CHA-RHO type composite molecular sieve as well as preparation method and application thereof

A composite molecular sieve and molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, and hydrocarbon production from oxygen-containing organic compounds, etc., can solve the problems of reduced selectivity of low-carbon olefins, easy deactivation life, low catalyst activity, etc., to achieve Effect of high olefin selectivity, long service life, and long reaction life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

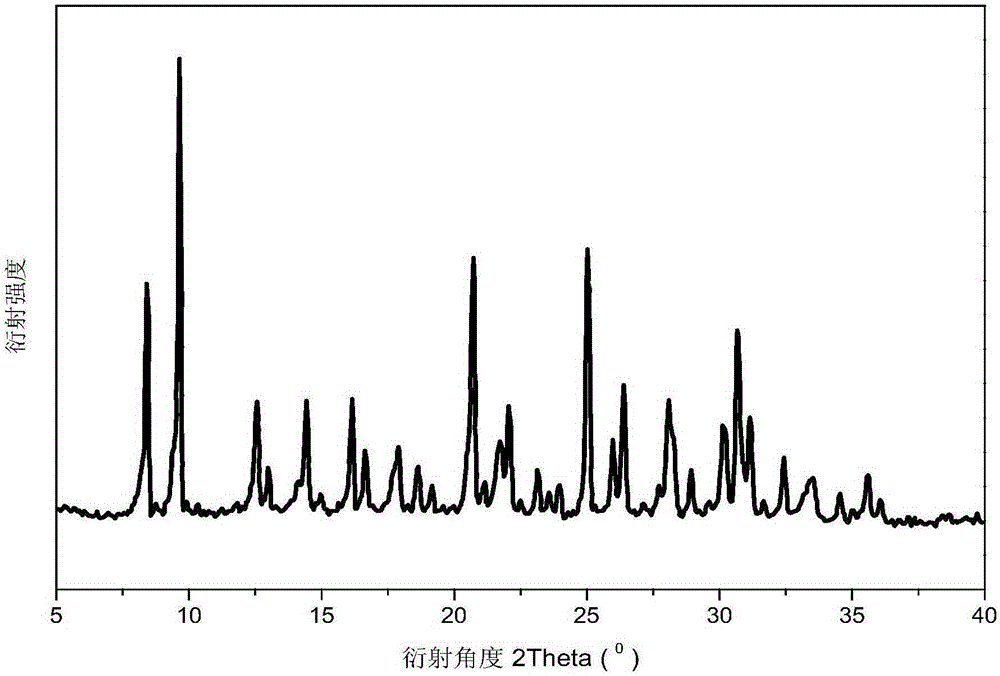

[0030] A CHA-RHO type composite molecular sieve is prepared by the following method:

[0031] (1) Weigh 14.57g of SB powder, dissolve it in 88.27g of deionized water and stir evenly at room temperature, then add 11.53g of orthophosphoric acid with a mass fraction of 85% and continue to stir evenly for 2 hours, filter the slurry, and dry at 120°C for 2h. Roast at 450°C for 2 hours to obtain phosphor-aluminum dry glue, and then pulverize to obtain particles of ≤100 μm;

[0032] (2) All the phosphoraluminum dry glue particles obtained in step (1) are mixed with 0.31g white carbon black, 45g deionized water, 0.431g n-propylamine and 4.38g triethylamine to obtain a mixture;

[0033](3) Transfer the mixture obtained in step (2) to an autoclave, stir at 500r / min for 0.5h, stir and crystallize at 140°C for 24h, then raise the temperature to 170°C for 48h; crystallization is complete After cooling with water quickly to stop the crystallization, the product is separated by suction filt...

Embodiment 2

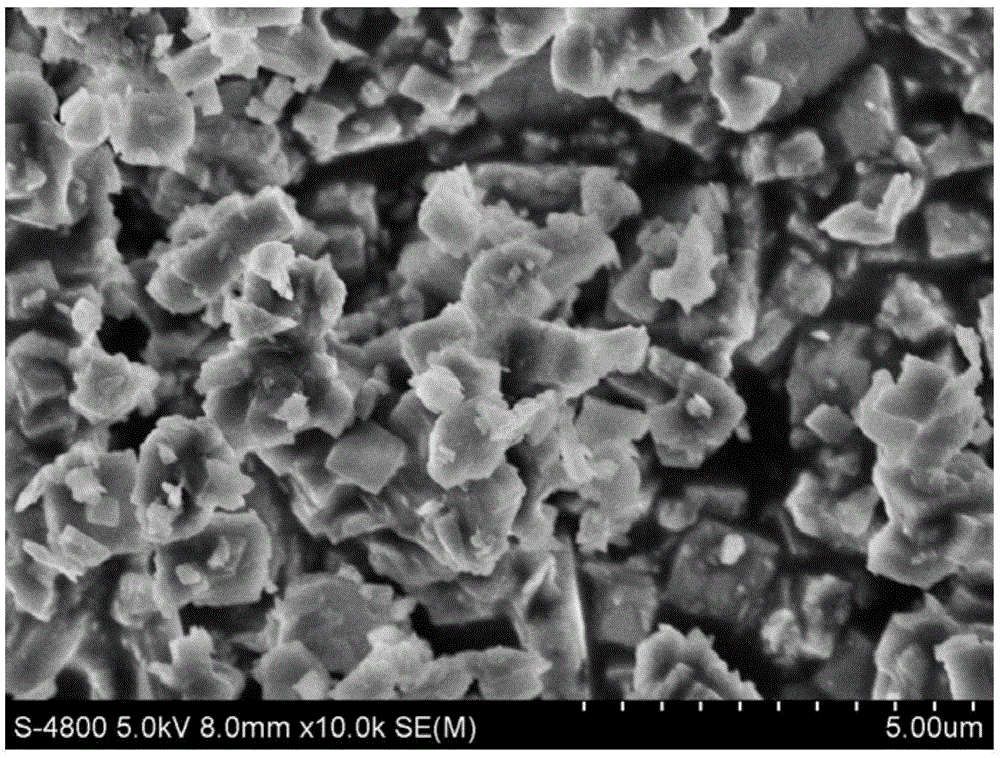

[0036] A CHA-RHO type composite molecular sieve is prepared by the following method:

[0037] (1) Weigh 13.59g of pseudo-boehmite, dissolve it in 108g of deionized water and stir evenly at room temperature, then add 23.24g of ammonium dihydrogen phosphate into it and continue to stir evenly for 2 hours, filter the slurry, dry at 110°C for 4h, 500 Roasting at ℃ for 2 hours to obtain phosphor-aluminum dry glue, and then pulverize to obtain particles of ≤100 μm;

[0038] (2) All the phosphoraluminum dry colloid particles obtained in step (1) are mixed with 0.61g chromatographic silica gel, 54g deionized water, 7.7g morpholine and 1.815g tripropylamine to obtain a mixture;

[0039] (3) Transfer the mixture obtained in step (2) to a stainless steel autoclave, stir at 600r / min for 0.5h, stir and crystallize at 150°C for 24h, then heat up to 180°C for 48h; crystallize After completion, quickly cool with water to stop the crystallization, and the product is separated by suction filtr...

Embodiment 3

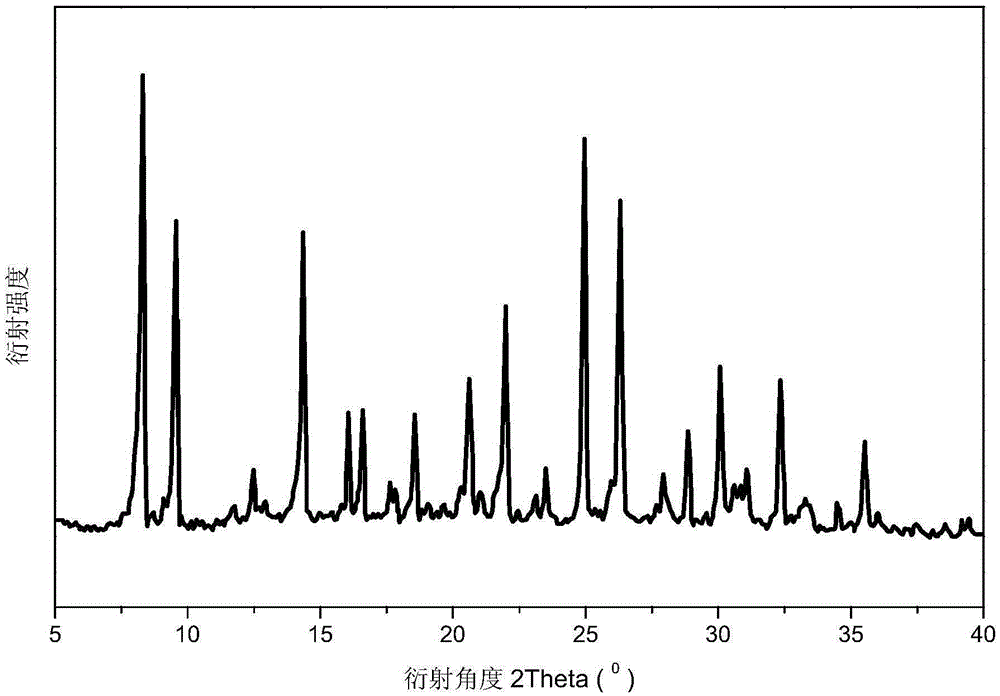

[0042] A CHA-RHO type composite molecular sieve is prepared by the following method:

[0043] (1) Weigh 75.78g of aluminum nitrate, dissolve it in 126g of deionized water and stir evenly at room temperature, then add 40.02g of diammonium hydrogen phosphate into it and continue to stir evenly for 2 hours, filter the slurry, dry at 120°C for 2h, and roast at 500°C for 2h Obtain phosphoaluminum dry glue, and then pulverize to obtain particles of ≤100 μm;

[0044] (2) All the phosphoraluminum dry glue particles obtained in step (1) are mixed with 3.19g ethyl silicate, 63g deionized water, 14.34g piperidine and 2.06g 2-hydroxyethylamine to obtain a mixture;

[0045] (3) Transfer the mixture obtained in step (2) to a stainless steel autoclave, stir at 450r / min for 1h, stir and crystallize at 160°C for 24h, then heat up to 190°C for 48h; crystallization is complete After cooling with water quickly to stop the crystallization, the product is separated by suction filtration, washed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com