorus on a basis of P2O5, and 0-10 wt% of rare earth on a basis of oxide; in the ZSM-5 molecular sieve, the content of alkali metal is less than 0.2 wt% on a basis of oxide, the mole ratio of SiO2 to Al2O3 is 100-1000, the BET-method specific surface area determined by a nitrogen adsorption method is 300-600 m2 / g, the total pore volume is 0.2-0.6 mL / g, and the pore volume of mesopores with a pore diameter more than 2 nm accounts for 30-70% of the total pore volume. The catalyst of the invention can be used in reaction for preparing propylene by methanol catalytic dehydration, and has the characteristics of high activity, good propylene selectivity, and long reaction life.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of metal modified ZSM-5 molecular sieve catalyst and its preparation method and application

ActiveCN106140266BIncrease profitHigh selectivityMolecular sieve catalystsHydrocarbon by hydrocarbon crackingCarbon numberAlkane

The invention provides a metal modification ZSM-5 molecular sieve based catalyst. The catalyst is characterized in that the catalyst is prepared by modifying and preparing a ZSM-5 molecular sieve through a hydrothermal method by means of modification elements, wherein the modification elements are La and / or Ce; the total mass of ZSM-5 in ZSM-5 molecular sieve based catalyst is 100%, and the mass content of modified elements is 0.01-15%; preferentially, the metal modification ZSM-5 molecular sieve is used for light dydrocarbon catalytic cracking to prepare low carbon olefin, and light hydrocarbon is alkane or olefin simple substance or a mixture with the carbon number being 4-8. The metal modification ZSM-5 molecular sieve based catalyst is easy and convenient to operate and free of high-temperature operation, lowers energy consumption and improves modified element utilization rate, the modification effect is better than a traditional mode, the addition amount of modification elements is reduced, the selectivity of catalyst for low-carbon olefin is improved, the reaction service life is enhanced greatly in the long-period reaction, and the better application value is achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

A core-shell type zsm-5 molecular sieve pellet catalyst

ActiveCN104056652BGood choiceLong reaction lifeMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMicrosphereCore component

A core-shell ZSM-5 molecular sieve microsphere catalyst is characterized in that the catalyst comprises a core component and a shell component. The core component comprises a ZSM-5 molecular sieve composition and an inorganic oxide; the diameter of the core component accounts for at least 50% of the diameter of the microsphere; the shell component comprises a ZSM-5 molecular sieve composition and an inorganic oxide; on a basis of the weight of the catalyst, the ZSM-5 molecular sieve composition accounts for 30-95%, and the inorganic oxide accounts for 5-70%; the ZSM-5 molecular sieve composition comprises 0.1-10 wt% of phosphorus on a basis of P2O5, and 0-10 wt% of rare earth on a basis of oxide; in the ZSM-5 molecular sieve, the content of alkali metal is less than 0.2 wt% on a basis of oxide, the mole ratio of SiO2 to Al2O3 is 100-1000, the BET-method specific surface area determined by a nitrogen adsorption method is 300-600 m2 / g, the total pore volume is 0.2-0.6 mL / g, and the pore volume of mesopores with a pore diameter more than 2 nm accounts for 30-70% of the total pore volume. The catalyst of the invention can be used in reaction for preparing light olefin by methanol catalytic dehydration, and has the characteristics of high activity, good propylene selectivity, and long reaction life.

Owner:CHINA PETROLEUM & CHEM CORP +1

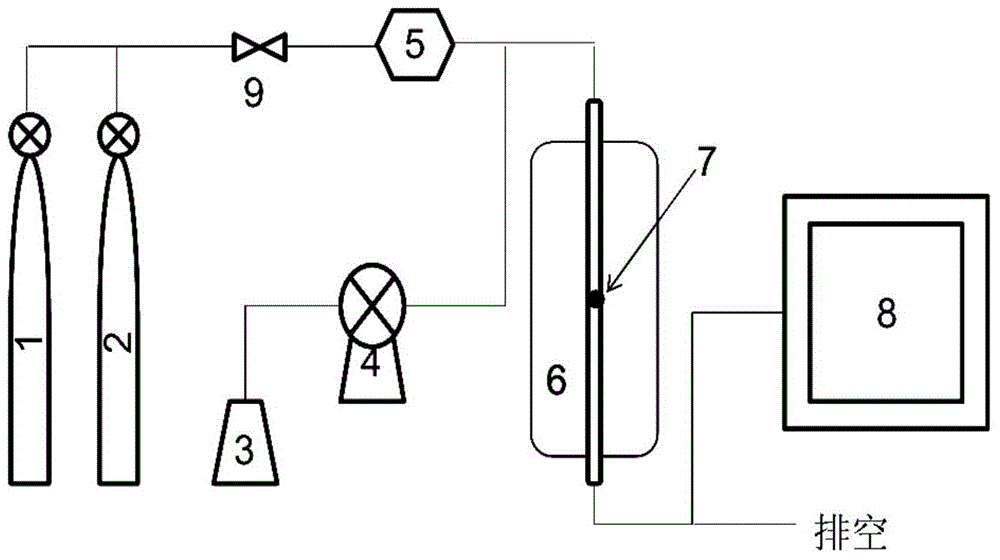

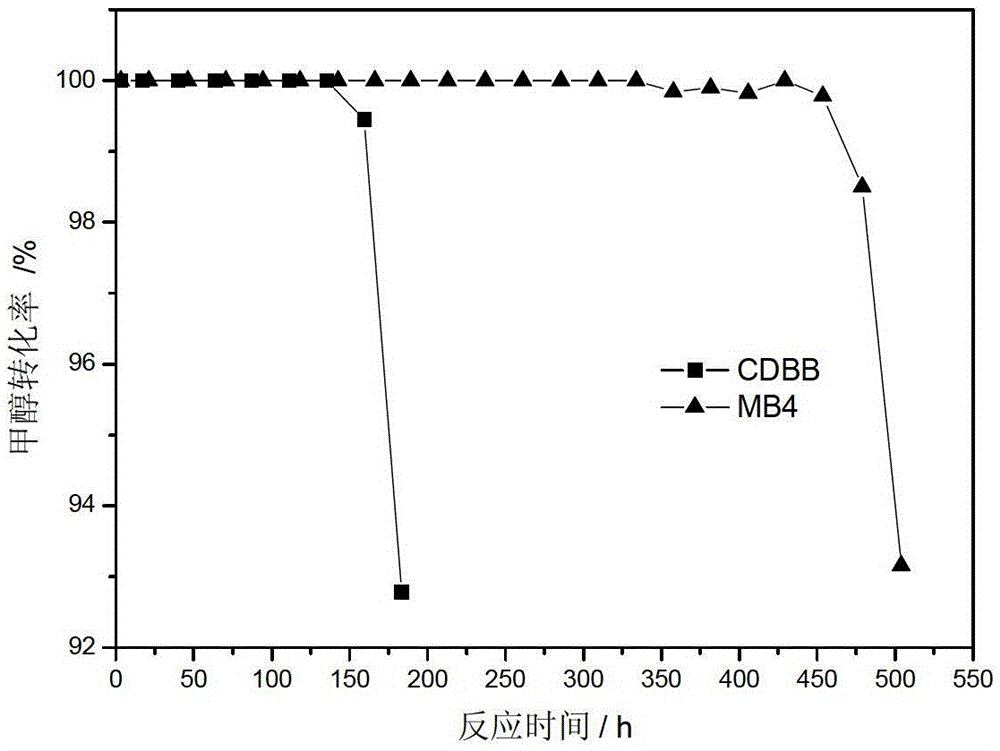

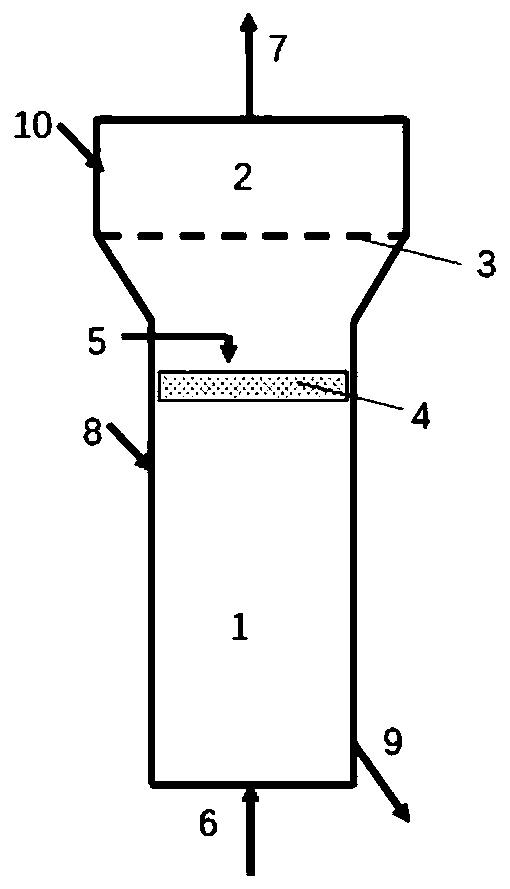

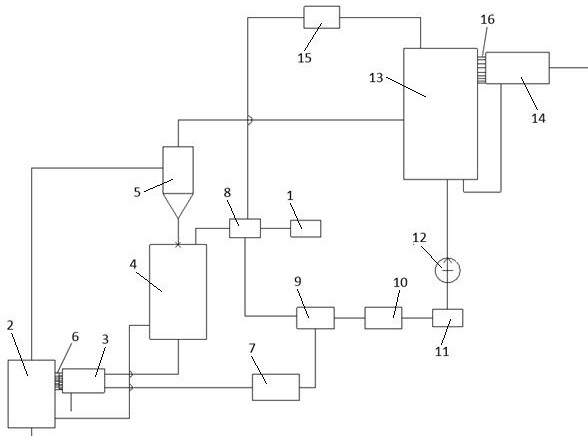

Device and method for efficiently converting volatile organic compounds

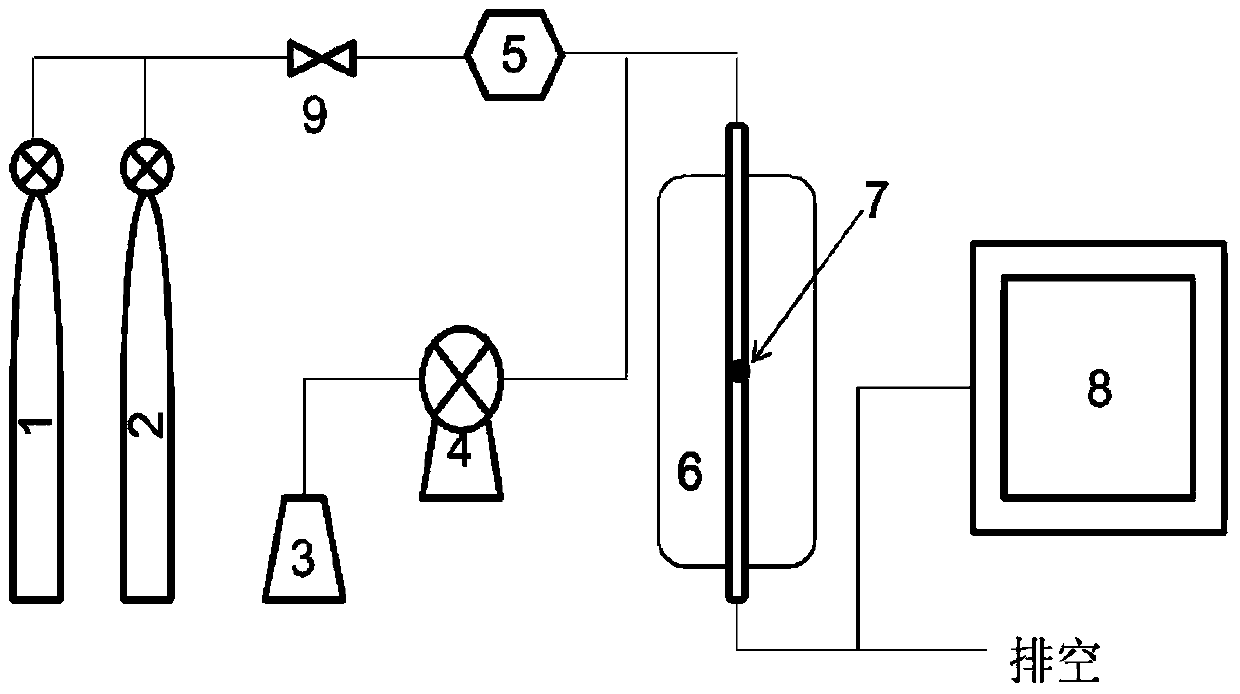

ActiveCN111229026ALow installation costLong reaction lifeGas treatmentDispersed particle separationVolatile organic compoundFixed bed

The invention discloses a device and method for efficiently converting volatile organic compounds. The lower section of the device is a fluidized bed section, the upper section of the device is a fixed bed section, the fluidized bed section and the fixed bed section are separated by a porous distribution plate, and a metal wire mesh layer for preventing solids of the fluidized bed section from moving upwards, inlets of volatile organic compounds, water vapor and catalysts and outlets of a carbon product and a gas product are arranged. The method comprises the following steps: respectively filling the fluidized bed section and the fixed bed section with the nano-metal supported catalysts with different particle sizes. Conversion energy is provided through external heating, and heat is supplied to the catalyst of the fixed bed section through gas of the fluidized bed section, water vapor is introduced into the middle of the reaction device, the fluidized bed section is controlled to produce a large number of the carbon product, carbon deposition is avoided in the fixed bed section, and a long catalyst life is maintained. By utilizing the method, the volatile organic compounds are efficiently converted and directly discharged, meanwhile, the carbon nano material is prepared, and the additional value is increased. The device has the advantages of compact structure, low investment and easiness in amplification.

Owner:TSINGHUA UNIV

A core-shell pellet catalyst

ActiveCN104056655BHigh activityLong reaction lifeMolecular sieve catalystsHydrocarbon from oxygen organic compoundsAlkali metal oxideRare earth

A core-shell pellet catalyst, characterized in that it consists of an inner core component and an outer shell component, said inner core component is composed of 30-95% by weight ZSM-5 molecular sieve composition and 5-70% by weight of inorganic oxides , the diameter of the inner core component accounts for at least 50% of the diameter of the sphere, said shell component is composed of 30-95 wt% ZSM-11 molecular sieve and 5-70 wt% inorganic oxide, said ZSM-5 molecular sieve combination substance, containing P 2 o 5 0.1-10% by weight of phosphorus and 0-10% by weight of rare earth oxides, in the ZSM-5 molecular sieve, the content of alkali metals in oxides is less than 0.2% by weight, SiO 2 with A1 2 o 3 The molar ratio is 100-1000, and the BET method specific surface area measured by nitrogen adsorption method is 300-600m 2 / g, the total pore volume is 0.2-0.6mL / g, and the mesopore volume with pore diameter>2nm accounts for 30-70% of the total pore volume. The molecular sieve catalyst of the present invention is used in the reaction of producing propylene by catalytic dehydration of methanol, and has the characteristics of high activity, good propylene selectivity and long reaction life.

Owner:CHINA PETROLEUM & CHEM CORP +1

CO2 trapping system based on chemical-looping combustion coupled supercritical hydrothermal reaction, and working method

PendingCN111947139AAvoid Reactive Performance ImpactReduced Possibility of PoisoningGaseous fuelsLiquid carbonaceous fuelsReaction rateWater storage tank

The invention relates to a CO2 trapping system based on a chemical-looping combustion coupled supercritical hydrothermal reaction, and a working method. In an existing chemical-looping combustion cycle reaction, an oxygen carrier is sintered and melted, and consequently the cycle reaction rate is decreased. The CO2 trapping system comprises a chemical-looping combustion system which comprises an air reactor, a pyrolyzing furnace, a fuel reactor and a cyclone separator, and the pyrolyzing furnace is connected with the air reactor. The CO2 trapping system is characterized by further comprising aCO2 storage device, a coal water slurry system and a supercritical hydrothermal reaction system, wherein the coal water slurry system comprises coal grinding equipment, a water storage tank, a mixingtank, a colloid tank and a slurry storage tank, and the water storage tank, the mixing tank, the colloid tank and the slurry storage tank are sequentially connected through pipelines; and the supercritical hydrothermal reaction system comprises a high-pressure coal water slurry pump, a supercritical water oxidation reactor, a preheater and a CO2 separator, and the preheater is connected with thesupercritical water oxidation reactor. The chemical-looping combustion economy and the energy utilization efficiency are improved, and CO2 can be trapped with the low cost and low energy consumption.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

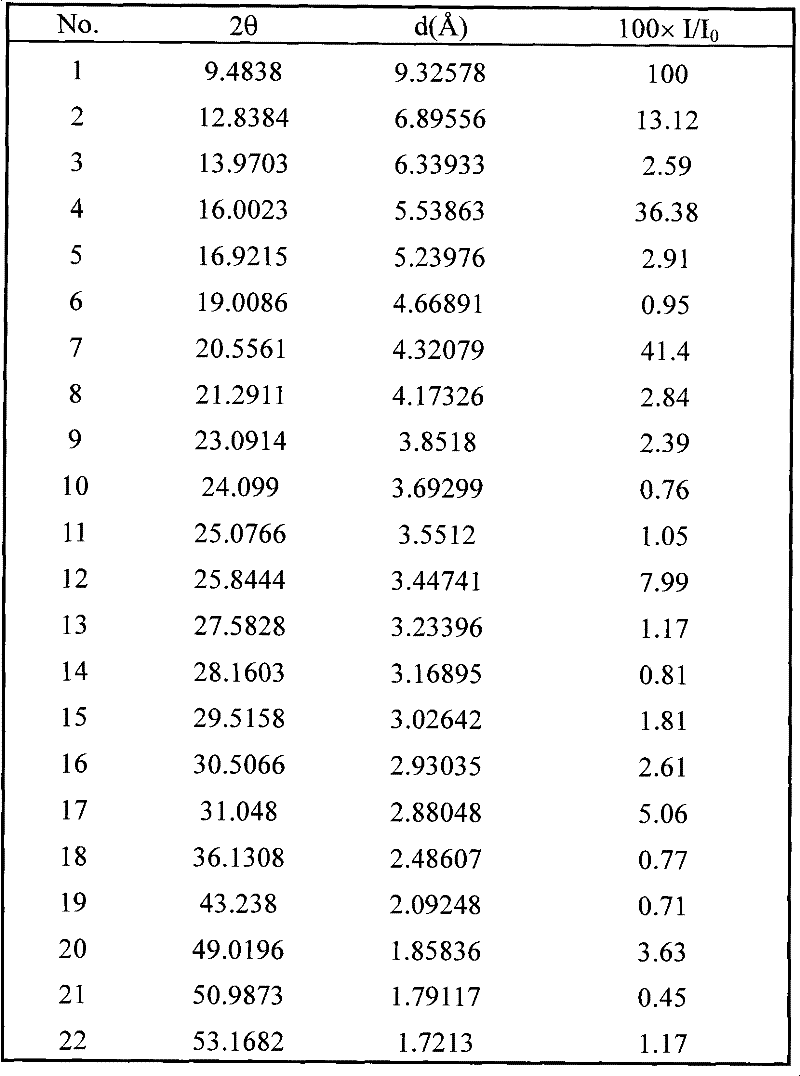

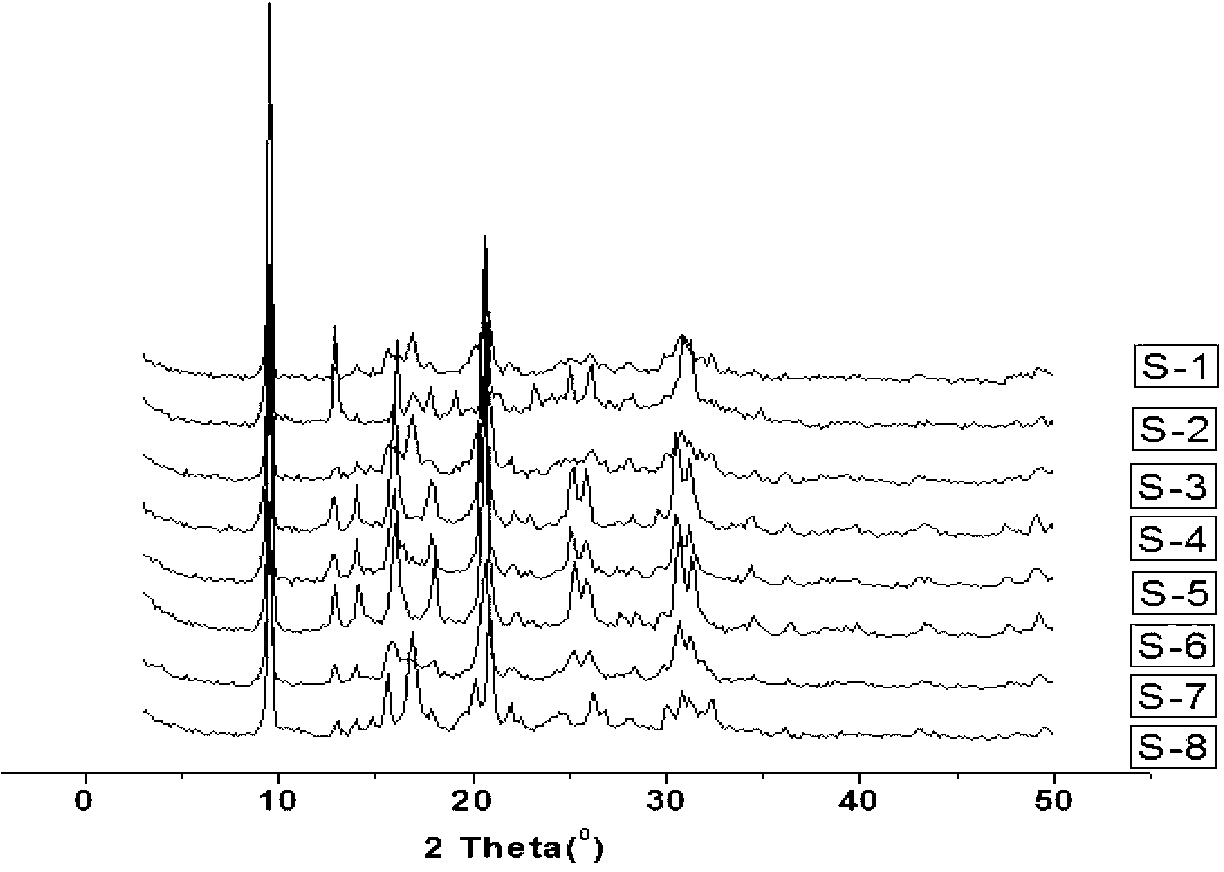

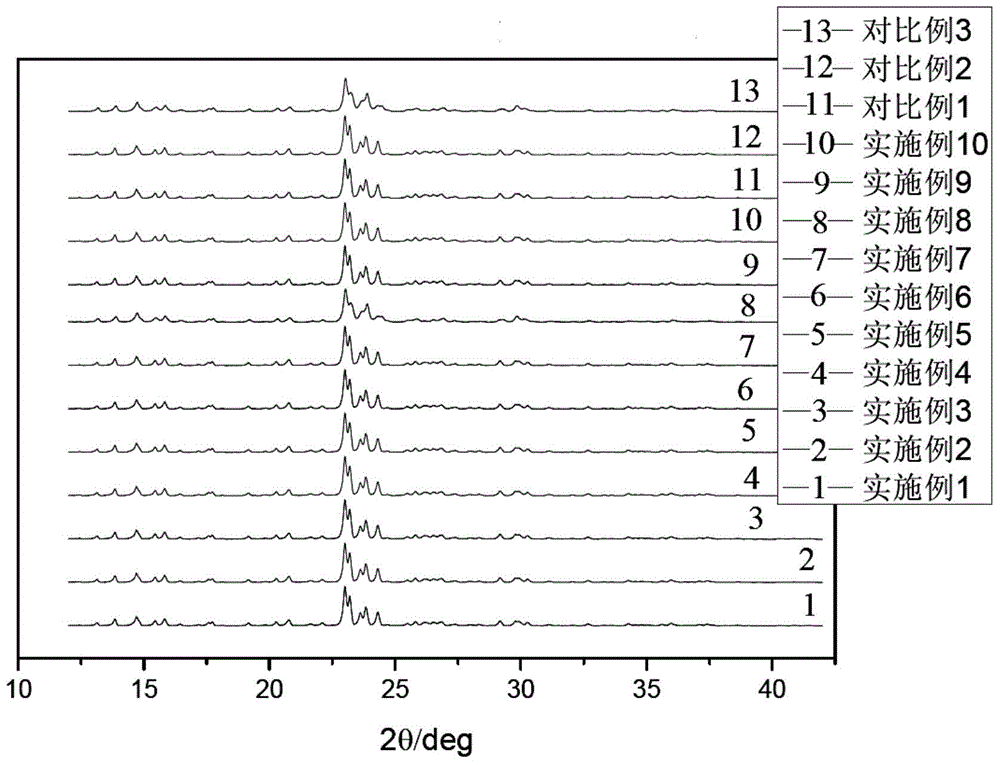

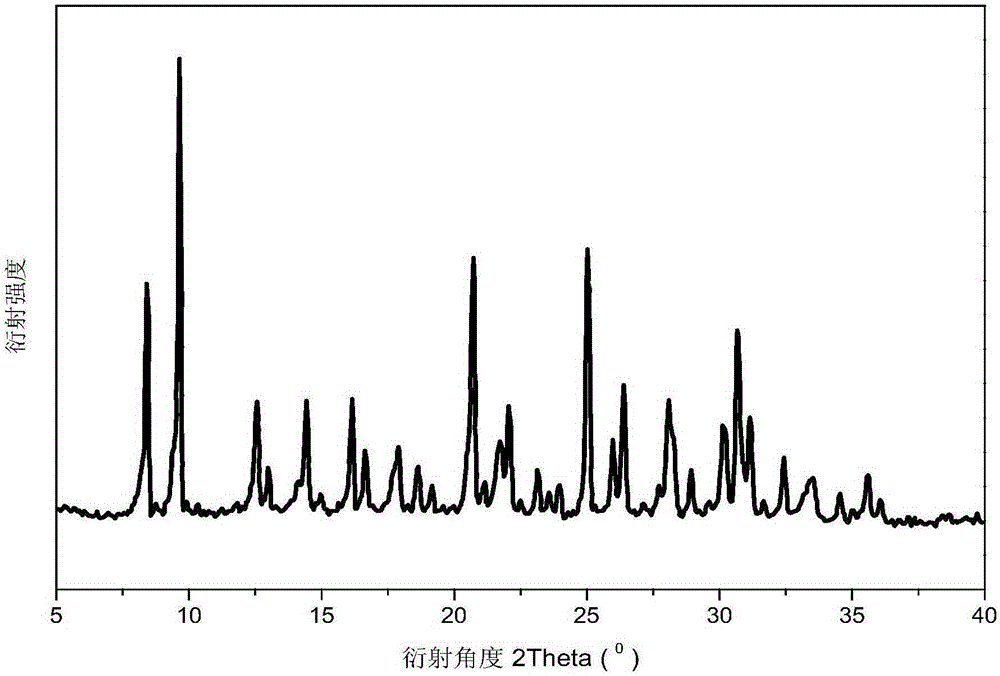

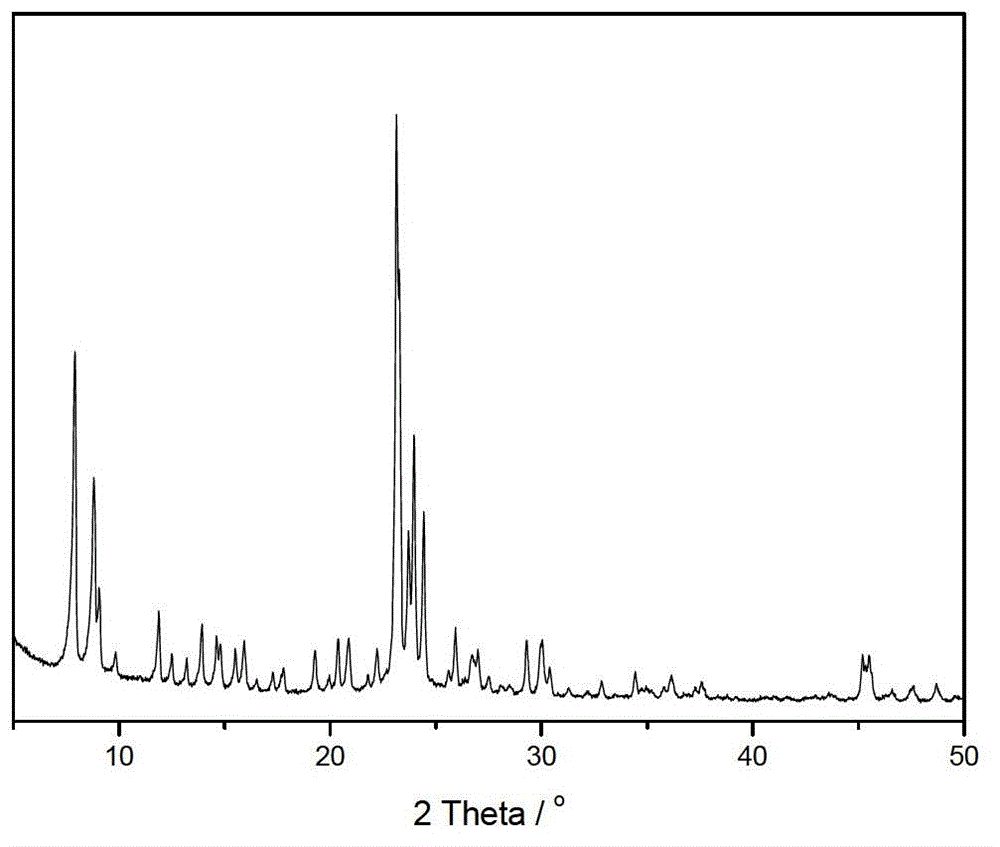

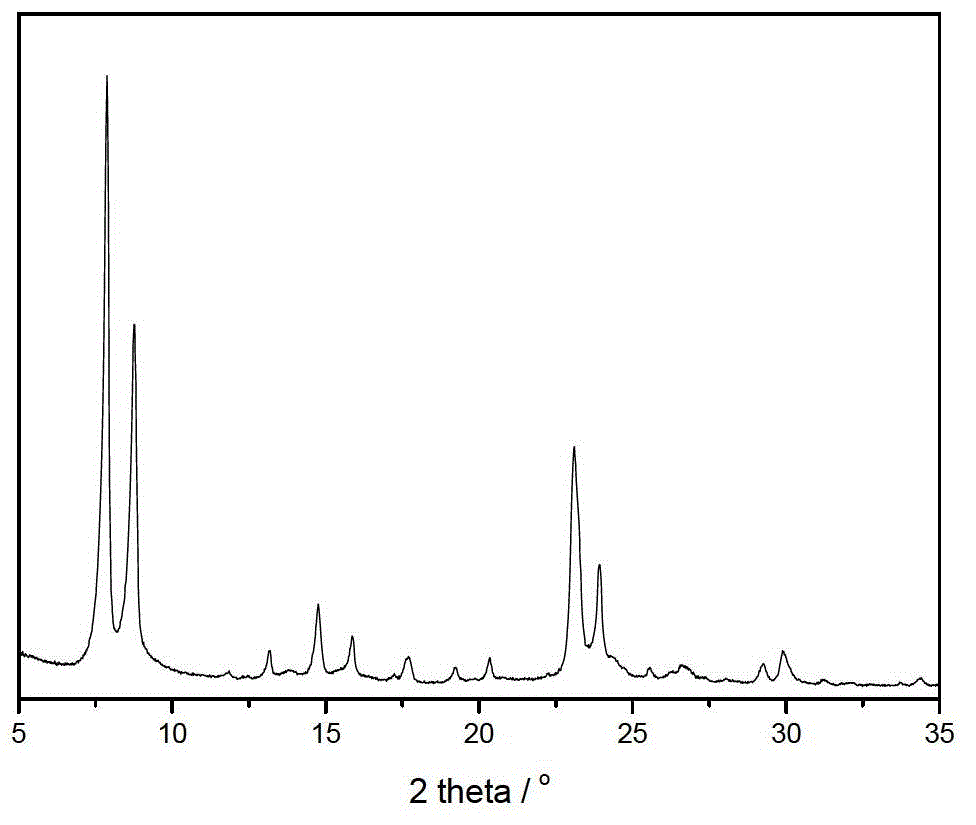

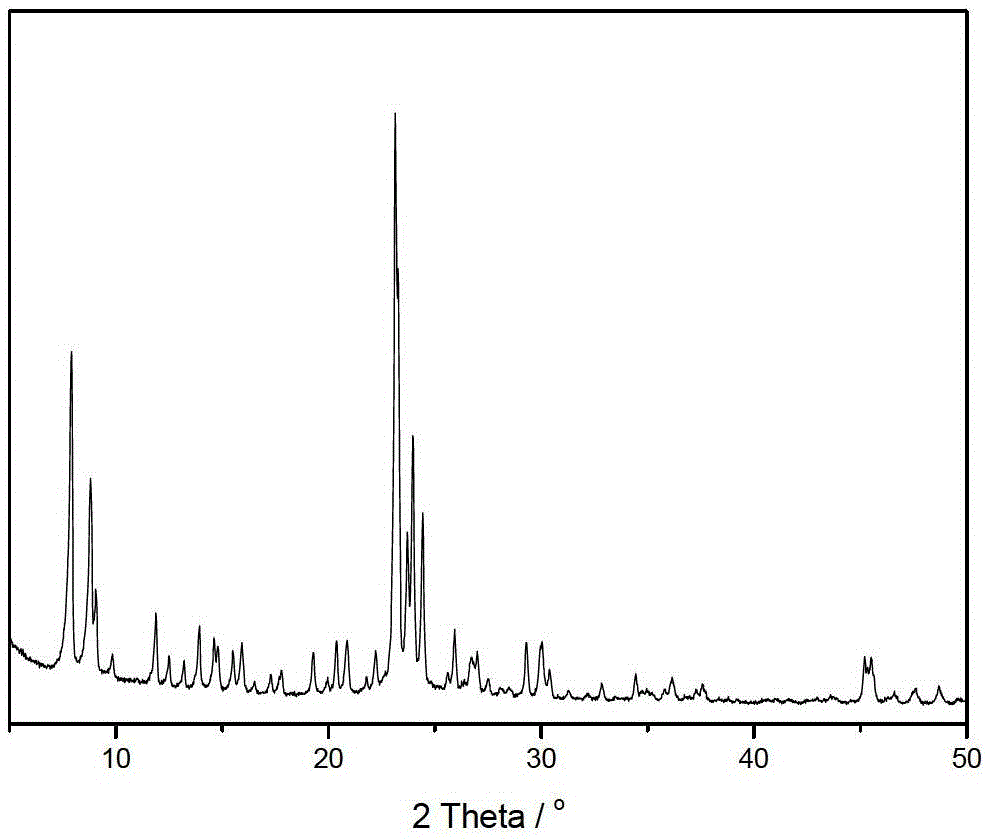

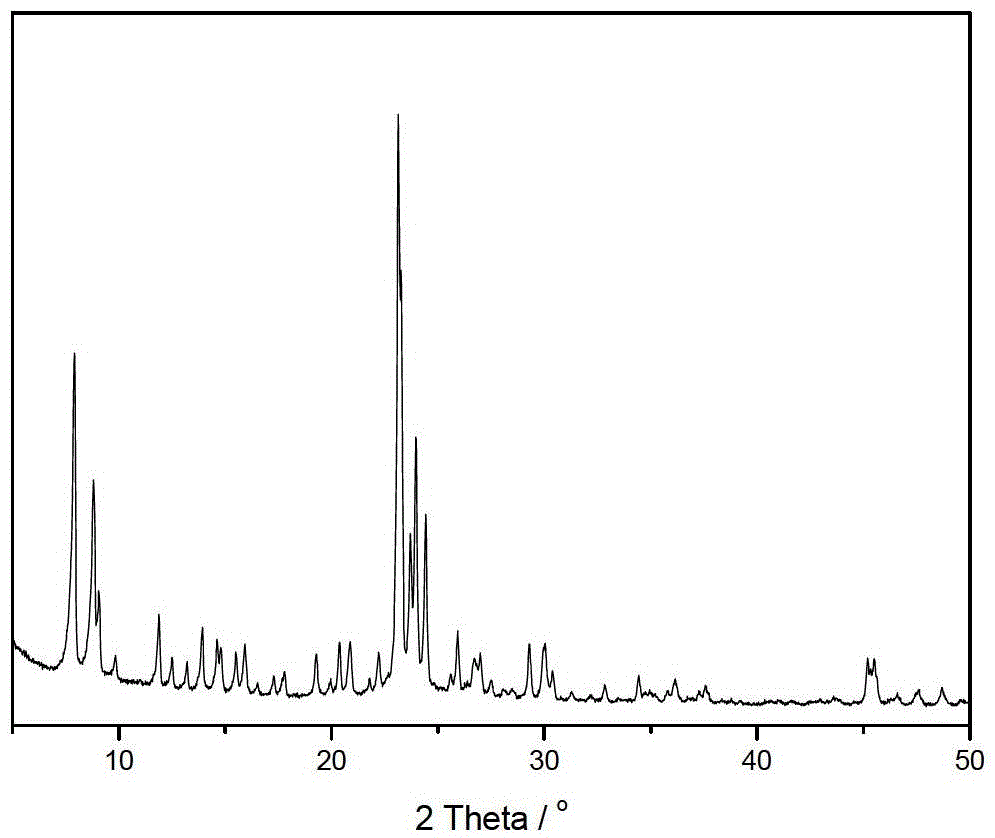

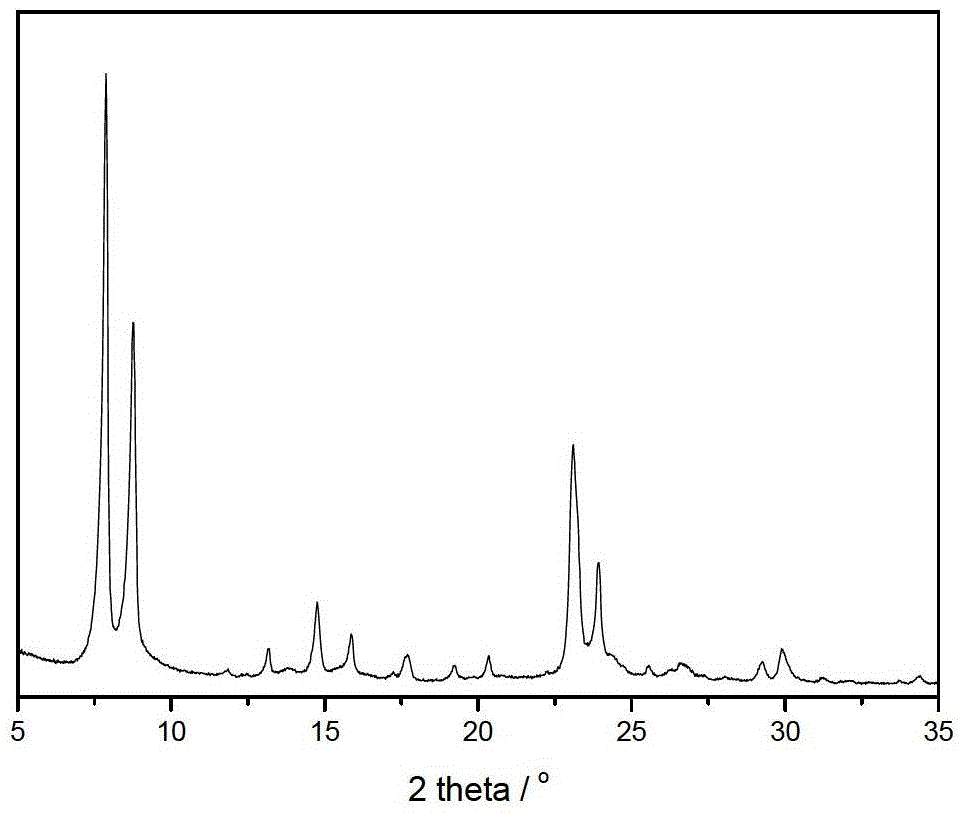

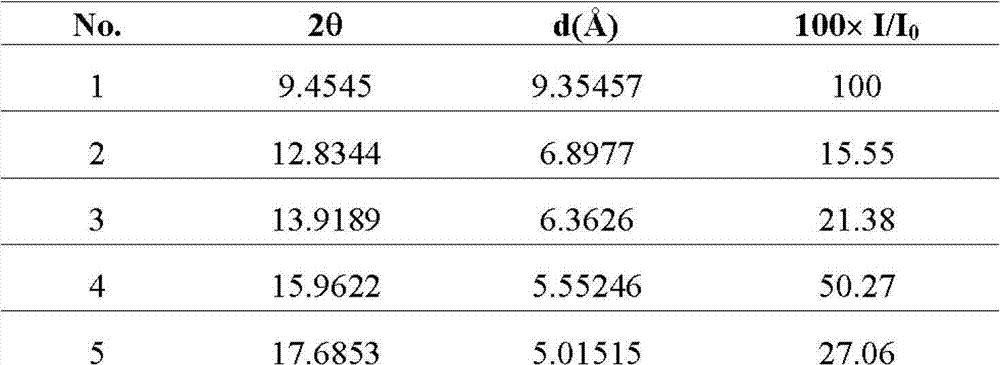

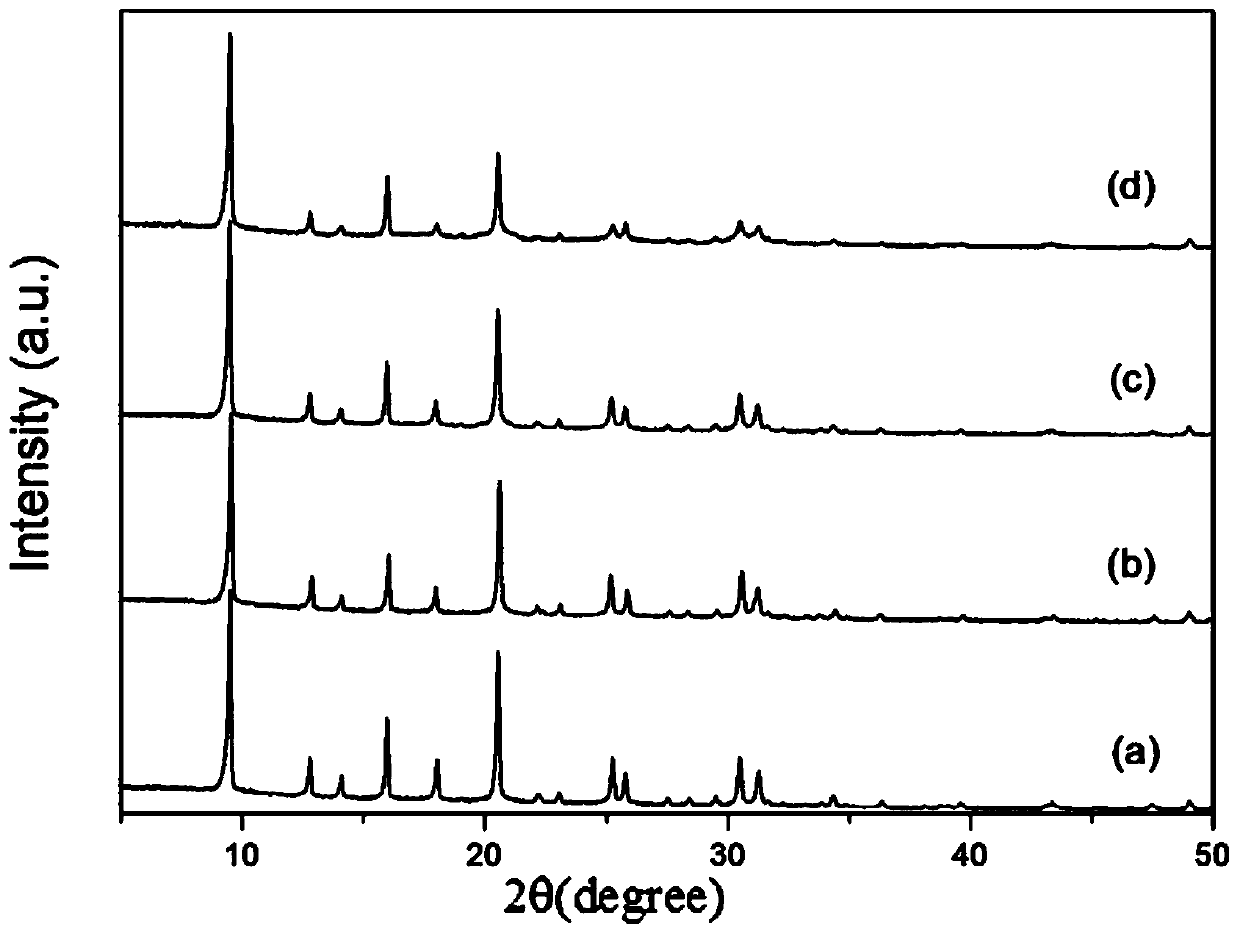

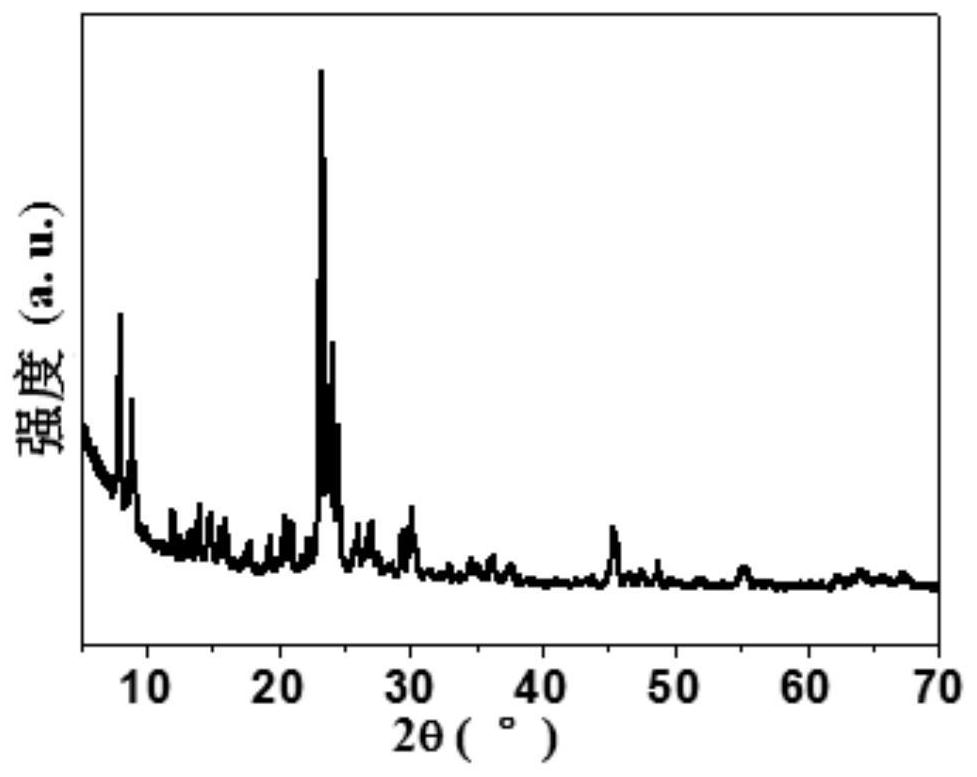

Symbiotic composite molecular sieve catalyst applied to MTO reaction, and preparation method thereof

PendingCN111135862AHigh selectivityLong reaction lifeMolecular sieve catalystsCatalyst activation/preparationMolecular sievePtru catalyst

The invention discloses a symbiotic composite molecular sieve catalyst applied to a MTO reaction, and a preparation method thereof. The catalyst is mainly formed by symbiotic compounding of SAPO-34 and RUB-50 molecular sieve structures, wherein the SAPO-34 molecular sieve accounts for 60-99% of the total weight of the catalyst, the RUB-50 molecular sieve accounts for 1.0-40% of the total weight ofthe catalyst, the silicon-to-aluminum molar ratio of the oxide in the symbiotic composite molecular sieve is 20-200, and the X-ray diffraction spectrogram of the symbiotic composite molecular sieve shows that the symbiotic composite molecular sieve has a characteristic diffraction peak with relative intensity at a specific 2theta angle. According to the invention, the RUB-50 with the LEV structure and the SAPO-34 with the CHA structure form a symbiotic composite molecular sieve, and the symbiotic composite molecular sieve has two molecular sieve structure characteristics to generate the specificity of the structure, so that the composite molecular sieve has reasonably distributed acidity and good hydrothermal stability, overcomes the limitations of the components, has good catalytic activity, high ethylene and / or propylene selectivity and excellent service life in MTO reaction, well meets the requirements of industrial application, and has broad application prospects.

Owner:中催技术有限公司

Method for quickly synthesizing SAPO(silicoaluminophosphate)-34 molecular sieve and catalyst prepared from molecular sieve

ActiveCN103663484BIncrease profitFast crystallizationMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveSolvent

The invention discloses a method for quickly synthesizing an SAPO-34 molecular sieve and a catalyst prepared from the molecular sieve. The method is characterized in that the organic amine with a (CH3)2NR structure is used as a major solvent and a template agent for synthesis to perform molecular sieve synthesis.

Owner:中科催化新技术(大连)股份有限公司

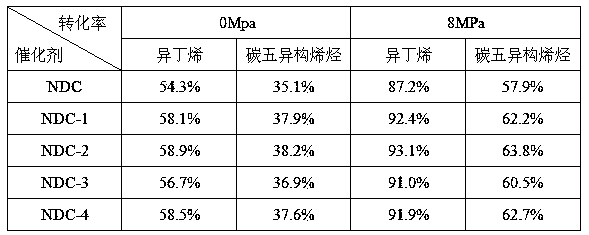

Catalyst for synthesizing methyl tertiary butyl ether (MTBE) and methyl isoamyl ether, and preparation method

InactiveCN103143382BLong overall regeneration lifeSimple regeneration methodMolecular sieve catalystsEther preparation by compound additionMolecular sievePtru catalyst

Owner:天津市南天新材料研究中心有限公司

Preparation method for hollow micro-mesoporous ZSM-5 molecular sieve

ActiveCN109607564AEasy to synthesizeSynthetic Phase WideningPentasil aluminosilicate zeoliteRoom temperatureEvaporation

The invention relates to a preparation method for a hollow micro-mesoporous ZSM-5 molecular sieve. The preparation method comprises the following steps: dispersing a template agent into a pH regulatorso as to obtain a dispersion A of the template agent, then dissolving an aluminum source into the dispersion A so as to obtain a uniformly-mixed solution B, then adding a silicon source so as to obtain a gel C, wherein the molar ratio of Al2O3 to SiO2 to M2O to R to H2O is 1: (8-200): (20-60): (10-20): (200-1000), M represents Na or K, R represents the template agent with a structural formula which is described in the specification, and in the structural formula, R is CH3(CH2)n, n has a value range of 1 to 6, and X- is Br- or Cl-; subjecting the gel C to evaporation and concentration so as toobtain a gel D, wherein the mass of the gel D accounts for 50% to 60% of the mass of the gel C; crystallizing the gel D in a temperature range of 180 DEG C to 220 DEG C for 1 to 3 d, and carrying outcooling to a room temperature; and filtering a product obtained in the step (3), and carrying out washing, drying and calcining so as to obtain the hollow micro-mesoporous ZSM-5 molecular sieve.

Owner:SHANDONG DAMING FINE CHEM CO LTD

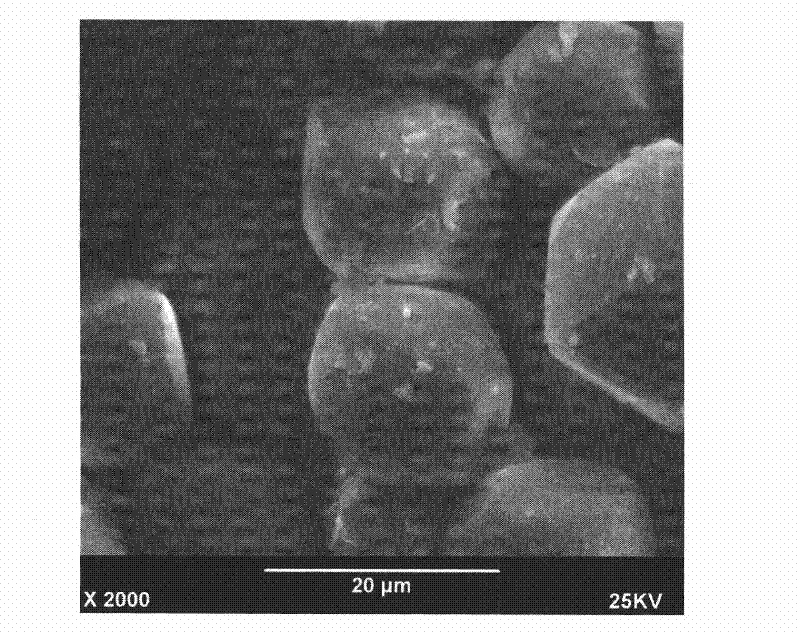

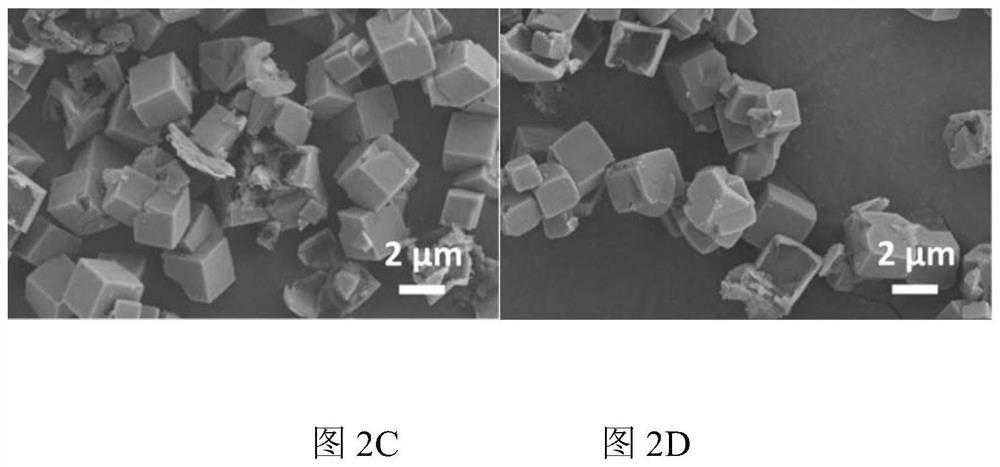

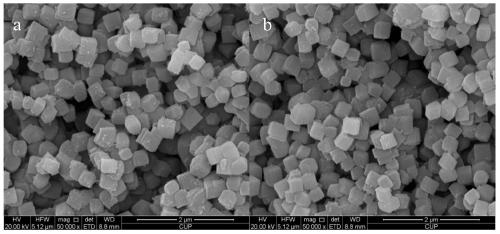

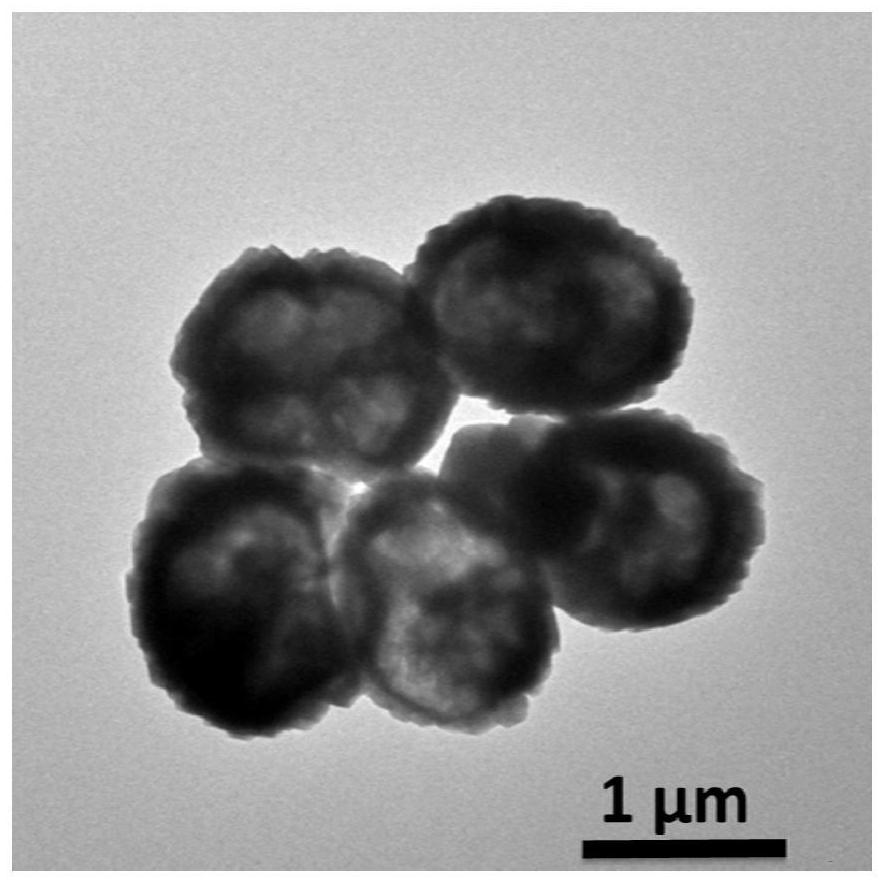

Metal-modified hollow SAPO-34 molecular sieve and production method and application thereof

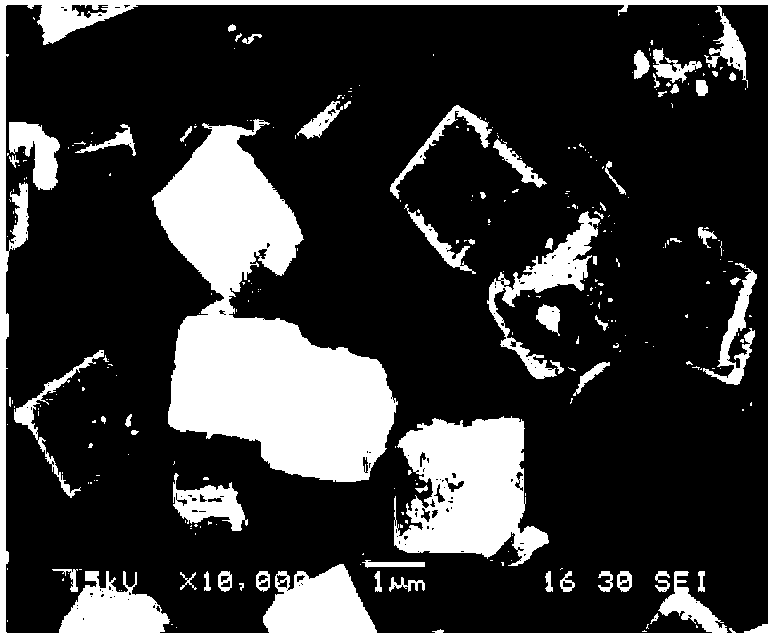

ActiveCN110255579AIncrease mass transfer rateSmall sizeMolecular sieve catalystsMolecular sieve catalystMolecular sieveAlcohol

The invention discloses a metal-modified hollow SAPO-34 molecular sieve and a production method and application thereof. The molecular sieve is of a structure with a locally-transparent surface and cubic hollow interior. Production of the molecular sieve comprises the steps of adopting a cheap organic amine as a template, introducing a structure promoter and a metal element, and conducting crystallization under a traditional hydrothermal condition. The synthesized SAPO-34 molecular sieve is high in crystallinity degree, the average grain size is 2-10 [mu]m, and the molecular sieve structure of the locally-transparent surface and the cubic hollow interior benefits diffusion and mass transfer of reactants and products in a catalytic reaction. A synthesized SAPO-34 molecular sieve catalyst is used for a reaction of methyl alcohol or dimethyl ether transformation to a low-carbon olefin, the ethylene selectivity and the propylene selectivity are high, and meanwhile, the metal-modified hollow SAPO-34 molecular sieve has the character of a long service life. The method is simple in process, fast, low in cost and suitable for industrial scale-up application.

Owner:CHIA TAI ENERGY MATERIALS DALIAN

Synthesis method of SAPO-34 molecular sieve with surface defects

ActiveCN108217686AChange grain morphologyChanging the external specific surface areaMolecular sieve catalystsMolecular sieve catalystMolecular sieveTime condition

The invention provides a synthesis method of a SAPO-34 molecular sieve with surface defects. The method comprises the following steps: after mixing a silicon source, an aluminum source, a phosphorus source, a template agent and water according to the mol ratio of SiO2 to Al2O3 to P2O5 to R to H2O of (0.5 to 0.8) to 1 to (0.8 to 1.2) to (1 to 3) to (40 to 80), carrying out dynamic hydrothermal crystallization at the low temperature of 170 to 190 DEG C and under a short-time condition of 2 to 15h, so as to obtain a cubic-shape SAPO-34 molecular sieve with the surface defects. According to the technical scheme provided by the invention, the obtained SAPO-34 molecular sieve has the surface defects and excellent methanol to olefin catalytic performance.

Owner:PETROCHINA CO LTD +1

A kind of preparation method of hollow multi-stage pore zsm-5 molecular sieve

ActiveCN108328625BGood dispersionLong reaction lifePentasil aluminosilicate zeoliteMolecular sieveActive agent

A kind of preparation method of hollow multi-stage hole ZSM-5 molecular sieve, the present invention relates to the preparation method of ZSM-5 molecular sieve, the present invention is to solve the technology that existing ZSM-5 molecular sieve aperture distribution is single, dispersion is poor, hydrothermal stability is poor question. In this method, the surfactant, water, inorganic alkali and aluminum source are mixed uniformly first, then the silicon source is added dropwise, stirred at 70-90°C, then the organic template is added, and then stirred at 70-90°C, and then hydrothermally Crystallization and calcination to obtain a hollow hierarchical porous ZSM-5 molecular sieve, which has a composite hierarchical porous structure of mesoporous micropores, high dispersion, and can be used in catalytic reactions.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com