A kind of hierarchical porous ZSM-5 molecular sieve and its preparation method and the method for preparing MTA catalyst

A ZSM-5, molecular sieve technology, applied in the field of catalyst synthesis, can solve the problem that the self-assembly and dispersion of cationic surfactants and non-ionic surfactants cannot be effectively coordinated and controlled, ZSM-5 molecular sieves are heavily stacked, and are unfavorable for application in the field of catalysis. and other problems, to achieve the effect of easy subsequent separation, obvious synergy, and strong mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

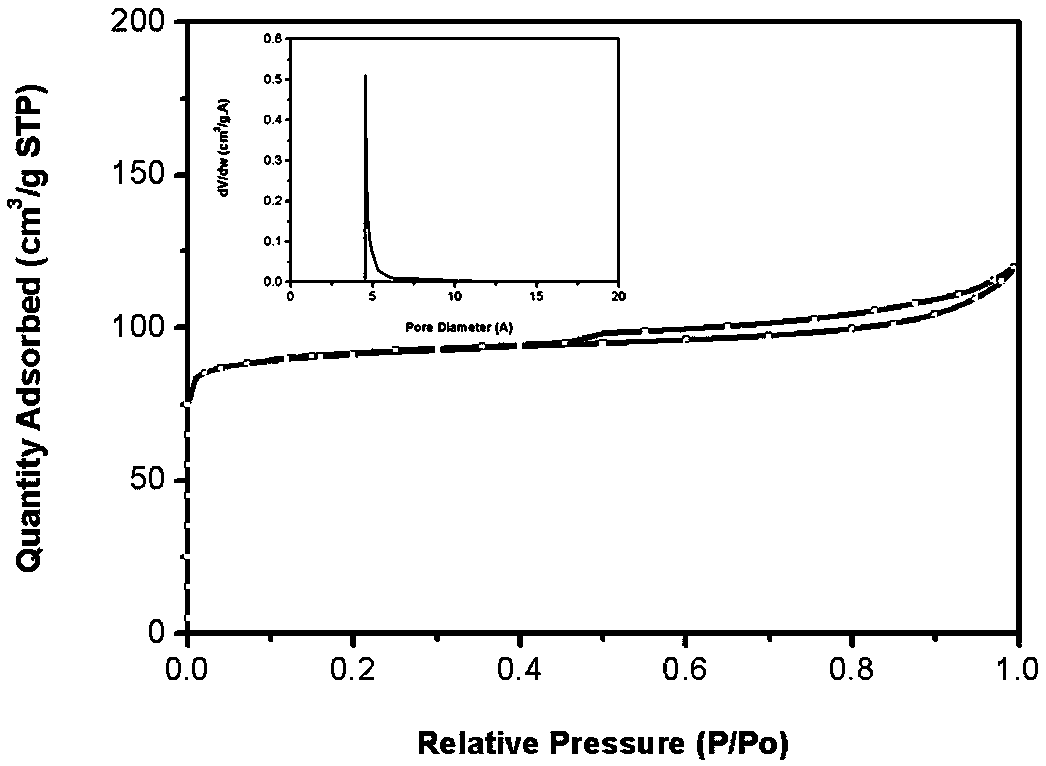

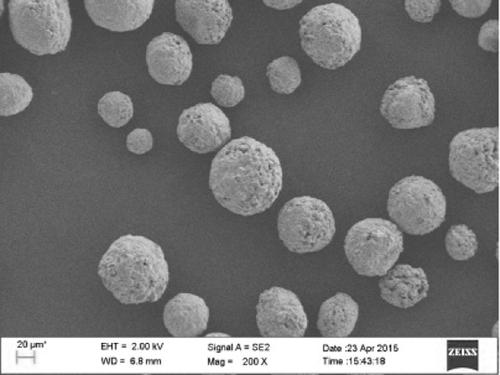

Embodiment 1

[0079] 97.9g of sodium hydroxide, 100.4g of sodium metaaluminate and 1698.0g of deionized water were stirred in a 10L polytetrafluoroethylene bucket to form a mixed solution A. Add 209g of sodium dodecylbenzenesulfonate and 95.5g of ethylene glycol into 1000g of deionized water, and stir to form solution B. Drop the B solution into the mixed solution A at a speed of 110r / min, and stir to form the mixed solution C. Add 2253.0 g of silica sol (40%) and 15 g of nano ZSM-5 seed crystals into C, and continue stirring for 2 h to obtain mixed liquid D. The mixed liquid D was transferred into a 10L stainless steel reaction kettle and sealed, and it took 30min to rise from room temperature to 180°C, and then reacted at 180°C for 8h. The product was centrifuged, washed and dried at 100 °C for 2 h. The product was treated with 1mol / L NH 4 The aqueous Cl solution was exchanged three times at 80 °C, and then dried at 120 °C for 4 h. Finally, the hierarchical porous ZSM-5 molecular siev...

Embodiment 2

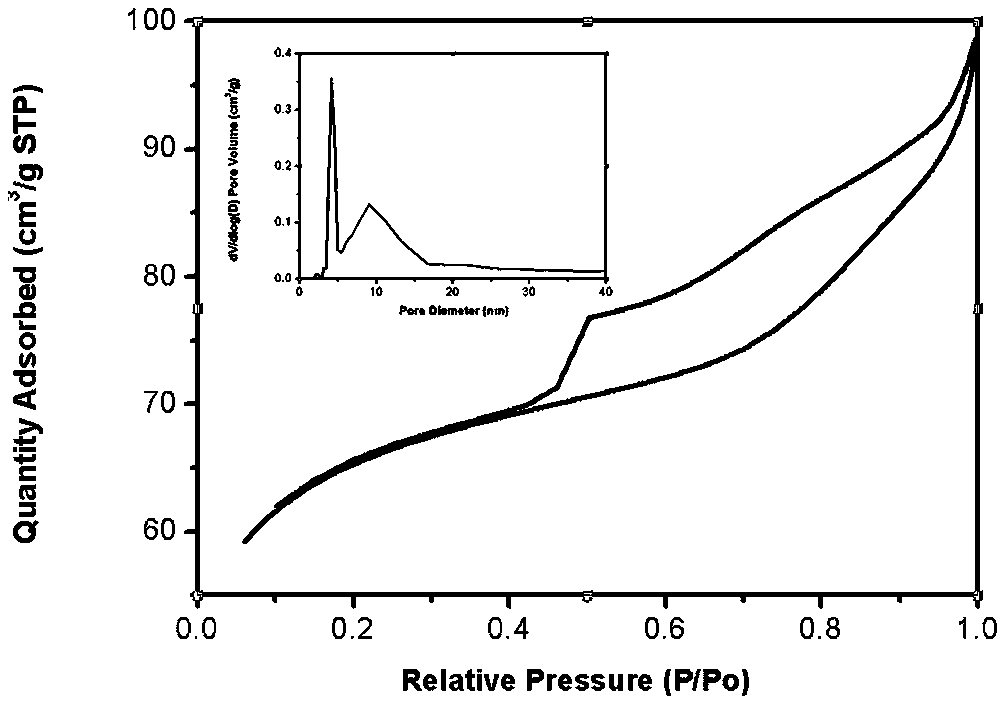

[0084] 146.9g of sodium hydroxide, 95.5g of aluminum hydroxide and 1698.0g of deionized water were stirred in a 10L polytetrafluoroethylene bucket to form a mixed solution A. Add 317.2 g of sodium fatty alcohol polyoxyethylene ether sulfate and 91.9 g of isopropanol alcohol into 1000 g of deionized water, and stir to form solution B. Drop solution B into mixed solution A at a speed of 80 r / min, and stir to form mixed solution C. Add 901.2g of white carbon black and 15g of nano ZSM-5 seed crystals into C, and continue to stir for 2h to obtain mixed liquid D. The mixed liquid D was transferred into a 10L stainless steel reaction kettle and sealed, and it took 30min to rise from room temperature to 140°C, and then reacted at 140°C for 16h. The product was centrifuged, washed and dried at 110 °C for 2 h. The product was treated with 1mol / L NH 4 The aqueous Cl solution was exchanged twice at 90°C and then dried at 120°C for 4h. Finally, the hierarchical porous ZSM-5 molecular s...

Embodiment 3

[0089] 49.0 g of sodium hydroxide, 250.1 g of aluminum isopropoxide and 1698.0 g of deionized water were stirred in a 10 L polytetrafluoroethylene barrel to form a mixed liquid A. Add 110.0 g of sodium cetyl sulfonate and 140.9 g of glycerol into 1000 g of deionized water, and stir to form solution B. Drop the B solution into the mixed solution A at a speed of 50r / min, and stir to form the mixed solution C. 3663.4g of water glass (24.6%) and 10g of nano ZSM-5 seed crystals were added to C, and the stirring was continued for 2h to obtain mixed liquid D. The mixed liquid D was transferred into a 10L stainless steel reaction kettle and sealed, and it took 30min to rise from room temperature to 180°C, and then reacted at 180°C for 12h. The product was centrifuged, washed and dried at 110 °C for 2.5 h. The product was treated with 1mol / L NH 4 The aqueous Cl solution was exchanged three times at 80 °C, and then dried at 120 °C for 5 h. Finally, the hierarchical porous ZSM-5 mole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com