Solvent thermal synthesis method of SAPO (silicoaluminophosphate) molecular sieve and catalyst prepared by SAPO molecular sieve

A synthesis method and technology of SAPO-34, applied in the synthesis field of SAPO molecular sieve, can solve the problems of increased synthesis cost, low crystallinity of RHO-SAPO molecular sieve, difficult separation, etc., and achieves improved ethylene propylene selectivity and excellent catalytic performance. , the effect of low waste liquid generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

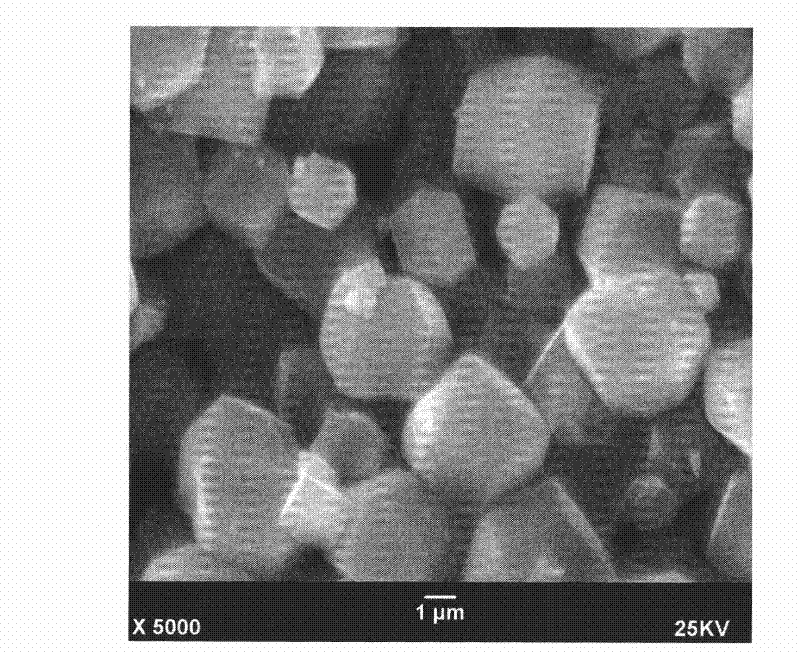

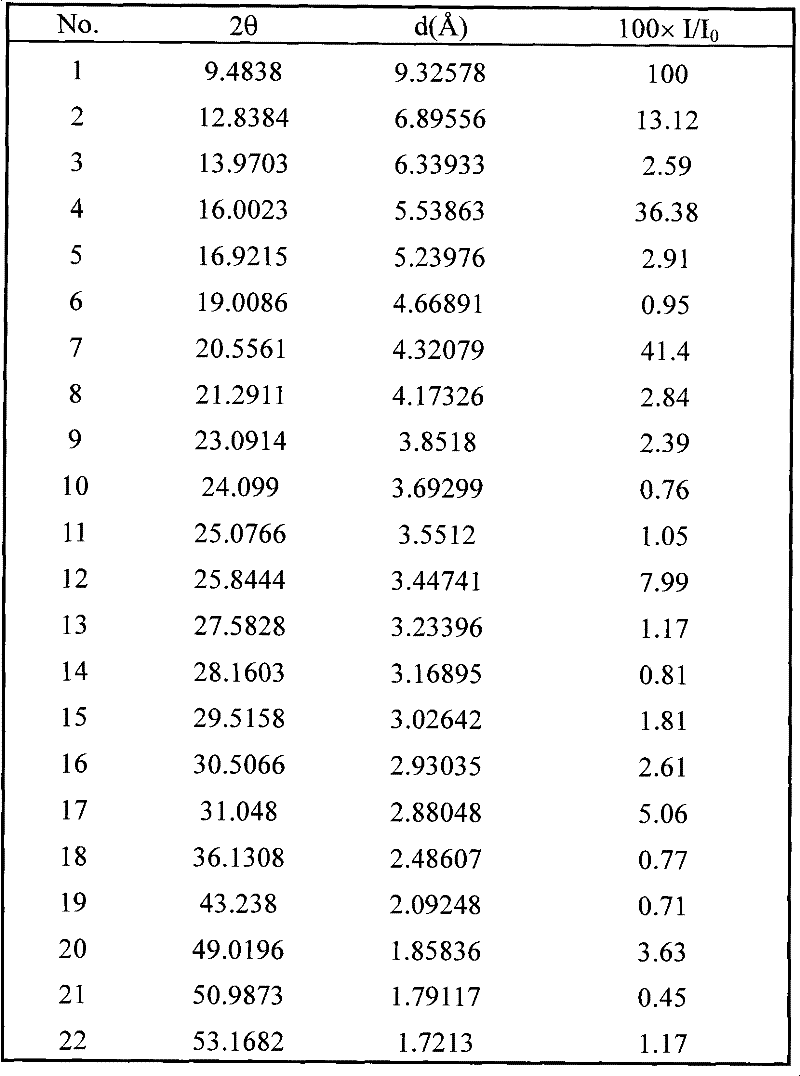

[0034] 7.03g activated alumina (Al 2 o 3 Mass percentage composition 72.5%) mixes and stirs with 60ml triethylamine, and adds 10.30g orthophosphoric acid (H 3 PO 4 Mass percent composition 85%), 5.69g silica sol (SiO 2 Mass percentage content 28.2%), 0.50g ethanol and 0.3g deionized water, stir vigorously to make it evenly mixed, and after stirring at 40°C for 10h, transfer the gel to a stainless steel reaction kettle, at a crystallization temperature of 180°C Under dynamic synthesis for 60 hours. After the crystallization, the solid product was centrifuged, washed, and dried in air at 100° C. to obtain 14.1 g of raw powder (15% weight loss on calcination). The samples were analyzed by XRD. The XRD data are shown in Table 1, and the results show that the synthesized product is SAPO-34 molecular sieve.

Embodiment 2

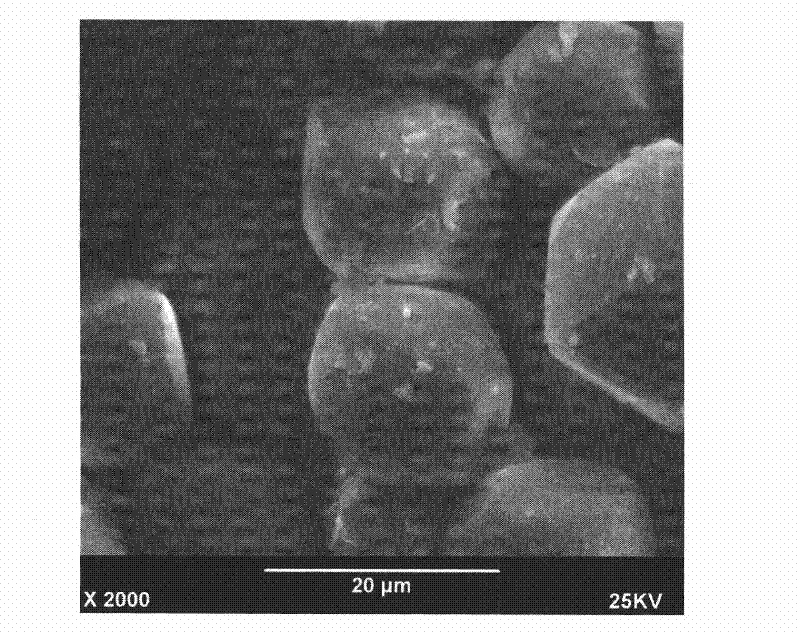

[0041] 7.03g activated alumina (Al 2 o 3 Mass percentage composition 72.5%) mixes with the triethylamine of 50ml diethylamine and 15ml and stirs, and in stirring state, once adds 9.5g orthophosphoric acid (H 3 PO 4 Mass percent composition 85%), 4.55g silica sol (SiO 2 Mass percent content 28.2%), 0.38g methanol, vigorously stirred to make it evenly mixed, and after stirring at 55°C for 12h, the gel was transferred to a stainless steel reactor, and dynamically synthesized at a crystallization temperature of 180°C for 100 hours. After the crystallization, the solid product was centrifuged, washed, and dried in air at 100° C. to obtain 13.0 g of the original powder (14.1% weight loss on calcination). The samples were analyzed by XRD. The XRD data are shown in Table 2, and the results show that the synthesized product is SAPO-34 molecular sieve.

Embodiment 3

[0045] 7.03g activated alumina (Al 2 o 3 Mass percentage composition 72.5%) mixes and stirs with the morpholine of 23.13ml triethylamine and 60ml, and once adds 10.30g orthophosphoric acid (H 3 PO 4 Mass percent composition 85%), 4.55g silica sol (SiO 2 mass percent content 28.2%), 1.0g ethanol and 2.04g deionized water, stir vigorously to make it evenly mixed, and after stirring at 35°C for 12h, transfer the gel to a stainless steel reaction kettle, and crystallize at 210°C Dynamic synthesis at temperature for 24 hours. The solid product was centrifuged, washed with deionized water until neutral, and dried in the air at 100° C. to obtain 13.6 g of raw powder (calcination weight loss 14.5%). The samples were analyzed by XRD, and the data are shown in Table 3. The XRD data indicated that the synthesized product was SAPO-34 molecular sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com