Synthesis method of low-silicon nano SAPO-34 molecular sieve

A technology of SAPO-34, synthesis method, applied in the field of molecular sieve, can solve the problem of high crystallization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

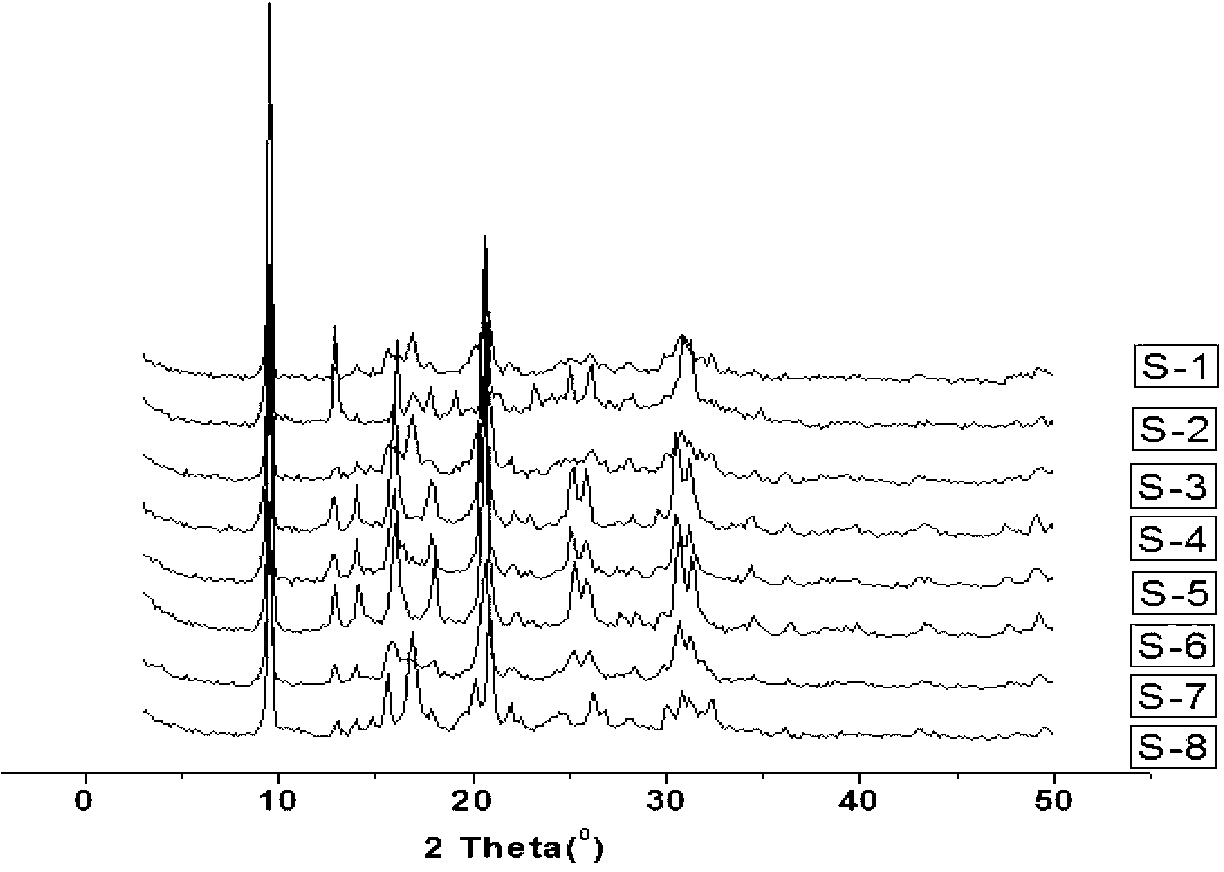

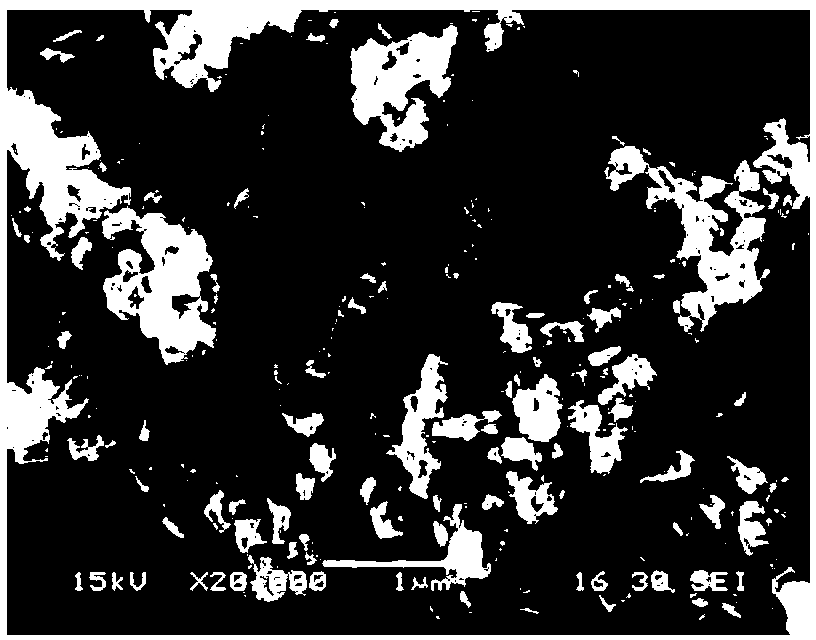

[0037] Silica sol, pseudo-boehmite, tetraethylammonium hydroxide, and deionized water are n (Al 2 o 3 ): n(P 2 o 5 ):n(SiO 2 ):n(TEAOH):n(H 2 (0)=1:2:0.4:3.5:140 mixed, stirred at 30°C for 2h, and then slowly added phosphoric acid solution dropwise. After continuing to stir for 2 hours, the obtained solution was put into a stainless steel autoclave lined with polytetrafluoroethylene, and then crystallized in a conventional reactor at 130°C for 3 hours to obtain primary crystals containing aging liquid, which were poured into primary crystals Add a certain volume of distilled water (the ratio of the volume of the aging solution is 1:2) and stir evenly, place it in an autoclave, crystallize in a microwave reactor at 160°C for 80min, wash, dry at 120°C, and dry at 550°C Calcination to obtain SAPO-34 molecular sieve (sample number S-1). Its XRD pattern is shown in figure 1 , SEM photo see figure 2 , It can be seen from the photo that the obtained SAPO-34 molecular sieve i...

Embodiment 2

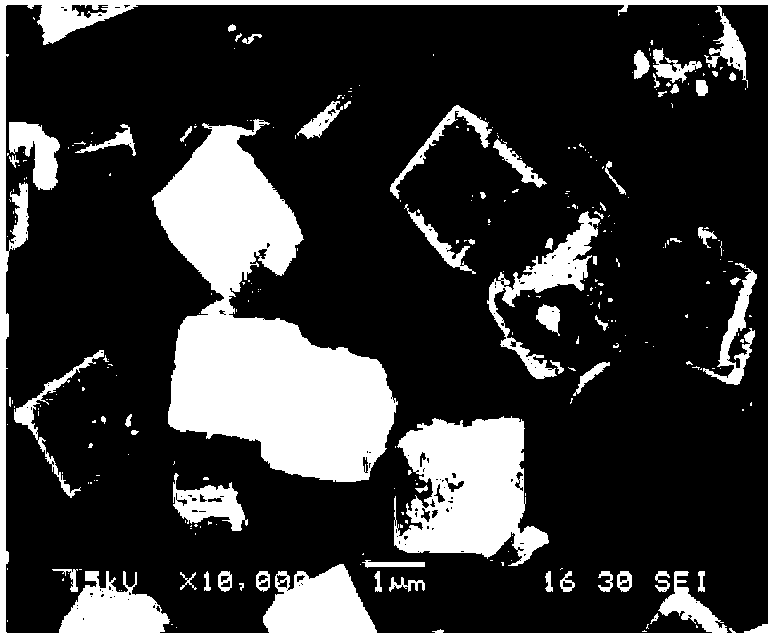

[0041]Silica sol, pseudo-boehmite, tetraethylammonium hydroxide, and deionized water are n (Al 2 o 3 ): n(P 2 o 5 ):n(SiO 2 ):n(TEAOH):n(H 2 (0)=1:2:0.4:3.5:140 mixed, stirred at 30°C for 2h, and then slowly added phosphoric acid solution dropwise. After continuing to stir for 2 hours, the obtained solution was put into a stainless steel autoclave lined with polytetrafluoroethylene, and then crystallized in a conventional reactor at 130°C for 3 hours to obtain primary crystals containing aging liquid, which were poured into primary crystals Add a certain amount of sodium lauryl sulfate solution S (S: Al 2 o 3 =0.01:1) and stirred evenly, placed in an autoclave, crystallized in a microwave reactor at 160°C for 80min, washed, dried at 120°C, and calcined at 550°C to obtain SAPO-34 molecular sieve (sample number S- 3). Its XRD pattern is shown in figure 1 , SEM photo see image 3 , It can be seen from the photo that the obtained SAPO-34 molecular sieve is in the form of...

Embodiment 3

[0043] Silica sol, pseudo-boehmite, tetraethylammonium hydroxide, and deionized water are n (Al 2 o 3 ): n(P 2 o 5 ):n(SiO 2 ):n(TEAOH):n(H 2 (0)=1:2:0.4:3.5:140 mixed, stirred at 30°C for 2h, and then slowly added phosphoric acid solution dropwise. After continuing to stir for 2 hours, the obtained solution was put into a stainless steel autoclave lined with polytetrafluoroethylene, and then crystallized in a conventional reactor at 130°C for 3 hours to obtain primary crystals containing aging liquid, which were poured into primary crystals Add a certain amount of sodium lauryl sulfate solution S (S: Al 2 o 3 = 1:1) and stirred evenly, placed in an autoclave, crystallized in a microwave reactor at 160°C for 80min, washed, dried at 120°C, and calcined at 550°C to obtain SAPO-34 molecular sieve (sample number S- 4). Its XRD pattern is shown in figure 1 , confirmed to be SAPO-34 molecular sieve and flake shape, about 50×300nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com