Preparation method for hollow micro-mesoporous ZSM-5 molecular sieve

A technology of ZSM-5 and molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of unfavorable industrial application, low single-pot synthesis efficiency and high cost, and achieve good results. Effects of crystallinity and purity, good catalytic reactivity, and high dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Disperse 0.10g template agent in a sodium hydroxide solution with a concentration of 0.1mol / L to obtain template agent dispersion A, then dissolve pseudo-boehmite in dispersion A to obtain uniformly mixed solution B , and finally add water glass with a modulus of 2.0 to obtain gel C, whose molar ratio is Al 2 o 3 :100SiO2 2 :20M 2 O:10R:200H2 O, M represents Na or K, R represents a templating agent;

[0031] (2) Evaporate and concentrate gel C to obtain gel D, so that the mass of gel D is 50% of the mass of gel C;

[0032] (3) Crystallize the gel D at a temperature range of 180°C for 1 day, and cool to room temperature;

[0033] (4) the product in step (3) is filtered, washed, dried and roasted to obtain a hollow microporous mesoporous ZSM-5 molecular sieve;

[0034] Wherein, the structural formula of templating agent is: where R=CH 3 (CH 2 ) n , the value of n is 1, X - for Br - .

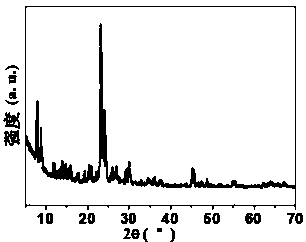

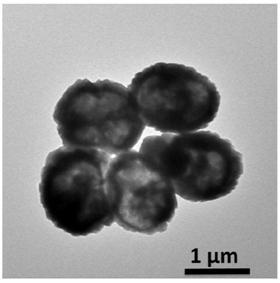

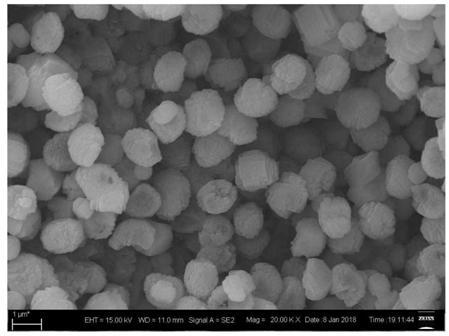

[0035] The XRD spectrum of the hollow microporous mesoporous ZSM-5 mol...

Embodiment 2

[0040] (1) Disperse 0.10g template agent in a sodium hydroxide solution with a concentration of 0.1mol / L to obtain template agent dispersion A, then dissolve pseudo-boehmite in dispersion A to obtain uniformly mixed solution B , and finally add water glass with a modulus of 2.0 to obtain gel C, whose molar ratio is Al 2 o 3 :100SiO2 2 :20M 2 O:10R:200H 2 O, M represents Na or K, R represents a templating agent;

[0041] (2) Evaporate and concentrate gel C to obtain gel D, so that the mass of gel D is 50% of the mass of gel C;

[0042] (3) Crystallize the gel D at a temperature range of 180°C for 1 day, and cool to room temperature;

[0043] (4) the product in step (3) is filtered, washed, dried and roasted to obtain a hollow microporous mesoporous ZSM-5 molecular sieve;

[0044] Wherein, the structural formula of templating agent is: where R=CH 3 (CH 2 ) n , the value of n is 2, X - for Br - .

Embodiment 3

[0046] (1) Disperse 0.10g template agent in a sodium hydroxide solution with a concentration of 0.1mol / L to obtain template agent dispersion A, then dissolve pseudo-boehmite in dispersion A to obtain uniformly mixed solution B , and finally add water glass with a modulus of 2.0 to obtain gel C, whose molar ratio is Al 2 o 3 :100SiO2 2 :20M 2 O:10R:200H 2 O, M represents Na or K, R represents a templating agent;

[0047] (2) Evaporate and concentrate gel C to obtain gel D, so that the mass of gel D is 50% of the mass of gel C;

[0048] (3) Crystallize the gel D at a temperature range of 180°C for 1 day, and cool to room temperature;

[0049] (4) the product in step (3) is filtered, washed, dried and roasted to obtain a hollow microporous mesoporous ZSM-5 molecular sieve;

[0050] Wherein, the structural formula of templating agent is: where R=CH 3 (CH 2 ) n , the value of n is 3, X - for Br - .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com