Catalyst and application of catalyst to method for preparing thymol

A thymol and catalyst technology, applied in the chemical field, can solve the problems of harsh reaction conditions, poor catalyst reactivity, and high equipment requirements, and achieve excellent product yield, easy activation and regeneration, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

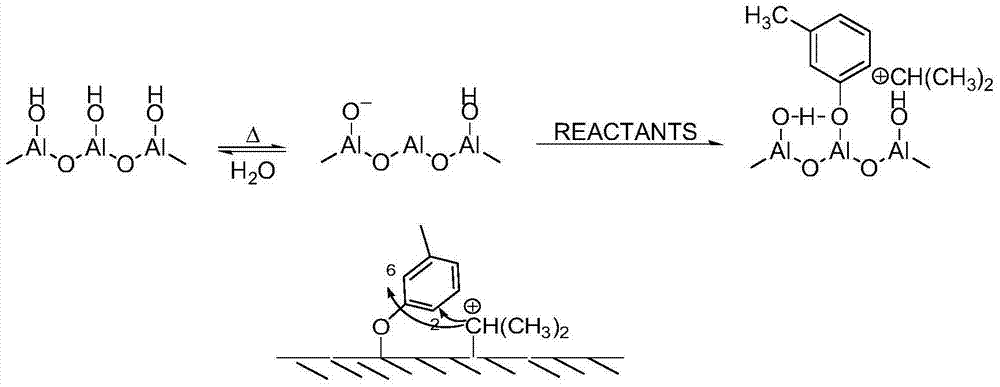

Method used

Image

Examples

Embodiment 1

[0034] A catalyst for the alkylation of m-cresol to thymol from commercial γ-Al 2 o 3 Al prepared by precipitation with ammonia water 2 o 3 composition, where Al 2 o 3 / γ-Al 2 o 3 The mass ratio is 1 / 0.5.

[0035] (1) Drop 0.5 mol / L ammonia solution into 500 mL of 1 mol / L aluminum nitrate solution, keep the pH at 7-7.5, and make precipitation solution A;

[0036] (2) Precipitate solution A was stirred at 75 °C for 5 hours, then cooled for 2 hours and then suction filtered; after drying at room temperature for 12 hours, it was dried in an oven at 120 °C for 12 hours; placed in a muffle furnace at 5 °C / min The speed is raised to 550 ℃, and calcined for 6 hours to prepare Al 2 o 3 .

[0037] (3) Al 2 o 3 with purchased commercial gamma-al 2 o 3 Mix, add 200 mL of nitric acid solution and make a slurry, inject the slurry into a specific mold, and dry it at 160 °C. The shaped particles were finally calcined at 620 °C for 2 hours to obtain a spherical catalyst Cat-1 f...

Embodiment 2

[0040] A catalyst for the synthesis of thymol by m-cresol alkylation in Example 1, that is, Al in Cat-1 2 o 3 / γ-Al 2 o 3 The mass ratio of 1 / 0.5 is changed to Al 2 o 3 / γ-Al 2 o 3 =1 / 0.75, and prepare a kind of catalyst that is used for m-cresol alkylation to synthesize thymol with the same preparation method of implementing 1, i.e. Cat-2.

[0041] The results of activity test showed that the conversion rate of m-cresol was 81.7%, the selectivity of thymol was 89.1%, and the conversion rate remained above 50% for 500 h.

Embodiment 3

[0043] A catalyst for the synthesis of thymol by m-cresol alkylation in Example 1, that is, Al in Cat-1 2 o 3 / γ-Al 2 o 3 The mass ratio of 1 / 0.5 is changed to Al 2 o 3 / γ-Al 2 o 3 =1, and prepare a kind of catalyst that is used for m-cresol alkylation to synthesize thymol, i.e. Cat-3 with the same preparation method as implementation 1.

[0044] The results of the activity test showed that the conversion rate of m-cresol was 86.3%, the selectivity of thymol was 84.7%, and the conversion rate remained above 50% for 548 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com